Brass Hose Ferrules & Crimping Ferrules for Hoses

We are one of the leading manufacturers and exporters of Brass Hose Ferrules and Brass Crimping Ferrules for Hoses from India. We have been supplying high-quality brass hydraulic ferrules to the world market for many decades. Our comprehensive range of precision-engineered brass hose ferrules serves diverse industrial applications across hydraulic systems, pneumatic assemblies, and fluid transfer operations. With advanced manufacturing capabilities and stringent quality control processes, we deliver superior crimping ferrules that ensure leak-proof connections and optimal performance in demanding environments. Our state-of-the-art production facility combines traditional craftsmanship with modern technology to produce brass ferrules that meet international standards and exceed customer expectations. From standard specifications to custom-designed solutions, we provide comprehensive ferrule manufacturing services with competitive pricing and reliable delivery schedules. Our experienced engineering team works closely with clients to develop application-specific brass hose end fittings that maximize system efficiency and longevity. We can also offer Stainless Steel ferrules in 304 and 316 grades.

Product Overview

Brass Hose Ferrules are precision-manufactured cylindrical sleeves designed to create secure, permanent connections between hoses and fittings in hydraulic and pneumatic systems. These essential components provide mechanical reinforcement and ensure leak-tight seals when properly crimped onto hose assemblies. Our brass ferrules are engineered to withstand high pressures, vibrations, and temperature variations while maintaining structural integrity throughout their service life.

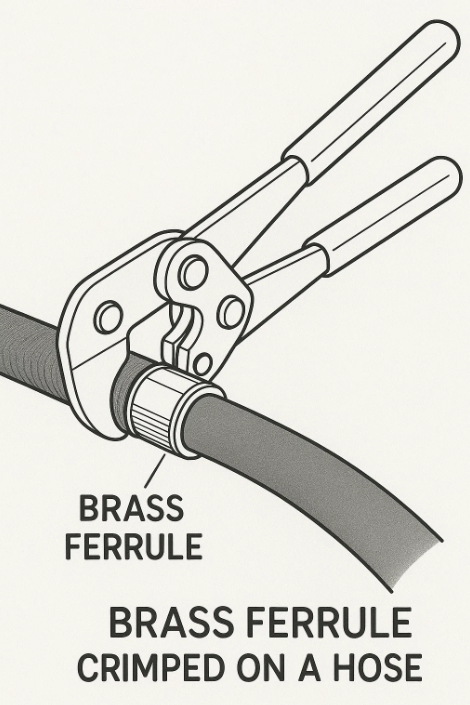

Crimping Ferrules for Hoses represent specialized connecting elements that undergo plastic deformation during the assembly process to create permanent joints between flexible hoses and rigid fittings. The crimping process involves applying controlled radial compression to the ferrule, causing it to grip both the outer hose cover and the inner mandrel of the fitting. This creates a mechanically secure connection that prevents hose blow-off under pressure while maintaining fluid-tight sealing capabilities.

Technical Specifications & Size Range

Our brass hose ferrules are available in comprehensive size ranges from 1/2 inch to 2 inches, accommodating various hose diameters and application requirements. Each size is manufactured to precise dimensional tolerances ensuring consistent performance and reliable assembly procedures.

| Nominal Size | Inner Diameter (mm) | Outer Diameter (mm) | Length (mm) | Wall Thickness (mm) | Appx Working Pressure (PSI) |

