Aluminum Inserts – Aluminum Molding Inserts, Aluminum Plastic Molding Inserts

We are one of the leading manufacturers and exporters of Aluminum inserts, Aluminum molding inserts, and Aluminum plastic molding inserts from India. We have been supplying high-quality precision engineered Aluminum inserts to the world market for many decades. Our comprehensive range of Aluminum inserts includes threaded inserts, knurled inserts, ultrasonic inserts, hex inserts, expansion inserts, injection molding inserts, and roto molding inserts. With over three decades of manufacturing excellence, we specialize in producing premium grade Aluminum inserts that meet international standards including IS, BS, ASTM, DIN, and JIS specifications. Our state-of-the-art manufacturing facility in India combines advanced CNC machining technology with skilled craftsmanship to deliver superior quality Aluminum inserts for diverse industrial applications. We offer both metric and imperial thread specifications including BSW, BSP, UNC, and UNF threading options to cater to global market requirements. Our extensive experience in precision engineering and commitment to quality has established us as a trusted partner for customers worldwide seeking reliable Aluminum insert solutions.

Price: US$ 8/kilogram

Overview

Aluminum inserts are precision-engineered fastening components designed to provide strong, durable threaded connections in various materials, particularly plastics and composite materials. These inserts are manufactured from high-grade Aluminum alloys, offering excellent corrosion resistance, lightweight properties, and superior mechanical strength. Our Aluminum inserts are extensively used in automotive, aerospace, electronics, medical devices, and consumer goods industries where reliable fastening solutions are critical for product performance and longevity.

The manufacturing process involves precision CNC machining, cold forming, and specialized surface treatments to achieve tight tolerances and optimal surface finishes. Our Aluminum inserts undergo rigorous quality control testing to ensure compliance with international standards and customer specifications. The unique design features of our Aluminum inserts include precise thread profiles, consistent dimensions, and specialized surface textures that enhance installation performance and holding strength.

Aluminum Inserts

Our standard Aluminum inserts are engineered for general-purpose applications where lightweight, corrosion-resistant fastening solutions are required. These inserts are manufactured from high-grade Aluminum alloys such as 6061-T6, 2024-T4, and 7075-T6, providing excellent strength-to-weight ratios and dimensional stability. The inserts feature precision-machined threads that comply with ISO, ANSI, and DIN standards, ensuring compatibility with standard fasteners. Our manufacturing process includes precision turning, thread rolling, and surface treatment operations to achieve superior quality and performance characteristics.

The design incorporates optimized wall thickness and thread engagement length to maximize holding strength while minimizing material usage. Special attention is given to thread profile accuracy, surface finish quality, and dimensional consistency to ensure reliable installation and long-term performance. Our Aluminum inserts are available in various configurations including straight-wall, flanged, and tapered designs to accommodate different application requirements.

Aluminum Molding Inserts

Aluminum molding inserts are specifically designed for integration into molded plastic components during the manufacturing process. These inserts provide robust threaded connections in plastic parts where traditional fastening methods may be inadequate. Our molding inserts feature specialized external configurations including knurls, grooves, and undercuts that enhance mechanical bonding with the surrounding plastic material. The inserts are manufactured to precise tolerances to ensure proper fit within mold cavities and consistent positioning during the molding process.

The surface treatment of our Aluminum molding inserts includes specialized coatings and textures that promote strong adhesion to various plastic materials including ABS, PC, PA, POM, and other engineering plastics. Our design expertise ensures optimal insert geometry for different molding processes while maintaining thread integrity and dimensional accuracy. The inserts are tested for pull-out strength, torque resistance, and thermal cycling performance to validate their suitability for demanding applications.

Aluminum Inserts for Plastic Molding

Our Aluminum inserts for plastic molding applications are engineered to provide permanent threaded connections in molded plastic components. These inserts are designed with specialized external features that create strong mechanical bonds with the surrounding plastic material during the molding process. The inserts feature precision-machined threads, optimal wall thickness, and surface treatments that ensure reliable performance in various plastic materials and molding conditions.

The manufacturing process includes precision CNC machining, thread rolling, and specialized surface treatments to achieve the required mechanical properties and surface characteristics. Our inserts are compatible with various molding processes including injection molding, compression molding, and transfer molding. The design considerations include thermal expansion compatibility, shrinkage compensation, and stress distribution optimization to prevent cracking or loosening during service.

