Premium Quality Copper Studs, Copper Threaded Studs & Copper Transformer Studs, Threaded Rods of Copper

PRICE: US$ 11.90/Kilo

High-Performance Copper Studs, Threaded Copper studs, Copper Threaded Rods for Electrical and Transformer Applications

We are one of the leading manufacturers and exporters of Copper Studs, Copper Threaded Studs, and Transformer Studs from India. We have been supplying high-quality Copper studs to the world market for many decades. Our advanced manufacturing facilities, stringent quality control processes, and dedicated team of engineers ensure that each product meets the highest international standards. With an extensive range of sizes and threading options, we cater to diverse electrical applications, particularly in the transformer manufacturing industry. Our commitment to excellence, timely delivery, and customer satisfaction has made us a trusted supplier globally. We offer Half threaded Copper studs and Full threaded Copper studs both as needed.

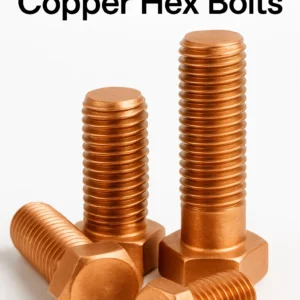

Copper Studs

Copper Studs are critical components used in various electrical applications, particularly in power transmission and distribution equipment. Manufactured from high-conductivity Copper alloys, these studs offer exceptional electrical conductivity, thermal performance, and corrosion resistance. Our Copper studs are precision-engineered to provide reliable electrical connections in transformers, switchgear, and other high-voltage equipment. The studs feature uniform material composition throughout, ensuring consistent electrical properties and mechanical strength. We utilize advanced CNC machining technology to achieve precise dimensions and smooth surface finishes. Available in various sizes ranging from small diameters of 6mm to larger 20mm variants, our Copper studs are designed to withstand high temperatures and electrical loads while maintaining structural integrity over extended operational periods. Each stud undergoes rigorous testing for electrical conductivity, tensile strength, and dimensional accuracy before dispatch.