|---|---|---|---|---|---|

| 1/2″ | 12.7 ± 0.1 | 19.0 ± 0.15 | 25.0 ± 0.2 | 1.5 | 4000 |

| 5/8″ | 15.9 ± 0.1 | 22.2 ± 0.15 | 28.0 ± 0.2 | 1.5 | 3800 |

| 3/4″ | 19.1 ± 0.1 | 25.4 ± 0.15 | 30.0 ± 0.2 | 2 | 3600 |

| 1″ | 25.4 ± 0.15 | 31.8 ± 0.2 | 35.0 ± 0.25 | 2 | 3200 |

| 1-1/4″ | 31.8 ± 0.15 | 38.1 ± 0.2 | 38.0 ± 0.25 | 2 | 2800 |

| 1-1/2″ | 38.1 ± 0.2 | 44.5 ± 0.25 | 42.0 ± 0.3 | 3 | 2400 |

| 2″ | 50.8 ± 0.2 | 57.2 ± 0.25 | 45.0 ± 0.33 | 2000 |

Material Grades & Specifications for Brass Hose Ferrules and Brass Crimping Ferrules for Hoses

Our Brass hose ferrules are manufactured using premium quality Lead free Brass alloys that comply with multiple international standards. The material selection ensures optimal performance characteristics including corrosion resistance, mechanical strength, and dimensional stability across various operating conditions.

International Standards

ASTM B16: Standard for Free-Cutting Brass Rod, Bar and Shapes

BS 2874: Copper and Copper Alloys – Rods and Sections

DIN 17660: Copper-Zinc Alloys – Wrought Products

JIS H3250: Copper Alloy Rods and Bars

IS 319: Brass Rod, Sections and Forgings

Common Brass Grades

CuZn39Pb3 (CW614N): Lead brass with excellent machinability

CuZn37 (CW508L): Standard brass for general applications

CuZn40 (CW509L): High strength brass alloy

C36000: Free-cutting brass (US designation)

C26000: Cartridge brass for precision components

| Property | CuZn39Pb3 | CuZn37 | CuZn40 | Unit |

|---|---|---|---|---|

| Tensile Strength | 380-420 | 340-380 | 350-400 | N/mm² |

| Yield Strength | 140-180 | 120-160 | 130-170 | N/mm² |

| Elongation | 15-25 | 25-35 | 20-30 | % |

| Hardness (HB) | 85-110 | 70-95 | 75-100 | HB |

| Density | 8.5 | 8.4 | 8.4 | g/cm³ |

Manufacturing Processes & Machinery

Our advanced manufacturing facility employs multiple precision processes to produce high-quality brass hose ferrules. The manufacturing sequence begins with material preparation and progresses through forming, machining, and finishing operations using state-of-the-art equipment and quality control systems.

Primary Manufacturing Processes: Cold drawing operations transform brass rod stock into precise ferrule profiles using hydraulic drawing benches and carbide dies. CNC turning centers perform secondary machining operations including bore finishing, chamfering, and dimensional refinement. Progressive stamping and forming operations create specialized ferrule geometries for specific applications. Heat treatment processes optimize material properties and relieve manufacturing stresses.

Machinery & Equipment: Multi-spindle CNC lathes with live tooling capabilities ensure consistent dimensional accuracy and surface finish quality. Hydraulic tube drawing machines with precision die sets maintain tight tolerances on internal and external diameters. Progressive stamping presses equipped with carbide tooling handle high-volume production requirements. Induction heating systems provide controlled heat treatment cycles for optimal material properties.

Surface Finishes & Treatments for Brass Hose Ferrules and Brass Crimping Ferrules for Hoses

Our brass hose ferrules are available with multiple surface finish options to meet specific application requirements and environmental conditions. Standard finishes include natural brass appearance with protective clear coating, while specialized treatments provide enhanced corrosion resistance and aesthetic appeal.

| Finish Type | Description | Corrosion Resistance | Applications |

|---|---|---|---|

| Natural Brass | Mill finish with clear protective coating | Good | General industrial applications |

| Nickel Plated | Electroplated nickel coating 5-10 microns | Excellent | Marine and chemical environments |

| Chrome Plated | Decorative chrome plating over nickel base | Very Good | Automotive and decorative applications |

| Passivated | Chemical passivation treatment | Enhanced | Food processing and pharmaceutical |

Manufacturing Quality Control Process

Raw Material Inspection -> CNC Machining -> Precision Turning -> Dimensional Verification -> Surface Treatment -> Final Inspection ->Material Test Process ->Control ->CMM Inspection -> Final QC

Industries & Applications

Brass hose ferrules find extensive application across diverse industrial sectors where reliable fluid transfer systems are essential. The superior performance characteristics of brass make these ferrules particularly suitable for applications involving moderate pressures, temperature variations, and corrosive environments.