Aluminum Ultrasonic Inserts

Aluminum ultrasonic inserts are specifically designed for installation using ultrasonic welding technology, providing rapid and efficient assembly of threaded connections in plastic components. These inserts feature specialized external configurations including sharp-edged knurls, spiral grooves, and optimized geometries that facilitate ultrasonic energy transmission and plastic material displacement. The inserts are manufactured from high-grade Aluminum alloys with precise dimensional control to ensure consistent installation performance.

The design incorporates features such as controlled wall thickness, optimized knurl patterns, and precise thread specifications to maximize holding strength while minimizing installation time and energy requirements. Our ultrasonic inserts undergo extensive testing including pull-out strength evaluation, torque resistance measurement, and thermal cycling assessment to validate their performance characteristics. The inserts are compatible with various thermoplastic materials and ultrasonic welding equipment configurations.

Aluminum Roto Molding Inserts

Aluminum roto molding inserts are engineered for integration into rotational molding processes, providing threaded connections in hollow plastic components. These inserts feature specialized designs that accommodate the unique requirements of rotational molding including thermal cycling, material flow patterns, and wall thickness variations. The inserts are manufactured with precise dimensional control and surface treatments that ensure proper positioning and strong mechanical bonding during the molding process.

The design considerations include thermal expansion compatibility, material flow optimization, and stress distribution management to prevent insert displacement or plastic cracking during cooling. Our roto molding inserts are tested for various performance parameters including pull-out strength, thermal cycling resistance, and chemical compatibility with different plastic materials. The inserts are available in various configurations to accommodate different wall thicknesses and application requirements.

Aluminum Hex Inserts

Aluminum hex inserts feature hexagonal external configurations that provide anti-rotation capabilities and enhanced holding strength in various applications. These inserts are manufactured with precision-machined hex profiles that create strong mechanical bonds with surrounding materials while preventing rotation during fastener installation or removal. The hex design provides multiple engagement surfaces that distribute loads effectively and resist pull-out forces.

Our hex inserts are manufactured using precision CNC machining processes to achieve tight tolerances on both internal threads and external hex dimensions. The inserts are available in various hex sizes and internal thread specifications to accommodate different application requirements. Special attention is given to corner radius control, surface finish quality, and dimensional consistency to ensure reliable performance and ease of installation.

Aluminum Knurled Inserts

Aluminum knurled inserts feature precision-machined knurled external surfaces that provide superior holding strength and resistance to pull-out forces in various materials. The knurled pattern creates multiple engagement points that distribute loads effectively and enhance mechanical bonding with surrounding materials. Our knurled inserts are manufactured with consistent knurl patterns, precise thread specifications, and optimal dimensional control to ensure reliable performance.

The knurling process involves precision machining operations that create uniform knurl patterns with controlled pitch, depth, and profile angles. Our knurled inserts are available in various knurl configurations including straight, diamond, and spiral patterns to accommodate different application requirements. The inserts undergo rigorous quality testing including pull-out strength evaluation, torque resistance measurement, and dimensional verification to ensure consistent performance.

Aluminum Expansion Inserts

Aluminum expansion inserts are designed to provide secure fastening in hollow or thin-walled materials through controlled expansion mechanisms. These inserts feature specialized designs that expand when fasteners are installed, creating strong mechanical bonds with surrounding materials. The expansion mechanism provides high holding strength while accommodating material tolerances and installation variations.

Our expansion inserts are manufactured with precision-controlled expansion characteristics, optimal wall thickness, and precise thread specifications to ensure consistent performance. The design incorporates stress distribution features that prevent material damage during expansion while maximizing holding strength. The inserts are tested for various performance parameters including expansion force, holding strength, and fatigue resistance to validate their suitability for demanding applications.

Aluminum Threaded Inserts

Aluminum threaded inserts provide precision-engineered internal threads in various materials, offering superior fastening solutions for applications requiring lightweight, corrosion-resistant connections. These inserts are manufactured from high-grade Aluminum alloys with precise thread specifications that comply with international standards including ISO, ANSI, and DIN. The inserts feature optimized wall thickness, controlled thread tolerances, and specialized surface treatments to ensure reliable performance.

