A leading manufacturer and supplier from India of Stainless Steel 316 Parts, AISI 316 Components, using Advanced Manufacturing Processes

Introduction to Stainless Steel 316 and AISI 316 Material Specifications

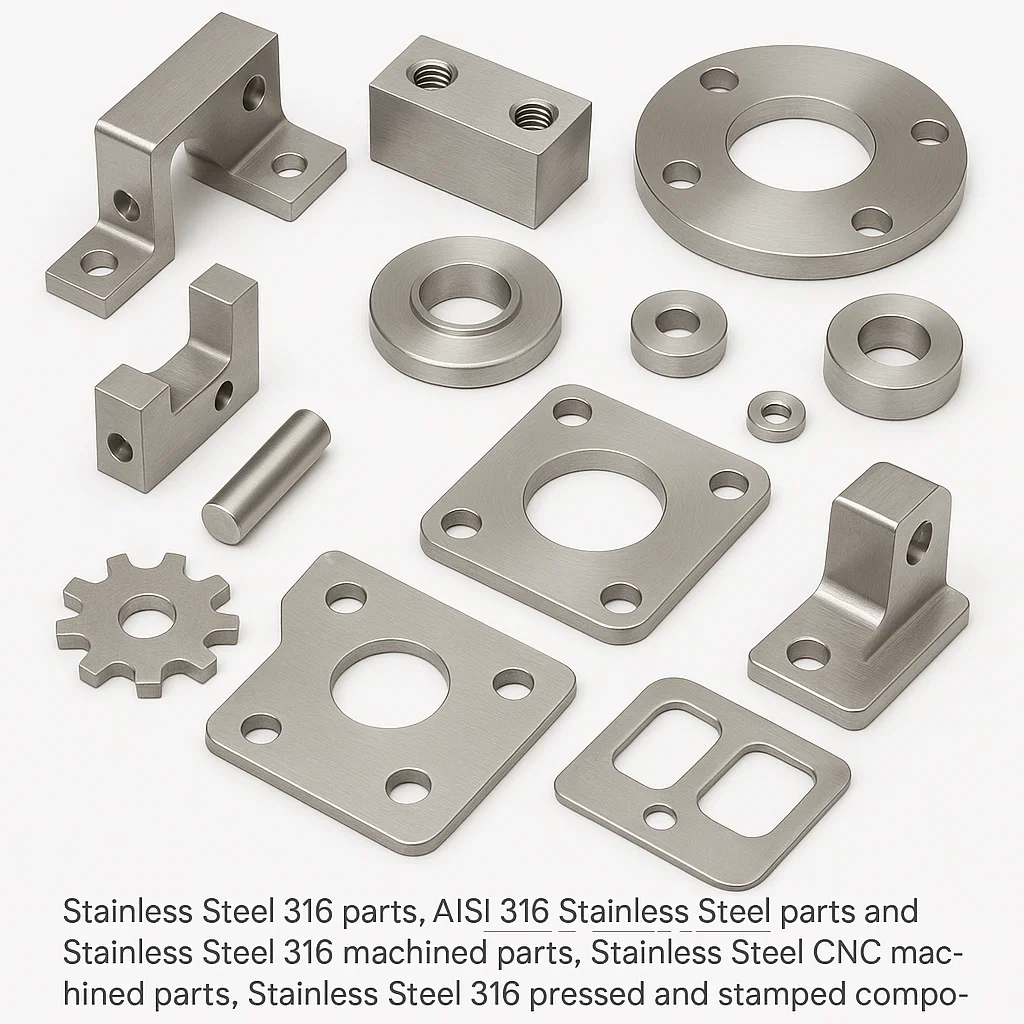

Stainless Steel 316 parts and AISI 316 stainless steel components represent the pinnacle of corrosion-resistant alloy engineering in modern industrial applications. This austenitic stainless steel grade, designated as UNS S31600 according to ASTM standards, has established itself as the premier choice for Stainless Steel 316 CNC machined parts, pressed and stamped components, and complex geometrical configurations across diverse industrial sectors including pharmaceutical, chemical processing, marine engineering, and food grade applications.

The superior metallurgical properties of Stainless Steel 316 components stem from their enhanced molybdenum content, which significantly improves pitting resistance and crevice corrosion resistance compared to standard 304 grade stainless steel. This fundamental characteristic makes AISI 316 stainless steel parts indispensable in chloride-rich environments and high-temperature applications where conventional austenitic grades fail to maintain structural integrity and corrosion resistance.

