Bronze Mechanical Connectors & Bronze Mechanical Lugs – Premium Electrical Connection Solutions

Price: US$ 12/Kilogram

We are one of the leading manufacturers and exporters of Bronze Mechanical Connectors and Bronze Mechanical Lugs from India. We have been supplying high-quality Bronze electrical connectors and lugs to the world market for many decades. Our extensive manufacturing expertise spans over three decades, providing superior Bronze connector solutions for power distribution, switchgear applications, and electrical installations across diverse industries. Our Bronze mechanical connectors are engineered using high-strength corrosion-resistant Copper alloys, manufactured to meet international quality standards including ASTM, DIN, JIS, and IS specifications. With advanced casting and machining capabilities, we deliver precision-engineered Bronze connectors that ensure reliable electrical connections in demanding environments. Our manufacturing facility in Jamnagar, Gujarat, India, employs state-of-the-art technology and stringent quality control processes to produce Bronze mechanical lugs that exceed customer expectations. We specialize in customized solutions with flexible production schedules and customer-specific packaging requirements.

Overview

Bronze Mechanical Connectors and Bronze Mechanical Lugs are essential electrical components designed to provide secure, long-lasting connections in power distribution systems. These connectors are manufactured from high-grade Bronze alloys, offering exceptional electrical conductivity, superior corrosion resistance, and mechanical strength. Bronze connectors are widely used in electrical panels, transformers, switchgear, motors, generators, and grounding systems where reliability and durability are paramount.

The unique properties of Bronze make these connectors ideal for applications requiring resistance to saltwater corrosion, wear resistance, and excellent electrical performance. Our Bronze mechanical connectors feature precision-engineered design with optimized conductor entry ports, secure bolt connections, and consistent electrical contact surfaces that ensure maximum power transmission efficiency.

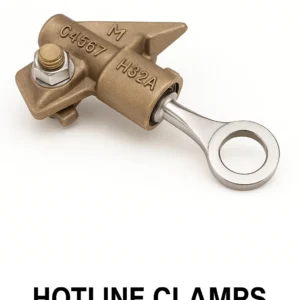

Bronze Mechanical Connectors

Bronze Mechanical Connectors are multi-conductor electrical connection devices manufactured from high-strength Bronze alloys. These connectors feature multiple wire entry ports with mechanical clamping mechanisms that provide secure connections for various conductor sizes. The connector body is precision-cast using advanced Bronze casting techniques, ensuring dimensional accuracy and consistent electrical properties.

Our Bronze mechanical connectors incorporate silicon Bronze or stainless steel bolts for enhanced durability and corrosion resistance. The design allows for easy installation and maintenance while providing reliable electrical connections in harsh environmental conditions. These connectors are engineered to accommodate both Copper and Aluminum conductors with appropriate contact compounds and anti-oxidation treatments.

The connector housing features smooth interior surfaces to prevent conductor damage during installation, while the exterior surfaces are finished to prevent corrosion and provide long-term reliability. Our Bronze mechanical connectors are available in various configurations including straight-through connections, T-taps, and parallel connectors to meet specific application requirements.

Bronze Mechanical Lugs

Bronze Mechanical Lugs are single or multi-conductor terminal connectors designed for secure electrical connections to busbars, panels, and equipment terminals. These lugs are manufactured from high-quality Bronze alloys using precision casting and machining processes. The lug body features a conductor entry barrel with mechanical compression mechanisms that ensure tight, reliable connections.

Our Bronze mechanical lugs are engineered with optimized barrel designs that accommodate specific conductor ranges while maintaining proper compression ratios for maximum electrical contact. The mounting portion features precisely machined holes with smooth edges to ensure proper fit with standard bolts and hardware. The lug design incorporates stress relief features to prevent conductor fatigue and maintain long-term connection integrity.

Bronze mechanical lugs offer superior performance in corrosive environments, particularly in marine applications, chemical processing facilities, and outdoor installations. The natural patina formation on Bronze surfaces provides additional corrosion protection while maintaining electrical conductivity. Our lugs are available in various barrel configurations including straight, offset, and angled designs to accommodate different installation requirements.

