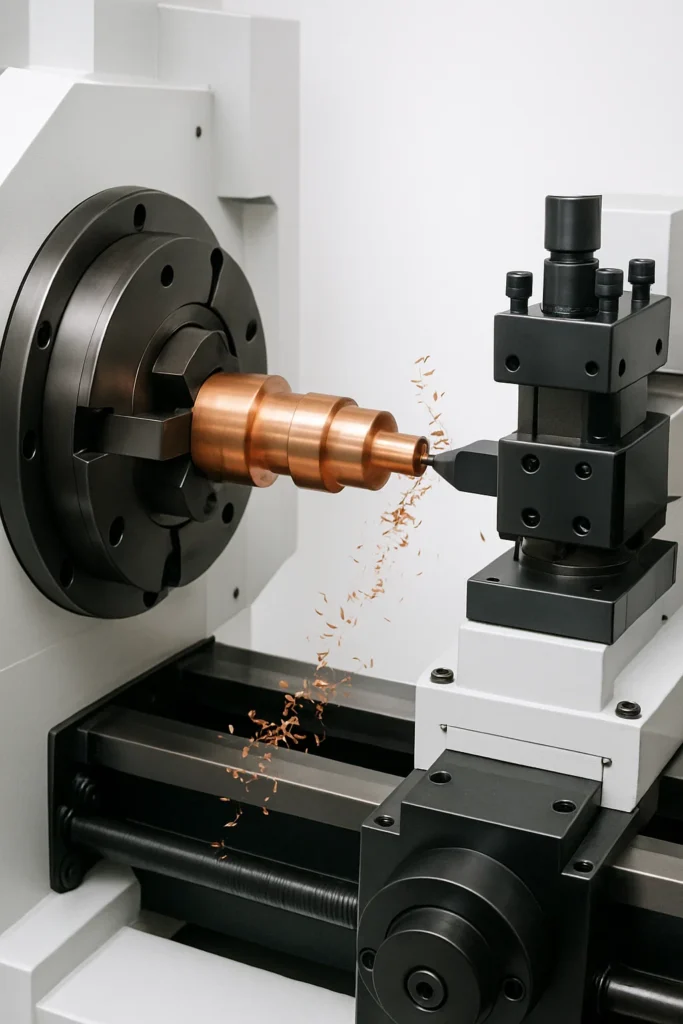

Copper Screw Machine Parts CNC Turned Parts Copper CNC turned Machined Parts

Rate: US$ 12.40/kilogram

As a premier manufacturer of precision-engineered copper components, we specialize in creating high-quality Copper screw machine parts and CNC machine components , Copper CNC machined Parts and Copper CNC machined components tailored to meet the unique demands of various industries. Our state-of-the-art manufacturing facilities and skilled workforce ensure exceptional precision, durability, and reliability for all our products.

Copper Materials and Grades Machined

We utilize premium-grade copper materials to deliver components that excel in performance and longevity. Common grades include:

| Material Grade | Properties | Applications |

|---|---|---|

| C101 (Oxygen-Free) | High conductivity, excellent corrosion resistance | Electrical connectors, transformer components |

| C110 (ETP) | Superior electrical and thermal conductivity | Power systems, switchgear, HVAC parts |

| C122 (Phosphorized) | Ideal for brazing and welding, corrosion resistant | Plumbing, industrial fittings, custom components |

Typical Copper Parts Manufactured

We produce a wide variety of copper components, including but not limited to:

| Part Name | Application |

| Electrical Contacts, Copper contacts, Copper cable lugs terminals | Ensuring efficient power transfer in electrical systems. |

| Bus Bars, Copper terminal bars, Copper Grounding bars | Power distribution systems and switchgear. |

| Transformer Terminals, Copper spade terminals | Critical components for power transformers. |

| HVAC Fittings | Durable and reliable parts for heating and cooling. |

| Custom Copper Fasteners Copper Nuts Copper and Bronze washers | High-strength fasteners for industrial use. |

| Plumbing Components, Copper Olives, Copper Sleeves | Corrosion-resistant parts for water systems. |

| Heat Exchanger Tubes | Superior thermal conductivity for cooling systems. |

| Copper Studs, Copper Terminal Blocks, Grounding clamps | Essential for electrical and electronic devices. |

Machines Used

To achieve unparalleled precision, we employ advanced machinery that meets the diverse requirements of our customers:

- CNC Lathes: For high-accuracy turning and threading operations.

- Swiss-Type Machines: Ideal for small and intricate parts with high repeatability.

- Vertical and Horizontal Milling Machines: For versatile and complex machining tasks.

- Grinding Machines: Precision surface and cylindrical grinding for tight tolerances.

- Hobbing Machines: Specialized for creating gears and splines with high precision.

Machining Services Offered

We provide a wide range of machining services to ensure your components meet exact specifications:

| Service | Description |

| Turning | High-speed turning for complex geometries and accurate dimensions. |

| Milling | Multi-axis milling for intricate designs and complex profiles. |

| Threading | Internal and external threading, including UNC, UNF, metric, and custom types. |

| Grinding | Achieving ultra-fine finishes and precise dimensions. |

| Drilling | High-precision drilling and boring for performance-critical applications. |

| Broaching | Cutting unique internal shapes, such as keyways. |

| Knurling | Adding texture for enhanced grip and functionality. |

Inspection and Quality Assurance

Our commitment to quality is unwavering, and we employ stringent inspection processes to ensure every part meets the highest standards:

- First Article Inspection (FAI): Comprehensive verification of the first batch of components.

- In-Process Inspections: Continuous monitoring during production to maintain precision.

- CMM Inspection: Coordinate Measuring Machines for precise dimensional checks.

- Material Certifications: Full compliance with required standards.

- Final Inspection: 100% quality checks of all critical features and dimensions.

Tolerances and Precision

We excel in delivering components with ultra-tight tolerances and exceptional surface finishes:

| Specification | Capability |

| Dimensional Tolerance | Up to ±0.0001 inches. |

| Surface Finish | Achieving up to Ra 8 microinches. |

| Thread Accuracy | Conforming to international standards. |

Finishing Services

We provide a comprehensive range of finishing options to enhance the functionality and aesthetics of your copper components:

| Finishing Type | Benefits |

| Polishing | Smooth, mirror-like finishes for aesthetics. |

| Plating | Nickel, tin, and silver plating for corrosion resistance and conductivity. |

| Powder Coating | Durable, corrosion-resistant coatings. |

| Passivation | Enhanced corrosion resistance for long life. |

Industries Served

Our copper components serve a wide range of industries, including:

- Electrical and Power Distribution: Components for transformers, switchgear, and connectors.

- HVAC: Durable parts for heating, ventilation, and cooling systems.

- Automotive: Reliable components for electrical and mechanical systems.

- Industrial Equipment: Precision parts for heavy machinery and tooling.

- Renewable Energy: Copper components for solar and wind power systems.

Why Choose Us?

- Expertise: Decades of experience in machining high-quality copper components.

- State-of-the-Art Facilities: Equipped with advanced machinery for unparalleled precision.

- Customization: Tailored solutions to meet your specific needs.

- Quality Assurance: Rigorous inspection processes ensure top-notch quality.

- Timely Delivery: Efficient production processes for on-time delivery.

Contact Us

Partner with Conex Screws and Fasteners for all your Copper screw machine parts, Copper Turned parts, Copper machined components, Copper CNC machined Parts , Copper Turned Components, and CNC machine components. Reach out to us for inquiries, quotes, or to discuss your project requirements.