Brass Panel Nuts, Stainless Steel Panel nuts, Copper Panel Nuts, Aluminum Panel Nuts: Your Trusted Manufacturer from India

We are one of the leading manufacturers and exporters of high-precision Panel Nuts from India, supplying a comprehensive range of industrial fasteners to the world market for many decades. Our specialization encompasses a vast array of materials, including Brass Panel Nuts, Stainless Steel Panel Nuts, Aluminum Panel Nuts, and specialized Copper Panel Nuts, all engineered to meet the most demanding international standards. Whether your application requires the excellent conductivity of Brass Cold Forged Panel Nuts or the exceptional corrosion resistance of Stainless Steel Pressed Lock Nuts, our commitment to quality, dimensional accuracy, and consistent performance remains unwavering. Our advanced manufacturing facilities and seasoned engineering team allow us to offer both standard and completely customized panel nut solutions with flexibility in production time and volume, making us a preferred partner for industries across the globe. We understand the critical role these small yet vital components play in the integrity of your assemblies, from electrical enclosures to sophisticated aerospace instrumentation.

In-Depth Look at Panel Nut Types and Materials

Panel Nuts are a specialized category of fastener designed primarily for use with threaded studs or screws mounted on sheets or panels. Their key function is to provide a secure, reusable threaded connection in thin materials where tapping a thread directly is not feasible. The selection of the correct type of panel nut and its material is paramount for the performance and longevity of the final product.

Brass Panel Nuts are highly sought after for their excellent electrical conductivity, natural corrosion resistance, and non-magnetic properties. These characteristics make Brass electrical panel nuts an ideal choice for electrical and electronic applications, including PCB mounts, terminal blocks, and electrical enclosures where preventing galvanic corrosion is a concern. The malleability of Brass also allows for the creation of secure, non-marring fastenings. We produce these from various grades, including CW507L (CZ121/C36000), ensuring high machinability and consistent quality for both standard and custom brass fastener requirements.

Stainless Steel Panel Nuts offer superior strength and exceptional resistance to rust and oxidation, making them indispensable in harsh environments. Common grades include SS304 and the more corrosion-resistant SS316, suitable for marine, chemical, and food processing applications. Stainless Steel Pressed Lock Nuts, a subtype, feature a designed-in locking element, such as a crimped section or nylon insert, that resists loosening under vibration, which is a critical requirement in automotive and aerospace industries.

Aluminum Panel Nuts provide a unique combination of light weight, good corrosion resistance, and decent conductivity. They are often specified in applications where weight reduction is critical, such as in aviation components, electronic chassis, and lightweight framing systems. The natural oxide layer of Aluminum provides a protective barrier, though plating is sometimes applied for enhanced properties or aesthetic matching.

Sheet Metal Panel Nuts is a broad term that refers to nuts manufactured from sheet metal stock, typically through stamping and forming processes. This category includes Brass Sheet Metal Nuts and Stainless Steel Sheet Metal Nuts. They are generally cost-effective solutions for high-volume production runs and are commonly used in consumer appliances, automotive interiors, and office furniture.

Copper Panel Nuts, while less common, are specified for their unparalleled electrical and thermal conductivity. They are primarily used in specialized high-current electrical applications and in certain thermal management systems where maximizing heat dissipation is crucial.

Manufacturing Processes and Our Capabilities

The performance of a panel nut is deeply influenced by its manufacturing process. We employ several advanced techniques to ensure optimal quality:

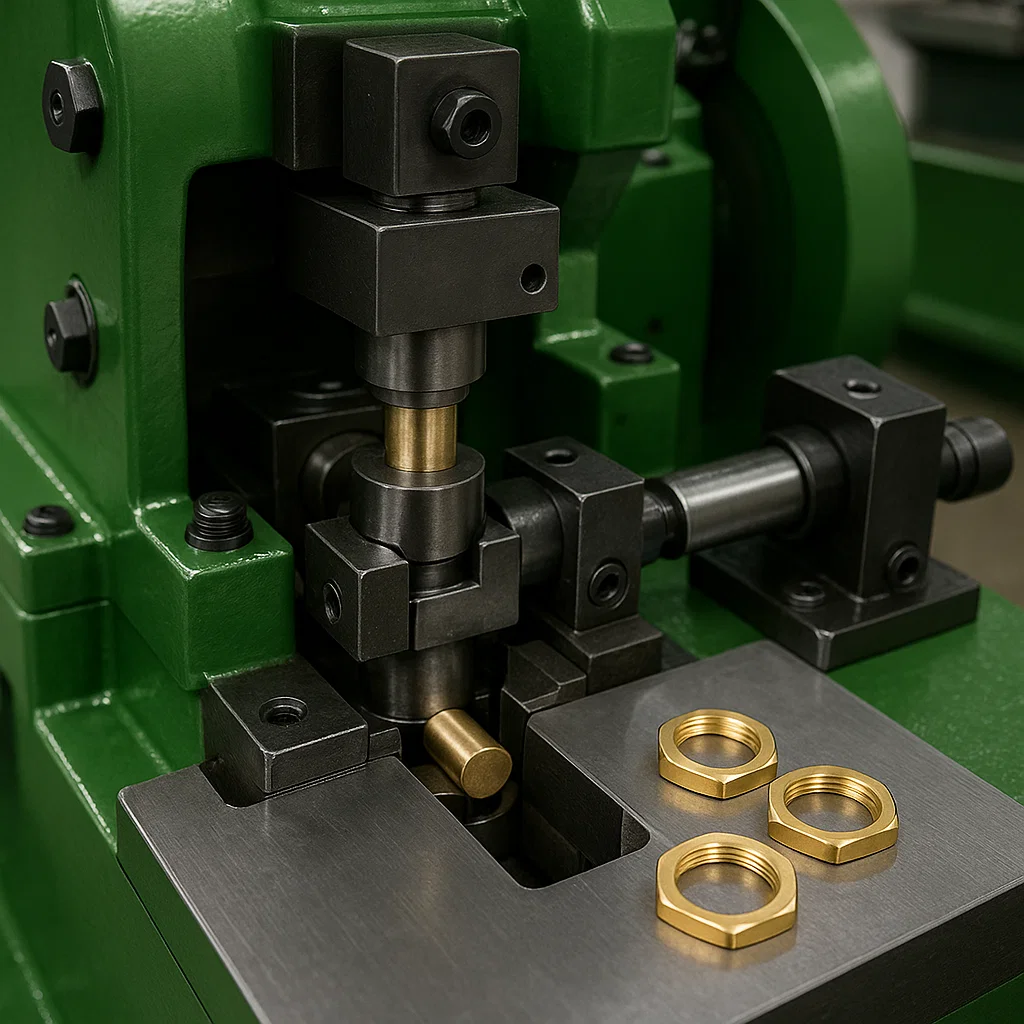

Cold Forging: This process involves shaping metal at room temperature using high pressure. Brass Cold Forged Panel Nuts produced this way have superior grain flow, resulting in higher strength, better surface finish, and minimal material waste. It is ideal for high-volume production of strong, durable nuts.

Machining: For prototypes, low-volume batches, or complex geometries that cannot be forged, we offer precision Brass Machined Panel Nuts. Our CNC machining centers deliver exceptional dimensional tolerances and allow for complete customization.

Stamping and Pressing: This is the primary method for producing Sheet Metal Panel Nuts. Metal sheets are fed into high-speed presses that stamp and form the nut shape. This process is highly efficient for large quantities and allows for the integration of features like locking teeth or knurls.

Our machinery includes state-of-the-art multi-station cold forging machines, CNC lathes, high-tonnage stamping presses, and automated threading equipment, ensuring we can meet any production demand.

Material Grades and International Standards

We manufacture panel nuts conforming to a wide range of international material standards.

| Material | Common Grades (USA – ASTM) | Common Grades (Europe – EN/DIN) | Common Grades (India – IS) | Common Grades (Japan – JIS) |

|---|---|---|---|---|

| Brass | C36000 (Free-Cutting), C26000 | CW510L, CW507L | IS 319 (Grade 1, 2) | C3604 |

| Stainless Steel | ASTM A276 (304, 316) | EN 1.4301 (A2/304), EN 1.4401 (A4/316) | IS 5520 (Grade 10, 11) | SUS304, SUS316 |

| Aluminum | 6061, 2024, 5052 | EN AW-6061, EN AW-2024 | IS 734 (Gr. 10C) | A6061, A2014 |

| Copper | C11000 (ETP Copper) | CW004A, CW008A | IS 50 | C1100 |

Dimensional Chart: Common Panel Nut Sizes

Below is a reference chart for standard panel nut dimensions. We can manufacture to virtually any custom size and thread specification.

| Thread Size (Metric) | Thread Size (UNC) | Thread Size (UNF) | Hex Size (A/F) | Typical Thickness |

|---|---|---|---|---|

| M3 | #4-40 | #4-48 | 5.5 mm | 1.8 mm |

| M4 | #6-32 | #6-40 | 7.0 mm | 2.0 mm |

| M5 | #8-32 | #8-36 | 8.0 mm | 2.4 mm |

| M6 | #10-24 | #10-32 | 10.0 mm | 3.0 mm |

| M8 | 1/4″-20 | 1/4″-28 | 13.0 mm | 4.0 mm |

Note: A/F stands for “Across Flats” of the hex. Dimensions are typical; please consult our engineering team for precise drawings and tolerances.

Industries Served and Applications

Our precision panel nuts are trusted by a diverse range of industries worldwide:

Electronics & Electrical: For securing components in enclosures, power supplies, and communication devices.

Automotive: In instrumentation panels, control units, and lighting assemblies.

Aerospace & Defense: For avionics, radar systems, and military-grade equipment requiring high reliability.

Telecommunications: In base stations, server racks, and network hardware.

Industrial Machinery: For control panels, access covers, and sensor mounts.

Why Choose Us Over Other Panel Nut Suppliers?

Three Decades of Global Experience: Our deep-rooted experience of over 30 years in manufacturing and exporting gives us unparalleled insight into global quality and logistical requirements.

