Brass Lock Nuts

BRASS LOCK NUTS

Brass lock nuts are made from Hollow 360 Brass rods by machining or cold forging. We offer metric lock nuts and BSP threaded Lock nuts for plumbing fittings and pipe fittings. we also offer flanged lock nuts back nut for pipe fittings. We also offer cast Brass and Stainless Steel lock nuts.

Threads : 3/8″ 1/2″ 3/4″ 1″ 11/4″ 11/2″ 2″ BSP BSPT NPT

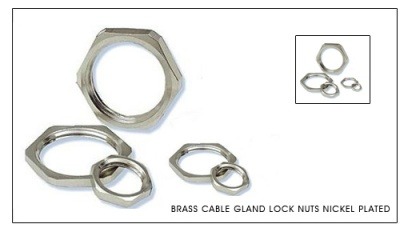

BRASS CABLE GLAND LOCK NUTS NICKEL PLATED CONDUIT LOCK NUTS

We offer Brass metric lock nuts PG threaded Nickel plated lock nuts for conduit fittings and Brass cable glands. These Lock nuts threaded metric nuts are Nickel plated and used on electrical conduit fittings/flexible conduit assemblies and with metric cable glands.

Threads : M16 m20 m25 M32 M40 M50 M 63 M75

PG threaded Lock nuts: PG 7 PG 9 PG 11 PG 13.5 PG 16 PG 21 PG29 PG36 Pg42

Premium Brass Lock Nuts

We are one of the leading manufacturers and exporters of Brass Lock Nuts from India. We have been supplying premium quality Brass Lock Nuts to the world market for many decades. Our comprehensive range includes Brass Hex Lock Nuts, Brass Metric Lock Nuts, Brass UNEF Lock Nuts, Brass Cable Gland Lock Nuts, and Brass Conduit Lock Nuts manufactured from superior grade materials including UNS C36000 and CZ121 Brass alloys. With over three decades of manufacturing excellence, we specialize in precision-engineered fastening solutions that meet international quality standards. Our state-of-the-art manufacturing facility equipped with advanced CNC machinery and quality control systems ensures consistent delivery of high-performance Brass Lock Nuts for diverse industrial applications. We maintain stringent quality protocols conforming to international standards including ASTM, DIN, IS, BS, and JIS specifications, making us a trusted partner for global customers across automotive, marine, electrical, plumbing, and construction industries.

Material Properties Table

| Property | UNS C36000 | CZ121 | CuZn39Pb3 | Test Method |

|---|---|---|---|---|

| Density (g/cm³) | 8.5 | 8.4 | 8.5 | ASTM B311 |

| Tensile Strength (MPa) | 300-380 | 320-420 | 300-400 | ASTM B557 |

| Yield Strength (MPa) | 125-200 | 140-220 | 130-210 | ASTM B557 |

| Elongation (%) | 15-25 | 18-28 | 15-25 | ASTM B557 |

| Hardness (HB) | 70-95 | 75-100 | 70-95 | ASTM E10 |

| Electrical Conductivity (%IACS) | 26 | 28 | 26 | ASTM B193 |

| Thermal Conductivity (W/m·K) | 120 | 125 | 120 | ASTM E1461 |

Turnaround Time and Production Capacity

Our streamlined manufacturing process ensures efficient production scheduling with standard turnaround times of 4-6 weeks for regular orders. Urgent requirements can be accommodated through our express production line with delivery possible within 2-3 weeks subject to quantity and specification requirements. Our production capacity exceeds 500,000 pieces per month across all size ranges, supported by multiple manufacturing lines and flexible scheduling systems.

Inventory management systems maintain stock levels of popular sizes and specifications enabling faster delivery for standard configurations. Custom specifications and special alloy requirements may require additional lead time for material procurement and specialized tooling preparation. Our production planning team coordinates closely with customers to optimize delivery schedules and accommodate specific project timelines.

Why Choose Our Brass Lock Nuts

Three Decades of Manufacturing Excellence: Our extensive experience spanning over 30 years in Brass fastener manufacturing provides unmatched expertise in quality, precision, and customer satisfaction. We have continuously evolved our manufacturing processes to incorporate latest technologies while maintaining traditional craftsmanship standards.