Our threaded inserts are available in various thread specifications including metric (M3 to M24) and imperial (4-40 to 1/2-13) configurations with options for coarse and fine pitch threads. The manufacturing process includes precision CNC machining, thread rolling, and quality control operations to achieve superior dimensional accuracy and surface finish quality. The inserts undergo comprehensive testing including thread gauging, pull-out strength evaluation, and torque resistance measurement.

Aluminum Injection Molding Inserts

Aluminum injection molding inserts are specifically engineered for integration into injection molding processes, providing robust threaded connections in molded plastic components. These inserts feature specialized external configurations that enhance mechanical bonding with plastic materials during the injection molding process. The inserts are manufactured with precise dimensional control and surface treatments that ensure proper positioning and strong adhesion.

The design incorporates features such as controlled wall thickness, optimized external geometry, and precise thread specifications to maximize holding strength while minimizing molding defects. Our injection molding inserts are compatible with various thermoplastic materials and injection molding conditions. The inserts undergo extensive testing including pull-out strength evaluation, thermal cycling assessment, and dimensional verification to ensure consistent performance.

Aluminum Threaded and Knurled Inserts

Our combination threaded and knurled inserts provide the benefits of both precision internal threads and enhanced external holding characteristics. These inserts feature knurled external surfaces for superior grip and resistance to pull-out forces, combined with precision-machined internal threads for reliable fastener engagement. The combination design provides optimal performance in applications requiring both strong holding power and precise threaded connections.

The manufacturing process involves precision CNC machining, controlled knurling operations, and thread rolling to achieve the required mechanical properties and dimensional accuracy. Our threaded and knurled inserts are available in various configurations including different knurl patterns, thread specifications, and external dimensions to accommodate diverse application requirements. The inserts undergo comprehensive quality testing to ensure consistent performance and reliability.

Thread Specifications

Our Aluminum inserts are available with both metric and imperial thread specifications to meet global market requirements. The thread options include comprehensive ranges of metric threads (M3 to M24) and imperial threads covering BSW (British Standard Whitworth), BSP (British Standard Pipe), UNC (Unified National Coarse), and UNF (Unified National Fine) specifications. Each thread type is manufactured to precise tolerances ensuring compatibility with standard fasteners and optimal performance.

| Thread Type | Size Range | Pitch Options | Tolerance Class | Applications |

|---|---|---|---|---|

| Metric | M3 to M24 | 0.5 to 3.0mm | 6H, 6G | General purpose, automotive |

| BSW | 1/8″ to 1″ | Variable | 2B, 3B | British standard applications |

| BSP | 1/8″ to 2″ | Variable | 2B, 3B | Pipe connections, hydraulics |

| UNC | 4-40 to 1/2-13 | Coarse | 2B, 3B | North American standard |

| UNF | 4-48 to 1/2-20 | Fine | 2B, 3B | Precision applications |

Material Grades

Our Aluminum inserts are manufactured from premium grade Aluminum alloys sourced from certified suppliers and tested to meet international standards. The material selection includes various alloy grades optimized for specific applications and performance requirements.

| Grade | International | USA (ASTM) | Europe (EN) | China (GB) | Japan (JIS) | Properties |

|---|---|---|---|---|---|---|

| 6061-T6 | ISO 6361 | A96061 | EN AW-6061 | 6061 | A6061 | High strength, good corrosion resistance |

| 2024-T4 | ISO 6361 | A92024 | EN AW-2024 | 2024 | A2024 | High strength, aerospace grade |

| 7075-T6 | ISO 6361 | A97075 | EN AW-7075 | 7075 | A7075 | Ultra high strength, premium grade |

| 5052-H32 | ISO 6361 | A95052 | EN AW-5052 | 5052 | A5052 | Excellent corrosion resistance |

| 1100-H14 | ISO 6361 | A91100 | EN AW-1100 | 1100 | A1100 | High purity, good formability |