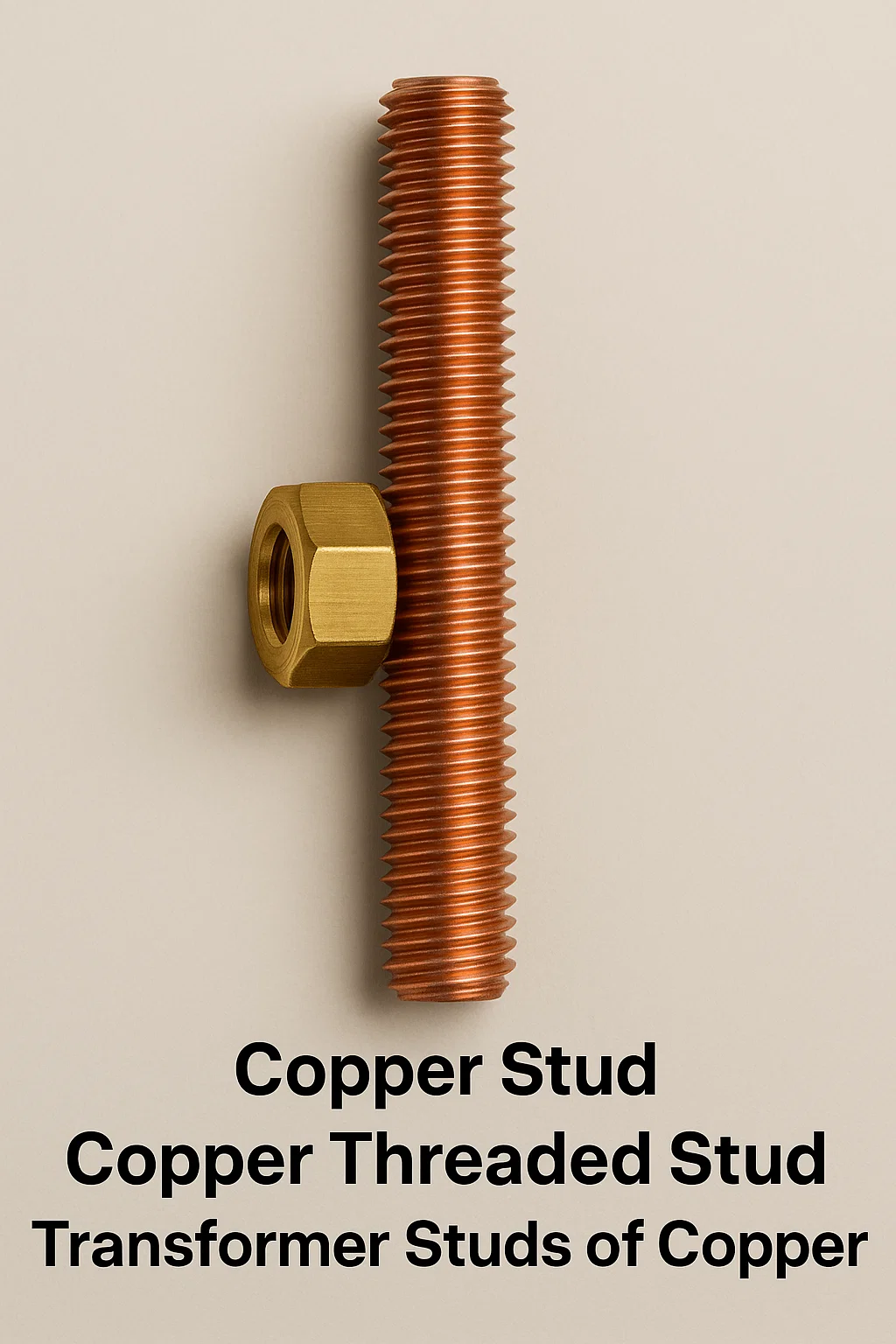

Copper Threaded Studs

Copper Threaded Studs represent our specialized offering designed for applications requiring secure, high-conductivity electrical connections. These precision-engineered components feature meticulously cut threads in both Metric (M6-M20) and UNC (1/4″, 5/16″, 3/8″, 1/2″, and 3/4″) standards, with lengths extending up to 12 inches (300mm). We manufacture these threaded studs using premium-grade Electrolytic Tough Pitch (ETP) Copper and Oxygen-Free High Conductivity (OFHC) Copper to ensure optimal electrical performance. The manufacturing process involves multi-stage machining, where high-precision thread cutting ensures uniform thread profiles with tight tolerances. The threading process is carefully controlled to prevent material fatigue and ensure long-term reliability. These threaded studs are particularly valuable in transformer terminals, busbars, and other electrical connection points where consistent torque retention and vibration resistance are essential. Our Copper threaded studs maintain excellent electrical connectivity even under thermal cycling and provide superior corrosion resistance compared to plated alternatives, making them ideal for installations in challenging environmental conditions.