Unmatched Customization: We don’t just sell standard parts. Our engineering team can work with your technical drawings to suggest optimizations for manufacturability and cost-effectiveness.

Flexibility in Production: We understand urgent demands. Our production planning is flexible to accommodate both large-volume orders and smaller, time-sensitive projects.

Superior Customer Support & Communication: We pride ourselves on responsive and clear communication. You will have a dedicated point of contact to track your order from inquiry to delivery.

Customized Packaging: We offer packaging tailored to your needs, including vacuum sealing, bulk packing, or custom boxes with your company’s labels and logos for seamless integration into your supply chain.

Frequently Asked Questions (FAQ)

1. What are the primary benefits of using Brass for panel nuts?

Brass offers an excellent balance of good corrosion resistance, high electrical conductivity, and non-magnetic properties, making it ideal for electrical and electronic applications.

2. Can you supply panel nuts with a specific plating or finish?

Yes, we offer various finishes including nickel plating, zinc plating, tin plating, and passivation for Stainless Steel to enhance corrosion resistance or meet specific aesthetic requirements.

3. What is the difference between a cold forged and a machined panel nut?

Cold forging produces stronger parts with better material grain structure and is cost-effective for large runs. Machining offers greater flexibility for complex designs and is suitable for prototypes or small batches.

4. What file formats do you accept for custom panel nut drawings?

We can work with 2D drawings in PDF or DWG format, and 3D models in STEP or IGES format.

5. How do your Stainless Steel Pressed Lock Nuts prevent loosening?

They typically have a pre-formed section that creates a friction fit with the screw thread, or a non-metallic (e.g., nylon) insert that elastically deforms to lock the thread.

6. What is your standard lead time for production?

Our standard turnaround time for most orders is 4-6 weeks, depending on the quantity and complexity. We also offer expedited services for urgent requirements.

7. Do you provide material certifications?

Yes, we can provide Mill Test Certificates (MTCs) or Material Test Reports (MTRs) for traceability and quality assurance, complying with international standards.

8. What packaging options are available for export?

We use sturdy, export-worthy packaging like corrugated cartons, plywood boxes, or pallets, and can customize the packaging with your branding upon request.

9. Are your products compliant with RoHS and REACH regulations?

Absolutely. We are committed to producing environmentally compliant fasteners and can provide the necessary documentation.

10. What is the minimum order quantity (MOQ) for custom panel nuts?

We try to be as flexible as possible. While we have standard MOQs, we are open to discussing requirements for prototype and small-batch orders.

11. How do I determine the right material grade for my application?

Our technical sales team can assist you based on your application’s requirements for strength, corrosion resistance, conductivity, and operating environment.

12. Can you manufacture panel nuts to DIN, JIS, or other international standards?

Yes, we regularly manufacture fasteners to DIN, JIS, ASTM, BS, and IS standards, among others.

13. What is the advantage of using a sheet metal nut?

Sheet metal nuts are a very cost-effective solution for high-volume applications and are perfectly suited for use in thin panels.

14. How do you ensure quality control during production?

We have a rigorous QC process that includes raw material inspection, in-process checks, and final inspection using calibrated tools like micrometers, thread gauges, and optical comparators.

15. What are your payment terms for new international customers?

Typically, we work with a 50% advance and 50% against copy of shipping documents. Terms can be discussed based on the order value and long-term relationship.

Customer Testimonials

“John Matthews, Procurement Manager, USA: “We have been sourcing our Stainless Steel Panel Nuts from this manufacturer for over five years. Their quality is consistently excellent, and their ability to meet our tight deadlines has been invaluable. Their communication is top-notch.”

“Sarah Chen, Engineering Lead, Australia: “The technical support we received for a custom Aluminum Panel Nut design was exceptional. Their engineers suggested a minor change that saved us 15% on unit cost without compromising performance. A truly collaborative partner.”

Glossary of Terms

A/F (Across Flats): The distance between two parallel flats of the hex on a nut.

Cold Forging: A metal shaping process performed at room temperature that increases the strength of the part.

Knurl: A patterned surface (often diamond-shaped) rolled onto the nut to provide a better grip or to aid in press-fitting.

Passivation: A chemical treatment for Stainless Steel that enhances the natural corrosion-resistant oxide layer.

Thread Pitch: The distance from one thread crest to the next.

UNC (Unified National Coarse): A standard for coarse-threaded fasteners.

UNF (Unified National Fine): A standard for fine-threaded fasteners.

Related Parts:

Precision fastener manufacturer, UNC panel nuts, Enclosure nuts, mounting nuts, Control panel nuts, Sheet metal nuts, export quality panel nuts, Indian industrial hardware supplier, custom threaded inserts, electrical mounting nuts, vibration resistant lock nuts, metric hardware, UNF thread nuts, CNC machined components, cold forging company India.

Ready for a Precision Partnership?

If you are looking for a reliable, high-quality source for Panel Nuts or any custom fastener requirement, your search ends here. Contact our engineering and sales team today to discuss your project needs, request a detailed quotation, or ask for our comprehensive product brochure.

Email: sales@conexscrews.com

Phone/WhatsApp: +91-22-43449300

CTA: Request a Free Quote Today