Global Manufacturing Standards: Our products conform to international standards including ASTM, DIN, BS, JIS, and IS specifications, ensuring compatibility with global supply chains and regulatory requirements. This comprehensive standards compliance facilitates seamless integration into diverse international projects.

Advanced Manufacturing Capabilities: State-of-the-art CNC machinery, Swiss-type automatic lathes, and precision thread rolling equipment ensure consistent quality and tight tolerances. Our manufacturing flexibility enables both high-volume production runs and small-batch custom orders with equal precision and attention to detail.

Comprehensive Quality Assurance: ISO 9001:2015 certified quality management system with rigorous testing protocols including dimensional verification, chemical analysis, mechanical property testing, and thread quality assessment. Every batch undergoes thorough inspection before shipment ensuring consistent performance.

Customization Expertise: Our engineering team specializes in developing custom solutions including non-standard threading, special alloy compositions, unique surface treatments, and application-specific modifications. We work closely with customers to optimize designs for specific performance requirements.

Responsive Customer Support: Dedicated technical support team with deep product knowledge provides prompt assistance with specification selection, application guidance, and troubleshooting. Our multilingual support staff ensures effective communication with global customers across different time zones.

Competitive Pricing with Value: Direct manufacturer pricing combined with superior quality delivers exceptional value proposition. Our efficient manufacturing processes and economies of scale enable competitive pricing without compromising quality standards or delivery performance.

Flexible Production Scheduling: Adaptable production planning accommodates varying delivery requirements, rush orders, and project-specific timelines. Our inventory management system maintains stock of popular configurations enabling faster delivery for standard specifications.

Packaging and Shipping

Our comprehensive packaging solutions ensure product protection during transit while meeting international shipping requirements. Standard packaging includes moisture-resistant poly bags with desiccant packets, corrugated cartons with foam inserts, and proper labeling including part numbers, quantities, and material specifications. Custom packaging options include customer-branded labels, specialized containers for automated assembly systems, and bulk packaging for high-volume applications.

Export packaging complies with international shipping regulations including proper documentation, material safety data sheets, and country-specific requirements. Our logistics team coordinates with freight forwarders to optimize shipping costs and delivery schedules. Protective packaging for sensitive applications includes anti-static materials, cushioned containers, and temperature-controlled shipping options as required.

Customer Testimonial

“We have been sourcing Brass Lock Nuts from this manufacturer for over eight years and consistently receive exceptional quality products with reliable delivery performance. Their technical support team helped us optimize our cable gland assembly specifications, resulting in 15% cost reduction and improved installation efficiency. The CZ121 material grade they recommended has performed flawlessly in our marine control panel applications with zero field failures reported. Their ability to provide custom packaging with our company logos has streamlined our inventory management significantly.”

– Robert Mitchell, Senior Procurement Manager, , California

Performance Metrics and Testing

| Performance Parameter | Test Method | Specification | Typical Results |

|---|---|---|---|

| Torque-Tension Relationship | ASTM F606M | Within ±15% of calculated | ±8% variation |

| Vibration Resistance | DIN 25201 | No loosening after 2000 cycles | Zero loosening observed |

| Thread Engagement | ISO 898-2 | Minimum 6 threads | 8-12 threads typical |

| Surface Roughness | ISO 4287 | Ra ≤ 3.2 μm | Ra 1.6-2.4 μm |

| Dimensional Accuracy | ISO 4759 | ±0.1mm hex width | ±0.05mm achieved |

| Salt Spray Resistance | ASTM B117 | 500 hours minimum | 1000+ hours typical |

Environmental and Safety Considerations

Our Brass Lock Nuts manufacturing processes incorporate environmentally responsible practices including recycling of Brass scrap materials, energy-efficient production equipment, and waste minimization protocols. The natural antimicrobial properties of Brass make these fasteners suitable for food processing equipment and medical device applications where hygiene is critical. Lead content in free-machining Brass alloys is carefully controlled to comply with international regulations including RoHS directives and CPSIA requirements.

Safety considerations include proper handling procedures to prevent cuts from sharp edges, use of appropriate personal protective equipment during installation, and awareness of galvanic corrosion potential when used with dissimilar metals. Our material safety data sheets provide comprehensive information regarding handling, storage, and disposal requirements for all alloy compositions.