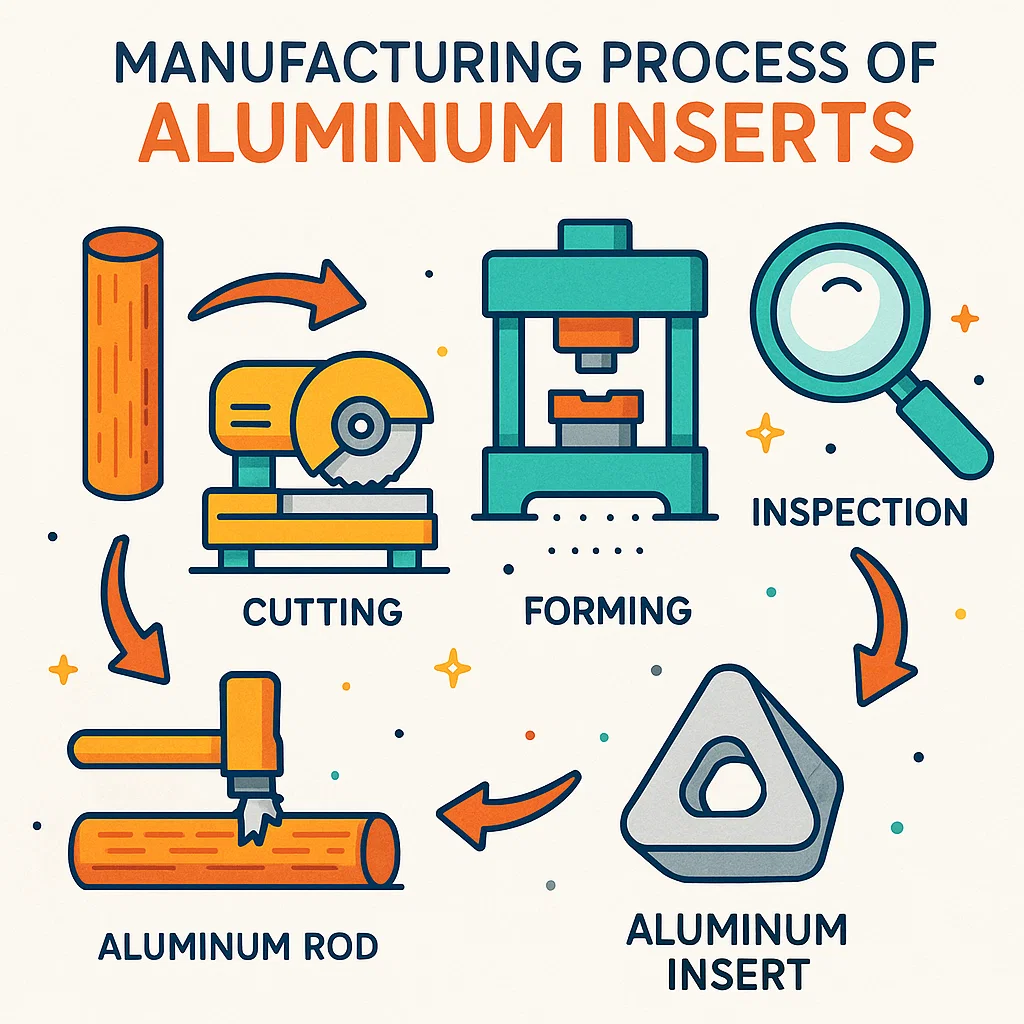

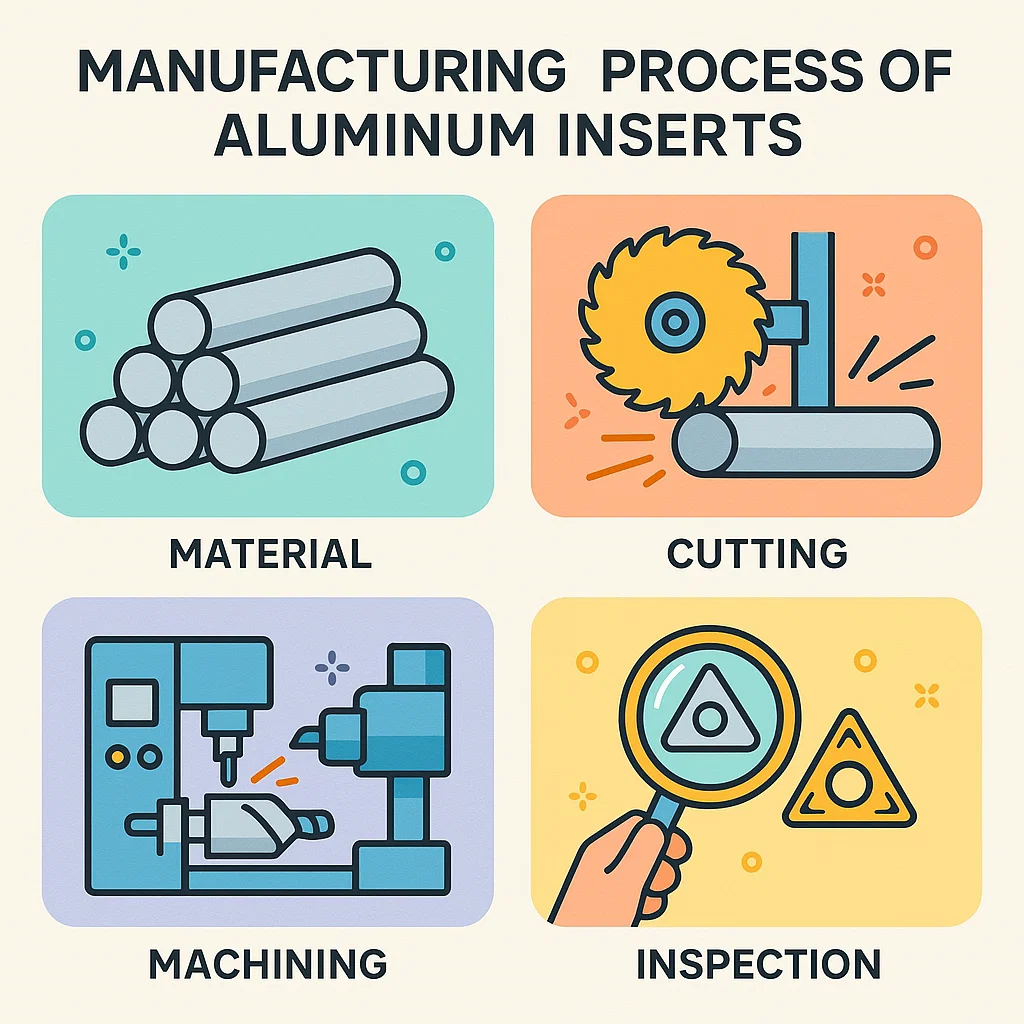

Manufacturing Processes

Our advanced manufacturing processes combine precision CNC machining, specialized forming operations, and quality control systems to produce superior quality Aluminum inserts. The manufacturing sequence includes material preparation, precision machining, thread formation, surface treatment, and comprehensive quality testing to ensure consistent performance and reliability.

The primary manufacturing processes include CNC turning for external geometry creation, thread rolling for internal thread formation, knurling operations for enhanced grip surfaces, and specialized surface treatments for improved performance characteristics. Each process is controlled through statistical process control methods and regular quality audits to maintain consistency and meet customer specifications.

Machinery Used

Our manufacturing facility is equipped with state-of-the-art machinery including high-precision CNC lathes, multi-spindle automatic machines, thread rolling equipment, and specialized knurling machines. The machinery selection includes leading manufacturers such as Haas, Mazak, Citizen, and Tornos to ensure superior quality and productivity.

| Machine Type | Manufacturer | Model | Capabilities | Tolerance Achievement |

|---|---|---|---|---|

| CNC Lathe | Haas | ST-30 | Precision turning, threading | ±0.01mm |

| Multi-Spindle | Citizen | L32 | High volume production | ±0.02mm |

| Thread Rolling | Tornos | TR-45 | Thread formation | ±0.05mm |

| Knurling Machine | Mazak | KM-25 | Surface texturing | ±0.03mm |

Typical Parts Produced

Our manufacturing capabilities enable production of diverse Aluminum insert configurations for various industries and applications. The typical parts produced include standard threaded inserts, specialized molding inserts, custom-designed inserts, and application-specific variations that meet unique customer requirements.

Common applications include automotive interior components, electronic device housings, medical equipment assemblies, aerospace panel connections, consumer appliance fastening, and industrial machinery components. Each application requires specific design considerations including thread specifications, external geometry, material selection, and surface treatments to achieve optimal performance.

