Copper Deep Drawn Parts, Copper Deep Drawn Components, Copper Pressing, Copper Sheet Metal Components

Copper Deep Drawn Parts & Copper Pressed Components

Product Overview

We are one of the leading manufacturers and exporters of Copper Deep Drawn Parts and Copper Deep Drawn Components from India. We have been supplying precision-engineered copper components to the world market for many decades. Our extensive manufacturing capabilities encompass a comprehensive range of copper deep drawing operations, copper pressing techniques, and specialized copper sheet metal fabrication processes. With state-of-the-art infrastructure and advanced manufacturing technologies, we deliver high-quality copper deep drawn parts that meet international standards and specifications. Our expertise spans across various industrial applications including electrical components, plumbing systems, HVAC equipment, automotive parts, and railway applications. The copper deep drawing process enables us to create complex three-dimensional shapes with exceptional dimensional accuracy and surface finish quality. Our manufacturing facility is equipped with modern deep drawing presses, compound die systems, and precision tooling that ensures consistent quality and optimal material utilization in every copper component we produce.

Copper Deep Drawn Parts

Copper deep drawn parts represent a specialized category of metal forming components manufactured through the deep drawing process, where copper sheets are mechanically formed into three-dimensional hollow shapes using specialized dies and punches. This manufacturing technique allows for the creation of seamless copper components with exceptional strength-to-weight ratios and superior dimensional precision. The deep drawing process involves placing a copper blank over a die cavity and using a punch to draw the material into the desired shape, creating parts with varying wall thicknesses and complex geometries. Our copper deep drawn parts exhibit excellent electrical conductivity properties, making them ideal for electrical applications, while their corrosion resistance and thermal conductivity characteristics make them suitable for plumbing and heat exchange applications. The manufacturing process ensures minimal material waste and produces components with superior mechanical properties compared to traditional machining methods.

Copper Deep Drawn Components

Copper deep drawn components encompass a wide range of engineered parts that serve critical functions in various industrial applications, manufactured using advanced deep drawing techniques that ensure optimal material properties and dimensional accuracy. These components are characterized by their seamless construction, which eliminates potential weak points that might occur in welded or joined assemblies. The deep drawing process allows for the creation of components with complex internal geometries, varying wall thicknesses, and precise dimensional tolerances that are difficult to achieve through other manufacturing methods. Our copper deep drawn components undergo rigorous quality control processes to ensure they meet specific industry standards and customer requirements. The inherent properties of copper, including excellent electrical and thermal conductivity, corrosion resistance, and antimicrobial characteristics, make these components particularly valuable in applications where these properties are essential for optimal performance.

Copper Pressed Parts

Copper pressed parts are manufactured using mechanical pressing operations that shape copper materials into specific configurations through the application of controlled force and specialized tooling systems. This manufacturing approach encompasses various pressing techniques including stamping, forming, bending, and shaping operations that transform flat copper sheets or blanks into functional components. The copper pressing process offers excellent reproducibility and cost-effectiveness for high-volume production runs while maintaining consistent quality standards across all manufactured parts. Our copper pressed parts benefit from the inherent properties of copper materials, including excellent formability, which allows for complex shapes and configurations without compromising material integrity. The pressing operations can be combined with secondary operations such as trimming, piercing, and finishing processes to create complete components that meet specific dimensional and functional requirements.

Copper Press Work

Copper press work encompasses comprehensive metal forming operations that utilize various types of mechanical presses to transform copper materials into finished components through controlled deformation processes. This manufacturing approach includes progressive die operations, compound die pressing, transfer die operations, and single-stage pressing techniques that are selected based on component complexity, production volume requirements, and dimensional specifications. Our copper press work capabilities include precision stamping operations for intricate patterns and features, forming operations for three-dimensional shapes, blanking operations for precise cutting, and coining operations for enhanced surface finish and dimensional accuracy. The press work operations are supported by specialized tooling design and manufacturing capabilities that ensure optimal material flow, minimal springback, and consistent dimensional accuracy across all produced components.

Copper Pressing from India

Copper pressing from India represents a significant segment of the global manufacturing industry, leveraging the country’s extensive expertise in metal forming technologies, skilled workforce, and cost-effective production capabilities. Indian manufacturers have developed advanced copper pressing capabilities that combine traditional metalworking knowledge with modern manufacturing technologies to produce high-quality components for global markets. The copper pressing industry in India benefits from access to quality raw materials, established supply chain networks, and comprehensive quality management systems that ensure compliance with international standards and specifications. Our copper pressing operations from India offer competitive advantages including flexible production scheduling, customized manufacturing solutions, comprehensive technical support, and efficient logistics capabilities that enable timely delivery to customers worldwide. The manufacturing infrastructure in India supports various copper pressing applications ranging from simple stamped components to complex deep drawn parts that require specialized expertise and equipment.