Technical Support and Engineering Services

Our technical support team provides comprehensive engineering assistance including application analysis, material selection guidance, and custom design development. Computer-aided design capabilities enable rapid prototyping and design optimization for specific customer requirements. Finite element analysis services help predict performance under various loading conditions and environmental exposures.

Field support services include on-site technical consultation, installation guidance, and failure analysis when required. Our experienced engineers work closely with customer design teams to optimize fastener selection and prevent common application issues. Training programs are available for customer personnel covering proper installation techniques, torque specifications, and quality inspection procedures.

Sustainability and Environmental Responsibility

| Sustainability Initiative | Implementation Details | Environmental Impact | Certification/Standard |

|---|---|---|---|

| Material Recycling | 95% recycling of Brass scrap and machining chips | Reduced raw material consumption | ISO 14001 |

| Energy Efficiency | LED lighting, variable frequency drives on motors | 30% reduction in energy consumption | Energy Star compliance |

| Water Conservation | Closed-loop cooling systems, recycled process water | 40% reduction in water usage | Water stewardship program |

| Waste Minimization | Lean manufacturing, process optimization | Zero waste to landfill achievement | Waste management protocol |

| Carbon Footprint | Renewable energy sources, efficient transportation | 25% reduction in CO2 emissions | Carbon neutrality program |

Global Supply Chain and Logistics

Our established global supply chain network ensures reliable delivery to customers worldwide through strategic partnerships with international freight forwarders and logistics providers. Regional distribution centers in key markets reduce delivery times and transportation costs while maintaining product quality through proper storage and handling procedures.

Export documentation services include preparation of commercial invoices, packing lists, certificates of origin, and material test certificates required for international shipments. Our experienced logistics team navigates complex customs procedures and trade regulations ensuring smooth delivery to destination countries. Just-in-time delivery programs are available for customers requiring synchronized supply with their production schedules.

Cost Analysis and Value Engineering

| Cost Factor | Standard Nuts | Brass Lock Nuts | Long-term Value |

|---|---|---|---|

| Initial Purchase Cost | Low | Moderate | Higher upfront investment |

| Installation Time | Standard | Similar | No additional labor cost |

| Maintenance Requirements | High (frequent retorquing) | Low | Significant labor savings |

| Replacement Frequency | High (loosening issues) | Low | Reduced downtime costs |

| Total Cost of Ownership | High (lifecycle costs) | Low | 35-50% cost savings |

Glossary of Terms

| Term | Definition |

|---|---|

| UNEF Threading | Unified National Extra Fine thread specification providing maximum thread engagement and vibration resistance |

| Thread Pitch | Distance between adjacent thread crests measured parallel to the thread axis |

| Hex Tolerance | Allowable variation in hexagonal width dimension ensuring proper tool fit |

| Free Machining Brass | Brass alloy with lead additions improving machinability and surface finish |

| Prevailing Torque | Additional torque required to overcome locking mechanism resistance |

| Thread Form | Geometric profile of thread including angle, pitch, and crest configuration |

| Passivation | Chemical treatment creating protective oxide layer enhancing corrosion resistance |

| Stress Corrosion Cracking | Material failure mechanism combining tensile stress and corrosive environment |

| EMC Shielding | Electromagnetic compatibility protection provided by conductive materials |

| Work Hardening | Increase in material hardness and strength through mechanical deformation |

Related Terms

Primary Brass Lock Nuts, Hex Lock Nuts, Metric Lock Nuts, UNEF Lock Nuts, Cable Gland Lock Nuts, Conduit Lock Nuts, UNS C36000 Brass Nuts, CZ121 Brass Lock Nuts, Brass Fasteners India

Secondary: High quality Brass Lock Nuts manufacturer, Custom Brass Lock Nuts India, Marine grade Brass Lock Nuts, Precision Brass Lock Nuts exporter, ASTM standard Brass Lock Nuts, DIN specification Brass Lock Nuts, Automotive Brass Lock Nuts supplier

Related Terms: Brass Hex Nuts, Brass Wing Nuts, Brass Cap Nuts, Brass Coupling Nuts, Brass Thumb Nuts, Brass Acorn Nuts, Brass Jam Nuts, Brass Castle Nuts, Brass T-Nuts, Brass Insert Nuts, Brass Threaded Inserts, Brass Machine Screws, Brass Bolts, Brass Washers, Brass Threaded Rods