Dimensional Specifications

Standard Insert Dimensions (Example: M6 Insert)

Length (L)ODThread Ø

| Thread Size | External Diameter (mm) | Length Range (mm) | Internal Diameter (mm) | Wall Thickness (mm) |

|---|---|---|---|---|

| M3 | 4.5 – 5.5 | 3 – 20 | 3.0 | 0.75 – 1.25 |

| M4 | 5.5 – 6.5 | 4 – 25 | 4.0 | 0.75 – 1.25 |

| M5 | 6.5 – 7.5 | 5 – 30 | 5.0 | 0.75 – 1.25 |

| M6 | 7.5 – 8.5 | 6 – 35 | 6.0 | 0.75 – 1.25 |

| M8 | 9.5 – 11.0 | 8 – 40 | 8.0 | 0.75 – 1.5 |

| M10 | 12.0 – 14.0 | 10 – 50 | 10.0 | 1.0 – 2.0 |

Surface Finishes

Our Aluminum inserts are available with various surface finishes to meet specific application requirements and enhance performance characteristics. The finish selection includes natural Aluminum, anodized coatings, chemical treatments, and specialized coatings that provide corrosion resistance, wear protection, and aesthetic appeal.

| Finish Type | Specification | Thickness (μm) | Properties | Applications |

|---|---|---|---|---|

| Natural | As machined | N/A | Basic corrosion resistance | General purpose |

| Anodized | Type II, Class 2 | 12-25 | Enhanced corrosion resistance | Outdoor applications |

| Hard Anodized | Type III | 25-75 | Wear resistance, hardness | High-wear applications |

| Chromate | MIL-DTL-5541 | 1-3 | Corrosion protection | Military, aerospace |

| Passivated | ASTM B912 | 0.1-0.5 | Corrosion resistance | Medical, food grade |

Industries and Applications

Our Aluminum inserts serve diverse industries including automotive, aerospace, electronics, medical devices, consumer goods, and industrial machinery. Each industry has specific requirements for material properties, dimensional accuracy, surface treatments, and performance characteristics that our manufacturing capabilities are designed to meet.

| Industry | Applications | Key Requirements | Typical Insert Types | Volume Range |

|---|---|---|---|---|

| Automotive | Dashboard assemblies, door panels, interior trim | Crash resistance, temperature cycling | Molding inserts, knurled inserts | 10K – 1M pieces |

| Aerospace | Panel assemblies, avionics housings | Weight reduction, vibration resistance | Threaded inserts, hex inserts | 100 – 50K pieces |

| Electronics | Device housings, PCB assemblies | EMI shielding, thermal management | Ultrasonic inserts, expansion inserts | 1K – 500K pieces |

| Medical | Equipment housings, surgical devices | Biocompatibility, sterilization resistance | Threaded inserts, injection molding inserts | 100 – 10K pieces |

| Consumer Goods | Appliances, furniture, sports equipment | Durability, aesthetic appeal | Knurled inserts, roto molding inserts | 1K – 100K pieces |

Tolerances and Quality Standards

Our manufacturing processes are designed to achieve tight tolerances and meet international quality standards. We maintain statistical process control systems and conduct regular quality audits to ensure consistent performance and customer satisfaction. Our quality management system is certified to ISO 9001:2015 standards.

| Dimension | Standard Tolerance | Precision Tolerance | Measurement Method | Inspection Frequency |

|---|---|---|---|---|

| External Diameter | ±0.05mm | ±0.02mm | Micrometer | Every 50 pieces |

| Internal Thread | 6H tolerance | 5H tolerance | Thread gauges | Every 25 pieces |

| Length | ±0.1mm | ±0.05mm | Caliper | Every 100 pieces |

| Concentricity | 0.05mm TIR | 0.02mm TIR | CMM | Sample basis |

| Surface Finish | Ra 1.6μm | Ra 0.8μm | Profilometer | Sample basis |

Turnaround Time

Our standard turnaround time for Aluminum inserts is 4-6 weeks from order confirmation, depending on quantity, complexity, and customization requirements. We maintain strategic inventory levels of raw materials and common configurations to minimize lead times. For urgent requirements, we offer expedited production services with reduced turnaround times of 2-3 weeks for standard configurations.

The production scheduling includes material procurement, manufacturing operations, quality control testing, finishing processes, and packaging. We provide regular progress updates throughout the manufacturing cycle and maintain flexible production capabilities to accommodate schedule changes when possible. Our production planning system optimizes resource utilization and minimizes lead times while maintaining quality standards.

