PRICE: US$ 11.20/kilogram

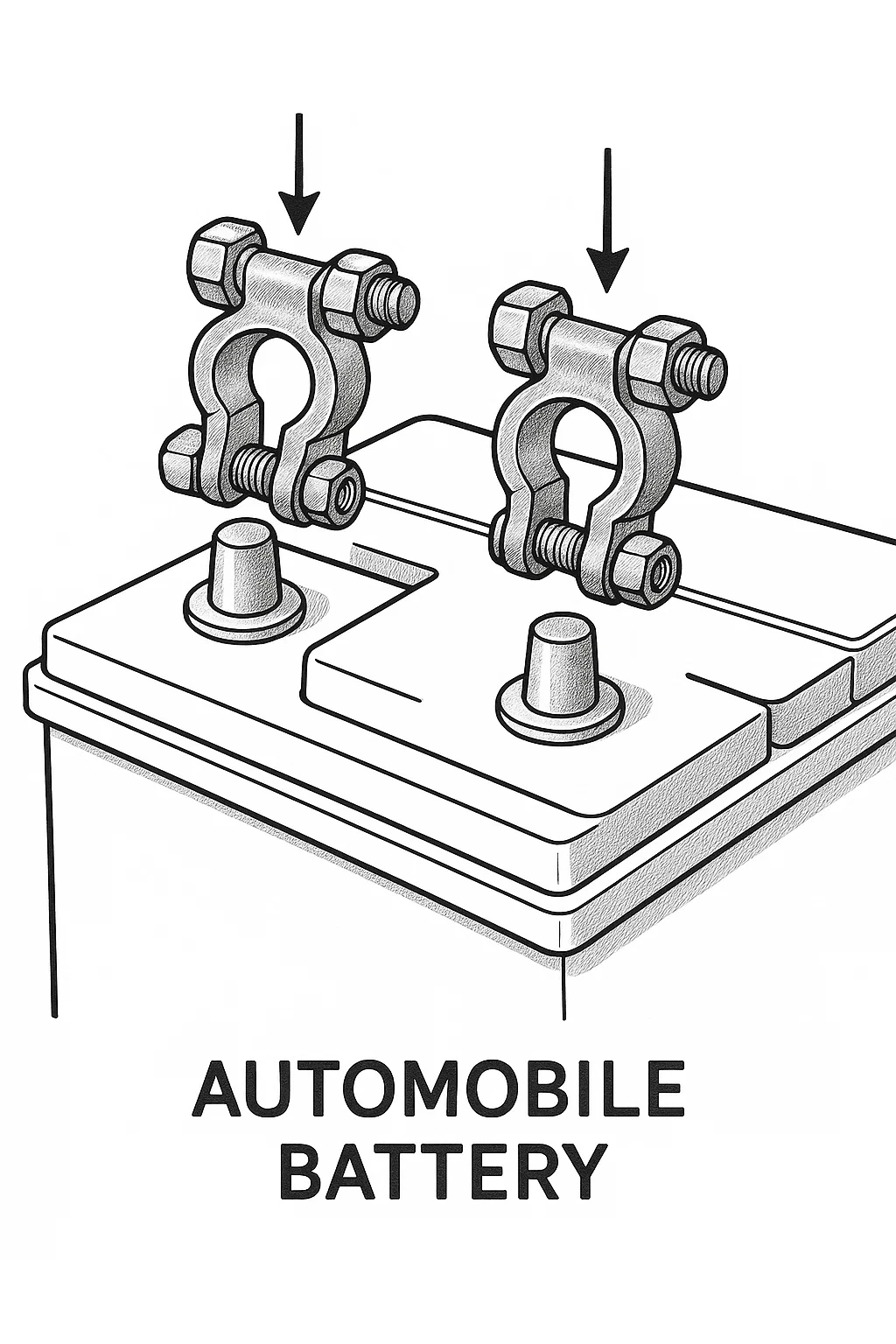

Premium Copper Battery Terminals, Copper Terminals – Cast or Forged & Machined Solutions

We are one of the leading manufacturers and exporters of high-quality Copper battery terminals and Copper Terminals from India. We have been supplying precision-engineered automotive battery terminals to the world market for many decades. Our extensive experience in manufacturing cast and machined Copper battery terminals has established us as a trusted partner for automotive OEMs, battery manufacturers, and electrical component distributors globally. We specialize in producing superior quality battery terminals using advanced casting and precision machining techniques, ensuring optimal electrical conductivity and mechanical strength. Our state-of-the-art manufacturing facilities are equipped with modern CNC machining centers and automated casting equipment to deliver consistent quality products. Each terminal undergoes rigorous quality testing to meet international automotive standards including ISO/TS 16949 certification. Our comprehensive range includes terminals with and without tin plating, complete with high-grade steel hardware including bolts, nuts, and washers for secure automotive battery connections.