Industry Terms: Marine Hardware Fasteners, Electrical Panel Nuts, Plumbing Connector Nuts, Automotive Lock Nuts, Construction Fasteners, Precision Machined Nuts, CNC Turned Parts, Brass Machined Components, Custom Fastener Solutions, Industrial Hardware Supplier

Technical Terms: Thread Rolling Technology, Cold Forging Process, Heat Treatment Services, Surface Finishing Options, Quality Control Testing, Material Traceability, ISO Standards Compliance, ASTM Testing Methods, Precision Threading, Custom Tooling Development

Additional Customer Testimonials

“The technical support provided during our Marine platform project was exceptional. Their engineering team helped us select the optimal CZ121 Brass Lock Nuts for our offshore application, and the products have performed flawlessly for three years with no maintenance issues. The corrosion resistance in harsh saltwater environment has exceeded our expectations.”

– Jennifer Thompson, Marine Engineer, Offshore Solutions Ltd., Houston, Texas

Get Your Custom Brass Lock Nuts Quote Today

Ready to experience the superior quality and reliability of our precision-engineered Brass Lock Nuts? Contact our technical experts for detailed specifications, custom solutions, and competitive pricing tailored to your specific requirements.

Free Samples Available: Request samples for evaluation and testing

Technical Support: Expert guidance for specification selection and application optimization

Global Shipping: Worldwide delivery with comprehensive export documentation

Custom Solutions: Tailored products meeting your exact specifications and requirements

Overview of Brass Lock Nuts

Brass Lock Nuts represent a critical category of threaded fasteners designed to provide secure, vibration-resistant connections in various industrial and commercial applications. These specialized nuts incorporate locking mechanisms that prevent loosening under dynamic loads, temperature fluctuations, and vibrational stress. The inherent properties of Brass, including excellent corrosion resistance, electrical conductivity, and machinability, make these fasteners ideal for marine environments, electrical installations, plumbing systems, and precision machinery applications.

Our manufacturing process incorporates advanced metallurgical techniques ensuring optimal grain structure and mechanical properties. Each Brass Lock Nut undergoes rigorous quality testing including dimensional verification, thread inspection, torque testing, and surface finish analysis. The superior anti-seize properties of Brass combined with precision threading guarantee reliable performance in both standard and challenging environmental conditions.

Types of Brass Lock Nuts

Brass Hex Lock Nuts

Brass Hex Lock Nuts feature a six-sided external configuration providing optimal gripping surface for standard wrenches and socket tools. These nuts incorporate either nylon inserts, metal inserts, or deformed thread locking mechanisms to prevent loosening under vibration. The hexagonal design ensures uniform load distribution and facilitates easy installation and removal. Available in metric and imperial thread specifications, these nuts are extensively used in automotive applications, machinery assembly, and structural connections where reliable fastening is critical. The Brass construction provides excellent corrosion resistance while maintaining structural integrity under varying temperature conditions.

Brass Metric Lock Nuts

Brass Metric Lock Nuts conform to international metric threading standards including ISO 262 and DIN 13. These precision-manufactured fasteners feature metric pitch threads ranging from M3 to M64 sizes with standard and fine pitch options. The metric specification ensures compatibility with global manufacturing standards and facilitates seamless integration with metric bolt systems. Advanced manufacturing processes guarantee thread accuracy within ±0.1mm tolerance limits. These nuts are particularly suited for European and Asian machinery applications, precision instruments, and equipment requiring metric fastening solutions. The consistent thread geometry ensures reliable torque transmission and prevents cross-threading issues.

Brass UNEF Lock Nuts

Brass UNEF (Unified National Extra Fine) Lock Nuts represent the premium category of fine-thread fasteners designed for applications requiring maximum thread engagement and superior holding power. The extra-fine thread pitch provides increased threads per inch, resulting in enhanced resistance to loosening and improved fatigue life. These specialized nuts are essential in aerospace applications, precision machinery, and high-stress environments where standard threading may prove inadequate. The UNEF specification ensures compatibility with corresponding bolts and provides superior vibration resistance. Manufacturing involves precise thread cutting operations using specialized tooling to maintain exact pitch dimensions and thread form geometry.