Performance Metrics

Our Aluminum inserts are tested for various performance parameters to ensure they meet application requirements and provide reliable long-term performance. The testing protocols include mechanical property evaluation, environmental resistance testing, and application-specific performance validation.

| Performance Parameter | Test Method | Typical Values | Units | Test Standard |

|---|---|---|---|---|

| Pull-out Strength | Tensile testing | 500-2000 | N | ASTM D4762 |

| Torque Strength | Torsion testing | 2-15 | Nm | ASTM D5649 |

| Fatigue Life | Cyclic loading | 10,000-100,000 | Cycles | ASTM D7791 |

| Temperature Range | Thermal cycling | -40 to +120 | °C | ASTM D1693 |

| Corrosion Resistance | Salt spray testing | 500-1000 | Hours | ASTM B117 |

Frequently Asked Questions

Q1: What is the minimum order quantity for Aluminum inserts?

A: Our minimum order quantity is typically 1,000 pieces for standard configurations. However, we can accommodate smaller quantities for prototyping and testing purposes with adjusted pricing. Custom configurations may have different minimum quantities based on setup requirements.

Q2: Can you provide Aluminum inserts with custom thread specifications?

A: Yes, we specialize in custom thread specifications including non-standard pitches, left-hand threads, and specialized thread profiles. Our engineering team can work with your specifications to develop custom solutions that meet your exact requirements.

Q3: What is the typical lead time for custom Aluminum inserts?

A: Custom Aluminum inserts typically require 6-8 weeks from design approval to delivery. This includes tooling preparation, sample approval, and production. We provide detailed project timelines and progress updates throughout the development process.

Q4: Do you offer material certification for your Aluminum inserts?

A: Yes, we provide complete material certification including mill test certificates, chemical composition analysis, and mechanical property verification. Our quality documentation meets aerospace, automotive, and medical industry requirements.

Q5: What surface treatments are available for Aluminum inserts?

A: We offer various surface treatments including natural finish, anodizing (Type II and Type III), chromate conversion coating, passivation, and specialized coatings. The selection depends on application requirements and environmental conditions.

Q6: Can Aluminum inserts be used in high-temperature applications?

A: Yes, our Aluminum inserts can operate in temperatures up to 120°C continuously and up to 150°C intermittently. For higher temperature applications, we recommend specialized alloys and surface treatments. We can provide detailed thermal performance data for specific applications.

Q7: How do you ensure consistent quality across large production runs?

A: We maintain statistical process control systems, regular calibration of measuring equipment, and comprehensive quality audits. Our quality management system includes incoming material inspection, in-process monitoring, and final inspection protocols.

Q8: What packaging options are available for Aluminum inserts?

A: We offer various packaging options including bulk packaging, counted quantities in boxes, specialized anti-static packaging for electronics applications, and custom packaging with customer labeling. We can also provide automated feeding systems for high-volume applications.

Q9: Do you provide technical support for insert selection and application?

A: Yes, our technical team provides comprehensive support including material selection guidance, design optimization recommendations, installation procedures, and troubleshooting assistance. We also offer on-site technical support for complex applications.

Q10: Can you supply Aluminum inserts for automated assembly processes?

A: Yes, we can supply Aluminum inserts in formats suitable for automated assembly including vibratory bowl feeding, tape and reel packaging, and bulk handling systems. Our inserts are designed to be compatible with standard automation equipment.

Material Properties

The mechanical and physical properties of our Aluminum alloys are carefully controlled and tested to ensure consistent performance. These properties are critical for determining the suitability of specific alloys for different applications and environmental conditions.

| Property | 6061-T6 | 2024-T4 | 7075-T6 | 5052-H32 | Units | Test Standard |

|---|---|---|---|---|---|---|

| Tensile Strength | 310 | 470 | 570 | 228 | MPa | ASTM E8 |

| Yield Strength | 276 | 325 | 505 | 193 | MPa | ASTM E8 |

| Elongation | 12 | 20 | 11 | 25 | % | ASTM E8 |

| Hardness | 95 | 120 | 150 | 60 | HB | ASTM E10 |

| Density | 2.70 | 2.78 | 2.81 | 2.68 | g/cm³ | ASTM B311 |

| Thermal Conductivity | 167 | 121 | 130 | 138 | W/m·K | ASTM E1461 |

| Melting Point | 582-652 | 502-638 | 477-635 | 607-649 | °C | DSC |

Our Unique Selling Propositions

Customization Capability

Our engineering team specializes in developing custom Aluminum insert solutions tailored to specific application requirements. We offer complete design services from concept to production including prototyping, testing, and validation.

Flexible Production Times

We maintain flexible production scheduling to accommodate urgent requirements and varying order volumes. Our production planning system optimizes resource utilization while maintaining quality standards and delivery commitments.