Product Overview

Copper battery terminals are critical electrical connection components designed for automotive battery applications requiring high current carrying capacity and corrosion resistance. Our terminals are manufactured using premium grade electrolytic Copper through precision casting and CNC machining processes. The terminals feature robust construction with integrated clamping mechanisms for secure battery post connections. Optional tin plating provides enhanced corrosion protection and improved electrical contact characteristics in harsh automotive environments.

🔋 COPPER BATTERY TERMINALS

⚡ High Conductivity

99.9% Pure Copper

Low Resistance Connection

🛡️ Corrosion Resistant

Tin Plating Available

Extended Service Life

🔧 Precision Machined

CNC Manufacturing

Tight Tolerances

Key Features and Benefits

Our Copper battery terminals offer exceptional electrical conductivity with minimal voltage drop across connections. The cast Copper construction provides superior mechanical strength and durability under vibration and thermal cycling conditions typical in automotive applications. Precision machining ensures accurate dimensional tolerances for proper fitment with standard battery posts. The optional tin plating significantly reduces oxidation and galvanic corrosion when used with lead-acid batteries.

Material Grades and Specifications

| Standard | Grade | Copper Content (%) | Conductivity (% IACS) | Applications |

|---|---|---|---|---|

| ASTM B152 | C11000 (ETP) | 99.90 min | 101 | High conductivity terminals |

| BS EN 13599 | Cu-ETP | 99.90 min | 58.5 MS/m | European automotive standards |

| JIS H3100 | C1100 | 99.90 min | 101 | Japanese automotive applications |

| IS 191 | Grade 1 | 99.90 min | 100 | Indian standard terminals |

| DIN EN 13599 | Cu-ETP | 99.90 min | 58.5 MS/m | German automotive standards |

| GB/T 5231 | T2 | 99.90 min | 101 | Chinese automotive market |

Copper Material Properties

Mechanical Properties

Tensile Strength: 220-290 MPa

Yield Strength: 70-240 MPa

Elongation: 45-60%

Hardness: 40-80 HB

Electrical Properties

Electrical Conductivity: 101% IACS

Electrical Resistivity: 1.71 μΩ.cm

Temperature Coefficient: 0.00393/°C

Physical Properties

Density: 8.96 g/cm³

Melting Point: 1083°C

Thermal Conductivity: 391 W/m.K

Coefficient of Expansion: 16.5 μm/m.K

Manufacturing Processes

Casting Process

Our gravity die casting process utilizes high-grade permanent steel molds to produce consistent terminal shapes with excellent surface finish. The molten Copper is poured at precisely controlled temperatures of 1150-1200°C to ensure complete mold filling and minimize porosity. Post-casting heat treatment at 350-400°C relieves internal stresses and optimizes mechanical properties. Sand casting is employed for larger terminals or prototypes, utilizing high-quality silica sand with appropriate binders for dimensional accuracy.

Precision Machining Operations

CNC turning operations create precise internal threading and external dimensions with tolerances of ±0.05mm. Milling operations produce flat surfaces and keyways for proper cable connection alignment. Thread rolling processes create superior thread profiles with enhanced fatigue resistance compared to cut threads. Surface finishing operations including polishing and deburring ensure smooth contact surfaces and eliminate sharp edges that could damage battery cables.

Manufacturing Equipment and Machinery

| Equipment Type | Model/Specification | Capacity | Application |

|---|---|---|---|

| Induction Melting Furnace | Medium Frequency 500 Hz | 100 kg/hour | Copper melting and temperature control |

| CNC Turning Center | Multi-axis with live tooling | Φ200mm max swing | Precision machining operations |

| Gravity Die Casting Machine | Hydraulic operated | 50-500g casting weight | Terminal casting operations |

| Thread Rolling Machine | Two-die type | M6-M20 thread range | Hardware thread formation |

| Electroplating Line | Automated barrel plating | 1000 pieces/batch | Tin plating application |

| CMM Inspection | 3D Coordinate measuring | 0.001mm accuracy | Dimensional quality control |