Copper Compound Die Press Work

Copper compound die press work represents an advanced manufacturing technique that combines multiple forming operations within a single press stroke, enabling the simultaneous execution of cutting, forming, and finishing operations in a single manufacturing step. This sophisticated approach to copper component manufacturing offers significant advantages in terms of production efficiency, dimensional accuracy, and cost-effectiveness for complex parts that would otherwise require multiple manufacturing operations. The compound die systems used in copper press work incorporate precision-engineered die sets that coordinate multiple operations including blanking, piercing, forming, and trimming in a synchronized sequence. Our copper compound die press work capabilities enable the production of intricate components with tight tolerances, complex geometries, and multiple features that are completed in a single press operation, resulting in reduced handling, improved dimensional consistency, and enhanced production throughput.

Copper Sheet Metal Parts

Copper sheet metal parts represent a diverse category of components manufactured from copper sheet materials through various forming, cutting, and shaping operations that transform flat stock into functional three-dimensional components. The manufacturing of copper sheet metal parts encompasses multiple processes including laser cutting, waterjet cutting, punching, forming, bending, and welding operations that are selected based on component requirements, material thickness, and production volume considerations. Our copper sheet metal parts manufacturing capabilities include precision cutting operations for complex profiles and patterns, forming operations for three-dimensional shapes, joining operations for multi-component assemblies, and finishing operations for enhanced appearance and performance characteristics. The versatility of copper sheet metal processing allows for the creation of components ranging from simple brackets and enclosures to complex assemblies with multiple features and tight dimensional tolerances that meet specific application requirements across various industries.

| Material Grade | International Standard | Composition | Applications |

|---|---|---|---|

| C11000 (ETP Copper) | ASTM B152, BS EN 1172 | 99.90% Cu min | Electrical, Plumbing, Heat Exchangers |

| C10200 (OF Copper) | ASTM B152, DIN EN 1976 | 99.95% Cu min | High-frequency applications, Vacuum tubes |

| C12200 (DHP Copper) | ASTM B152, JIS H3100 | Cu + 0.015-0.040% P | Plumbing fittings, Heat exchangers |

| C14500 (Tellurium Copper) | ASTM B152, IS 191 | Cu + 0.4-0.7% Te | Electrical contacts, Switches |

| C17200 (Beryllium Copper) | ASTM B196, DIN 17662 | Cu + 1.8-2.0% Be | Springs, Electrical contacts |

Deep Drawing Process Flow

→

→

→

→

→

Manufacturing Processes and Machinery

Our comprehensive manufacturing processes encompass multiple advanced techniques including hydraulic deep drawing operations utilizing precision-controlled hydraulic presses with tonnage capacities ranging from 50 to 500 tons, mechanical deep drawing operations using high-speed mechanical presses for rapid production cycles, and progressive die operations for complex multi-stage forming sequences. The machinery infrastructure includes state-of-the-art hydraulic presses equipped with servo-controlled systems for precise ram positioning and force control, mechanical presses with adjustable stroke lengths and variable speed capabilities, and specialized deep drawing equipment with blank holding systems for material flow control. Secondary processing equipment includes CNC machining centers for precision finishing operations, laser cutting systems for precise trimming and hole cutting, and automated handling systems for efficient material flow throughout the manufacturing process.

| Dimension Parameter | Standard Range | Tolerance | Measurement Method |

|---|---|---|---|

| Outside Diameter (OD) | 10mm – 500mm | ±0.05mm to ±0.2mm | Caliper/CMM |

| Wall Thickness | 0.5mm – 10mm | ±0.02mm to ±0.1mm | Ultrasonic/Micrometer |

| Height/Depth | 5mm – 200mm | ±0.05mm to ±0.3mm | Height Gauge/CMM |

| Concentricity | – | 0.02mm to 0.1mm | CMM/Roundness Tester |

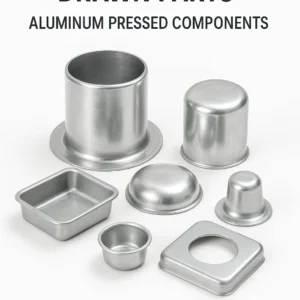

Typical Parts Produced

Our manufacturing capabilities enable the production of diverse copper deep drawn components including electrical connector housings with precise internal geometries for optimal conductivity, cylindrical copper cups and containers for industrial applications, rectangular copper enclosures for electronic equipment protection, complex copper heat sink components with integrated cooling fins, copper plumbing fittings including reducers and adapters, automotive copper components such as radiator tanks and oil cooler housings, railway electrical components including contact assemblies and bushing systems, HVAC copper components for heat exchange applications, and specialized copper components for telecommunications equipment. Each component type requires specific tooling design, material selection, and processing parameters to achieve optimal performance characteristics and dimensional accuracy requirements.