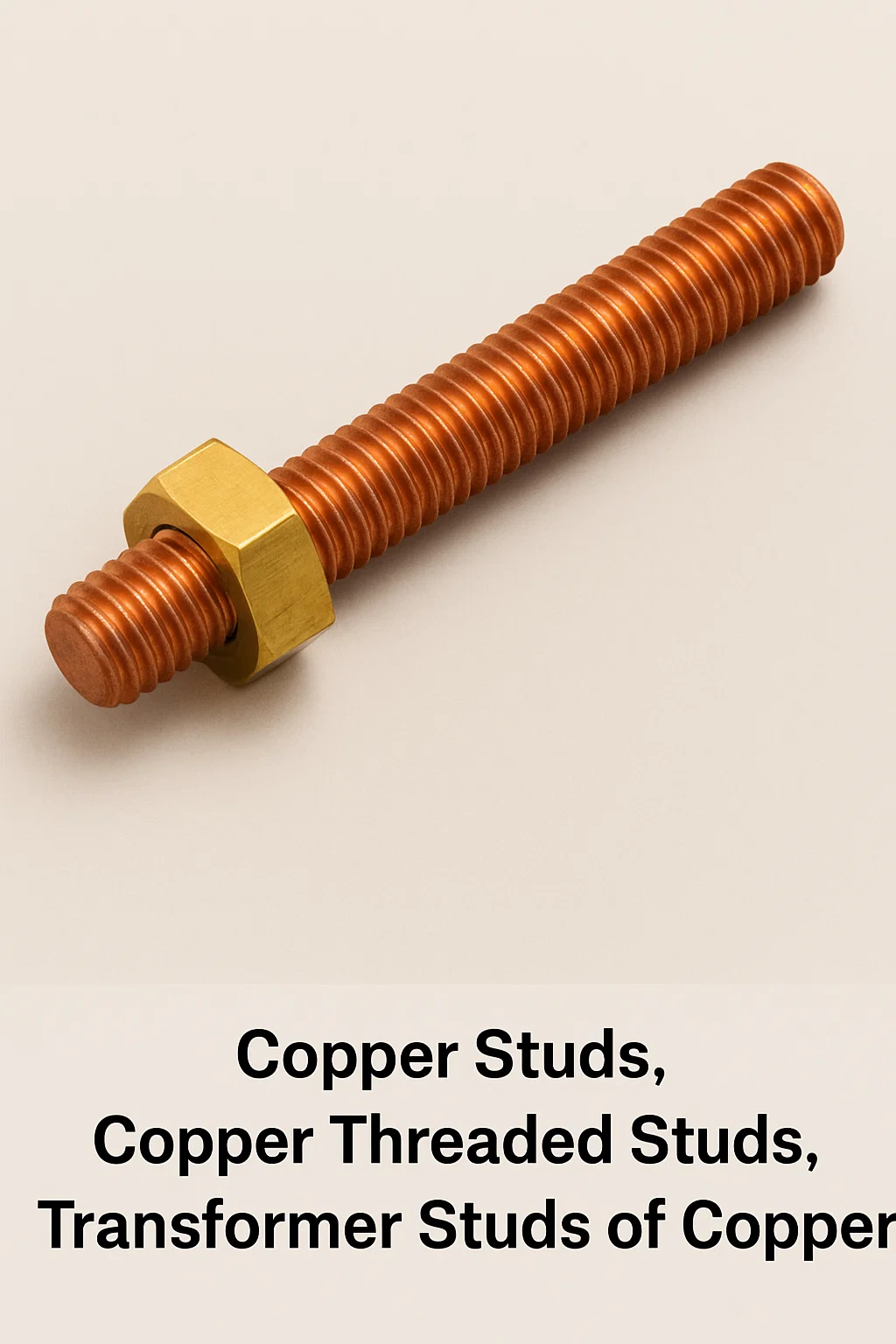

Transformer Studs of Copper

Transformer Studs of Copper are specialized components designed explicitly for transformer bushings and related applications in power distribution equipment. These high-performance studs are manufactured from premium C11000 Electrolytic Tough Pitch (ETP) Copper and C10200 Oxygen-Free (OF) Copper for applications requiring exceptional electrical conductivity and heat dissipation. Our transformer studs feature precision-engineered threading and dimensional consistency critical for proper installation and operation in transformer assemblies. The manufacturing process involves CNC turning, threading, and surface finishing to achieve the exact specifications required for transformer bushing applications. These studs serve as crucial connectors between transformer windings and external circuits, handling significant electrical loads while maintaining thermal stability. We produce transformer studs in various configurations, including special designs with stepped diameters, custom head shapes, and application-specific threading patterns. Each transformer stud undergoes comprehensive electrical testing, dimensional verification, and surface inspection before being approved for shipment. These components are essential for maintaining the operational integrity of power transformers in substations, industrial facilities, and utility infrastructure projects.