Chemical Composition and Metallurgical Properties of AISI 316 Stainless Steel

The chemical composition of Stainless Steel 316 parts adheres to stringent ASTM A240, ASTM A276, and ASTM A479 specifications, ensuring consistent metallurgical properties across all manufactured components. The precise elemental composition directly influences the performance characteristics of 316 Stainless Steel CNC machined parts and other manufacturing applications.

AISI 316 Chemical Composition (Weight Percentage):

| Element | Minimum % | Maximum % | Typical % |

|---|---|---|---|

| Carbon (C) | – | 0.08 | 0.03 |

| Manganese (Mn) | – | 2.00 | 1.75 |

| Phosphorus (P) | – | 0.045 | 0.025 |

| Sulfur (S) | – | 0.030 | 0.015 |

| Silicon (Si) | – | 0.75 | 0.50 |

| Chromium (Cr) | 16.00 | 18.00 | 17.00 |

| Nickel (Ni) | 10.00 | 14.00 | 12.00 |

| Molybdenum (Mo) | 2.00 | 3.00 | 2.50 |

| Nitrogen (N) | – | 0.10 | 0.05 |

| Iron (Fe) | Balance | Balance | Balance |

The molybdenum content in AISI 316 stainless steel parts provides enhanced resistance to pitting corrosion in chloride environments, making it superior to 304 grade stainless steel. This increased molybdenum percentage directly contributes to the superior performance of Stainless Steel 316 pipe fittings, marine hardware, and chemical processing equipment components.

International Equivalent Alloys and Standards for Stainless Steel 316 Components

Understanding the international equivalent designations for Stainless Steel 316 parts ensures proper material selection and compliance across global supply chains and manufacturing specifications.

| Standard | Designation | Country/Region | Notes |

|---|---|---|---|

| AISI/ASTM | 316 | United States | Primary US designation |

| UNS | S31600 | United States | Unified Numbering System |

| EN | 1.4401 | European Union | European Norm standard |

| DIN | X5CrNiMo17-12-2 | Germany | German Industrial Standard |

| JIS | SUS316 | Japan | Japanese Industrial Standard |

| BS | 316S31 | United Kingdom | British Standard |

| AFNOR | Z6CND17-12 | France | French Association for Standardization |

| GOST | 08Х17Н13М2 | Russia/CIS | Russian State Standard |

| GB | 0Cr17Ni12Mo2 | China | Chinese National Standard |

These equivalent designations ensure that Stainless Steel 316 CNC machined parts, forged components, and stamped parts maintain consistent properties regardless of manufacturing location or supply chain source.

Stainless Steel 316 Forged Parts: Advanced Hot and Cold Forging Processes

Stainless Steel 316 forged parts represent one of the most demanding manufacturing processes for AISI 316 material, requiring precise temperature control and sophisticated metallurgical understanding. The forging process for 316 stainless steel components involves heating the material to temperatures between 1900°F and 2100°F (1038°C to 1149°C) to achieve optimal workability while maintaining grain structure integrity.

Hot forging of Stainless Steel 316 parts provides superior mechanical properties through controlled deformation and grain refinement. The process parameters for 316 stainless steel forged components include:

Hot Forging Parameters:

- Forging temperature range: 1900°F – 2100°F (1038°C – 1149°C)

- Final forging temperature: Above 1800°F (982°C)

- Cooling rate: Air cooling or controlled cooling

- Post-forging heat treatment: Solution annealing at 1900°F – 2050°F

Cold forging of AISI 316 stainless steel parts offers dimensional precision and superior surface finish, though it requires significantly higher forming forces due to the work-hardening characteristics of austenitic stainless steel. Cold forged 316 stainless steel components exhibit increased yield strength but reduced ductility compared to their hot-forged counterparts.

The grain flow characteristics achieved through forging processes make Stainless Steel 316 forged parts ideal for high-stress applications including valve bodies, pump components, marine hardware, and pressure vessel fittings where directional strength properties are crucial for performance reliability.