Material Grades and International Standards

ASTM Standards

- ASTM B505 – Continuous Cast Bronze specifications

- ASTM B271 – Centrifugal Cast Bronze specifications

- ASTM B124 – Standard specification for Copper and Copper alloy forgings

- ASTM B283 – Standard specification for Copper and Copper alloy die forgings

European Standards (DIN/EN)

- DIN 17660 – Copper-tin casting alloys

- EN 1982 – Copper and Copper alloys – Ingots and castings

- DIN 17672 – Brazing filler metals for hard brazing

British Standards (BS)

- BS 1400 – Copper alloy ingots and castings

- BS EN 12163 – Copper and Copper alloys – Rod

Japanese Standards (JIS)

- JIS H 5401 – Copper alloy castings

- JIS H 5111 – Bronze ingots for castings

Indian Standards (IS)

- IS 318 – Bronze ingots and castings

- IS 6912 – Copper alloy castings

Chinese Standards (GB)

- GB/T 13929 – Tin Bronze castings

- GB/T 1176 – Cast Copper and Copper alloy ingots

Common Bronze Alloy Grades

| Standard | Grade | Composition | Applications | Tensile Strength |

|---|---|---|---|---|

| ASTM | C90300 | Cu-88%, Sn-10%, Zn-2% | General bearings, gears | 310 MPa |

| ASTM | C90700 | Cu-89%, Sn-11% | High strength bearings | 415 MPa |

| ASTM | C93200 | Cu-83%, Sn-7%, Pb-7%, Zn-3% | Heavy duty bearings | 275 MPa |

| ASTM | C93700 | Cu-80%, Sn-10%, Pb-10% | High load bearings | 310 MPa |

| ASTM | C93900 | Cu-78%, Sn-6%, Pb-15%, Ni-1% | Marine bearings | 240 MPa |

| ASTM | C94300 | Cu-70%, Sn-5%, Pb-25% | Low friction applications | 190 MPa |

| ASTM | C95200 | Cu-81%, Al-9%, Fe-3%, Ni-1% | Marine hardware | 620 MPa |

| ASTM | C95400 | Cu-85%, Al-11%, Fe-4% | Marine propellers | 655 MPa |

| ASTM | C95500 | Cu-81%, Al-9%, Ni-4%, Fe-4% | High strength marine | 690 MPa |

| ASTM | C95800 | Cu-81%, Al-9%, Ni-5%, Fe-4% | Premium marine grade | 725 MPa |

| ASTM | C86200 | Cu-60%, Zn-25%, Mn-6%, Al-3%, Fe-3% | High tensile manganese | 450 MPa |

| ASTM | C86300 | Cu-62%, Zn-23%, Mn-5%, Al-3%, Fe-3% | Manganese bronze | 485 MPa |

| ASTM | C86400 | Cu-59%, Zn-23%, Mn-5%, Al-4%, Fe-4%, Pb-1% | Leaded manganese | 415 MPa |

| ASTM | C86500 | Cu-57%, Zn-40%, Mn-1%, Al-1%, Fe-1% | Low tensile manganese | 380 MPa |

| ASTM | C51000 | Cu-95%, Sn-5%, P-0.2% | Phosphor bronze springs | 520 MPa |

| ASTM | C52100 | Cu-92%, Sn-8%, P-0.25% | Electrical contacts | 485 MPa |

| ASTM | C54400 | Cu-96%, Sn-4%, P-0.25% | Marine hardware | 415 MPa |

| ASTM | C65100 | Cu-97%, Si-3% | Silicon bronze casting | 380 MPa |

| ASTM | C65500 | Cu-97%, Si-3%, Mn-1% | Silicon bronze high strength | 450 MPa |

| DIN | CuSn10 | Cu-90%, Sn-10% | General purpose casting | 320 MPa |

| DIN | CuSn12 | Cu-88%, Sn-12% | Tin bronze premium | 380 MPa |

| DIN | CuAl10Fe5Ni5 | Cu-80%, Al-10%, Fe-5%, Ni-5% | Aluminum bronze | 650 MPa |

| DIN | CuSn5Zn5Pb2 | Cu-88%, Sn-5%, Zn-5%, Pb-2% | Leaded tin bronze | 280 MPa |

| JIS | CAC406 | Cu-90%, Sn-10%, P-0.3% | Electrical contacts | 415 MPa |

| JIS | CAC702 | Cu-85%, Al-10%, Fe-3%, Ni-2% | Marine applications | 620 MPa |

| BS | PB1 | Cu-88%, Sn-10%, Zn-2% | British standard tin bronze | 310 MPa |

| BS | AB1 | Cu-90%, Al-8%, Fe-1%, Ni-1% | British aluminum bronze | 550 MPa |

Manufacturing Processes and Machinery

Sand Casting Process

Our Bronze mechanical connectors are manufactured using advanced sand casting techniques with precision-molded sand cores. The process involves:

- Pattern creation using CNC-machined Aluminum tooling

- Green sand molding with automated molding machines

- Core assembly and mold preparation

- Bronze alloy melting in induction furnaces at controlled temperatures (1050-1100°C)

- Pouring and solidification under controlled conditions

- Shake-out and cleaning operations

Investment Casting Process

For high-precision Bronze mechanical lugs, we employ investment casting (lost-wax) process:

- Wax pattern injection using precision dies

- Ceramic shell building through multiple dipping cycles

- Dewaxing in steam autoclaves

- Shell firing and Bronze pouring

- Shell removal and finishing operations

Machining Operations

Secondary machining operations include:

- CNC Turning – Precision bore machining and external profiling

- CNC Milling – Flat surface machining and hole drilling

- Thread Rolling – Internal thread formation

- Honing – Internal surface finishing

- Grinding – Precision dimensional control

Machinery Used

- Induction Furnaces (500kg – 2000kg capacity) for Bronze melting

- Automatic Molding Lines for consistent sand mold production

- CNC Machining Centers (3-axis and 4-axis) for precision finishing

- Coordinate Measuring Machines (CMM) for dimensional verification

- Spectrometers for chemical composition analysis

- Tensile Testing Machines for mechanical property verification

Technical Specifications and Dimensions

Comprehensive Conductor Range Compatibility

Small Size Bronze Mechanical Lugs

| AWG Size | Stranded AWG | Solid AWG | MCM Range | Metric mm² | Bolt Size | Current Rating (A) | Lug Length (mm) | Barrel Diameter (mm) |

|---|---|---|---|---|---|---|---|---|

| 22 | 22 | 22 | – | 0.34 | #8-32 | 15 | 12 | 3.2 |

| 20 | 20 | 20 | – | 0.52 | #10-24 | 20 | 15 | 3.8 |

| 18 | 18 | 18 | – | 0.82 | #10-24 | 25 | 18 | 4.5 |

| 16 | 16 | 16 | – | 1.31 | 1/4″ | 30 | 20 | 5.2 |

| 14 | 14 | 14 | – | 2.08 | 1/4″ | 35 | 22 | 6.0 |

| 12 | 12 | 12 | – | 3.31 | 5/16″ | 45 | 25 | 7.5 |

| 10 | 10 | 10 | – | 5.26 | 5/16″ | 60 | 28 | 9.0 |

Medium Size Bronze Mechanical Lugs

| AWG Size | Stranded AWG | Solid AWG | MCM Range | Metric mm² | Bolt Size | Current Rating (A) | Lug Length (mm) | Barrel Diameter (mm) |

|---|---|---|---|---|---|---|---|---|

| 8 | 8 | 8 | – | 8.37 | 3/8″ | 75 | 32 | 11.5 |

| 6 | 6 | 6 | – | 13.3 | 3/8″ | 100 | 38 | 14.0 |

| 4 | 4 | 4 | – | 21.2 | 7/16″ | 130 | 45 | 17.5 |

| 2 | 2 | 2 | – | 33.6 | 1/2″ | 175 | 52 | 22.0 |

| 1 | 1 | 1 | – | 42.4 | 1/2″ | 200 | 58 | 25.0 |

| 1/0 | 1/0 | – | – | 53.5 | 1/2″ | 230 | 65 | 28.5 |

| 2/0 | 2/0 | – | – | 67.4 | 1/2″ | 265 | 72 | 32.0 |

Large Size Bronze Mechanical Lugs

| AWG Size | Stranded AWG | Solid AWG | MCM Range | Metric mm² | Bolt Size | Current Rating (A) | Lug Length (mm) | Barrel Diameter (mm) |

