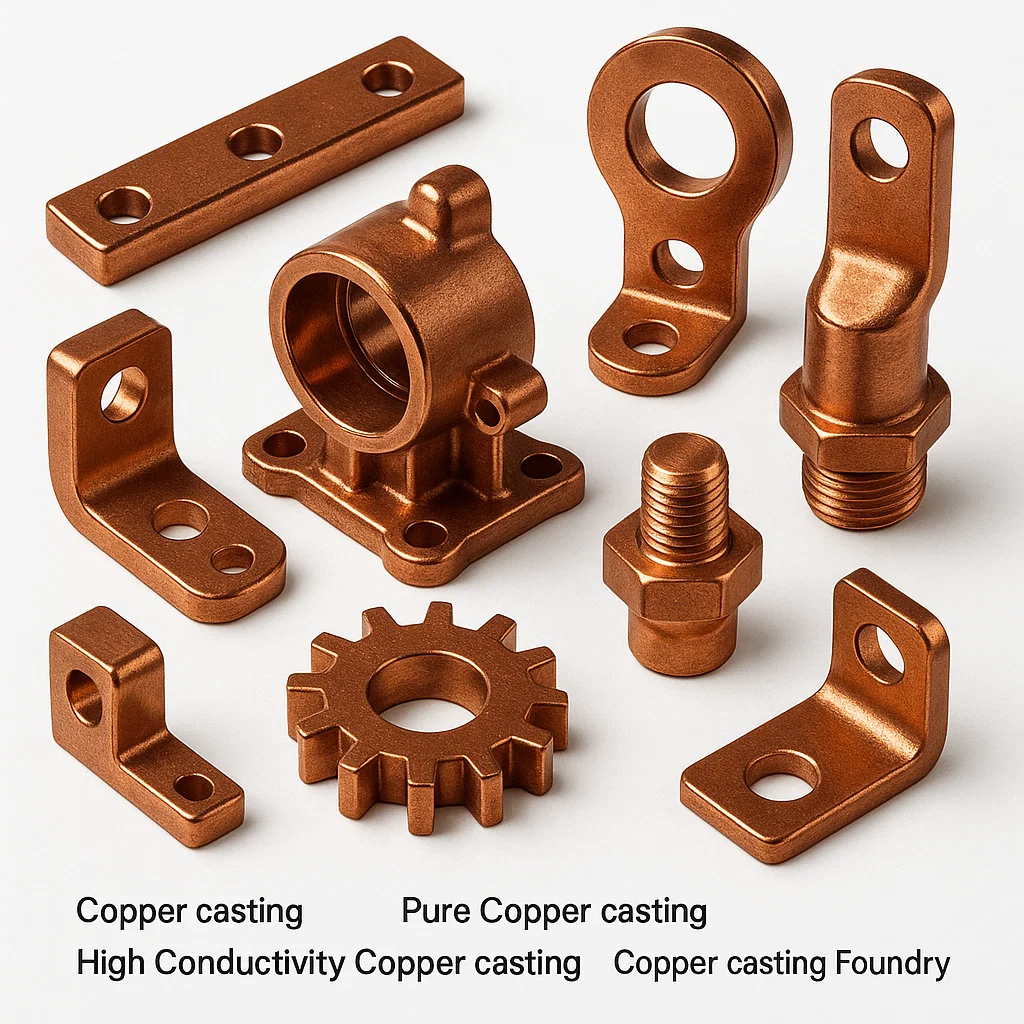

Copper Casting is one of the most demanding metallurgical processes due to Copper’s high thermal conductivity, oxygen sensitivity, and its requirement for precise metallurgical control. We are one of the leading manufacturers and exporters of Copper Castings from India. We have been supplying high-conductivity Copper components, Copper Sand Castings, Copper Permanent Mold Castings, and custom-engineered C11000, C10100, and C10200 Copper Castings to the world market for many decades.