Industries and Applications

Our copper deep drawn parts serve critical functions across multiple industries including the electrical and electronics industry where components are used in power transmission systems, motor assemblies, transformer components, and electronic device housings. The plumbing and HVAC industry utilizes our components in water distribution systems, heating systems, cooling systems, and specialized fittings that require corrosion resistance and thermal conductivity. The automotive industry incorporates our copper components in cooling systems, electrical systems, braking systems, and fuel delivery systems where copper’s properties provide enhanced performance and reliability. Railway applications include electrical contact systems, signaling equipment, power distribution components, and specialized fittings that must withstand harsh operating conditions while maintaining electrical conductivity and mechanical integrity.

| Property | C11000 (ETP) | C10200 (OF) | C12200 (DHP) | Test Standard |

|---|---|---|---|---|

| Electrical Conductivity (%IACS) | 100-103 | 100-103 | 85-95 | ASTM B193 |

| Tensile Strength (MPa) | 220-250 | 200-240 | 210-240 | ASTM B152 |

| Thermal Conductivity (W/m·K) | 394 | 394 | 339 | ASTM E1461 |

| Elongation (%) | 35-45 | 35-45 | 25-35 | ASTM B152 |

Quality Standards and Tolerances

Our manufacturing processes adhere to stringent international quality standards including ISO 9001:2015 quality management systems, ASTM material specifications for copper alloys, DIN European standards for metal forming processes, JIS Japanese industrial standards for precision components, and IS Indian standards for metal products. Dimensional tolerance capabilities range from ±0.02mm for critical features to ±0.2mm for general dimensions, depending on component size, complexity, and application requirements. Geometric tolerances including concentricity, perpendicularity, and surface finish are maintained according to customer specifications and international standards. Our quality control processes include incoming material inspection, in-process dimensional verification, final inspection using coordinate measuring machines, and comprehensive documentation for traceability and compliance verification.

Turnaround Time and Production Scheduling

Standard turnaround time for copper deep drawn parts ranges from 4-6 weeks from order confirmation to shipment, depending on component complexity, tooling requirements, and production volume. Rush orders can be accommodated with expedited scheduling for critical applications, while high-volume production runs may require extended lead times for optimal resource allocation and quality assurance. Our production planning system enables flexible scheduling to accommodate customer requirements, seasonal demand variations, and special project timelines. Tooling development for new components typically requires 2-3 weeks for simple parts and up to 4-5 weeks for complex geometries requiring specialized die design and manufacturing.

“We have been sourcing copper deep drawn components from this manufacturer for over 8 years and consistently receive exceptional quality products with on-time delivery. Their technical expertise and customer service excellence make them our preferred supplier for all copper forming requirements. The dimensional accuracy and surface finish quality exceed our expectations every time.”

– Michael Thompson, Procurement Manager, UK

TYPICAL COPPER PARTS:

1. Electrical & Electronic Components

A. Connectors

Battery Terminals: Cylindrical or tapered cups for automotive/industrial batteries.

Pin & Socket Contacts: Precision-drawn for PCB headers, power connectors.

RF Shield Cans: EMI shielding for circuit boards.

- Copper Fuse Holders, Copper fuse terminals, Copper Fuse Contacts

- Copper Transformer conenctors, Copper transformer terminals

B. Ferrules & Sleeves

Wire Ferrules: Crimped onto stranded wires for secure terminal connections.

Cable End Sleeves: Protects and insulates cable ends.

C. Caps & Covers

Electrical End Caps: Seals for capacitors, transformers, or busbars.

Fuse Caps: Enclosures for high-voltage fuses.

2. Plumbing & HVAC

Copper Pipe Fittings: Flared or compression fittings for refrigerant lines.

Valve Housings: Corrosion-resistant bodies for water/gas valves.

Heat Exchanger Tubes: Thin-walled, seamless tubes for cooling systems.

3. Automotive & Aerospace

Fuel Injector Nozzles: Precision-drawn for controlled fuel delivery.

Sensor Housings: Protective shells for oxygen/temperature sensors.

Bearing Sleeves: Low-friction liners for rotating assemblies.

4. Industrial Hardware

Bushings & Spacers: Wear-resistant components for machinery.

Light Reflectors: Lamp housings with high reflectivity.