|---|---|---|---|---|---|---|---|---|

| 3/0 | 3/0 | – | – | 85.0 | 5/8″ | 310 | 78 | 36.0 |

| 4/0 | 4/0 | – | – | 107.2 | 5/8″ | 360 | 85 | 40.5 |

| – | – | – | 250 | 127 | 5/8″ | 415 | 92 | 45.0 |

| – | – | – | 300 | 152 | 5/8″ | 455 | 98 | 48.5 |

| – | – | – | 350 | 177 | 3/4″ | 495 | 105 | 52.0 |

| – | – | – | 400 | 203 | 3/4″ | 535 | 112 | 55.5 |

| – | – | – | 500 | 253 | 3/4″ | 600 | 125 | 62.0 |

Extra Large Size Bronze Mechanical Lugs

| AWG Size | Stranded AWG | Solid AWG | MCM Range | Metric mm² | Bolt Size | Current Rating (A) | Lug Length (mm) | Barrel Diameter (mm) |

|---|---|---|---|---|---|---|---|---|

| – | – | – | 600 | 304 | 7/8″ | 665 | 135 | 68.0 |

| – | – | – | 700 | 355 | 7/8″ | 730 | 145 | 74.0 |

| – | – | – | 750 | 380 | 7/8″ | 760 | 150 | 76.5 |

| – | – | – | 800 | 405 | 1″ | 790 | 155 | 79.0 |

| – | – | – | 900 | 456 | 1″ | 850 | 165 | 84.0 |

| – | – | – | 1000 | 507 | 1″ | 900 | 175 | 89.0 |

| – | – | – | 1250 | 633 | 1-1/8″ | 1050 | 195 | 98.5 |

| – | – | – | 1500 | 760 | 1-1/4″ | 1200 | 215 | 108.0 |

| – | – | – | 1750 | 886 | 1-3/8″ | 1350 | 235 | 117.5 |

| – | – | – | 2000 | 1013 | 1-1/2″ | 1500 | 255 | 127.0 |

Bronze Mechanical Connectors (Multi-Port)

| Port Configuration | Conductor Range | Main Line | Tap Line | Bolt Size | Overall Length (mm) | Width (mm) |

|---|---|---|---|---|---|---|

| 2-Port Straight | 14-4 AWG | 14-4 AWG | 14-4 AWG | 3/8″ | 85 | 25 |

| 2-Port Straight | 2-250 MCM | 2-250 MCM | 6-250 MCM | 1/2″ | 125 | 38 |

| 2-Port Straight | 300-750 MCM | 300-750 MCM | 6-500 MCM | 5/8″ | 165 | 48 |

| 3-Port T-Tap | 6-1/0 AWG | 6-1/0 AWG | 10-1/0 AWG | 7/16″ | 95 | 35 |

| 3-Port T-Tap | 2/0-350 MCM | 2/0-350 MCM | 6-250 MCM | 1/2″ | 135 | 45 |

| 4-Port Cross | 8-2/0 AWG | 8-2/0 AWG | 10-1/0 AWG | 3/8″ | 105 | 42 |

| 4-Port Cross | 4/0-500 MCM | 4/0-500 MCM | 6-350 MCM | 5/8″ | 155 | 58 |

Specialty Bronze Lugs

| Type | Conductor Range | Special Features | Bolt Size | Dimensions (L×W×H mm) |

|---|---|---|---|---|

| Offset Tongue | 14-500 MCM | 45° angled mounting | 1/4″-5/8″ | Variable |

| Long Barrel | 6-300 MCM | Extended grip length | 3/8″-5/8″ | +25mm barrel |

| Wide Tongue | 2/0-750 MCM | Double bolt holes | 1/2″-3/4″ | Double width |

| Compression Type | 8-1000 MCM | Hex die compression | N/A | Hex tool required |

| Marine Grade | 10-500 MCM | Enhanced corrosion resistance | 1/4″-5/8″ | Nickel plated |

Dimensional Tolerances

- Machined Surfaces: ±0.1mm (±0.004″)

- Cast Surfaces: ±0.3mm (±0.012″)

- Hole Diameters: +0.1/-0.0mm (+0.004/-0.000″)

- Thread Pitch: ISO 2768-2 Class M

- Surface Roughness: Ra 1.6μm for machined surfaces

Material Properties

| Property | Value | Test Method |

|---|---|---|

| Tensile Strength | 350-450 MPa | ASTM B557 |

| Yield Strength | 200-300 MPa | ASTM B557 |

| Elongation | 15-25% | ASTM B557 |

| Hardness | 85-120 HB | ASTM E10 |

| Electrical Conductivity | 15-25% IACS | ASTM B193 |

| Density | 8.7-8.9 g/cm³ | ASTM B311 |

Surface Finishes and Coatings

Standard Finishes

- Natural Bronze Finish – Mill finish with protective oxide layer

- Tin Plating – 5-10 micron thickness for enhanced conductivity

- Nickel Plating – 10-15 micron thickness for corrosion resistance

- Passivation – Chemical treatment for improved corrosion resistance

Specialty Coatings

- Silver Plating – For high-conductivity applications

- Cadmium Plating – For marine environments (where permitted)