Product Range and Typical Parts

Standard Terminal Types

Positive terminals feature red color coding and right-hand thread configuration for standardized automotive applications. Negative terminals incorporate left-hand threads and black color identification to prevent reverse polarity connections. Heavy-duty terminals designed for commercial vehicle applications feature reinforced construction and larger contact areas for higher current capacity. Marine grade terminals include enhanced corrosion protection through specialized alloy compositions and protective coatings.

| Terminal Type | Dimensions (mm) | Current Rating (A) | Weight (g) | Thread Size |

|---|---|---|---|---|

| Standard Positive | 120 x 80 x 25 | 400 | 185 | M8 x 1.25 |

| Standard Negative | 115 x 75 x 25 | 400 | 175 | M8 x 1.25 LH |

| Heavy Duty Positive | 140 x 90 x 30 | 600 | 285 | M10 x 1.5 |

| Heavy Duty Negative | 135 x 85 x 30 | 600 | 275 | M10 x 1.5 LH |

| Marine Grade | 125 x 82 x 28 | 450 | 210 | M8 x 1.25 |

Surface Finishes and Coatings

Tin Plating Specifications

Electroplated tin coating provides excellent corrosion resistance and maintains low contact resistance over extended service periods. Our tin plating process applies uniform coating thickness of 5-15 microns in accordance with ASTM B545 specifications. The plating bath utilizes pure tin anodes and organic additives to ensure bright, smooth finish with excellent adhesion to the Copper substrate. Post-plating heat treatment at 150°C for 1 hour enhances coating durability and whisker resistance.

| Finish Type | Coating Thickness (μm) | Standard | Corrosion Resistance | Applications |

|---|---|---|---|---|

| Bright Tin Plating | 8-12 | ASTM B545 | 480 hours salt spray | Standard automotive batteries |

| Matte Tin Plating | 10-15 | IPC-4552 | 720 hours salt spray | Marine and industrial applications |

| Natural Copper | – | – | Limited outdoor exposure | Indoor/protected environments |

| Nickel + Tin | 5-8 Ni + 8-12 Sn | ASTM B689 | 1000+ hours salt spray | Severe environmental conditions |

Industries and Applications

Automotive original equipment manufacturers utilize our terminals in passenger vehicles, commercial trucks, and specialty vehicle applications. Battery manufacturers integrate our terminals into maintenance-free and conventional lead-acid batteries for reliable electrical connections. Marine industry applications include boat batteries, yacht electrical systems, and offshore equipment power supplies. Industrial applications encompass uninterruptible power supplies, backup battery systems, and renewable energy storage installations.

Automotive Sector Applications

Passenger car batteries require terminals with precise dimensional tolerances for automated assembly processes. Commercial vehicle applications demand higher current carrying capacity and enhanced mechanical strength for vibration resistance. Electric vehicle auxiliary batteries utilize specialized terminal designs for 12V system integration. Motorcycle and ATV batteries require compact terminal configurations with space-optimized designs.

Industrial and Marine Applications

Telecommunications backup systems rely on our terminals for critical power supply reliability in data centers and communication networks. Solar energy storage systems integrate our terminals in battery bank configurations for residential and commercial installations. Fork lift and material handling equipment batteries utilize heavy-duty terminals designed for frequent charging cycles and harsh operating environments.

Quality Standards and Tolerances

| Parameter | Tolerance | Standard | Test Method |

|---|---|---|---|

| Overall Dimensions | ±0.1 mm | ISO 2768-m | CMM Measurement |

| Thread Pitch | ±0.02 mm | ISO 965-1 | Thread Gauge |

| Surface Roughness | Ra 1.6 μm | ISO 4287 | Profilometer |

| Plating Thickness | ±2 μm | ASTM B568 | XRF Analysis |

| Electrical Resistance | <10 μΩ | IEC 60512-2-1 | Micro-ohmmeter |

Production Lead Time and Delivery

Standard Production Lead Time: 4-6 weeks from confirmed purchase order receipt for regular production quantities. Express delivery options available for urgent requirements with expedited manufacturing schedules. Our flexible production planning accommodates seasonal demand fluctuations and customer-specific delivery requirements. Just-in-time delivery programs support automotive OEM assembly line synchronization with weekly or daily shipment schedules.

Production Capacity and Scheduling

Monthly production capacity exceeds 50,000 pieces across all terminal configurations with scalable manufacturing capabilities. Multiple production lines enable simultaneous processing of different terminal types and customer specifications. Advanced planning systems optimize material procurement and production sequencing to minimize lead times while maintaining quality standards.