Threaded Rods of Copper

Threaded Rods of Copper represent the pinnacle of continuous-thread fasteners for electrical applications requiring superior conductivity and corrosion resistance. These precision-engineered components feature continuous threading along their entire length, manufactured from high-purity Copper alloys including ETP (Electrolytic Tough Pitch) and OFHC (Oxygen-Free High Conductivity) grades. Our Copper threaded rods offer exceptional electrical performance with conductivity ratings of 100-101% IACS while maintaining excellent mechanical properties and thread integrity. Available in both metric (M6-M20) and imperial (1/4″ to 3/4″ UNC) thread standards with lengths up to 3 meters, these versatile components can be easily cut to custom lengths for specific applications. The continuous threading allows for precise adjustment and positioning in assemblies, making them ideal for electrical panel construction, bus bar connections, earthing systems, and various power distribution applications. Each threaded rod undergoes rigorous quality inspection including conductivity testing, dimensional verification, and thread profile analysis to ensure consistent performance in demanding electrical environments.

We are one of the leading manufacturers and exporters of Copper Studs, Copper Threaded Studs, Threaded Rods, and Transformer Studs from India. We have been supplying high-quality Copper studs to the world market for many decades. Our advanced manufacturing facilities, stringent quality control processes, and dedicated team of engineers ensure that each product meets the highest international standards. With an extensive range of sizes and threading options, we cater to diverse electrical applications, particularly in the transformer manufacturing industry. Our commitment to excellence, timely delivery, and customer satisfaction has made us a trusted supplier globally.

Material Grades and Properties

Our Copper studs are manufactured using premium-grade Copper alloys, selected based on specific application requirements:

| Material Grade | Composition | Electrical Conductivity | Tensile Strength | Application Suitability |

|---|---|---|---|---|

| C11000 (ETP Copper) | 99.90% Cu min | 100% IACS | 220-250 MPa | General electrical applications |

| C10200 (OF Copper) | 99.95% Cu min | 101% IACS | 220-250 MPa | High-reliability applications |

| C10100 (OFE Copper) | 99.99% Cu min | 101.5% IACS | 220-240 MPa | Premium transformer applications |

| C10700 (Oxygen-free Silver-bearing Copper) | 99.90% Cu + Ag | 100% IACS | 250-280 MPa | Enhanced temperature resistance |

Material Properties

| Property | Value | Standard |

|---|---|---|

| Electrical Conductivity | 100-101.5% IACS | ASTM B193 |

| Thermal Conductivity | 391-394 W/m·K | ASTM E1225 |

| Coefficient of Thermal Expansion | 17.7 x 10^-6 /°C | ASTM E228 |

| Density | 8.94 g/cm³ | ASTM B311 |

| Melting Point | 1083°C | – |

| Modulus of Elasticity | 117 GPa | ASTM E111 |

Manufacturing Process

Our Copper studs are manufactured through a sophisticated, multi-stage process that ensures consistency and quality:

- Material Selection: Premium Copper billets are sourced and certified for composition and quality.

- CNC Machining: Advanced multi-axis CNC machines transform raw material into precisely dimensioned studs.

- Threading Operations: High-precision thread cutting tools create accurate thread profiles according to international standards. We can offer roll threaded Copper studs or Cut threaded.

- Heat Treatment: Controlled annealing processes optimize mechanical properties while maintaining electrical conductivity.

- Surface Finishing: Specialized techniques are employed to achieve the required surface characteristics.

- Quality Inspection: Comprehensive testing including dimensional verification, conductivity measurements, and mechanical property validation.

Machinery Employed

Our state-of-the-art production facility utilizes:

- CNC Swiss-Type Automatic Lathes: For high-precision turning and threading operations

- CNC Multi-Spindle Automatics: For high-volume production with consistent quality

- Specialized Thread Rolling Equipment: For enhanced thread strength and finish

- Advanced Heat Treatment Furnaces: For controlled annealing processes

- Roll Threading machines: High Strength rolled threads

- Coordinate Measuring Machines (CMM): For precision dimensional inspection

- Electrical Conductivity Testing Equipment: For verifying material properties

- Metallurgical Analysis Systems: For material composition verification and quality control