Stainless Steel 316 CNC Machined Parts: Precision Manufacturing and Machining Parameters

Stainless Steel 316 CNC machined parts require specialized machining parameters and cutting tool selection due to the work-hardening characteristics and gummy nature of austenitic stainless steel. The machining of AISI 316 stainless steel components demands continuous chip removal and adequate coolant application to prevent work hardening and maintain dimensional tolerances.

Optimal CNC Machining Parameters for 316 Stainless Steel:

| Operation | Surface Speed (SFM) | Feed Rate (IPR) | Depth of Cut | Tool Material |

|---|---|---|---|---|

| Turning | 200-400 | 0.008-0.020 | 0.050-0.250 | Carbide/Ceramic |

| Milling | 300-600 | 0.005-0.015 | 0.025-0.125 | Carbide/HSS-Co |

| Drilling | 100-200 | 0.003-0.010 | – | HSS-Co/Carbide |

| Threading | 50-150 | – | – | Carbide/HSS-Co |

The work-hardening tendency of Stainless Steel 316 CNC machined parts necessitates continuous cutting action and sharp cutting tools. Interrupted cuts or dwelling can result in rapid work hardening, making subsequent machining operations extremely difficult and potentially damaging cutting tools.

Advanced CNC machining centers equipped with high-pressure coolant systems and rigid spindle configurations are essential for producing precision 316 stainless steel CNC machined parts. The coolant selection for AISI 316 machining typically includes water-soluble cutting fluids with extreme pressure additives to reduce friction and heat generation during the cutting process.

Tool path optimization for Stainless Steel 316 CNC machined parts should incorporate trochoidal milling strategies, climb milling techniques, and consistent feed rates to maintain optimal chip formation and prevent work hardening. The surface finish requirements for precision 316 stainless steel components often necessitate additional finishing operations including grinding, polishing, or electropolishing.

Stainless Steel 316 Stampings and Stamped Parts: Advanced Sheet Metal Forming

Stainless Steel 316 stampings and stamped parts encompass a wide range of sheet metal forming processes including blanking, piercing, bending, drawing, and complex progressive die operations. The forming characteristics of AISI 316 stainless steel sheet require careful consideration of material properties, tooling design, and process parameters to achieve dimensional accuracy and surface quality requirements.

The work-hardening rate of 316 stainless steel during stamping operations is approximately 2.5 times that of mild steel, necessitating specialized tooling materials and die design considerations. Stainless Steel 316 stamped parts typically require:

Stamping Process Parameters:

- Blanking clearance: 8-12% of material thickness

- Bend radius: Minimum 1.5 times material thickness

- Draw ratio limitations: 2.0:1 for deep drawing operations

- Tooling materials: D2, A2, or carbide for high-volume production

- Lubrication: Chlorine-free drawing compounds

The spring-back characteristics of Stainless Steel 316 stampings require precise overbending calculations, typically 15-30% greater than the desired final angle depending on material thickness and bend radius. Progressive die design for 316 stainless steel stamped parts must incorporate adequate stock stripping force calculations due to the increased material strength and work-hardening effects.

Deep drawing of AISI 316 stainless steel components requires multiple draw operations with intermediate annealing cycles for complex geometries. The drawing compound selection is critical for Stainless Steel 316 stampings, as chlorinated lubricants can cause stress corrosion cracking in the finished components.

Quality control for Stainless Steel 316 stamped parts includes dimensional verification, surface finish inspection, and corrosion resistance testing to ensure compliance with material specifications and performance requirements.

Stainless Steel 316 Pipe Fittings: Manufacturing and Performance Standards

Stainless Steel 316 pipe fittings represent critical components in fluid handling systems across chemical processing, pharmaceutical, food and beverage, and marine applications. The manufacturing of AISI 316 pipe fittings encompasses multiple production methods including forging, casting, machining, and specialized forming processes.

Standard Specifications for 316 Stainless Steel Pipe Fittings:

- ASTM A182 – Forged or rolled alloy and stainless steel pipe flanges

- ASTM A351 – Castings, austenitic, for pressure-containing parts

- ASTM A403 – Wrought austenitic stainless steel piping fittings

- ASME B16.9 – Factory-made wrought butt-welding fittings

- ASME B16.11 – Forged fittings, socket-welding and threaded

The corrosion resistance properties of Stainless Steel 316 pipe fittings make them particularly suitable for chloride-rich environments where standard 304 grade fittings experience premature failure due to pitting and crevice corrosion. The molybdenum content in 316 stainless steel pipe fittings provides enhanced resistance to seawater, brine solutions, and chemical processing environments.