Performance Metrics and Testing

| Test Parameter | Specification | Test Standard | Frequency |

|---|---|---|---|

| Tensile Strength | ≥220 MPa | ASTM E8/E8M | Per lot |

| Electrical Conductivity | ≥100% IACS | ASTM E1004 | Per batch |

| Corrosion Resistance | 480 hours min | ASTM B117 | Monthly |

| Contact Resistance | <10 μΩ | IEC 60512-2-1 | 100% inspection |

| Vibration Resistance | 20g, 10-2000 Hz | ISO 16750-3 | Type approval |

| Temperature Cycling | -40°C to +120°C | IEC 60068-2-14 | Type approval |

Frequently Asked Questions

1. What is the minimum order quantity for Copper battery terminals?

Our minimum order quantity starts from 100 pieces for standard configurations. Custom specifications may require higher minimum quantities depending on tooling requirements and complexity. We offer flexible packaging options to accommodate smaller order quantities for prototype and testing applications.

2. Can you provide terminals with custom dimensions and specifications?

Absolutely. Our engineering team specializes in developing custom terminal solutions based on customer drawings and specifications. We provide comprehensive design support including 3D modeling, finite element analysis, and prototype development services. Custom tooling development typically requires 3-4 weeks lead time.

3. What quality certifications do your terminals comply with?

Our terminals are manufactured in ISO 9001:2015 and ISO/TS 16949:2016 certified facilities. All products comply with RoHS and REACH regulations for environmental safety. We maintain comprehensive quality documentation including material certificates, dimensional reports, and electrical test data.

4. Do you offer tin plating services for enhanced corrosion protection?

Yes, we provide bright tin and matte tin plating services with coating thickness from 5-15 microns. Our electroplating facility operates in accordance with ASTM B545 standards with strict process control for uniform coating distribution. Additional coating options include nickel-tin and specialized marine-grade treatments.

5. What is the current carrying capacity of your standard battery terminals?

Standard automotive terminals are rated for 400 amperes continuous current with proper cable connections. Heavy-duty versions can handle up to 600 amperes for commercial vehicle applications. Current rating depends on terminal size, cable connection method, and ambient temperature conditions.

6. Can you supply complete Battery terminal assemblies with steel hardware?

Yes, we provide complete assemblies including high-grade steel bolts, nuts, and washers. Hardware is available in zinc-plated or stainless steel options for enhanced corrosion resistance. All hardware components are dimensionally matched to ensure proper assembly torque specifications.

7. What packaging options are available for bulk shipments?

Standard packaging includes anti-corrosion paper wrapping with moisture barrier bags and corrugated cartons. Custom packaging solutions include customer-branded labels, specialized protective packaging, and automated assembly-friendly packaging formats. We can accommodate specific packaging requirements for automotive assembly line integration.

8. Do you provide technical support for terminal selection and application?

Our technical team provides comprehensive application support including terminal selection guidelines, installation procedures, and troubleshooting assistance. We offer finite element analysis for custom applications and can provide material property data and certification documents for engineering validation.

9. What is your global distribution and shipping capability?

We maintain strategic partnerships with international freight forwarders and logistics providers for worldwide shipping. Express delivery options include air freight for urgent requirements. Our export documentation team handles all customs and regulatory requirements for seamless international deliveries.

10. Can you accommodate just-in-time delivery schedules for automotive OEMs?

Yes, we maintain inventory management programs and flexible production scheduling to support just-in-time delivery requirements. Our ERP system integrates with customer demand forecasting systems for synchronized production planning. Weekly and daily delivery schedules are available for established automotive partnerships.

11. What material traceability documentation do you provide?

Complete material traceability is maintained from raw material receipt through final inspection. Mill test certificates provide chemical composition and mechanical property verification. We maintain comprehensive batch records enabling full traceability for quality audits and regulatory compliance requirements.

12. Do you offer cost-effective solutions for high-volume production?

Our automated manufacturing processes and economies of scale provide competitive pricing for high-volume requirements. Long-term supply agreements include price stability provisions and volume-based pricing tiers. Value engineering services help optimize designs for cost reduction without compromising performance.

Customer Testimonial

“We have been sourcing Copper battery terminals from this manufacturer for over 8 years and their consistency in quality and delivery performance has been exceptional. Their technical team provided excellent support during our new product development, and their ability to customize packaging with our company logo has streamlined our assembly operations. The tin-plated terminals have shown outstanding corrosion resistance in our harsh marine applications. Their competitive pricing and reliable supply chain management make them our preferred supplier for all battery terminal requirements.”

