Stainless Steel Hose Ferrules & Stainless Steel Crimp Ferrules – Precision Engineered Components

Price: US$ 10.50/Kilogram

We are one of the leading manufacturers and exporters of Stainless Steel Hose Ferrules and Crimp Ferrules from India. We have been supplying high-quality precision Stainless Steel ferrules (Stainless Steel 316 ferrules, Stainless Steel crimping hose ferrules, Stainless Steel Braid collars) to the world market for many decades. Our extensive experience spans over three decades in manufacturing custom CNC machined ferrules for diverse industrial applications. These precision-engineered components are manufactured from premium grade sheet metal, pipe stock, and bar stock using advanced CNC machining processes. Our Stainless Steel ferrules are designed to fit over flexible hoses of multiple types including PTFE hoses, hydraulic hoses, pneumatic hoses, and various industrial fluid transfer systems. With our state-of-the-art manufacturing facility and skilled engineering team, we deliver consistent quality products that meet international standards. Our global clientele trusts us for reliable supply of custom ferrules with precise dimensional accuracy, superior surface finish, and exceptional durability. We specialize in both standard and custom configurations to meet specific application requirements across industries worldwide.

Product Overview

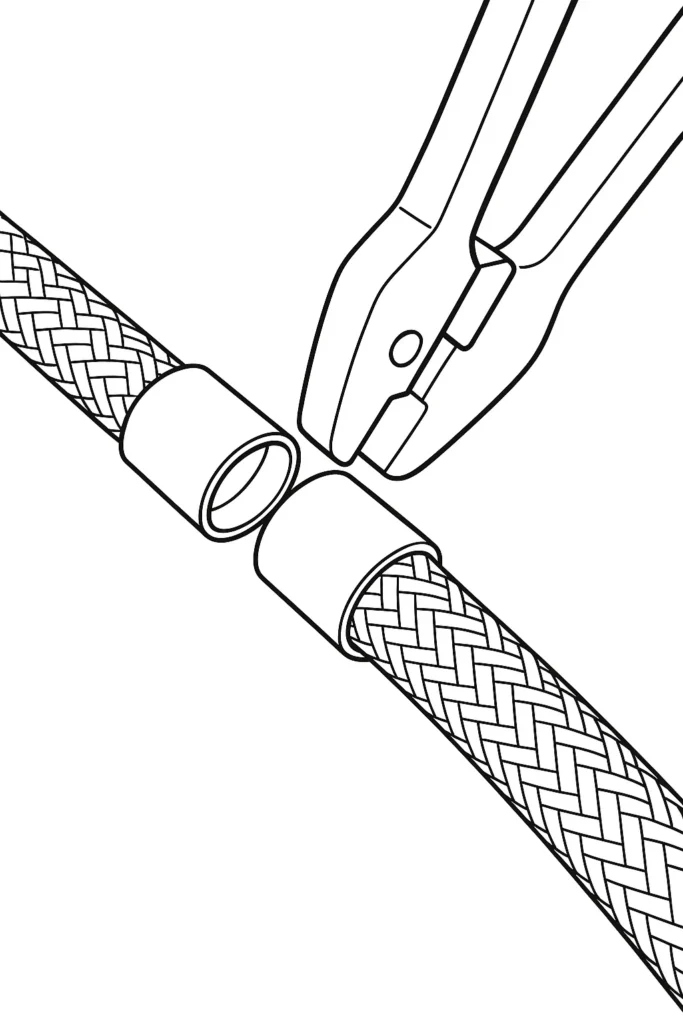

Stainless Steel Hose Ferrules and Stainless Steel Crimp Ferrules, Stainless Steel braid collars, Stainless Steel crimp collars are critical components in fluid transfer systems, providing secure connections between hoses and fittings. These precision-machined components ensure leak-proof sealing while maintaining system integrity under high pressure and temperature conditions. Our ferrules are manufactured to accommodate various hose types including PTFE (Polytetrafluoroethylene) hoses, braided stainless steel hoses, rubber hoses, thermoplastic hoses, silicone hoses, and composite hoses used in industrial, automotive, aerospace, and marine applications.