Manufacturing processes for AISI 316 pipe fittings include hot forging for standard pressure ratings, precision machining for high-tolerance applications, and investment casting for complex geometrical configurations. The heat treatment requirements for 316 stainless steel pipe fittings typically include solution annealing at temperatures between 1900°F and 2050°F followed by rapid cooling to maintain optimal corrosion resistance properties.

Pressure testing and non-destructive examination of Stainless Steel 316 pipe fittings ensure compliance with applicable pressure vessel codes including ASME Section VIII Division 1 and Division 2 for high-pressure applications.

Stainless Steel 316 Screw Machine Parts: High-Volume Precision Manufacturing

Stainless Steel 316 screw machine parts represent high-volume precision manufacturing applications utilizing automatic screw machines, Swiss-type lathes, and multi-spindle automatic machines for producing small to medium-sized components with exceptional dimensional accuracy and surface finish quality. The production of AISI 316 screw machine parts requires specialized tooling configurations, optimized cutting parameters, and advanced coolant delivery systems to overcome the work-hardening characteristics inherent in austenitic stainless steel.

Screw Machine Operations for 316 Stainless Steel:

- Turning operations with carbide tooling and sharp cutting edges

- Threading with single-point or die head configurations

- Cross-drilling and cross-hole machining operations

- Form turning for complex profile generation

- Cutoff operations with parting tools designed for stainless steel

- Secondary operations including milling, drilling, and tapping

The work-hardening tendency of Stainless Steel 316 screw machine parts necessitates continuous cutting action without dwelling or interrupted cuts. Swiss-type lathes are particularly well-suited for 316 stainless steel screw machine parts due to their rigid workpiece support and high-pressure coolant capabilities, enabling consistent chip evacuation and heat dissipation during machining operations.

Optimized Screw Machine Parameters for AISI 316:

- Surface speeds: 150-300 SFM depending on operation

- Feed rates: 0.003-0.012 IPR for turning operations

- Threading speeds: 50-150 SFM with flood coolant

- Tooling materials: Uncoated carbide or TiN-coated tools

- Coolant concentration: 8-12% synthetic or semi-synthetic

The production efficiency of Stainless Steel 316 screw machine parts depends heavily on proper tool geometry selection, including positive rake angles of 5-15 degrees and sharp cutting edges to minimize work hardening. Tool life optimization requires balancing cutting speeds with feed rates to maintain consistent surface finish while maximizing production throughput.

Quality control for 316 stainless steel screw machine parts includes statistical process control (SPC) monitoring of critical dimensions, surface finish verification, and thread quality inspection using appropriate gauging systems. The high-volume nature of screw machine production necessitates automated inspection systems and real-time process monitoring to maintain dimensional consistency across production runs.

Stainless Steel 316 Milled Parts: Advanced Milling Operations and Surface Finish Requirements

Stainless Steel 316 milled parts require sophisticated milling strategies due to the work-hardening characteristics and thermal conductivity properties of austenitic stainless steel. The milling of AISI 316 components demands continuous engagement cutting tools, adequate coolant flow, and optimized cutting parameters to achieve dimensional tolerance and surface finish requirements.

Advanced Milling Techniques for 316 Stainless Steel:

- Trochoidal milling for pocket operations

- High-speed machining with ceramic cutting tools

- Climb milling to reduce work hardening

- Multi-axis simultaneous machining for complex geometries

- Adaptive toolpath strategies for consistent material removal rates

The cutting tool selection for Stainless Steel 316 milled parts typically includes carbide end mills with sharp cutting edges, positive rake angles, and specialized coatings such as titanium aluminum nitride (TiAlN) or aluminum chromium nitride (AlCrN) to reduce friction and heat generation during the milling process.

Surface finish requirements for precision 316 stainless steel milled parts often specify Ra values between 32 and 125 microinches, achievable through proper cutting parameter selection and post-machining finishing operations. The work-hardening layer generated during milling operations may require removal through electropolishing or chemical passivation treatments.

Complex geometrical features in Stainless Steel 316 milled parts, including undercuts, deep pockets, and intricate contours, require multi-axis CNC machining centers with advanced CAM programming to maintain dimensional accuracy while avoiding excessive work hardening of the material.