- Chromate Conversion – For additional corrosion protection

Industries and Applications

Power Generation

- Transformers – High-voltage connections and grounding

- Generators – Rotor and stator connections

- Switchgear – Bus connections and protective circuits

Marine Industry

- Ship Electrical Systems – Saltwater-resistant connections

- Offshore Platforms – Corrosion-resistant power distribution

- Port Infrastructure – Shore power connections

Industrial Manufacturing

- Heavy Machinery – Motor connections and control circuits

- Chemical Processing – Corrosion-resistant electrical systems

- Mining Equipment – Rugged electrical connections

Infrastructure

- Railway Systems – Signal and power connections

- Telecommunications – Equipment grounding and bonding

- Data Centers – Power distribution and grounding

Renewable Energy

- Solar Installations – Array connections and grounding

- Wind Turbines – Generator and control connections

- Hydroelectric – Turbine and generator connections

Performance Metrics and Testing

Electrical Performance

- Contact Resistance: <50 microhms (ASTM B539)

- Current Carrying Capacity: Per NEC/IEC standards

- Voltage Rating: Up to 600V AC/DC

- Temperature Rise: <30°C above ambient at rated current

Mechanical Performance

- Pull-Out Strength: 2000-5000 lbs (depending on size)

- Vibration Resistance: IEC 60068-2-6 standards

- Thermal Cycling: -40°C to +150°C (IEC 60068-2-14)

- Salt Spray Resistance: 500+ hours (ASTM B117)

Quality Testing Procedures

- Dimensional Inspection – 100% inspection using CMM

- Chemical Analysis – Batch-wise spectrometer testing

- Mechanical Testing – Sample-based tensile and hardness testing

- Electrical Testing – Contact resistance and continuity testing

- Corrosion Testing – Salt spray and humidity testing

Manufacturing Lead Times and Delivery

Standard Products

- Turnaround Time: 4-6 weeks from order confirmation

- Sample Production: 1-2 weeks for evaluation samples

- Prototype Development: 2-3 weeks for custom designs

Express Production Options

- Rush Orders: 2-3 weeks with premium pricing

- Inventory Program: Consignment stock for key customers

- Just-in-Time Delivery: Scheduled releases based on customer requirements

Production Capacity

- Monthly Capacity: 50,000-100,000 pieces (size dependent)

- Minimum Order Quantity: 100 pieces for standard items

- Custom Tooling: 4-6 weeks for new designs

Frequently Asked Questions (FAQ)

Q1: What Bronze alloys are used in your mechanical connectors? A: We primarily use high-strength Copper-tin Bronze alloys conforming to ASTM B505 and ASTM B271 standards. Common grades include C90300, C93200, and C95400, selected based on specific application requirements for strength, conductivity, and corrosion resistance.

Q2: Are your Bronze connectors suitable for Aluminum conductors? A: Yes, our Bronze mechanical connectors are compatible with both Copper and Aluminum conductors. For Aluminum conductor applications, we recommend using appropriate anti-oxidant compounds and ensuring proper torque specifications to prevent galvanic corrosion.

Q3: What is the maximum current rating for your Bronze mechanical lugs? A: Current ratings vary by size and design, ranging from 35 Amps for small AWG sizes up to 800 Amps for large MCM sizes. Specific ratings are determined per NEC and IEC standards based on conductor size and ambient temperature conditions.

Q4: Do you provide custom designs for specific applications? A: Absolutely. We specialize in custom Bronze connector designs based on customer specifications. Our engineering team can develop tailored solutions with specific dimensional requirements, conductor ranges, and mounting configurations.

Q5: What quality certifications do your products meet? A: Our Bronze mechanical connectors are manufactured to meet various international standards including ASTM, DIN, JIS, and IS specifications. We provide material test certificates, dimensional reports, and can arrange third-party testing as required.

Q6: How do you ensure consistent quality across production batches? A: We implement comprehensive quality control including incoming material inspection, in-process monitoring, final inspection using CMM equipment, and batch-wise chemical analysis. All products are traceable through our quality management system.