– Robert Martinez, Senior Procurement Manager, Advanced Battery Systems LLC, Detroit, USA

Why Choose Our Copper Battery Terminals?

Competitive Advantages and Unique Selling Propositions

Three Decades of Manufacturing Excellence: Our 30+ years of experience in precision Copper component manufacturing ensures proven expertise and reliable quality systems. We have successfully supplied millions of terminals to automotive OEMs and battery manufacturers worldwide, building a reputation for consistency and technical innovation.

Advanced Manufacturing Capabilities: Our state-of-the-art CNC machining centers and automated casting equipment enable tight tolerance control and high-volume production efficiency. Investment in latest technology ensures superior product quality while maintaining competitive pricing for our global customers.

Customization Flexibility: Unlike many suppliers, we offer extensive customization capabilities including modified dimensions, special alloy compositions, and unique plating specifications. Our in-house tooling and engineering capabilities enable rapid prototype development and seamless transition to production volumes.

Superior Customer Communication: Our dedicated export team provides multilingual support with prompt email responses and real-time project updates. Regular communication protocols keep customers informed throughout the manufacturing process, from order confirmation to shipment tracking. Our technical specialists are available for application support and troubleshooting assistance.

Global Market Experience: Having served customers across North America, Europe, Asia, and Australia, we understand diverse market requirements and regulatory standards. Our export documentation expertise ensures smooth customs clearance and compliance with international trade requirements.

Competitive Lead Times: Our streamlined production processes and strategic inventory management enable faster delivery compared to traditional suppliers. Standard products ship within 4-6 weeks, with express options available for urgent requirements. Established supply chain partnerships ensure consistent raw material availability.

Comprehensive Quality Assurance: ISO/TS 16949 certified quality systems with 100% dimensional inspection and electrical testing ensure zero-defect delivery. Statistical process control and continuous improvement programs maintain consistent quality performance across all production batches.

Packaging and Shipping Solutions

Standard Packaging Options

Individual terminals are wrapped in anti-corrosion VCI paper to prevent oxidation during storage and transportation. Bulk packaging utilizes moisture barrier polyethylene bags with desiccant packets for long-term protection. Heavy-duty corrugated cartons with foam inserts provide mechanical protection during shipping and handling operations.

Custom Packaging Services

Customer-branded packaging includes printed labels with company logos, part numbers, and specifications for inventory management. Automated assembly-friendly packaging features oriented positioning and easy-access configurations to reduce assembly time. Specialized packaging for hazardous goods compliance when shipping with batteries or chemical products.

| Packaging Type | Quantity per Package | Dimensions (mm) | Weight (kg) | Applications |

|---|---|---|---|---|

| Individual VCI Wrapping | 1 piece | 150 x 100 x 50 | 0.25 | High-value prototypes |

| Bulk Polyethylene Bags | 50 pieces | 300 x 200 x 100 | 10.5 | Standard production quantities |

| Corrugated Cartons | 200 pieces | 500 x 400 x 300 | 42 | Export shipments |

| Wooden Crates | 1000+ pieces | 1200 x 800 x 600 | 210 | Large volume orders |

| Custom Branded Boxes | 25-100 pieces | Variable | Variable | OEM assembly integration |

International Shipping and Logistics

Air freight services provide expedited delivery for urgent requirements with door-to-door tracking capabilities. Ocean freight offers cost-effective shipping for large volume orders with full container and less-than-container load options. Our logistics partners provide comprehensive insurance coverage and specialized handling for sensitive electronic components.

International Standards Compliance

Our manufacturing processes and quality systems comply with multiple international standards ensuring global market acceptance. Comprehensive testing protocols verify conformance to electrical, mechanical, and environmental performance requirements across different regional specifications.

| Standard | Region | Scope | Key Requirements |

|---|---|---|---|

| ISO/TS 16949 | Global | Automotive quality management | Process control, continuous improvement |

| ASTM B152 | USA | Copper sheet and strip | Chemical composition, mechanical properties |

| BS EN 13599 | Europe | Copper and alloys | Material specifications, testing methods |

| JIS H3100 | Japan | Copper and copper alloys | Purity requirements, conductivity standards |

| DIN EN 13599 | Germany | Copper products | Dimensional tolerances, surface quality |

| IS 191 | India | Electrolytic copper | Chemical analysis, conductivity testing |

| RoHS Directive | EU | Hazardous substances restriction | Lead, mercury, cadmium limitations |

| REACH Regulation | EU | Chemical safety | Substance registration, safety data |

Related Terms

Glossary of Technical Terms

- IACS (International Annealed Copper Standard)

- A measurement standard for electrical conductivity where pure annealed Copper is assigned a value of 100% IACS, used as reference for comparing conductivity of other materials.

