Aluminum Deep Drawn Parts, Aluminum Deep Drawn Components, Aluminum Pressed Parts and Components, Aluminum Sheet Metal Deep Drawn Parts

Aluminum Deep Drawn Parts, Components, Pressed Parts, and Sheet Metal Deep Drawn Parts Manufacturer in India

Welcome to our premier manufacturing hub for Aluminum Deep Drawn Parts, Aluminum Deep Drawn Components, Aluminum Pressed Parts and Components, and Aluminum Sheet Metal Deep Drawn Parts. We are one of the leading manufacturers and exporters of Aluminum Deep Drawn Parts from India. We have been supplying precision-engineered Aluminum Deep Drawn Components to the world market for many decades, earning a reputation for quality, innovation, and reliability. With over three decades of global exposure, our expertise spans across industries such as automotive, aerospace, electronics, HVAC, and telecommunications. Our state-of-the-art facility in India is equipped with advanced machinery, enabling us to deliver high-precision Aluminum Pressed Parts that meet international standards like ASTM, DIN, JIS, BS, and IS. We pride ourselves on our ability to customize, offer flexible production timelines, and provide customized packaging with customer labels or logos, ensuring a seamless experience for our global clientele.

Overview of Aluminum Deep Drawn Parts, Components, Pressed Parts, and Sheet Metal Deep Drawn Parts