316 Stainless Steel Pressed and Sheet Metal Parts: Advanced Forming Technologies

316 Stainless Steel pressed and sheet metal parts encompass a comprehensive range of forming operations including brake press forming, roll forming, hydroforming, and specialized stretch forming processes. The forming characteristics of AISI 316 sheet metal require careful consideration of material grain direction, forming speeds, and tooling design to achieve optimal results.

Sheet Metal Forming Parameters for 316 Stainless Steel:

- Minimum bend radius: 1.0-1.5 times material thickness

- Forming speed: Slow to moderate to minimize work hardening

- Tooling clearances: 10-15% greater than material thickness

- Springback compensation: 20-35% depending on bend angle

- Surface protection: Plastic film or paper backing to prevent scratching

The work-hardening rate of 316 stainless steel sheet during forming operations necessitates specialized press brake tooling with adequate tonnage capacity and precise angle control systems. Air bending techniques are typically preferred over bottoming operations to minimize work hardening and tool wear.

Roll forming of Stainless Steel 316 sheet metal components requires multiple forming stations with gradual bend increments to prevent excessive work hardening and material thinning. The roll tooling materials for 316 stainless steel forming operations typically include hardened tool steel or carbide inserts for high-volume production applications.

Hydroforming processes for complex 316 stainless steel pressed parts offer uniform wall thickness distribution and reduced springback compared to conventional stamping operations. The fluid pressure requirements for hydroforming AISI 316 components range from 5,000 to 60,000 PSI depending on material thickness and forming complexity.

Quality assurance for 316 Stainless Steel pressed and sheet metal parts includes dimensional verification using coordinate measuring machines (CMM), surface roughness testing, and bend angle verification to ensure compliance with engineering specifications.

316 Stainless Steel Casting: Investment Casting and Sand Casting Processes

316 Stainless Steel casting processes encompass both investment casting (lost-wax process) and sand casting methodologies, each offering distinct advantages for specific component applications. The casting of AISI 316 stainless steel requires precise temperature control, specialized refractory materials, and controlled solidification rates to achieve optimal metallurgical properties.

Casting Process Parameters for 316 Stainless Steel:

- Pouring temperature: 2900°F – 3000°F (1593°C – 1649°C)

- Mold temperature: 1800°F – 2000°F (982°C – 1093°C)

- Solidification rate: Controlled cooling to prevent carbide precipitation

- Post-casting heat treatment: Solution annealing required

- Casting tolerances: ±0.005″ to ±0.015″ per inch depending on process

Sand casting of Stainless Steel 316 components utilizes specialized molding sands with low thermal expansion characteristics and adequate permeability to prevent casting defects. The mold design for 316 stainless steel sand casting must incorporate adequate risering systems to compensate for solidification shrinkage and prevent porosity formation.

The gating system design for AISI 316 stainless steel casting requires careful consideration of metal flow patterns and solidification sequences to minimize turbulence and oxide inclusion formation. Ceramic foam filters are commonly employed in the gating system to remove non-metallic inclusions and improve casting quality.

Post-casting operations for 316 Stainless Steel casting components include heat treatment, machining allowance removal, surface finishing, and dimensional inspection to ensure compliance with engineering specifications and metallurgical requirements.

Investment Casting of Stainless Steel 316 Material: Precision Casting Technology

Investment casting of Stainless Steel 316 material represents the pinnacle of precision casting technology, capable of producing complex geometrical configurations with exceptional dimensional accuracy and surface finish quality. The investment casting process for AISI 316 components utilizes ceramic shell molds created through multiple dipping and coating operations.

Investment Casting Process Sequence for 316 Stainless Steel:

- Pattern creation using injection molded wax or stereolithography

- Assembly of patterns onto runner and sprue systems

- Primary ceramic slurry coating application

- Stucco particle application for shell building

- Multiple secondary coating cycles for shell thickness development

- Wax pattern removal through autoclave or flash firing

- Ceramic shell firing and preheating

- Metal pouring and solidification

- Shell removal and component finishing

The ceramic shell materials for Stainless Steel 316 investment casting typically consist of colloidal silica binders with zircon or alumina aggregate particles. The shell firing temperature for 316 stainless steel investment casting ranges from 1800°F to 2000°F to achieve adequate strength and permeability characteristics.