Our production facility integrates CNC Machining, Sand Casting, Gravity Permanent Mold Casting, Centrifugal Casting, Heat Treatment, Metallography, Spectrochemical Analysis, and pressure testing under a controlled ISO-certified environment.

With more than 30 years of global exposure, we deliver tight tolerances, excellent metallurgical integrity, and fast turnaround (4–6 weeks). Our engineering team frequently collaborates with customer R&D teams to optimize drawings, reduce weight, improve conductivity, and enhance performance life, ensuring we remain a preferred supplier across the USA, Europe, Middle East, and Australia.

Copper Casting

Copper Casting refers to the controlled melting, pouring, and solidification of pure Copper or Copper-alloy grades to produce industrial components requiring high electrical conductivity, thermal performance, corrosion resistance, and mechanical strength. Modern Copper Casting uses advanced gating design, solidification simulation, riser optimization, and furnace-temperature control to obtain a dense, low-porosity structure suitable for Electrical, Power Distribution, Heating, Marine, and Industrial Automation applications. The process allows excellent customization for both small batches and high-volume production.

Copper Casting Foundry

A Copper Casting Foundry is a specialized metallurgical facility equipped with Induction Furnaces, Permanent Molds, Sand-Molding Lines, Centrifugal Cast Machines, Shot-blasting units, Heat-Treatment Furnaces, and CNC/VMC Machining Centers dedicated to producing high-precision Copper parts. Our foundry operates with ASTM, BS, DIN, EN, IS, and JIS standards, offering complete traceability from raw material to dispatch. With in-house tooling, pattern development, spectro analysis, and CMM inspection, we offer high repeatability and superior surface finish even for complex geometries.

High Conductivity Copper Casting (HC Copper / ETP / OFE Copper)

High Conductivity Copper Casting involves the manufacturing of parts where electrical conductivity above 97–101% IACS, excellent solderability, and superior thermal performance are essential. These castings are widely used in busbars, switchgear parts, high-current connectors, welding arms, earthing components, electrical-distribution terminals, and power-transmission hardware. Proper control of oxygen, hydrogen pickup, and melt cleanliness is critical to maintaining high conductivity and weldability.

Copper Permanent Mold Casting

Copper Permanent Mold Casting (also called Gravity Die Casting) uses reusable steel/iron molds, giving excellent surface finish (Ra 1.6–3.2 µm), improved dimensional accuracy, better mechanical properties, and higher productivity than sand molds. This process is suitable for C11000 ETP Copper, C10200 OF Copper, C10100 OFE Copper, Chromium Copper, Tellurium Copper, and Phosphor-Deoxidized Copper. Permanent molds help reduce shrinkage defects and are ideal for electrical hardware, rotor components, conductive plates, and motor parts.

C10100 Oxygen-Free Electronic (OFE) Copper Casting

C10100 OFE Copper contains 99.99% purity, oxygen content < 10 ppm, making it ideal for semiconductor, vacuum-electronics, high-frequency equipment, and medical-grade thermal components. OFE Copper castings require strict furnace-atmosphere control, inert-gas blanketing, and ultra-clean refractory practices. They offer maximum conductivity, superior thermal transfer, and excellent grain uniformity, making them suitable for high-precision machined components.

C10200 Oxygen-Free Copper Casting

C10200 OF Copper provides extremely high conductivity with slightly relaxed oxygen-content requirements vs C10100. It is extensively used in electrical connectors, high-current terminals, switchgear parts, bus-coupler plates, RF components, and thermal-transfer hardware. The material machines very well after casting and retains outstanding corrosion resistance.

C11000 ETP Copper Casting Foundry

C11000 Electrolytic Tough Pitch (ETP) Copper is the most common high-conductivity material (> 101% IACS). Our foundry specializes in casting complex C11000 electrical connectors, grounding components, welding equipment parts, transformer terminals, and high-heat-load conductive blocks. ETP Copper requires controlled melt handling to avoid porosity and hydrogen pickup. Our spectro analysis (ASTM E1251) ensures consistent chemistry and mechanical properties.