Hydraulic Systems: Mobile and stationary hydraulic equipment in construction machinery, agricultural implements, and industrial automation systems rely on brass ferrules for leak-tight hose connections. The excellent fatigue resistance and pressure handling capabilities make them ideal for dynamic applications with frequent pressure cycling.

Pneumatic Applications: Compressed air systems in manufacturing facilities, automotive assembly lines, and packaging machinery utilize brass ferrules for their superior sealing properties and resistance to moisture-related corrosion. The smooth internal finish minimizes pressure drop and turbulence in air flow systems.

Marine Industry: Boat manufacturers and marine equipment suppliers choose brass ferrules for fuel lines, cooling systems, and hydraulic steering applications due to their excellent resistance to saltwater corrosion and marine environmental conditions.

Automotive Sector: Brake systems, power steering assemblies, and transmission cooler lines incorporate brass ferrules for their reliability under vibration and temperature cycling. The compatibility with various automotive fluids makes them versatile components for multiple vehicle systems.

Performance Metrics & Testing Standards

Our brass hose ferrules undergo comprehensive testing procedures to ensure consistent performance and reliability across all operating conditions. Testing protocols include pressure testing, dimensional verification, material composition analysis, and accelerated corrosion testing.

| Test Parameter | Standard | Specification | Frequency |

|---|---|---|---|

| Proof Pressure Test | ISO 1402 | 2 x Working Pressure | 100% Production |

| Burst Pressure Test | ISO 1402 | 4 x Working Pressure | Sample Basis |

| Dimensional Inspection | ISO 4759-3 | ±0.1mm tolerance | Statistical Sampling |

| Material Composition | ASTM E415 | Per Grade Specification | Per Batch |

| Salt Spray Test | ASTM B117 | 120 hours minimum | Per Lot |

Manufacturing Tolerances

Precision manufacturing processes enable us to maintain tight dimensional tolerances essential for proper ferrule performance and assembly procedures. Our quality control systems ensure consistent dimensional accuracy across all production batches.

| Dimension | Size Range | Standard Tolerance | Precision Tolerance |

|---|---|---|---|

| Inner Diameter | 1/2″ – 1″ | ±0.1 mm | ±0.05 mm |

| Inner Diameter | 1-1/4″ – 2″ | ±0.15 mm | ±0.08 mm |

| Outer Diameter | All Sizes | ±0.15 mm | ±0.1 mm |

| Length | All Sizes | ±0.2 mm | ±0.1 mm |

| Concentricity | All Sizes | 0.05 mm TIR | 0.03 mm TIR |

Production Timeline & Delivery

Standard Turnaround Time: 4-6 weeks from order confirmation for regular production quantities. Our efficient manufacturing processes and inventory management systems ensure reliable delivery schedules while maintaining quality standards. Rush orders can be accommodated with expedited processing for critical applications.

Production scheduling flexibility allows us to handle both small prototype quantities and large-volume orders with equal attention to quality and delivery commitments. Our streamlined order processing system provides regular updates on production status and shipping schedules.

“We have been sourcing brass hose ferrules from this Indian manufacturer for over 8 years now, and their consistency in quality and delivery has been exceptional. The dimensional accuracy and surface finish quality consistently meet our stringent automotive industry requirements. Their technical support team is knowledgeable and responsive, helping us optimize our assembly processes. The competitive pricing combined with reliable supply chain performance makes them our preferred supplier for brass hydraulic components.”

– Robert Mitchell, Procurement Manager

Frequently Asked Questions

Q1: What is the minimum order quantity for brass hose ferrules?