The manufacturing process for Stainless Steel Hose Ferrules and Stainless Steel Crimp Ferrules, Stainless Steel braid collars, Stainless Steel crimp collars involves precision CNC machining of high-grade Stainless Steel materials to achieve exact dimensional tolerances and superior surface finish. Our ferrules feature chamfered edges, smooth internal surfaces, and precise external dimensions that ensure optimal crimping performance and long-term reliability in demanding service conditions.

Material Grades & Specifications

We manufacture Stainless Steel Hose Ferrules using various internationally recognized material grades to meet diverse application requirements:

| Standard | Grade | Composition | Applications |

|---|---|---|---|

| ASTM A276 | 304/304L | 18-20% Cr, 8-12% Ni | General purpose, food grade |

| ASTM A276 | 316/316L | 16-18% Cr, 10-14% Ni, 2-3% Mo | Marine, chemical processing |

| ASTM A276 | 321 | 17-19% Cr, 9-12% Ni, Ti stabilized | High temperature applications |

| DIN 1.4301 | X5CrNi18-10 | Equivalent to 304 | European standard applications |

| DIN 1.4404 | X2CrNiMo17-12-2 | Equivalent to 316L | Corrosion resistant applications |

| JIS SUS304 | SUS304 | Japanese standard | Industrial applications |

| GB/T 1220 | 0Cr18Ni9 | Chinese standard | Cost-effective solutions |

| IS 6911 | Grade 304 | Indian standard | Domestic applications |

Manufacturing Processes & Machinery

Our advanced manufacturing facility employs multiple precision machining processes to produce high-quality Stainless Steel Hose Ferrules:

CNC Turning Operations: We utilize multi-axis CNC turning centers equipped with live tooling capabilities for complex ferrule geometries. Our CNC lathes include DMG Mori, Haas, and Mazak machines capable of handling diameters from 3mm to 150mm with exceptional accuracy.

CNC Milling Operations: For specialized features such as keyways, flats, and custom profiles, we employ 3-axis and 4-axis CNC milling centers. These machines ensure precise dimensional control and surface finish requirements.

Swiss-type Automatic Machining: For high-volume production of smaller diameter ferrules, we use Swiss-type automatic lathes that provide superior accuracy and surface finish while maintaining cost-effectiveness.

Secondary Operations: Our capabilities include deburring, chamfering, knurling, threading, and specialized surface treatments to meet customer specifications.

Technical Drawing – Stainless Steel Hose Ferrule

Length (L)ODID

| Dimension | Symbol | Range (mm) | Tolerances |

|---|---|---|---|

| Outer Diameter | OD | 6.0 – 76.2 | ±0.05 |

| Inner Diameter | ID | 3.0 – 70.0 | ±0.03 |

| Length | L | 8.0 – 100.0 | ±0.1 |

| Wall Thickness | t | 0.5 – 5.0 | ±0.05 |

Hose Types & Applications

Our Stainless Steel Hose Ferrules are designed to accommodate various flexible hose types used across industries:

PTFE (Polytetrafluoroethylene) Hoses: Chemical processing, pharmaceutical, food and beverage, high-purity applications requiring excellent chemical resistance and non-contaminating properties.

Hydraulic Hoses: Heavy machinery, construction equipment, mobile hydraulics, industrial hydraulic systems operating under high pressure conditions up to 6000 PSI.

Pneumatic Hoses: Compressed air systems, automation equipment, pneumatic tools, and air brake systems in automotive and industrial applications.

Braided Stainless Steel Hoses: High-temperature applications, steam systems, cryogenic applications, and corrosive media handling in chemical plants.

Rubber Hoses: General industrial applications, water systems, low-pressure hydraulics, and various fluid transfer applications.

Thermoplastic Hoses: Paint spray systems, chemical transfer, high-pressure cleaning equipment, and specialized industrial applications.

Silicone Hoses: Food processing, pharmaceutical manufacturing, biotechnology applications, and high-temperature fluid transfer systems.

Surface Finish & Quality Standards

Our Stainless Steel Hose Ferrules feature superior surface finish achieved through controlled machining parameters and post-processing operations. Standard surface finish ranges from 0.8 to 3.2 Ra (micro-inches) depending on application requirements. We offer various surface treatments including:

Mechanical Polishing: Achieving mirror-like finish for sanitary applications with surface roughness as low as 0.4 Ra. This finish is ideal for food processing, pharmaceutical, and biotechnology applications where cleanliness is paramount.