Product Specifications and Dimensions

Standard Dimensional Range

| Parameter | Metric Range | Imperial Range |

|---|---|---|

| Thread Sizes | M6, M8, M10, M12, M16, M20 | 1/4″, 5/16″, 3/8″, 1/2″, 3/4″ |

| Length | 20mm to 300mm | 0.75″ to 12″ |

| Shank Diameter | 6mm to 20mm | 0.25″ to 0.75″ |

| Head Styles | Hex, Round, Custom | Hex, Round, Custom |

Typical Dimensional Specifications for Copper Transformer Studs

| Thread Size | D (Thread Diameter) | L (Total Length) | A (Threaded Length) | B (Unthreaded Length) | Torque Rating |

|---|---|---|---|---|---|

| M8 | 8.0 mm | 50-200 mm | 20-40 mm | Variable | 15-18 Nm |

| M10 | 10.0 mm | 60-200 mm | 25-45 mm | Variable | 28-33 Nm |

| M12 | 12.0 mm | 80-250 mm | 30-50 mm | Variable | 50-60 Nm |

| M16 | 16.0 mm | 100-300 mm | 40-60 mm | Variable | 120-140 Nm |

| 3/8″ UNC | 9.5 mm | 2″-10″ | 0.75″-1.5″ | Variable | 25-30 Nm |

| 1/2″ UNC | 12.7 mm | 3″-12″ | 1″-2″ | Variable | 55-65 Nm |

Note: Custom dimensions available upon request. Tolerances generally maintained at ±0.05mm for critical dimensions.

Applicable Standards

Our Copper studs comply with numerous international standards, ensuring global compatibility and acceptance:

- ASTM B187/B187M: Standard Specification for Copper, Bus Bar, Rod, and Shapes

- ASTM B133: Standard Specification for Copper Rod, Bar, and Shapes

- IS 1897: Copper strips for electrical purposes

- BS EN 12163: Copper and Copper alloys – Rod for general purposes

- DIN 17671: Copper and Copper alloy rods

- JIS H3250: Copper and Copper alloy rods and bars

- IEC 60137: Insulated bushings for alternating voltages above 1000 V

- IEEE C57.19.00: General Requirements and Test Procedures for Power Apparatus Bushings

Engineering Tolerances on Copper Studs, Copper Threaded Rods ,Threaded Copper Studs, Copper Transformer Studs

We maintain strict tolerances to ensure perfect fit and function across all applications:

| Dimension | Standard Tolerance | Precision Tolerance (Available on Request) |

|---|---|---|

| Diameter | ±0.05 mm | ±0.02 mm |

| Length | ±0.20 mm | ±0.10 mm |

| Thread Pitch | Class 6g (Metric) / Class 2A (UNC) | Class 4h (Metric) / Class 3A (UNC) |

| Concentricity | 0.05 mm TIR | 0.02 mm TIR |

| Surface Finish | Ra 1.6 μm | Ra 0.8 μm |

Industries and Applications

Our Copper studs serve critical roles across numerous industries:

Power Generation and Distribution

- Transformer bushings and terminals

- Switchgear connections

- Generator terminals

- Substation equipment

Heavy Electrical Equipment

- Industrial motor connections

- Power supply systems

- Circuit breaker terminals

- Control panel assemblies

Renewable Energy Systems

- Solar inverter connections

- Wind power generation equipment

- Energy storage systems

- Grid connection equipment

Transportation

- Electric locomotive systems

- Subway power distribution

- Electric vehicle charging infrastructure

- Marine electrical systems

Industrial Manufacturing

- Induction furnace connections

- Welding equipment terminals

- Electroplating equipment

- Industrial heating systems

Performance Metrics

Our Copper studs are designed to deliver exceptional performance across critical parameters:

| Performance Parameter | Typical Value | Test Method |

|---|---|---|

| Electrical Conductivity | >100% IACS | ASTM B193 |

| Maximum Current Density | 4-6 A/mm² | Application-specific |

| Temperature Rise | <45°C above ambient at rated current | IEC 60694 |

| Corrosion Resistance | >1000 hours in salt spray test | ASTM B117 |

| Thread Engagement Strength | >95% of material tensile strength | ASTM F606 |

| Contact Resistance | <5 μΩ | MIL-STD-1344 |

| Thermal Cycling Stability | <2% change in electrical properties after 500 cycles | Internal test method |

Why Choose Our Copper Studs?