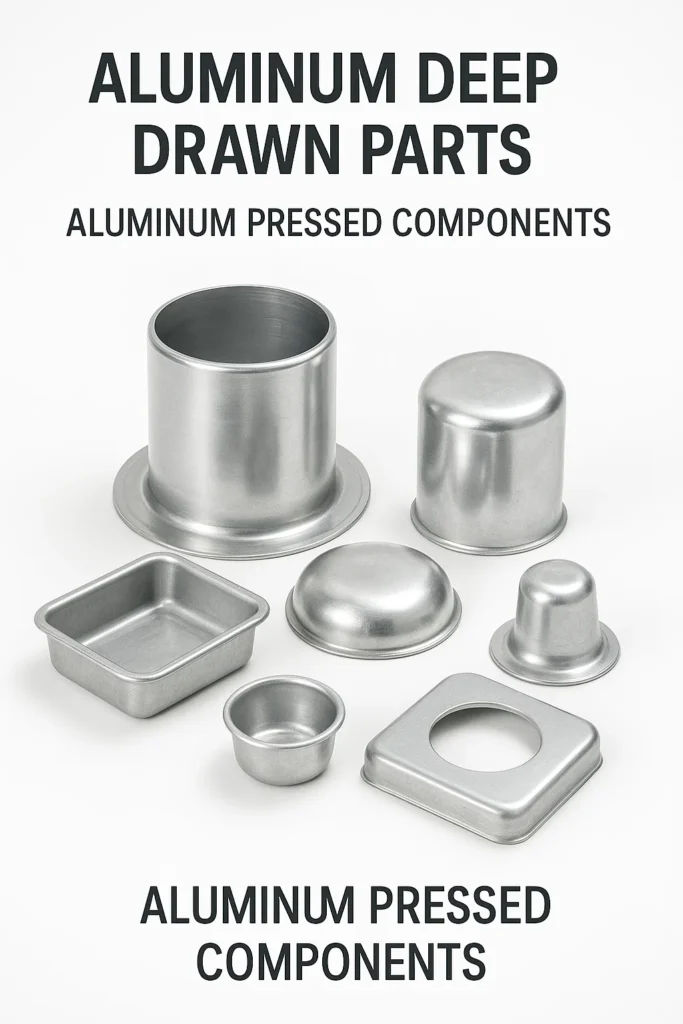

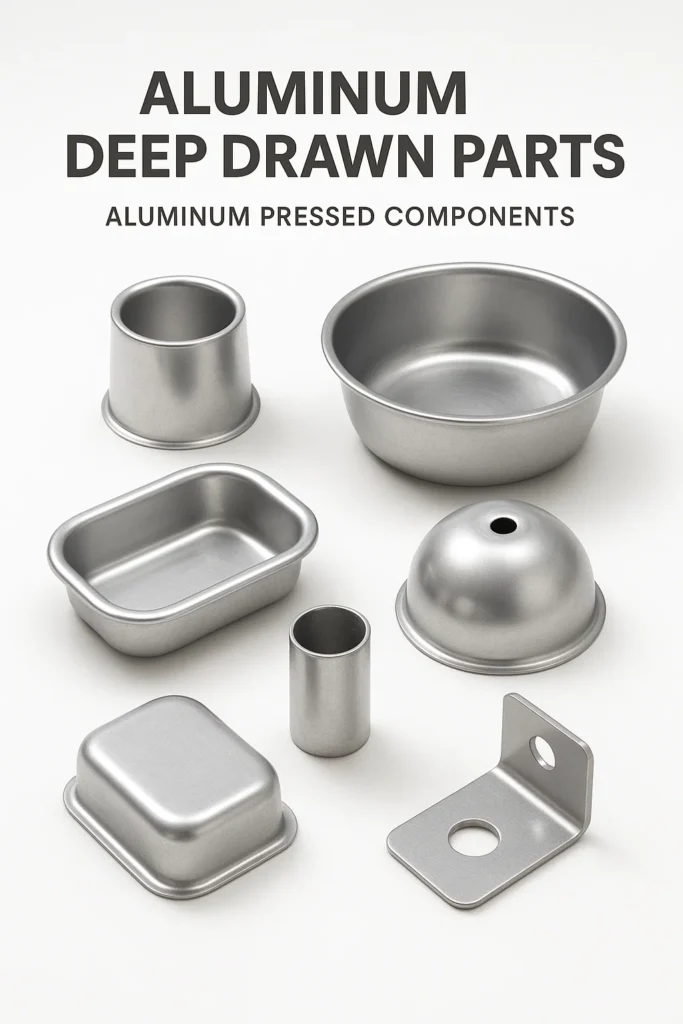

Aluminum Deep Drawn Parts are precision-engineered components manufactured through the deep drawing process, a metal forming technique that transforms flat Aluminum sheets into seamless, three-dimensional shapes. This process is ideal for creating complex geometries such as cylinders, enclosures, cups, and housings, which are widely used in industries requiring lightweight, corrosion-resistant, and durable parts. Our Aluminum Deep Drawn Parts are crafted using high-grade Aluminum alloys, ensuring excellent strength-to-weight ratio, formability, and resistance to harsh environments, making them a preferred choice for applications in automotive, aerospace, and medical sectors.

Aluminum Deep Drawn Components are specialized parts produced through a series of deep drawing operations, allowing for intricate shapes with tight tolerances. These components are known for their seamless construction, eliminating the need for welding or assembly, which enhances structural integrity and reduces production costs. We manufacture Aluminum Deep Drawn Components using advanced tooling and progressive dies, ensuring repeatability and precision for high-volume production runs. These components are widely utilized in electronics for enclosures, in automotive for fuel filters, and in industrial machinery for protective housings.

Aluminum Pressed Parts and Components are created through cold forming techniques, where Aluminum sheets are blanked, punched, bent, or embossed into desired shapes. These parts are lightweight, conductive, and corrosion-resistant, making them suitable for a wide range of applications, from electrical connectors to HVAC systems. Our Aluminum Pressed Parts are manufactured with a focus on dimensional accuracy and aesthetic finish, catering to industries like telecommunications, appliances, and automotive, where precision and durability are paramount.

Aluminum Sheet Metal Deep Drawn Parts are formed by drawing Aluminum sheets into dies to create seamless, hollow shapes with high structural integrity. This process is highly efficient for producing parts like cans, caps, and battery cases, offering excellent material utilization and cost-effectiveness. Our Aluminum Sheet Metal Deep Drawn Parts are available in various thicknesses ranging from 0.4 mm to 4 mm, and we ensure compliance with international standards such as ASTM, DIN, and JIS, making them ideal for applications in packaging, electronics, and consumer goods industries.

Material Grades and Properties

We use a wide range of Aluminum alloys to manufacture our deep drawn and pressed parts, ensuring compliance with international standards such as ASTM, DIN, JIS, BS, and IS. Below is a table of commonly used Aluminum grades along with their properties:

Grade | Standard | Key Properties | Typical Applications

-----------|------------|-----------------------------------------|------------------------------

1050 | ASTM B209 | High corrosion resistance, excellent formability | Electrical enclosures, reflectors

3003 | DIN 3.0517 | Good workability, moderate strength | Automotive fuel tanks, cookware

5052 | JIS H4000 | High fatigue strength, corrosion resistance | Aerospace components, marine parts

6061 | BS 1470 | High strength, good machinability | Structural components, machinery

1100 | IS 737 | High ductility, excellent conductivity | Heat exchangers, packaging cansThese Aluminum alloys are selected based on their strength-to-weight ratio, corrosion resistance, and formability, ensuring optimal performance in demanding applications.