A1: Our minimum order quantity varies by size and specification, typically ranging from 500 to 1000 pieces per size. We can accommodate smaller quantities for prototyping or special applications with adjusted pricing.

Q2: Can you manufacture custom brass ferrules according to our drawings?

A2: Yes, we specialize in custom manufacturing based on customer drawings and specifications. Our engineering team can review your requirements and provide technical recommendations for optimal performance and manufacturability.

Q3: What certifications do you provide with the brass ferrules?

A3: We provide material test certificates, dimensional inspection reports, and compliance certificates for relevant international standards. Additional certifications like ISO 9001 quality system certification and specific industry certifications are available upon request.

Q4: How do you ensure consistent quality across different production batches?

A4: Our quality management system includes statistical process control, regular calibration of measuring equipment, and comprehensive testing protocols. Each batch undergoes material verification, dimensional inspection, and performance testing before shipment.

Q5: What brass grades do you recommend for high-pressure hydraulic applications?

A5: For high-pressure applications, we recommend CuZn40 or CuZn39Pb3 grades which offer superior mechanical properties and pressure handling capabilities. The final selection depends on specific pressure requirements, environmental conditions, and compatibility with hydraulic fluids.

Q6: Can you provide ferrules with special surface treatments or coatings?

A6: Yes, we offer various surface treatments including nickel plating, chrome plating, and specialized coatings for enhanced corrosion resistance. Custom coating specifications can be accommodated based on application requirements.

Q7: What is your typical lead time for large volume orders?

A7: Large volume orders typically require 6-8 weeks depending on quantity and complexity. We can provide detailed production schedules and milestone updates for better planning and coordination of your assembly operations.

Q8: Do you provide technical support for ferrule selection and application?

A8: Our experienced technical team provides comprehensive application support including ferrule selection, crimping specifications, and troubleshooting assistance. We can also recommend optimal ferrule designs for specific hose and fitting combinations.

Q9: What quality standards do your brass ferrules comply with?

A9: Our ferrules comply with international standards including ISO, ASTM, DIN, BS, and JIS specifications. We maintain certifications for various quality systems and can provide compliance documentation for specific industry requirements.

Q10: Can you supply ferrules with customer-specific marking or identification?

A10: Yes, we can provide laser marking, stamping, or color coding for customer identification. Custom marking options include part numbers, size designations, date codes, and company logos for traceability and inventory management.

Why Choose Our Brass Hose Ferrules

Three Decades of Global Experience: Our extensive manufacturing experience spanning over 30 years has established us as a trusted supplier to customers worldwide. This experience translates into deep understanding of diverse application requirements, quality expectations, and supply chain challenges across different markets and industries.

Superior Customer Support: Our dedicated customer service team provides prompt response to inquiries, technical support throughout the selection process, and ongoing assistance with application challenges. Clear communication channels and regular project updates ensure smooth collaboration from initial inquiry through delivery and beyond.

Faster Turnaround Times: Our streamlined manufacturing processes and efficient inventory management enable us to deliver standard products within 4-6 weeks, significantly faster than many competitors. Emergency orders receive priority processing with expedited manufacturing schedules to meet critical project deadlines.

Customization Flexibility: Unlike many manufacturers who focus only on standard products, we excel in custom ferrule design and manufacturing. Our engineering team works closely with customers to develop application-specific solutions that optimize performance and reduce total system costs.

Customized Packaging Solutions: We offer flexible packaging options including custom labeling with customer logos, specialized packaging for automated assembly processes, and protective packaging for sensitive surface finishes. Our packaging team can develop solutions that integrate seamlessly with your inventory and production systems.

Competitive Global Pricing: Our efficient manufacturing operations and strategic location in India enable us to offer highly competitive pricing without compromising quality standards. Volume discounts and long-term supply agreements provide additional cost advantages for our customers.