Technical Excellence

Our dedicated R&D team continuously improves our manufacturing processes and product designs to deliver components that exceed industry standards. With state-of-the-art production facilities and rigorous quality control, we ensure each Copper stud meets precise specifications.

Manufacturing Expertise

With three decades of global experience in metal component manufacturing, we’ve refined our processes to achieve exceptional quality and consistency. Our skilled technicians and engineers bring unmatched expertise to every production run.

Customization Capabilities

We understand that standard solutions don’t always meet specialized requirements. Our flexible manufacturing approach allows us to accommodate custom designs, special threading requirements, and unique dimensional specifications with minimal setup time.

Quality Assurance

Our comprehensive quality management system includes material certification, in-process inspection, and final verification. Each batch undergoes testing for electrical conductivity, dimensional accuracy, and mechanical properties before shipment.

Global Supply Chain Experience

As established exporters, we’ve optimized our logistics processes to ensure reliable delivery anywhere in the world. Our experience navigating international shipping requirements means your order arrives on time, every time.

Responsive Customer Support

Our dedicated account managers provide personalized service, technical consultation, and prompt communication throughout your ordering process. We pride ourselves on being accessible and responsive to customer needs.

Packaging and Shipping

We employ industry-leading packaging methods to ensure your Copper studs arrive in perfect condition:

- Primary Protection: Each Copper stud is individually wrapped in VCI (Volatile Corrosion Inhibitor) paper to prevent oxidation

- Organizational Packaging: Components are arranged in custom-designed trays or compartmentalized boxes to prevent contact damage

- Moisture Protection: Vacuum-sealed pouches with desiccant for humidity-sensitive applications

- Cushioning: Impact-absorbing materials protect components during transit

- Outer Packaging: Heavy-duty export-grade cartons with reinforced corners

- Customization Available: Custom labeling with your company logo, part numbers, and handling instructions

- Documentation: Complete packing lists, material certifications, and quality inspection reports included

Shipping Options

- Standard Air Freight: 7-10 business days to most global destinations

- Express Air Freight: 3-5 business days for urgent requirements

- Sea Freight: 30-45 days for economical shipping of larger orders

- Door-to-Door Delivery: Complete logistics management available

Turnaround Time

Our standard production lead time for Copper studs is 4-6 weeks from order confirmation, depending on quantity and specifications. For urgent requirements, we offer:

- Fast-Track Production: 2-3 weeks (subject to 15% expedite fee)

- Emergency Production: 1-2 weeks for critical requirements (subject to 30% expedite fee and quantity limitations)

Frequently Asked Questions

Q: What is the minimum order quantity for standard Copper studs? A: Our standard minimum order quantity is 500 pieces for catalog items. For custom designs, the minimum order is typically 1,000 pieces, though we can accommodate smaller quantities for specialized applications with adjusted pricing.

Q: Can you produce Copper studs with custom thread profiles? A: Yes, we can manufacture Copper studs with custom thread profiles, including specialized thread forms, multi-start threads, and application-specific pitch modifications. Our engineering team will work with you to develop the appropriate specifications.

Q: What is the electrical conductivity of your standard Copper studs? A: Our standard Copper studs have an electrical conductivity of 100-101% IACS (International Annealed Copper Standard), depending on the specific alloy used. For specialized high-conductivity applications, we offer alloys with up to 102% IACS.

Q: Do you provide material certifications with each order? A: Yes, we provide material certifications that include chemical composition analysis and mechanical property testing results with each shipment. Additional certification options are available upon request.