Manufacturing Processes and Machinery Used

Our manufacturing process for Aluminum Deep Drawn Parts and Aluminum Pressed Components involves advanced cold forming techniques. The process begins with blanking, where flat Aluminum sheets are cut into circular or rectangular blanks. These blanks are then drawn into a die using a punch, forming seamless shapes through single or multiple drawing operations. We utilize progressive dies, compound dies, and deep draw tooling to achieve complex geometries with depths up to 24 inches and diameters ranging from 0.5 inches to 48 inches.

The machinery used includes high-precision stamping and drawing machines with press capacities up to 1,000 tons, CNC press brakes, laser cutting systems, and automated material handling systems. Our facility also features 5-axis CNC milling and CNC dual spindle turning with live tooling, enabling us to produce intricate Aluminum Sheet Metal Deep Drawn Parts with tolerances as tight as ±0.1 mm. Surface treatments such as anodizing, powder coating, and protective film application are performed in-house to enhance durability and aesthetics.

Typical Parts Produced

We manufacture a wide range of Aluminum Deep Drawn Parts, including cups, cans, enclosures, battery cases, fuel filters, and sensor housings. Below is a line drawing of a typical Aluminum deep drawn cylindrical cup, followed by a table of dimensions.

![Line Drawing of Aluminum Deep Drawn Cylindrical Cup]

Infographic Description: The line drawing shows a cylindrical Aluminum cup with a diameter of 50 mm, height of 80 mm, and wall thickness of 1.5 mm. The base is flat, and the top edge has a slight flange for sealing purposes.

Infographic Description: The line drawing shows a cylindrical Aluminum cup with a diameter of 50 mm, height of 80 mm, and wall thickness of 1.5 mm. The base is flat, and the top edge has a slight flange for sealing purposes.

Dimension | Value | Tolerance

----------------|---------|-----------

Diameter | 50 mm | ±0.1 mm

Height | 80 mm | ±0.15 mm

Wall Thickness | 1.5 mm | ±0.05 mm

Flange Width | 5 mm | ±0.1 mmSurface Finish and Industries Using These Parts

Our Aluminum Pressed Parts and Components are available with various surface finishes, including anodizing, powder coating, and protective films, ensuring resistance to corrosion and wear. These finishes also provide an aesthetic appeal, making them suitable for visible applications in consumer electronics and appliances.

Industries utilizing our Aluminum Deep Drawn Components include automotive (fuel filters, battery cases), aerospace (lightweight enclosures), electronics (circuit board housings), HVAC (ducting components), telecommunications (antenna enclosures), and medical technology (surgical instrument housings). The seamless construction and high precision of our parts make them ideal for applications requiring durability and tight tolerances.

Tolerances and Turnaround Time

We maintain tight tolerances of up to ±0.1 mm on blanked and deep drawn parts, depending on the geometry and material thickness. Our typical production lead time is 4–6 weeks from tool finalization or drawing approval. For repeat orders or existing tools, we can expedite delivery to 2–3 weeks, and samples are provided within 10–15 working days, ensuring faster turnaround for prototyping and production.

Performance Metrics

Our Aluminum Sheet Metal Deep Drawn Parts are designed to meet stringent performance metrics, including a zero defects policy, high repeatability, and compliance with ISO 9001:2015 and IATF 16949 certifications. We achieve material utilization rates above industry averages through intelligent nesting and cutting strategies, reducing waste and costs for our customers.

Typical Q&A Session

- What materials are used for Aluminum Deep Drawn Parts?

We use high-grade Aluminum alloys such as 1050, 3003, 5052, and 6061, compliant with ASTM, DIN, JIS, BS, and IS standards. - What industries benefit from Aluminum Pressed Components?

Industries like automotive, aerospace, electronics, HVAC, and telecommunications rely on our pressed parts for their lightweight and durable properties. - What is the typical turnaround time for production?

Our standard lead time is 4–6 weeks, with expedited options of 2–3 weeks for repeat orders. - Can you customize Aluminum Deep Drawn Components?

Yes, we offer full customization, tailoring parts to specific dimensions, finishes, and packaging requirements. - What tolerances can you achieve?

We maintain tolerances as tight as ±0.1 mm, depending on the part geometry. - What surface finishes are available?

Options include anodizing, powder coating, and protective films for enhanced durability and aesthetics. - What is the maximum depth you can achieve in deep drawing?