Small Canisters: Sealed containers for medical or chemical use.

5. Specialty Applications

Waveguide Components: RF/microwave transmission parts.

Vacuum Interrupter Cups: Used in high-voltage circuit breakers.

Decorative Trim: Architectural accents (e.g., lamp bases).

Why Choose Our Products

Our competitive advantages include faster turnaround times through optimized production scheduling and efficient manufacturing processes, superior customer support with dedicated technical assistance and responsive communication throughout the project lifecycle, excellent communication skills with multilingual support capabilities for global customers, and extensive global exposure gained through three decades of international manufacturing experience. Our flexibility in production timing allows us to accommodate urgent requirements and special scheduling needs, while our customized packaging solutions include customer-specific labeling, logo printing, and protective packaging designed for international shipping. The combination of advanced manufacturing technology, skilled workforce, comprehensive quality management, and customer-focused service approach ensures optimal value proposition for customers seeking reliable copper component suppliers.

Packaging and Shipping

Our comprehensive packaging and shipping services include customized packaging solutions designed to protect components during international transportation, with options for customer-specific labeling and logo printing on packaging materials. Standard packaging includes anti-corrosion treatment for copper components, protective cushioning materials, moisture barrier protection, and secure packaging configurations optimized for various shipping methods. Shipping options encompass air freight for urgent deliveries, sea freight for cost-effective bulk shipments, and express courier services for sample and prototype deliveries. All shipments include comprehensive documentation including packing lists, material certificates, inspection reports, and customs documentation for international shipments.

Frequently Asked Questions

Q1: What is the minimum order quantity for copper deep drawn parts?

A: Our minimum order quantity varies depending on component complexity and tooling requirements. For standard components with existing tooling, MOQ can be as low as 100 pieces. For new components requiring tooling development, MOQ typically starts at 1000 pieces to justify tooling investment costs.

Q2: Can you provide samples before placing a bulk order?

A: Yes, we provide samples for evaluation and approval before bulk production. Sample lead time is typically 1-2 weeks depending on component complexity. Sample costs are usually adjusted against bulk order value.

Q3: What surface finishes are available for copper deep drawn parts?

A: Available surface finishes include natural copper finish, bright annealed finish, tin plating, nickel plating, silver plating, and specialized coatings for enhanced corrosion resistance or electrical conductivity requirements.

Q4: Do you provide material certificates with shipments?

A: Yes, we provide comprehensive material certificates including chemical composition analysis, mechanical property test results, and compliance certificates for applicable standards such as ASTM, DIN, or JIS requirements.

Q5: What is your capacity for high-volume production?

A: Our production capacity varies by component type, but we typically handle volumes ranging from small batches of 100 pieces to high-volume production runs exceeding 100,000 pieces per month, depending on component complexity and production scheduling.

Q6: Can you accommodate custom tooling for unique component designs?

A: Yes, we specialize in custom tooling design and manufacturing for unique component requirements. Our in-house tooling capabilities include progressive dies, compound dies, and specialized forming tools designed to meet specific dimensional and functional requirements.

Q7: What quality control measures are implemented during production?

A: Our quality control process includes incoming material inspection, first-piece inspection, in-process dimensional verification, final inspection using CMM equipment, surface finish verification, and comprehensive documentation for full traceability throughout the manufacturing process.

Q8: Are your manufacturing processes environmentally compliant?

A: Yes, our manufacturing processes comply with international environmental standards including ISO 14001 environmental management systems, waste minimization programs, recycling initiatives for copper scrap, and environmentally responsible disposal of processing materials.

Q9: Can you handle secondary operations such as machining and assembly?

A: Yes, we provide comprehensive secondary operations including CNC machining for precision features, drilling and tapping operations, assembly services for multi-component products, and testing services for functional verification of completed assemblies.

Q10: What payment terms and shipping options are available?

A: We offer flexible payment terms including letters of credit, wire transfers, and other internationally accepted payment methods. Shipping options include air freight, sea freight, and express courier services with comprehensive insurance coverage and tracking capabilities.

Q11: Do you provide technical support for component design optimization?

A: Yes, our technical team provides comprehensive design support including material selection recommendations, manufacturing process optimization, cost reduction suggestions, and design for manufacturability analysis to ensure optimal component performance and production efficiency.

Q12: What is your experience with international shipping and customs procedures?

A: With over three decades of export experience, we handle all aspects of international shipping including customs documentation, export licensing, freight forwarding coordination, and compliance with destination country requirements for smooth customs clearance.

Glossary of Technical Terms

Deep Drawing: A metal forming process where sheet metal is radially drawn into a forming die by mechanical action of a punch to create hollow cylindrical or box-shaped components.