Electropolishing: Removes microscopic surface irregularities, enhances corrosion resistance, and provides a smooth, easy-to-clean surface finish. This process is particularly beneficial for applications in corrosive environments.

Passivation: Chemical treatment that enhances the natural corrosion resistance of Stainless Steel by removing free iron and creating a protective oxide layer on the surface.

Industries & Applications

Our Stainless Steel Hose Ferrules serve diverse industries with specialized requirements:

Oil & Gas Industry: Offshore drilling platforms, refineries, petrochemical plants, pipeline systems, and subsea applications requiring corrosion-resistant components capable of withstanding harsh marine environments and aggressive hydrocarbons.

Chemical Processing: Chemical plants, pharmaceutical manufacturing, specialty chemical production, and research laboratories handling corrosive chemicals, acids, and solvents at various temperatures and pressures.

Food & Beverage: Dairy processing, brewery equipment, food manufacturing, beverage production, and sanitary systems requiring FDA-compliant materials and hygienic design features.

Aerospace & Defense: Aircraft hydraulic systems, fuel systems, environmental control systems, and military applications demanding lightweight, high-strength components with exceptional reliability.

Medical & Pharmaceutical: Medical device manufacturing, diagnostic equipment, pharmaceutical production, and biotechnology applications requiring biocompatible materials and sterile processing capabilities.

Marine & Shipbuilding: Vessel piping systems, ballast systems, cargo handling equipment, and offshore structures exposed to seawater and marine environments.

Power Generation: Nuclear power plants, thermal power stations, renewable energy systems, and steam generation equipment operating under extreme temperature and pressure conditions.

Dimensional Chart & Specifications

| Part Number | Hose Size (inches) | OD (mm) | ID (mm) | Length (mm) | Material Grade |

|---|---|---|---|---|---|

| SSF-04 | 1/4″ | 12.7 | 6.35 | 19.05 | 316L |

| SSF-06 | 3/8″ | 15.88 | 9.53 | 22.23 | 316L |

| SSF-08 | 1/2″ | 19.05 | 12.7 | 25.4 | 316L |

| SSF-12 | 3/4″ | 25.4 | 19.05 | 31.75 | 316L |

| SSF-16 | 1″ | 31.75 | 25.4 | 38.1 | 316L |

| SSF-20 | 1-1/4″ | 38.1 | 31.75 | 44.45 | 316L |

| SSF-24 | 1-1/2″ | 44.45 | 38.1 | 50.8 | 316L |

| SSF-32 | 2″ | 57.15 | 50.8 | 63.5 | 316L |

Material Properties

| Property | 304 Stainless Steel | 316L Stainless Steel | 321 Stainless Steel |

|---|---|---|---|

| Tensile Strength (MPa) | 515-620 | 485-620 | 515-655 |

| Yield Strength (MPa) | 205-310 | 170-310 | 205-345 |

| Elongation (%) | 40 min | 40 min | 40 min |

| Hardness (HRB) | 92 max | 95 max | 95 max |

| Operating Temperature (°C) | -196 to +800 | -196 to +800 | -196 to +900 |

| Corrosion Resistance | Good | Excellent | Good |

Quality Control & Tolerances

Our comprehensive quality control system ensures consistent product quality and dimensional accuracy. We maintain strict tolerances across all manufacturing processes:

Dimensional Tolerances: Our standard tolerances meet or exceed industry standards with typical dimensional accuracy of ±0.05mm for critical dimensions. Special applications requiring tighter tolerances can be accommodated with precision machining capabilities down to ±0.01mm.

Surface Finish Control: Surface roughness is controlled through optimized cutting parameters, tool selection, and post-processing operations. We regularly monitor surface finish using calibrated profilometers to ensure consistency.

Material Certification: All raw materials are procured from certified suppliers with complete material traceability. Each batch is accompanied by mill test certificates verifying chemical composition and mechanical properties.

Inspection Procedures: Our quality control laboratory is equipped with coordinate measuring machines (CMM), optical comparators, surface roughness testers, and hardness testing equipment for comprehensive inspection of finished products.

International Standards Compliance

Our Stainless Steel Hose Ferrules are manufactured in compliance with various international standards:

ASTM Standards: ASTM A276 for stainless steel bars, ASTM A479 for stainless steel bolting materials, and ASTM A193 for alloy steel bolting materials ensure material quality and performance.