We can produce parts with depths up to 24 inches, depending on the material and design. - Do you provide samples before full production?

Yes, samples are delivered within 10–15 working days for approval before production. - What international standards do your parts comply with?

Our parts meet ASTM, DIN, JIS, BS, and IS standards, ensuring global compatibility. - How do you ensure quality in production?

We employ in-line inspections, FAI, SPC, and maintain a zero defects policy, backed by ISO 9001:2015 certification.

Size-Dimensional Chart

Part Type | Diameter Range | Depth Range | Thickness Range | Tolerance

-----------------|---------------|--------------|-----------------|-----------

Cylindrical Cups | 0.5–48 inches | Up to 24 inches | 0.4–4 mm | ±0.1 mm

Enclosures | 1–24 inches | Up to 20 inches | 0.5–3 mm | ±0.15 mm

Battery Cases | 2–10 inches | Up to 15 inches | 0.8–2 mm | ±0.1 mm

Fuel Filters | 3–12 inches | Up to 18 inches | 1–3 mm | ±0.12 mmWhy Choose Us?

Our Aluminum Deep Drawn Parts stand out due to our faster turnaround times of 4–6 weeks, exceptional customer support, and excellent communication skills, ensuring a smooth collaboration with global clients. With over three decades of experience, we have extensive global exposure, supplying to regions like Southeast Asia, Europe, the Middle East, and the USA. Our ability to customize parts, offer flexible production timelines, and provide customized packaging with customer labels or logos sets us apart. We also implement sustainable practices, such as energy-efficient machinery and closed-loop recycling, reducing environmental impact while delivering cost-effective solutions.

Packaging and Shipping

We ensure safe delivery of our Aluminum Pressed Parts and Components through meticulous packaging. Parts are cleaned, deburred, and packed in polybags, bubble wrap, or foam trays. Export cartons are barcode-labeled with customer details, part number, and batch information. For sea shipments, we use palletization with shrink wrap or wooden crates, while air freight and courier options are available for urgent orders, ensuring timely delivery worldwide.

Customer Testimonials

“We’ve been sourcing Aluminum Deep Drawn Components from this team for over five years, and their consistency in quality and delivery is unmatched. The precision of their parts, coupled with their proactive communication, has made them our go-to supplier for automotive components. Their export packaging ensures our parts arrive in perfect condition every time.”

— John Miller, California, USA

— John Miller, California, USA

Glossary of Terms

Deep Drawing: A metal forming process where a flat sheet of Aluminum is drawn into a die to create seamless, three-dimensional shapes like cups and enclosures.

Aluminum Pressed Parts: Components formed through cold forming techniques such as blanking, punching, and bending, known for their lightweight and corrosion-resistant properties.

Tolerances: The allowable deviation in dimensions, such as ±0.1 mm, ensuring precision in Aluminum Sheet Metal Deep Drawn Parts.

Anodizing: A surface treatment process that enhances the corrosion resistance and aesthetic appeal of Aluminum parts.

Progressive Dies: Tooling used in deep drawing to perform multiple operations in a single press stroke, ensuring high-volume production efficiency.

Aluminum Pressed Parts: Components formed through cold forming techniques such as blanking, punching, and bending, known for their lightweight and corrosion-resistant properties.

Tolerances: The allowable deviation in dimensions, such as ±0.1 mm, ensuring precision in Aluminum Sheet Metal Deep Drawn Parts.

Anodizing: A surface treatment process that enhances the corrosion resistance and aesthetic appeal of Aluminum parts.

Progressive Dies: Tooling used in deep drawing to perform multiple operations in a single press stroke, ensuring high-volume production efficiency.

Related Terms

- Precision Aluminum Deep Drawn Parts Manufacturer

- Aluminum Pressed brackets, Aluminum Terminals

- Aluminum Transformer spades, Transformer terminals

- Custom Aluminum Pressed Components Exporter India

- High-Quality Aluminum Sheet Metal Deep Drawn Parts Supplier

- Aluminum Deep Drawn Enclosures for Electronics

- Automotive Aluminum Pressed Parts with Tight Tolerances

- Aerospace Aluminum Deep Drawn Components Manufacturer

Call-to-Action (CTA)

Looking for high-precision Aluminum Deep Drawn Parts or Aluminum Pressed Components? Contact us today to request a quote, email for a brochure, or reach out via phone/WhatsApp. Let us help you bring your vision to life with our expertise and global experience!