Global Experience

With over three decades of international experience, we understand diverse market requirements and regulatory standards. Our global exposure enables us to provide solutions that meet international quality and performance expectations.

Quality Assurance

Our comprehensive quality management system ensures consistent product quality through statistical process control, regular audits, and continuous improvement initiatives. We maintain ISO 9001:2015 certification and industry-specific quality standards.

Technical Support

Our technical team provides comprehensive application support including material selection guidance, design optimization, installation procedures, and troubleshooting assistance. We maintain ongoing relationships with customers throughout the product lifecycle.

Custom Packaging

We offer customized packaging solutions including customer labeling, logo printing, specialized anti-static packaging, and automated feeding systems. Our packaging options are designed to meet specific customer requirements and assembly processes.

Packaging and Shipping

Our packaging and shipping services are designed to ensure product integrity during transportation while minimizing costs and environmental impact. We offer various packaging options to meet different customer requirements and shipping destinations worldwide.

Standard packaging includes moisture-resistant bags, anti-static protection for electronics applications, and secure boxing with appropriate cushioning materials. We provide custom labeling services including customer part numbers, lot identification, and quantity verification. Our shipping partnerships with major logistics providers ensure reliable delivery to global destinations with comprehensive tracking and insurance coverage.

| Packaging Type | Quantity Range | Protection Level | Applications | Shipping Options |

|---|---|---|---|---|

| Bulk Boxes | 1,000-50,000 | Basic | General purpose | Standard freight |

| Counted Bags | 100-5,000 | Enhanced | Precise quantities | Express shipping |

| Anti-Static | 500-10,000 | ESD protection | Electronics | Specialized handling |

| Custom Trays | 100-1,000 | Premium | Automation ready | Air freight |

Customer Testimonial

“We have been working with this manufacturer for over 5 years and their Aluminum inserts consistently exceed our expectations. The quality is outstanding, delivery times are reliable, and their technical support team is incredibly knowledgeable. Their ability to customize solutions for our specific automotive applications has been invaluable to our product development process. The communication is excellent and they always keep us informed throughout the production cycle.”

– Robert Johnson, Senior Procurement Manager, Detroit Automotive Components

International Standards Compliance

Our Aluminum inserts are manufactured to comply with various international standards ensuring global acceptance and compatibility. We maintain certification and testing capabilities for major international standards including ISO, ASTM, DIN, BS, and JIS specifications.

| Standard | Organization | Scope | Key Requirements | Testing Methods |

|---|---|---|---|---|

| ISO 4762 | International Organization for Standardization | Threaded inserts | Dimensional requirements, thread specifications | Dimensional inspection, thread gauging |

| ASTM B557 | American Society for Testing and Materials | Mechanical properties | Tensile strength, yield strength, elongation | Tensile testing, mechanical evaluation |

| DIN 7991 | German Institute for Standardization | Insert geometry | Dimensional tolerances, material specifications | Coordinate measuring, material analysis |

| BS 4168 | British Standards Institution | Thread specifications | Thread profile, pitch accuracy | Thread measurement, profile verification |

| JIS B1021 | Japanese Industrial Standards | Insert applications | Performance requirements, test methods | Pull-out testing, torque evaluation |

Glossary of Terms

Aluminum Insert:

A precision-machined fastening component made from Aluminum alloy, designed to provide threaded connections in various materials.

Knurled Surface:

A textured external surface created by machining operations that provides enhanced grip and resistance to pull-out forces.

Thread Pitch:

The distance between adjacent threads measured parallel to the axis of the threaded insert.

Pull-out Strength:

The maximum force required to remove an insert from its installed position, measured in Newtons or pounds-force.

Ultrasonic Welding:

A joining process that uses high-frequency vibrations to create welds between thermoplastic materials and inserts.

Anodizing:

An electrochemical process that increases the thickness of the natural oxide layer on Aluminum surfaces for enhanced corrosion resistance.

Torque Strength:

The maximum rotational force that can be applied to an insert without causing failure or damage to the threaded connection.

Injection Molding:

A manufacturing process where molten plastic is injected into a mold cavity containing pre-positioned inserts.

Thread Tolerance:

The allowable variation in thread dimensions that ensures proper fit and function with mating fasteners.

Expansion Insert:

A type of insert that expands when a fastener is installed, creating a secure mechanical connection in hollow or thin-walled materials.