DIN Standards: DIN 2353 for cutting ring fittings, DIN 3852 for hydraulic fittings, and DIN 20066 for hose fittings provide European compliance for our products.

ISO Standards: ISO 8434 for metallic tube connections, ISO 4427 for fitting systems, and ISO 9001:2015 quality management system certification ensure consistent quality delivery.

JIS Standards: JIS B 8363 for pipe fittings and JIS G 4303 for stainless steel bars meet Japanese industrial requirements.

IS Standards: IS 6911 for stainless steel products and IS 1239 for steel tubes provide compliance with Indian standards.

BS Standards: BS 4825 for tube fittings and BS 970 for wrought steels ensure British standard compliance.

Manufacturing Process Flow

Inspection

Machining

Inspection

Treatment

Dispatch

Performance Metrics & Testing

Our Stainless Steel Hose Ferrules undergo rigorous testing to ensure optimal performance under various operating conditions:

Pressure Testing: All ferrules are tested to 1.5 times their rated working pressure to ensure leak-proof performance. Burst pressure testing is conducted to verify safety margins and structural integrity.

Fatigue Testing: Cyclic pressure testing simulates real-world operating conditions to evaluate long-term reliability and service life. Our ferrules typically withstand over 100,000 pressure cycles without failure.

Corrosion Testing: Salt spray testing per ASTM B117 standard evaluates corrosion resistance in marine and industrial environments. Our 316L grade ferrules demonstrate superior performance with minimal corrosion after 1000 hours of exposure.

Temperature Testing: Thermal cycling tests evaluate performance under extreme temperature variations from -40°C to +200°C, ensuring dimensional stability and mechanical properties retention.

| Test Parameter | Standard | Specification | Typical Results |

|---|---|---|---|

| Burst Pressure | ISO 4427 | 4x Working Pressure | Exceeds requirement |

| Fatigue Life | ISO 6803 | 100,000 cycles | 150,000+ cycles |

| Salt Spray Resistance | ASTM B117 | 500 hours | 1000+ hours |

| Dimensional Stability | ISO 6803 | ±0.1mm | ±0.05mm |

Turnaround Time & Production Capacity

Our efficient production planning and advanced manufacturing capabilities ensure reliable delivery schedules. Standard turnaround time for Stainless Steel Hose Ferrules is 4-6 weeks from order confirmation, depending on quantity and specifications. For urgent requirements, we offer expedited production with reduced lead times of 2-3 weeks for standard configurations.

Our production capacity includes multiple CNC machining centers operating in three shifts to accommodate high-volume orders while maintaining quality standards. We maintain strategic inventory of common raw materials to minimize lead times and ensure consistent supply to our global customers.

Frequently Asked Questions

Why Choose Our Stainless Steel Hose Ferrules

Three Decades of Manufacturing Excellence: With over 30 years of experience in precision machining and global supply, we have developed deep expertise in understanding customer requirements and delivering consistent quality products. Our extensive experience spans diverse industries and applications, enabling us to provide informed technical guidance and optimal solutions.

Advanced Manufacturing Capabilities: Our state-of-the-art CNC machining centers, Swiss-type automatic lathes, and multi-axis milling machines enable us to produce complex geometries with exceptional accuracy. We continuously invest in the latest technology to maintain our competitive edge and improve product quality.

Superior Customer Support: Our dedicated customer service team provides prompt response to inquiries, technical support, and order tracking. We maintain excellent communication throughout the project lifecycle, keeping customers informed about production progress and delivery schedules.

Flexible Production Scheduling: We understand the importance of meeting customer deadlines and offer flexible production scheduling to accommodate urgent requirements. Our efficient production planning system ensures optimal resource utilization while maintaining quality standards.

Global Supply Chain Expertise: Having supplied to customers across six continents, we have extensive experience in international shipping, customs procedures, and regulatory compliance. Our logistics team ensures smooth delivery to any destination worldwide.

Customization Capabilities: Unlike standard catalog suppliers, we specialize in custom manufacturing to meet specific customer requirements. Our engineering team can modify existing designs or develop completely new ferrule configurations based on unique application needs.