Copper Centrifugal Casting

Copper Centrifugal Casting produces dense, fine-grained cylindrical components by rotating the mold at high speed. This method eliminates porosity and yields exceptional mechanical strength. Typical applications include bushings, rings, collars, rotor sleeves, pump components, bearing housings, and wear-resistant industrial parts. Centrifugal Casting is suitable for pure Copper as well as Bronze, Aluminium Bronze, Nickel Bronze, and custom alloys.

Copper Sand Casting

Copper Sand Casting is the most flexible and economical process for low-volume custom parts or complex shapes. Our green-sand and no-bake sand molding lines support large castings up to 300 kg with excellent dimensional stability. Sand casting is ideal for electrical connectors, grounding hardware, heat-exchange components, decorative architecture, heavy-duty industrial hardware, and prototypes requiring fast tooling development.

International Copper Material Grades (Reference Table)

| Region | Standard | Typical Grades (Copper & Pure Copper Alloys) |

|---|---|---|

| USA / ASTM | ASTM B170, B152 | C10100 (OFE), C10200 (OF), C10300, C11000 (ETP), C12200 (DHP), C10400, C10500 |

| Europe / EN | EN 1976, EN 1652 | Cu-OF, Cu-OFE, Cu-ETP, Cu-DLP, Cu-DHP, Cu-HCP |

| UK / BS | BS 6017, BS 4570 | C101, C102, C103, C106, C107 |

| Japan / JIS | JIS H3100 | C1011, C1020, C1220 |

| India / IS | IS 14811 | Electrolytic Copper, Oxygen-Free Copper, Deoxidized Copper |

| China / GB | GB/T 5231 | T1, T2, TP1, TP2, TU1 |

Typical Copper Casting Machinery & Facilities

Induction Melting Furnaces (300–500 kg)

Sand-Molding Lines (Green Sand & No-Bake)

Permanent Mold Die Casting Machines

Centrifugal Casting Machines (Horizontal & Vertical)

Heat-Treatment Furnaces

CNC/VMC Machining Centres

Shot Blasters, Vibratory Polishers

Spectrometer (Optical Emission), CMM, Profile Projectors

Ultrasonic Flaw Detectors & Pressure Test Benches

Typical Parts Manufactured in Copper

Common components include:

Busbars, conductive plates, electrical terminals, grounding studs, transformer connectors, welding-machine arms, rotor components, heat exchangers, marine hardware, pump parts, architectural Copper castings, automation-equipment components, and vacuum-electronics parts.

Dimensional Reference Table

| Parameter | Range |

|---|---|

| Casting Weight | 50 g to 300 kg |

| Max Length | Up to 800 mm |

| Wall Thickness | 3–80 mm (depending on process) |

| Tolerances (as-cast) | ±0.5–1.5 mm depending on size |

| Machined Tolerances | ±0.05–0.1 mm |

| Surface Finish | Ra 1.6–6.3 µm |

Sample Line Diagram (Typical Block Casting)

| Dimension | Example |

|---|---|

| L | 80–200 mm |

| W | 40–150 mm |

| T | 10–60 mm |

Finishing, Plating & Surface Treatment

Copper castings can be delivered with:

Bright Polished Finish

Nickel Plating

Tin Plating

Silver Plating (Electrical Applications)

Protective Organic Coatings

Anti-tarnish Lacquer

Machined Finish (CNC/VMC)

Industries Using Copper Castings

Electrical & Power Distribution, Renewable Energy, Railways, Marine, Heavy Engineering, HVAC, Electronics, Semiconductor Fabrication, Welding Equipment, Industrial Automation, and Construction.

Turnaround Time

Standard Production Lead Time: 4–6 Weeks

Expedited programs available depending on tooling readiness and order size.

Performance Metrics (General)

Electrical Conductivity: Up to 101–102% IACS for OFE & ETP Copper

Thermal Conductivity: 390–401 W/m·K

Tensile Strength: 220–260 MPa (alloy-dependent)

Hardness: 45–85 HB

Why Choose Us Over Other Suppliers?