Packaging & Shipping

Our comprehensive packaging and shipping services ensure that brass hose ferrules reach customers in perfect condition while minimizing transportation costs and delivery times. Standard packaging includes protective plastic bags, foam inserts, and sturdy corrugated boxes with clear labeling and identification.

Standard Packaging Options: Small quantities are packed in anti-static plastic bags with foam padding inside labeled cardboard boxes. Medium quantities utilize multi-compartment boxes with individual size segregation and protective wrapping. Large volume orders are packed in wooden crates with moisture barriers and shock-absorbing materials for international shipping.

Custom Packaging Services: Customer-specific labeling includes part numbers, size designations, quantity information, and company logos. Automated packaging solutions for high-volume customers include specially designed dispensing boxes and automated counting systems. Environmental packaging options include recyclable materials and biodegradable protective inserts.

Shipping & Logistics: We maintain partnerships with leading international freight forwarders and shipping companies to provide reliable delivery services worldwide. Express shipping options are available for urgent orders, while consolidated shipping reduces costs for regular orders. Complete documentation including commercial invoices, packing lists, and certificates of origin facilitate smooth customs clearance.

Unique Selling Propositions

Advanced Quality Control Systems: Our manufacturing facility employs coordinate measuring machines (CMM), optical measuring systems, and automated inspection equipment to ensure consistent dimensional accuracy and surface quality. Statistical process control methods monitor critical parameters throughout production, maintaining quality standards that exceed customer expectations.

Flexible Production Scheduling: Our production planning system accommodates both planned orders and emergency requirements through flexible scheduling and capacity allocation. Multiple production lines enable parallel processing of different sizes and specifications, reducing overall lead times and improving delivery reliability.

Technical Innovation: Continuous investment in research and development enables us to introduce improved ferrule designs, enhanced materials, and innovative manufacturing processes. Our technical team collaborates with customers to develop next-generation solutions that address evolving industry requirements.

Global Supply Chain Management: Established distribution networks and strategic inventory locations enable us to serve customers across multiple continents with consistent service levels. Regional warehousing facilities reduce shipping times and provide local support for urgent requirements.

Related Terms & Search Keywords

Hydraulic hose ferrules, brass compression sleeves, hose end fittings, crimping sleeves for hydraulic hoses, brass tube ferrules, hydraulic hose end connectors, brass swaging ferrules, hose barb ferrules, pneumatic hose ferrules, brass ferrule fittings, hydraulic crimp ferrules, brass hose sleeves, compression ferrules for hoses, brass hydraulic connectors, hose ferrule manufacturers, custom brass ferrules, industrial hose ferrules, high pressure hose ferrules, marine hose ferrules, automotive hose ferrules, brass ferrule suppliers, hydraulic system components, brass machined parts, precision brass components, hose assembly components.

Glossary of Technical Terms

Crimping: The process of mechanically deforming a ferrule to create a permanent connection between a hose and fitting by applying radial compression force.

Ferrule: A cylindrical metal sleeve designed to be crimped onto hose assemblies to create secure, leak-tight connections with fittings.

Working Pressure: The maximum continuous operating pressure that a ferrule can safely handle under normal service conditions.

Burst Pressure: The minimum pressure at which a ferrule assembly will fail, typically 4 times the working pressure for safety margin calculations.

Proof Pressure: A test pressure, typically twice the working pressure, applied to verify the integrity of ferrule assemblies without permanent deformation.

Swaging: A cold forming process used to reduce the diameter of ferrules or create specific internal profiles for optimal hose retention.

Mandrel: The internal component of a hose fitting that provides support and sealing surface for the hose inner tube during ferrule crimping.

Hose Skive: The removal of the outer cover from a hose end to expose the reinforcement layer, allowing proper ferrule installation and crimping.

TIR (Total Indicator Reading): A measurement of concentricity or roundness deviation, indicating the maximum variation from perfect circular form.