Competitive Pricing: Our efficient manufacturing processes, strategic material sourcing, and optimized production planning enable us to offer competitive pricing without compromising quality. We provide value engineering suggestions to optimize costs while maintaining performance.

Quality Assurance: Our comprehensive quality management system ensures consistent product quality through rigorous inspection procedures, statistical process control, and continuous improvement initiatives. Every product undergoes thorough quality verification before shipment.

Customer Testimonial

“We have been sourcing Stainless Steel Hose Ferrules from this company for over 15 years, and their consistency in quality and delivery has been exceptional. Their ability to customize ferrules for our specialized hydraulic applications and provide technical support throughout the development process sets them apart from other suppliers. The quality of their 316L ferrules has significantly improved the reliability of our hose assemblies in offshore drilling applications.”

– Robert Martinez, Procurement Manager, USA

Packaging & Shipping

We understand the importance of proper packaging to ensure product integrity during transit. Our comprehensive packaging solutions are designed to protect Stainless Steel Hose Ferrules from damage, corrosion, and contamination during international shipping.

Primary Packaging: Individual ferrules are wrapped in anti-corrosion paper and placed in protective plastic tubes or foam-lined compartments to prevent surface damage and scratching during handling.

Secondary Packaging: Multiple ferrules are packed in moisture-resistant cardboard boxes with foam inserts for cushioning. Each box is labeled with part numbers, quantities, and handling instructions for easy identification.

Export Packaging: For international shipments, we use wooden crates or heavy-duty cardboard boxes with additional moisture barriers and shock-absorbing materials. All packaging complies with ISPM-15 international standards for wood packaging materials.

Custom Packaging Solutions: We offer customized packaging with customer logos, labels, and specific marking requirements. This includes direct shipment to customer locations with customer-branded packaging for OEM applications.

Documentation: All shipments include comprehensive documentation including packing lists, material certificates, test reports, and commercial invoices. We provide electronic copies of all documents for customer records and customs clearance.

Shipping Methods: We work with reliable international freight forwarders and shipping companies to ensure timely delivery. Options include air freight for urgent orders, sea freight for bulk shipments, and express courier services for samples and small quantities.

Unique Selling Propositions (USPs)

Complete Customization Flexibility: Unlike standard suppliers, we offer complete design flexibility to match customer specifications. Our engineering team can reverse-engineer existing ferrules, modify dimensions for improved performance, or develop entirely new designs based on application requirements.

Rapid Prototype Development: Our dedicated prototype machining capability enables quick turnaround of sample parts for testing and validation. We can produce prototype ferrules within 1-2 weeks to accelerate customer product development cycles.

Flexible Production Quantities: We accommodate both small-batch custom orders and high-volume production runs. Our flexible manufacturing setup allows economic production of specialty ferrules in quantities as low as 100 pieces.

Value Engineering Services: Our experienced engineers provide value engineering recommendations to optimize ferrule design for cost reduction, performance improvement, and manufacturing efficiency while maintaining quality standards.

Custom Branding and Packaging: We offer private labeling services with customer logos, part numbers, and specific packaging requirements. This enables OEM customers to maintain their brand identity throughout the supply chain.

Technical Documentation Support: We provide comprehensive technical documentation including 3D CAD models, detailed drawings, material specifications, and performance data to support customer engineering and quality requirements.

Global Quality Standards Compliance: Our products comply with multiple international standards including ASTM, DIN, ISO, JIS, and IS standards, ensuring acceptance in global markets and diverse applications.

Glossary of Technical Terms

Get Your Custom Quote Today

Ready to source high-quality Stainless Steel Hose Ferrules for your application? Our experienced team is standing by to assist with your requirements.

📧 Email: sales@conexscrews. com – Send us your specifications for a detailed quote

📞 Phone: +91 22 43449300- Speak directly with our technical experts

📄 Request Brochure: – Get our comprehensive product catalog

Why Contact Us?

✓ Free technical consultation and ferrule selection guidance

✓ Custom quotes within 24 hours for standard configurations

✓ Sample ferrules available for testing and validation

✓ Complete technical documentation and material certificates

✓ Global shipping with reliable logistics partners

✓ Three decades of manufacturing excellence and customer satisfaction

Contact us today and experience the difference of working with India’s leading Stainless Steel Hose Ferrule manufacturer!