Q: What surface finishes are available for Copper studs? A: Our standard finish is natural Copper with a clean, bright surface. We also offer tin plating, silver plating, nickel plating, and passivation treatments for specific application requirements.

Q: How do you ensure the quality of threaded components? A: Each threaded component undergoes comprehensive inspection including thread profile verification using specialized thread gauges, dimensional measurement with calibrated instruments, and visual inspection for surface defects. We maintain statistical process control throughout production.

Q: Can you match existing Copper studs if we provide samples? A: Yes, our reverse engineering capabilities allow us to analyze and reproduce existing components with precise matching of dimensions, material properties, and performance characteristics. Simply provide a sample along with your application requirements.

Q: What is the temperature rating of your Copper studs? A: Our standard Copper studs can operate continuously at temperatures up to 250°C without degradation of mechanical properties. For higher temperature applications, we recommend our silver-bearing Copper alloy variants which maintain strength at elevated temperatures.

Q: Do you offer any corrosion-resistant options for harsh environments? A: Yes, we offer several options for corrosion resistance including protective plating (tin, silver, or nickel), specialized passivation treatments, and corrosion-inhibiting packaging for long-term storage. Our engineering team can recommend the optimal solution for your specific environmental conditions.

Q: What testing do you perform on Copper studs before shipment? A: Each batch undergoes comprehensive testing including dimensional verification, material hardness testing, electrical conductivity measurement, and visual inspection. For critical applications, we can provide additional specialized testing such as tensile strength verification, microstructure analysis, and salt spray corrosion testing.

Customer Testimonial

“We’ve been sourcing Copper transformer studs from this manufacturer for our power distribution equipment for over five years now. Their attention to detail, consistent quality, and technical support have been exemplary. Even when we needed a custom design for a challenging application, their engineering team delivered a perfect solution within our timeline. The reliability of their products has significantly reduced our maintenance issues in the field.”

– Thomas Richards, Procurement Director, USA

Glossary of Terms

ETP Copper: Electrolytic Tough Pitch Copper with 99.9% minimum Copper content, the standard grade for electrical applications.

OFHC Copper: Oxygen-Free High Conductivity Copper with 99.95%+ purity, offering enhanced electrical performance.

IACS: International Annealed Copper Standard, the reference standard for electrical conductivity measurements.

Thread Class: Designation indicating the tolerance range for threads (e.g., Class 2A, 6g), affecting the fit and function.

Thread Pitch: The distance between adjacent thread crests, typically expressed in mm for metric threads or TPI (threads per inch) for imperial threads.

Bushing: An insulated device that allows an electrical conductor to pass safely through a grounded conducting barrier.

Major Diameter: The largest diameter of a thread on an external (male) thread.

Pitch Diameter: The theoretical intermediate diameter of a thread where thread width equals groove width.

Transformer Terminal: Connection point where electrical conductivity transfers from the transformer winding to external circuits.

Surface Finish: Measure of the texture of a surface, often expressed as Ra (Roughness average) in micrometers.

Related Terms

- Copper Bus Bars

- Transformer Bushing Connections

- Power Distribution Components

- Electrical Conductor Hardware

- High Conductivity Fasteners

- Copper Terminal Connectors

- Transformer Assembly Parts

- Substation Connection Hardware

- Electrical Grade Copper Components

- Power Transmission Hardware

- Switchgear Connection Studs

- Industrial Electrical Fasteners

- High Current Connection Systems

- Copper Electrical Terminals

- Electrical Conductor Studs

Call-to-Action

Ready to enhance your electrical systems with premium quality Copper studs?

Contact us today to discuss your specific requirements:

- Request a Quote: Email us with your specifications for prompt pricing

- Download Technical Brochure: Complete our quick form to receive our comprehensive product catalog

- Technical Consultation: Call our engineering team at for expert advice on your application

With our 30 years of manufacturing excellence and global supply experience, we’re ready to be your trusted partner for high-performance Copper Studs, Copper Nuts Bolts, Transformer studs, Threaded Copper studs and other Copper machined parts and components.