Q7: What surface finishes are available for corrosion protection? A: We offer various finishes including natural Bronze patina, tin plating, nickel plating, and passivation treatments. Surface finish selection depends on environmental conditions and electrical performance requirements.

Q8: Can you accommodate special packaging requirements? A: Yes, we provide customized packaging solutions including customer labeling, logos, and specialized protective packaging for export shipments. We can also arrange drop-shipping directly to your customers.

Q9: What is your minimum order quantity for custom designs? A: Minimum order quantities depend on design complexity and tooling requirements. Typically, we require 500-1000 pieces for custom Bronze connector designs to justify tooling costs.

Q11: What special Bronze alloys do you offer for extreme environment applications? A: We manufacture specialized Bronze alloys including C95500 Nickel Aluminum Bronze for extreme marine conditions, C86300 High Tensile Manganese Bronze for heavy-duty mechanical applications, and C65500 Silicon Bronze for superior corrosion resistance and weldability.

Q12: Can you provide Bronze connectors with custom conductor size combinations? A: Yes, we specialize in custom Bronze mechanical connectors with mixed conductor sizes. For example, main line 300 MCM with tap ports for 6 AWG to 250 MCM, or multi-port connectors accommodating different conductor types in a single unit.

Q13: What is the difference between continuous cast and centrifugal cast Bronze? A: Continuous cast Bronze (ASTM B505) offers uniform grain structure and consistent properties throughout, ideal for machined components. Centrifugal cast Bronze (ASTM B271) provides superior density and strength due to centrifugal force during casting, preferred for high-stress applications.

Q14: Do you manufacture Bronze connectors for high-voltage applications above 600V? A: Yes, we produce specialized Bronze mechanical connectors rated for medium voltage applications up to 15kV. These feature enhanced insulation standoff, increased creepage distances, and are manufactured to IEEE and IEC high-voltage standards.

Q15: What testing capabilities do you have for Bronze connector validation? A: Our testing laboratory includes current cycling tests per IEEE 837, temperature rise testing, contact resistance measurement, salt spray corrosion testing (ASTM B117), vibration testing (IEC 60068-2-6), and mechanical pull-out strength testing with full documentation and certification.

Q16: Can you supply Bronze connectors with integrated anti-oxidant compounds? A: Yes, we provide Bronze mechanical connectors pre-treated with Noalox or similar anti-oxidant compounds, particularly beneficial for Aluminum conductor applications. We also supply connectors with pre-installed inhibitor-filled sealing compounds for enhanced long-term performance.

Q17: What Bronze alloys offer the best electrical conductivity for power applications? A: C65500 Silicon Bronze offers excellent conductivity (25% IACS) with superior corrosion resistance. For maximum conductivity, C52100 Phosphor Bronze provides 15% IACS with good mechanical properties. We can also supply Silver-plated Bronze connectors for ultra-high conductivity requirements.

Q18: Do you provide Bronze connectors certified for underground and direct burial applications? A: Absolutely. Our Bronze mechanical connectors are available with UL listing for direct burial applications. We use specialized corrosion-resistant alloys and protective coatings that meet IEEE 837 standards for underground electrical distribution systems.

Q19: What is your capability for producing extra-large Bronze connectors above 2000 MCM? A: We manufacture Bronze mechanical connectors for conductors up to 3000 MCM (1520 mm²) using specialized casting and machining equipment. These extra-large connectors feature reinforced mounting brackets, multiple compression points, and enhanced conductor grip mechanisms.

Q20: Can you provide Bronze connectors with customer-specific torque requirements? A: Yes, we can customize bolt specifications, thread patterns, and recommend specific torque values based on your application requirements. We provide detailed torque specifications, installation instructions, and can supply calibrated torque tools for critical installations.

Why Choose Our Bronze Mechanical Connectors

Three Decades of Global Experience

With over 30 years of manufacturing expertise, we have supplied Bronze mechanical connectors to customers across six continents. Our extensive experience encompasses diverse applications from marine installations to heavy industrial machinery, providing us with unparalleled understanding of customer requirements and application challenges.

Superior Customer Communication

Our multilingual technical team ensures clear communication throughout the project lifecycle. We provide detailed technical documentation, installation guidelines, and comprehensive customer support. Regular project updates and responsive customer service distinguish us from competitors.