Brass Cable Gland Lock Nuts

Brass Cable Gland Lock Nuts are specifically engineered for electrical and telecommunications applications requiring secure cable entry and environmental sealing. These nuts feature specialized threading compatible with cable gland bodies and provide compression force for effective sealing against moisture, dust, and contaminants. The Brass construction offers excellent electrical conductivity and EMC shielding properties essential for sensitive electronic equipment. Available in various thread specifications including metric, PG (German standard), and NPT threads, these nuts ensure reliable cable management in control panels, junction boxes, and outdoor electrical installations. The anti-corrosion properties of Brass make them ideal for marine and industrial environments.

Brass Conduit Lock Nuts

Brass Conduit Lock Nuts are designed for electrical conduit systems requiring secure mechanical connection and electrical continuity. These nuts feature internal and external threading configurations to accommodate various conduit types including rigid metal conduit, flexible metal conduit, and liquid-tight conduit systems. The precision threading ensures proper engagement with conduit fittings while maintaining electrical ground continuity throughout the installation. Brass construction provides superior corrosion resistance in harsh environmental conditions and maintains electrical conductivity over extended service life. These nuts are essential components in industrial electrical installations, commercial buildings, and hazardous location wiring systems.

UNS C36000 Brass Lock Nuts

UNS C36000 Brass Lock Nuts are manufactured from free-machining Brass alloy containing approximately 61.5% Copper and 35.5% Zinc with lead additions for enhanced machinability. This alloy designation represents the industry standard for high-volume production applications requiring excellent threading characteristics and dimensional stability. The free-machining properties enable rapid production cycles while maintaining superior thread quality and surface finish. These nuts exhibit excellent strength-to-weight ratio and provide reliable performance in automotive, plumbing, and general industrial applications. The standardized chemical composition ensures consistent mechanical properties and facilitates quality control throughout the manufacturing process.

CZ121 Brass Lock Nuts

CZ121 Brass Lock Nuts conform to British Standard specifications representing a high-quality Brass alloy with optimized Copper-Zinc composition for superior mechanical properties. This alloy offers enhanced tensile strength, improved ductility, and excellent corrosion resistance compared to standard Brass formulations. The CZ121 designation ensures compliance with European quality standards and provides traceability for critical applications. These nuts are particularly suited for marine hardware, precision instruments, and applications requiring long-term durability under challenging environmental conditions. The controlled alloy composition maintains consistent performance characteristics and enables reliable torque specifications for assembly operations.

Material Grades and International Standards

| Standard | Material Grade | Composition (%) | Tensile Strength (MPa) | Applications |

|---|---|---|---|---|

| ASTM B16 | UNS C36000 | Cu: 60-63, Zn: Balance, Pb: 2.5-3.7 | 300-380 | General purpose, automotive |

| BS EN 12164 | CZ121 | Cu: 57-60, Zn: Balance, Pb: 2.5-3.5 | 320-420 | Marine, precision instruments |

| DIN 17660 | CuZn39Pb3 | Cu: 57-60, Zn: 36-42, Pb: 2.5-3.5 | 300-400 | Electrical, plumbing |

| JIS H3250 | C3604 | Cu: 57-61, Zn: Balance, Pb: 2.5-3.7 | 315-400 | Electronics, machinery |

| IS 319 | Grade-1 | Cu: 58-62, Zn: Balance, Pb: 2.0-3.5 | 290-370 | General engineering |

| GB/T 4423 | HPb59-1 | Cu: 57-60, Zn: Balance, Pb: 0.8-1.9 | 315-450 | Precision components |

Manufacturing Processes and Machinery

Our advanced manufacturing facility employs state-of-the-art production techniques to ensure consistent quality and precision in every Brass Lock Nut. The manufacturing process begins with careful selection and inspection of raw Brass rod materials conforming to specified alloy compositions. Hot forging operations using hydraulic presses ranging from 100-ton to 500-ton capacity create the initial hexagonal shape with optimal grain flow and mechanical properties.