- ETP Copper (Electrolytic Tough Pitch)

- High purity Copper containing 99.90% minimum Copper content with excellent electrical conductivity, commonly used in electrical applications requiring superior conductivity.

- Galvanic Corrosion

- Electrochemical corrosion occurring when dissimilar metals are in electrical contact in the presence of an electrolyte, leading to accelerated deterioration of the more active metal.

- Contact Resistance

- Electrical resistance measured across the interface between two conducting materials, typically expressed in micro-ohms (μΩ) for high-quality electrical connections.

- Tin Whiskers

- Spontaneous growth of thin metallic filaments from tin-plated surfaces that can cause electrical shorts, prevented through proper plating processes and heat treatment.

- Voltage Drop

- Reduction in electrical potential across a conductor or connection due to electrical resistance, minimized through high-conductivity materials and proper connection design.

- Current Carrying Capacity

- Maximum electrical current that a conductor or terminal can safely carry without exceeding temperature limits or causing performance degradation.

- Thermal Cycling

- Repeated heating and cooling cycles that test material durability and dimensional stability under temperature variations typical in automotive applications.

- Salt Spray Testing

- Corrosion testing method using sodium chloride solution spray to evaluate protective coating effectiveness and material corrosion resistance over time.

- Thread Rolling

- Cold forming process for creating threads by deforming material rather than cutting, resulting in stronger threads with improved fatigue resistance.

- VCI Paper (Vapor Corrosion Inhibitor)

- Specialized packaging material that releases corrosion-inhibiting vapors to protect metal components during storage and transportation.

- CMM (Coordinate Measuring Machine)

- Precision measurement equipment using probe systems to verify dimensional accuracy and geometric tolerances of manufactured components.

Environmental and Sustainability Considerations

Sustainable Manufacturing Practices

Our manufacturing processes incorporate environmental protection measures including waste minimization, energy efficient equipment, and responsible material sourcing. Copper recycling programs ensure maximum material utilization with minimal environmental impact. Water treatment systems for electroplating operations meet strict environmental discharge standards.

Material Recyclability

Copper battery terminals offer excellent end-of-life recyclability with nearly 100% material recovery potential. Recycled Copper maintains equivalent electrical and mechanical properties to virgin material, supporting circular economy principles. Our material certifications include recycled content documentation for environmentally conscious customers.

Request Your Custom Quote Today

Ready to source high-quality Copper battery terminals for your application? Our technical team is standing by to provide expert guidance and competitive pricing for your specific requirements.

📧 Email: sales@conexscrews .com for detailed quotations and technical specifications

📱 WhatsApp for instant communication and quick responses

📞 Phone: to speak directly with our export specialists

📋 Download Brochure: Email us for comprehensive product catalog and technical data sheets

Get Your Free Quote in 24 Hours!

Send us your drawings, specifications, and quantity requirements. Our engineering team will provide detailed technical proposals with competitive pricing and delivery schedules tailored to your project needs.

Similar parts:

Copper Terminals

Copper Battery Terminals

Copper Cable Lugs

Copper Lug Connectors

Copper Wire Terminals

Copper Crimp Terminals

Copper Cable Terminals

Copper Ring Terminals

Copper Spade Terminals

Copper Tube Terminals

⚡ Battery-Specific Components

Copper Battery Cable Lugs

Copper Terminal Ends for Battery

Heavy Duty Battery Terminals

Tinned Copper Battery Terminals

Automotive Battery Copper Terminals

Battery Cable End Terminals

Lead-Free Copper Battery Lugs

Marine Battery Copper Terminals

Universal Copper Battery Connectors

Copper Battery Terminal Clamps

🔩 Technical Parts

Bare Copper Terminals

Tinned Copper Lugs

Insulated Copper Terminals

Crimp Type Copper Terminals

Solder Type Copper Battery Lugs

Bimetallic Battery Terminals

Flat Type Copper Terminals

Tubular Copper Cable Lugs

DIN Standard Copper Terminals

Lug Size Calculator Copper Battery

🌍 Industry/Compliance Terms

UL complaint Copper Terminals

RoHS Compliant Battery Terminals

ISI Marked Copper Lugs

Copper Battery Terminals Manufacturer India

Copper Cable Terminals Exporters