Faster Turnaround Times

Our streamlined manufacturing processes and efficient supply chain management enable faster delivery compared to industry standards. Standard products ship within 4-6 weeks, while rush orders can be accommodated in 2-3 weeks with our express production capabilities.

Advanced Customization Capabilities

Unlike many suppliers who offer only standard products, we excel in custom Bronze connector design and manufacturing. Our in-house engineering team can develop specialized solutions with unique geometries, conductor ranges, and mounting configurations to meet specific customer requirements.

Flexible Production Scheduling

We understand that customer requirements vary significantly. Our flexible manufacturing approach allows for small prototype quantities, large production runs, and everything in between. We can accommodate schedule changes and provide inventory management solutions for key customers.

Comprehensive Quality Assurance

Our quality management system exceeds industry standards with 100% dimensional inspection, batch-wise chemical analysis, and comprehensive testing protocols. We provide detailed quality documentation and can arrange third-party testing and certification as required.

Global Logistics Support

Our experienced logistics team manages international shipping, documentation, and customs clearance. We have established partnerships with reliable freight forwarders to ensure timely delivery worldwide while minimizing shipping costs.

Value Engineering Services

Our technical team works collaboratively with customers to optimize designs for performance and cost-effectiveness. We provide value engineering suggestions that can reduce material costs while maintaining or improving product performance.

Packaging and Shipping

Standard Packaging

- Individual Protection: Each connector wrapped in anti-corrosion paper or protective film

- Partitioned Boxes: Custom-designed inserts prevent damage during transit

- Carton Labeling: Detailed labels include part numbers, quantities, and customer codes

- Export Packaging: Wooden crates and pallets for international shipments

Custom Packaging Options

- Customer Branding: Custom labels and packaging with customer logos

- Barcoding: Customer-specific barcode systems for inventory management

- Drop-Shipping: Direct shipping to customer’s end-users

- Special Handling: Temperature-controlled or cushioned packaging for sensitive applications

Global Shipping Network

We maintain partnerships with established logistics providers ensuring reliable delivery to over 80 countries. Our shipping documentation team handles all export requirements including certificates of origin, material test certificates, and customs documentation.

Material Property Tables

Chemical Composition (Typical Values – %)

| Element | C90300 | C90700 | C93200 | C93700 | C95400 | C95500 | C51000 | C52100 | C65500 | C86300 |

|---|---|---|---|---|---|---|---|---|---|---|

| Copper (Cu) | 88.0 | 89.0 | 83.0 | 80.0 | 85.0 | 81.0 | 95.0 | 92.0 | 97.0 | 62.0 |