CNC multi-spindle automatic lathes including Swiss-type machines perform precision turning operations to achieve exact external dimensions and hex tolerances within ±0.05mm limits. Thread rolling machinery using hardened steel dies creates superior internal threading with work-hardened surfaces providing enhanced fatigue resistance compared to cut threads. Our thread milling centers equipped with high-precision spindles ensure accurate thread profile geometry and surface finish.

Advanced heat treatment furnaces with controlled atmosphere systems perform stress relieving and annealing operations to optimize mechanical properties and dimensional stability. Automated inspection systems including optical comparators, coordinate measuring machines (CMM), and thread gauges verify dimensional accuracy, thread quality, and surface finish specifications. Surface treatment equipment provides various finishing options including passivation, plating, and protective coatings as required by specific applications.

Dimensional Specifications and Tolerances

| Thread Size | Hex Width (mm) | Overall Height (mm) | Thread Pitch | Tolerance Class | Weight (grams) |

|---|---|---|---|---|---|

| M3 | 5.5 | 4.0 | 0.5 | 6H | 0.8 |

| M4 | 7.0 | 5.0 | 0.7 | 6H | 1.5 |

| M5 | 8.0 | 5.5 | 0.8 | 6H | 2.3 |

| M6 | 10.0 | 6.0 | 1.0 | 6H | 3.8 |

| M8 | 13.0 | 8.0 | 1.25 | 6H | 7.2 |

| M10 | 17.0 | 10.0 | 1.5 | 6H | 12.5 |

| M20 | 24.0 | 3.5 | 1.5 | 6H | 4 |

| M25 | 30.0 | 4 | 1.5 | 6H | 7 |

| M32 | 40 | 4 | 1.5 | 6H | 15 |

| M40 | 59 | 4.5 | 1.5 | 6H | 22 |

Surface Finishes and Coatings

Our comprehensive range of surface finishes enhances both aesthetic appeal and functional performance of Brass Lock Nuts. Natural Brass finish provides the inherent golden appearance with excellent corrosion resistance suitable for decorative and functional applications. Passivated finish involves chemical treatment creating a protective oxide layer that enhances corrosion resistance and provides uniform appearance.

Nickel plating offers superior wear resistance and enhanced aesthetic appeal with thickness ranging from 5-25 microns depending on application requirements. Chrome plating provides exceptional hardness and corrosion resistance for demanding industrial applications. Zinc plating with chromate conversion coating delivers cost-effective corrosion protection with various color options including clear, yellow, and olive drab finishes.

Industries and Applications

| Industry Sector | Primary Applications | Key Requirements | Preferred Material Grade |

|---|---|---|---|

| Marine & Shipbuilding | Deck hardware, rigging, propulsion systems | Corrosion resistance, strength | CZ121, UNS C36000 |

| Electrical & Electronics | Panel mounting, cable glands, switchgear | Conductivity, EMC shielding | CZ121, C3604 |

| Automotive | Engine components, exhaust systems | Temperature resistance, durability | UNS C36000 |

| Plumbing & HVAC | Pipe fittings, valve assemblies | Pressure resistance, machinability | CuZn39Pb3 |

| Construction | Structural connections, architectural hardware | Weather resistance, aesthetics | CZ121 |

| Aerospace | Interior fittings, non-critical structures | Weight reduction, reliability | UNEF specifications |

Quality Control and Testing

Our comprehensive quality assurance program encompasses incoming material inspection, in-process monitoring, and final product verification. Chemical composition analysis using X-ray fluorescence spectroscopy ensures conformance to specified alloy requirements. Dimensional inspection utilizing coordinate measuring machines, optical comparators, and specialized thread gauges verifies compliance with drawing specifications and international standards.

Mechanical property testing includes tensile testing, hardness measurement, and stress-corrosion cracking evaluation performed according to ASTM and ISO test methods. Thread quality assessment involves go/no-go gauge inspection, thread profile analysis, and torque-tension relationship testing to ensure proper fit and function. Surface finish evaluation using profilometry and visual inspection standards guarantees consistent appearance and functionality.

Frequently Asked Questions

Yes, our express production line can accommodate urgent requirements with delivery within 2-3 weeks for standard specifications. Rush order capabilities depend on current production schedule, quantity requirements, and material availability. Additional charges may apply for expedited processing.

Kindly contact us at sales@conexscrews. com for all Brass Lock Nut needs.