Passivation: A chemical treatment process that removes surface contaminants and enhances corrosion resistance of brass components.

Dezincification: A form of corrosion in brass alloys where zinc is selectively removed, leaving behind porous copper-rich material with reduced mechanical properties.

Free-Cutting Brass: Brass alloys containing lead additions that improve machinability and surface finish quality during manufacturing operations.

Environmental Compliance & Sustainability

Our manufacturing processes incorporate environmental responsibility through efficient resource utilization, waste reduction programs, and compliance with international environmental standards. Brass material recycling programs ensure that production waste and customer returns are processed through environmentally responsible channels.

RoHS Compliance: All brass ferrules comply with RoHS (Restriction of Hazardous Substances) regulations, ensuring safe use in electronic and automotive applications. Lead-free brass grades are available for applications requiring complete RoHS compliance.

REACH Compliance: Our products comply with European REACH regulations regarding chemical substances, providing necessary documentation and safety data sheets for regulatory compliance in European markets.

Sustainable Manufacturing: Energy-efficient manufacturing equipment, optimized production processes, and waste reduction initiatives minimize environmental impact while maintaining product quality and cost competitiveness.

Technical Support & Engineering Services

Our experienced engineering team provides comprehensive technical support throughout the product selection, design, and implementation process. Services include application analysis, material selection guidance, custom design development, and troubleshooting assistance for field applications.

Application Engineering: Our engineers analyze customer applications to recommend optimal ferrule specifications, crimping parameters, and assembly procedures. Computer-aided design tools enable rapid evaluation of custom requirements and prototype development.

Testing & Validation: Complete testing services include pressure testing, dimensional verification, material analysis, and performance validation under simulated operating conditions. Test reports and certifications support customer quality requirements and regulatory compliance.

Training & Support: Technical training programs for customer personnel cover proper ferrule selection, assembly procedures, quality control methods, and troubleshooting techniques. On-site support services are available for critical applications and new product implementations.

SIMILAR PARTS-TERMS

- brass hose ferrules manufacturer India

- custom crimping ferrules for hydraulic hoses

- Stainless Steel crimp ferrules

- high pressure brass hose ferrules supplier

- precision machined brass ferrules exporter

- hydraulic hose crimping ferrules India

- brass compression ferrules for pneumatic systems

- marine grade brass hose ferrules manufacturer

- automotive brass hose end fittings supplier

- CNC machined brass hose ferrules India

- custom brass ferrules with fast turnaround

- brass hydraulic ferrules ISO certified manufacturer

- precision brass hose components exporter India

Geo-targeted Keywords:

- brass ferrules manufacturer Mumbai

- hose ferrules exporter India

- brass fittings supplier India

- hydraulic components manufacturer India

- brass machined parts India export

Quality Certifications & Standards

Our quality management system maintains certifications and compliance with multiple international standards, ensuring consistent product quality and customer satisfaction. Regular audits and continuous improvement programs maintain certification status and enhance quality performance.

| Certification/Standard | Scope | Certification Body | Validity |

|---|---|---|---|

| ISO 9001:2015 | Quality Management System | DNV GL | Valid through 2026 |

| ISO 14001:2015 | Environmental Management | DNV GL | Valid through 2026 |

| OHSAS 18001 | Occupational Health & Safety | DNV GL | Valid through 2025 |

| AS9100D | Aerospace Quality Management | NQA | Valid through 2025 |

Request Your Quote Today

Ready to source high-quality brass hose ferrules for your application? Our experienced team is standing by to assist with technical specifications, custom requirements, and competitive pricing.

Contact Methods:

Email us at sales@conexscrews. com

📞 Phone: Whatsapp: +91-22-43449300

What happens next?

✓ Technical consultation within 24 hours

✓ Detailed quotation with specifications

✓ Free samples for evaluation (where applicable)

✓ Custom design services for special requirements

Contact us today to experience the difference that three decades of manufacturing excellence can make for your brass hose ferrule requirements!