| Tin (Sn) | 10.0 | 11.0 | 7.0 | 10.0 | – | – | 5.0 | 8.0 | – | – |

| Lead (Pb) | – | – | 7.0 | 10.0 | – | – | – | – | – | – |

| Zinc (Zn) | 2.0 | – | 3.0 | – | – | – | – | – | – | 23.0 |

| Aluminum (Al) | – | – | – | – | 11.0 | 9.0 | – | – | – | 3.0 |

| Iron (Fe) | – | – | – | – | 4.0 | 4.0 | – | – | 1.0 | 3.0 |

| Nickel (Ni) | – | – | – | – | – | 4.0 | – | – | – | – |

| Phosphorus (P) | – | – | – | – | – | – | 0.2 | 0.25 | – | – |

| Silicon (Si) | – | – | – | – | – | – | – | – | 3.0 | – |

| Manganese (Mn) | – | – | – | – | – | – | – | – | 1.0 | 5.0 |

Physical Properties Comparison

| Property | Unit | C90300 | C93200 | C95400 | C51000 | C65500 | C86300 |

|---|---|---|---|---|---|---|---|

| Density | g/cm³ | 8.8 | 8.9 | 7.7 | 8.9 | 8.5 | 8.4 |

| Melting Point | °C | 1000 | 830 | 1050 | 1000 | 1025 | 900 |

| Thermal Conductivity | W/m·K | 50 | 60 | 70 | 42 | 75 | 38 |

| Electrical Resistivity | μΩ·cm | 11 | 9 | 8 | 12 | 7 | 15 |

| Coefficient of Expansion | 10⁻⁶/°C | 18 | 19 | 16 | 18 | 17 | 20 |

| Modulus of Elasticity | GPa | 103 | 100 | 110 | 110 | 105 | 95 |

| Hardness (Brinell) | HB | 65-85 | 60-75 | 140-170 | 85-120 | 75-95 | 120-140 |

| Tensile Strength | MPa | 310 | 275 | 655 | 520 | 450 | 485 |

| Yield Strength | MPa | 140 | 130 | 275 | 200 | 165 | 205 |

| Elongation | % | 20 | 18 | 12 | 15 | 25 | 18 |

Customer Testimonial

“We have been sourcing Bronze mechanical connectors from this Indian manufacturer for over 12 years for our marine electrical systems. Their technical expertise is exceptional, and the quality consistency has been outstanding. The Bronze connectors have performed flawlessly in harsh saltwater environments, and their customer service team is always responsive to our technical inquiries. The combination of competitive pricing, reliable quality, and excellent communication makes them our preferred supplier for Bronze electrical connectors.”

— Robert Martinez, Senior Procurement Engineer, Marine Electronics Division, USA

Glossary of Technical Terms

Bronze: Copper-based alloy primarily containing tin, offering superior strength and corrosion resistance compared to pure Copper.

Mechanical Connector: Electrical connector that uses mechanical pressure (bolts, screws) to secure conductors rather than welding or soldering.

Mechanical Lug: Terminal connector designed to attach conductors to electrical equipment using mechanical fastening methods.

MCM (Thousand Circular Mils): Unit of measurement for large electrical conductor cross-sectional area.

AWG (American Wire Gauge): Standard system for measuring electrical wire diameter and current-carrying capacity.

Contact Resistance: Electrical resistance at the interface between connector and conductor, measured in microhms.

Patina: Natural oxide layer that forms on Bronze surfaces, providing corrosion protection.

IACS (International Annealed Copper Standard): Standard for measuring electrical conductivity relative to pure Copper.

Galvanic Corrosion: Corrosion caused by electrochemical reaction between dissimilar metals in the presence of electrolyte.

Investment Casting: Precision casting process using expendable wax patterns and ceramic shells.

Centrifugal Casting: Casting process using centrifugal force to fill molds and improve material density.

Heat Treatment: Controlled heating and cooling process to modify material properties.

Torque Specification: Recommended tightening force for bolted connections to ensure proper contact pressure.

UL Listed: Products tested and certified by Underwriters Laboratories for safety and performance.

IP Rating: Ingress Protection rating indicating resistance to dust and moisture penetration.

Related Terms

- Bronze electrical connectors

- Copper alloy mechanical lugs

- Marine grade electrical terminals

- Corrosion resistant connectors

- High conductivity Bronze lugs

- Switchgear connection hardware

- Power distribution connectors

- Electrical panel terminals

- Heavy duty cable lugs

- Industrial electrical connectors

- Bronze casting electrical components

- Salt water resistant terminals

- Mechanical compression connectors

- Bronze alloy electrical hardware

- High amperage connector lugs

- Transformer connection terminals

- Generator electrical connections

- Solar panel connectors Bronze

- Wind turbine electrical terminals

- Substation connector hardware

Call to Action

Ready to enhance your electrical connections with our premium Bronze Mechanical Connectors and Lugs? Our technical experts are standing by to assist with your specific requirements.

Request a Comprehensive Quote: Email us your specifications, drawings, and quantity requirements for detailed pricing and technical recommendations.

Download Our Technical Brochure: Contact us to receive our complete catalog featuring dimensional drawings, technical specifications, and application guidelines.

Speak with Our Experts: Call us or Whatsapp us.

Schedule a Virtual Meeting: Arrange a video conference with our engineering team to discuss custom solutions and application-specific requirements.

Our commitment to excellence, combined with three decades of manufacturing expertise, makes us your ideal partner for Bronze electrical connector solutions. Contact us today to experience the difference that quality, service, and technical expertise can make in your projects.

USA SALES: We are a dependable global manufacturer and exporter of precision metal components for the electrical industry, working closely with established USA companies to support innovation and critical infrastructure. Our components are supplied to Fortune 500 manufacturers as well as fast-growing technology leaders, consistently meeting stringent U.S. standards for quality, reliability, and safety. Through advanced manufacturing capabilities, on-time deliveries, and responsive support aligned with U.S. business expectations, we help American customers simplify supply chains, optimize costs, and build next-generation electrical systems, renewable energy solutions, and smart grid networks. We are a supplier built for the realities of the U.S. market and can also offer DDP pricing across all states in the USA.