Our foundry provides global-standard quality, with the advantages of Indian manufacturing cost-efficiency. Customers choose us because:

3 decades of export experience to USA, UK, EU, Australia & Middle East

Engineering team that optimizes technical drawings for cost & performance

Flexible production schedules and faster delivery

Custom molds, customized packaging, private-label branding available

Transparent communication, daily updates, and multilingual support

In-house testing ensures zero-defect philosophy

Trusted by global OEMs for consistency & reliability

Customer Testimonials

Daniel R. (USA) – “Your Copper Castings helped us solve a long-standing conductivity issue. Surface finish, machining accuracy, and packaging were outstanding. Truly reliable global supplier.”

Mark Thomson (UK) – “Exceptional professionalism and support. They guided us through design changes that reduced weight and improved performance. Deliveries are always on time.”

Frequently Asked Questions (15+)

1. What Copper grades do you cast most frequently?

C10100, C10200, C11000, C12200, along with custom pure-Copper alloys for electrical and thermal applications.

2. What is your typical lead time?

Standard 4–6 weeks depending on tooling, batch size, and machining complexity.

3. Do you export Copper Castings globally?

Yes, we export extensively to USA, UK, Canada, Germany, Australia, and Middle East.

4. Can you develop parts from customer samples?

Yes, we reverse-engineer using CMM scanning, 3D modeling, and simulation before casting.

5. Do you offer CNC machining after casting?

Yes, fully finished and machined Copper components can be supplied.

6. What testing methods do you use?

Spectrochemical analysis, hardness testing, CMM, ultrasonic, pressure testing, and visual dimensional checks.

7. Can you handle high-conductivity Copper?

Yes, including OFE (C10100), OF (C10200), and ETP (C11000).

8. What industries do you serve?

Electrical, power distribution, HVAC, renewable energy, marine, industrial automation.

9. Do you assist in mold design?

Yes, our tooling engineers design gating, risers, and cooling paths in-house.

10. Can you supply small batches?

Absolutely—prototypes, pilot samples, and low-volume orders welcome.

11. What finishes do you offer?

Machined, polished, nickel plated, tin plated, silver plated, and anti-tarnish coatings.

12. Do you provide certificates?

Yes, including chemical composition, mechanical properties, dimensional reports, and PPAP on request.

13. Is custom packaging available?

Yes, with private labels, tags, and export-grade packaging.

14. Can Copper Castings be used for marine applications?

Yes, especially corrosion-resistant Copper or Bronze variants.

15. What machining tolerances can you achieve?

Typically ±0.05–0.10 mm depending on geometry.

16. What casting processes do you offer?

Sand Casting, Permanent Mold Casting, Centrifugal Casting, and investment in specialized CNC machining.

17. Do you provide drawing support?

Yes, engineering support and drawing-optimization are standard.

Glossary of Terms

ETP Copper (Electrolytic Tough Pitch): High-conductivity Copper grade C11000 used for electrical parts.

OFE Copper: Oxygen-Free Electronic Copper with purity 99.99% used for semiconductor and RF applications.

Centrifugal Casting: Process using rotational force to produce dense cylindrical Copper components.

Permanent Mold Casting: Gravity die-casting process that uses reusable steel molds.

Sand Casting: Economical casting method using silica sand molds.

IACS: International Annealed Copper Standard for electrical conductivity measurement.

Deoxidized Copper: Copper with reduced oxygen content to improve weldability and consistency.

Related Parts:

Copper Foundry India, Copper CNC Machined castings, Copper Sand Casting Manufacturer, OFC Copper Casting Supplier, C11000 Copper Exporter, Copper Permanent Mold Casting India, Copper Conductivity Components, Copper Casting OEM Supplier, Custom Copper Casting For Electrical Industry, High Conductivity Copper Casting Manufacturer

Call-To-Action (CTA)

For quotations, technical data sheets, drawings, or brochures, please contact us anytime.

We respond within 24 hours with complete technical support.

Updated: 2025-2026