Dimensional tolerances achievable through investment casting of AISI 316 stainless steel components typically range from ±0.003″ to ±0.005″ per inch, significantly superior to sand casting processes. The surface finish of as-cast 316 stainless steel investment castings typically ranges from 125 to 250 microinches Ra, often eliminating the need for extensive machining operations.

Post-casting heat treatment for Stainless Steel 316 investment castings includes solution annealing at 1900°F to 2050°F followed by water quenching to achieve optimal corrosion resistance properties. The rapid cooling rate prevents carbide precipitation and maintains the single-phase austenitic structure essential for corrosion resistance performance.

Quality Assurance and Testing Standards for 316 Stainless Steel Components

Quality assurance protocols for Stainless Steel 316 parts and AISI 316 components encompass comprehensive material certification, dimensional verification, and performance testing procedures. The testing requirements vary depending on the intended application and industry-specific regulations.

Standard Test Methods for 316 Stainless Steel:

- ASTM A262 – Detecting susceptibility to intergranular corrosion

- ASTM G48 – Pitting and crevice corrosion resistance testing

- ASTM E8 – Tensile testing of metallic materials

- ASTM E23 – Charpy impact testing procedures

- ASTM A380 – Cleaning and descaling stainless steel parts

- ASTM A967 – Chemical passivation treatments

Material traceability for Stainless Steel 316 components requires comprehensive mill test certificates (MTC) documenting chemical composition, mechanical properties, and heat treatment conditions. The certification process ensures compliance with applicable material specifications and provides quality assurance documentation for critical applications.

Non-destructive examination methods for 316 stainless steel parts include liquid penetrant testing, magnetic particle testing (where applicable), ultrasonic testing, and radiographic examination for casting components. The selection of appropriate NDT methods depends on component geometry, service requirements, and applicable code requirements.

Corrosion testing protocols for AISI 316 stainless steel components may include salt spray testing per ASTM B117, cyclic corrosion testing, and specialized environmental exposure testing depending on the intended service environment.

Applications and Industry Standards for Stainless Steel 316 Components

Stainless Steel 316 parts and components find extensive application across diverse industrial sectors due to their superior corrosion resistance, mechanical properties, and biocompatibility characteristics. The versatility of AISI 316 material makes it suitable for both standard industrial applications and highly specialized environments.

Primary Application Sectors:

- Chemical and petrochemical processing equipment

- Pharmaceutical and biotechnology manufacturing

- Food and beverage processing machinery

- Marine and offshore platform components

- Medical and surgical instrumentation

- Architectural and decorative applications

- Pulp and paper processing equipment

- Water treatment and desalination systems

The selection of Stainless Steel 316 material for specific applications requires consideration of operating temperature, corrosive environment characteristics, mechanical loading conditions, and regulatory requirements. The enhanced molybdenum content provides superior resistance to chloride-induced stress corrosion cracking compared to standard 304 grade stainless steel.

Industry-specific standards governing the use of 316 stainless steel components include FDA regulations for food contact surfaces, USP Class VI requirements for pharmaceutical applications, and NACE standards for corrosive service environments.

Conclusion: Advanced Manufacturing Excellence in Stainless Steel 316 Components

The comprehensive manufacturing capabilities for Stainless Steel 316 parts, AISI 316 components, and specialized forming processes represent the convergence of advanced metallurgical science and precision manufacturing technology. The superior performance characteristics of 316 stainless steel, combined with sophisticated manufacturing processes including CNC machining, forging, casting, stamping, and forming operations, provide unlimited possibilities for engineering applications requiring exceptional corrosion resistance and mechanical properties.

The continued advancement of manufacturing technologies for Stainless Steel 316 components, including additive manufacturing, advanced surface treatments, and precision forming processes, ensures that AISI 316 material will remain the premium choice for demanding industrial applications. The investment in advanced manufacturing capabilities, quality assurance protocols, and technical expertise continues to drive innovation in 316 stainless steel component production, meeting the evolving requirements of modern industrial applications while maintaining the highest standards of quality and performance reliability.

Understanding the comprehensive technical aspects of Stainless Steel 316 manufacturing processes, from basic material properties through advanced production methodologies, enables engineers and procurement specialists to make informed decisions regarding material selection, manufacturing process optimization, and quality requirements for critical applications across diverse industrial sectors.