Blank Holder: A component of the deep drawing die assembly that applies controlled pressure to the material blank to prevent wrinkling and control material flow during the forming process.

Drawing Ratio: The relationship between the blank diameter and the punch diameter, which determines the feasibility and number of drawing operations required for a specific component.

Springback: The elastic recovery of formed material after removal of forming forces, which must be compensated for in tooling design to achieve accurate final dimensions.

Annealing: A heat treatment process applied to copper materials to relieve internal stresses, restore ductility, and improve formability for complex deep drawing operations.

Progressive Die: A specialized tooling system that performs multiple forming operations in sequence as the material advances through different stations in a single press stroke.

Compound Die: A die system that combines multiple operations such as cutting, forming, and finishing in a single press stroke to create complex components efficiently.

Material Flow: The movement and deformation of material during the forming process, which must be carefully controlled to prevent defects and achieve desired component geometry.

Performance Metrics and Testing

Our copper deep drawn components undergo comprehensive performance testing to ensure they meet application-specific requirements and international standards. Electrical performance testing includes conductivity measurements using eddy current methods and resistance testing for electrical contact applications. Mechanical property testing encompasses tensile strength evaluation, hardness testing using Rockwell or Brinell methods, and fatigue testing for components subject to cyclic loading. Dimensional verification is performed using coordinate measuring machines (CMM) with accuracies up to ±0.001mm, surface finish measurement using profilometers, and geometric tolerance verification according to GD&T standards. Corrosion resistance testing includes salt spray testing per ASTM B117, electrochemical corrosion testing, and specialized environmental testing for specific application conditions.

| Test Parameter | Test Method | Typical Results | Acceptance Criteria |

|---|---|---|---|

| Surface Roughness | ISO 4287 | Ra 0.2-1.6 μm | As per customer specification |

| Dimensional Accuracy | CMM Measurement | ±0.02mm to ±0.2mm | Drawing tolerance requirements |

| Hardness | ASTM E18 (Rockwell) | HRB 40-80 | Material specification |

| Electrical Conductivity | ASTM B193 | 85-103% IACS | Grade-specific requirements |

Related Search Terms

Customers searching for copper deep drawn parts often use related terms including copper stamping components, copper formed parts, copper pressing services, precision copper components, custom copper parts manufacturing, copper electrical components, copper plumbing parts, copper HVAC components, copper automotive parts, copper railway components, copper heat exchanger parts, copper connector housings, copper enclosures, copper cups and containers, copper sheet metal fabrication, copper progressive die components, copper compound die parts, deep drawn copper bushings, copper cylindrical components, copper rectangular housings, copper seamless parts, and copper precision formed components. These terms reflect the diverse applications and manufacturing processes associated with copper deep drawing and pressing operations.

International Standards Compliance

Our manufacturing processes and products comply with comprehensive international standards including ISO 9001:2015 quality management systems for consistent quality assurance, ASTM B152 specifications for copper sheet, strip, and plate materials, DIN EN 1976 standards for copper and copper alloy sheets, BS EN 1172 British standards for copper and copper alloys, JIS H3100 Japanese industrial standards for copper and copper alloy sheets, IS 191 Indian standards for copper materials, IEC 60028 international standards for copper conductors, and ASME specifications for pressure vessel applications. Compliance with these standards ensures global acceptance of our products and facilitates international trade while meeting customer quality expectations and regulatory requirements.

Environmental Considerations and Sustainability

Our manufacturing operations incorporate environmentally responsible practices including efficient material utilization to minimize waste generation, comprehensive recycling programs for copper scrap and processing materials, energy-efficient manufacturing processes to reduce carbon footprint, water conservation measures in processing operations, and responsible disposal of processing chemicals and materials. Copper’s inherent recyclability makes it an environmentally sustainable material choice, with our recycled copper content reaching up to 95% in many applications without compromising material properties or performance characteristics. Our environmental management system complies with ISO 14001 standards and includes continuous improvement initiatives focused on waste reduction, energy efficiency, and environmental impact minimization throughout the manufacturing process.

Contact Us Today for Your Copper Deep Drawn Parts Requirements

Ready to discuss your copper component needs? Our technical team is available to provide customized solutions and competitive quotations.

📧 Email us for a detailed product brochure: sales@conexscrews. com

📞 Call us for immediate assistance: +91-22-43449300

Request a Quote Today! Send us your drawings, specifications, and requirements for a comprehensive quotation within 24 hours. Experience the difference of working with India’s leading copper component manufacturer with 30+ years of global expertise.

Quality • Precision • Reliability • Global Service