Brass CNC Machined Parts and Brass CNC Turned Components

We are one of the leading manufacturers and exporters of Brass CNC Machined Parts and Brass CNC Machined Components from India. We have been supplying precision-engineered Brass components to the world market for many decades. Our expertise in CNC machining, adherence to international standards such as ASTM, DIN, BS, JIS, and IS, and commitment to delivering high-quality, customized solutions make us a trusted partner for industries worldwide. From Brass CDA 360 CNC machined parts to Lead-Free CNC turned parts and DZR grade CNC machined components, we cater to diverse applications with precision, durability, and reliability. Our state-of-the-art manufacturing facilities and three decades of global experience ensure that every product meets stringent quality requirements, offering unparalleled performance and value to our customers.

Brass CNC Machined Parts

Overview: Brass CNC Machined Parts are precision-engineered components manufactured using advanced CNC (Computer Numerical Control) machining processes. These parts are crafted from high-quality Brass alloys, known for their excellent corrosion resistance, machinability, and aesthetic appeal. Brass CNC machined parts are widely used in industries such as automotive, aerospace, plumbing, electronics, and medical equipment due to their durability and versatility. Our manufacturing process adheres to international standards like ASTM B16, DIN 17660, JIS H3250, and IS 319, ensuring consistent quality. We offer customized solutions with flexible production timelines and tailored packaging options, including customer-specific labels and logos.

Material Grades: Common grades include Brass C36000 (CDA 360), C35300, C38500, C26000 (Cartridge Brass), C28000 (Muntz Metal), C46400 (Naval Brass) (USA); CuZn39Pb3, CuZn36Pb3, CuZn40, CuZn37, CuZn35Pb2 (Europe); C3601, C3602, C2600, C2801, C4641 (Japan); CZ121, CZ122, CZ114, CZ115, CZ108 (BS); and IS 319 Grade I, IS 319 Grade II, IS 320 (India). These grades offer varying levels of lead content, strength, and machinability to suit specific applications.

Manufacturing Processes: Our processes include CNC turning, milling, drilling, and threading, performed on multi-axis CNC machines for high precision. We use CAD/CAM software for design and programming, ensuring accuracy in complex geometries.

Machinery Used: 4-axis and 5-axis CNC lathes, vertical machining centers, and automated CNC turning centers equipped with live tooling.

Typical Parts Produced: Fittings, connectors, valves, bushings, and custom fasteners.

Finish: Options include polished, nickel-plated, chrome-plated, or passivated finishes for enhanced corrosion resistance and aesthetics.

Industries Served: Automotive, plumbing, electronics, aerospace, and marine industries.

Tolerances: Standard tolerances of ±0.01 mm, with tighter tolerances available upon request.

Turnaround Time: 4-6 weeks, with expedited options for urgent orders.

Performance Metrics: High tensile strength (up to 550 MPa for C36000), excellent corrosion resistance, and superior machinability (rated 100% for CDA 360).

Brass CNC Machined Components

Overview: Brass CNC Machined Components are specialized parts designed for high-precision applications requiring intricate designs and tight tolerances. These components are manufactured using advanced CNC machining techniques, ensuring repeatability and consistency. We cater to global industries with customized Brass CNC components, offering flexibility in design, material selection, and packaging. Our adherence to standards like IS 319, BS 2874, ASTM B455, and EN 12164 ensures compliance with international quality benchmarks.

Material Grades: Includes C37700, C46400, C26000, C27200, C36500, C38500 (USA); CuZn38Pb2, CuZn40Pb2, CuZn33, CuZn36 (Europe); C3771, C4641, C2720, C3604 (Japan); CZ128, CZ124, CZ109, CZ106 (BS); and IS 319 Grade III, IS 3488 (India).

Manufacturing Processes: CNC milling, turning, boring, and tapping, with secondary operations like deburring and surface finishing.

Machinery Used: Multi-spindle CNC machines and Swiss-type CNC lathes for complex components.

Typical Parts Produced: Precision screws, nozzles, couplings, and terminal blocks.

Finish: Satin, mirror-polished, or electroplated finishes for enhanced durability.

Industries Served: Telecommunications, HVAC, and instrumentation.

Tolerances: ±0.005 mm for critical dimensions.

Turnaround Time: 4-6 weeks, with rapid prototyping available.

Brass CDA 360 CNC Machined Parts

Overview: Brass CDA 360 CNC Machined Parts are crafted from Brass C36000, a free-machining alloy with excellent machinability and moderate strength. This grade is widely used for components requiring high precision and intricate designs. Our expertise in machining CDA 360 ensures compliance with ASTM B16, JIS H3250, and IS 319 standards, making these parts ideal for applications in plumbing, electrical, and automotive industries.

Material Grades: Primarily C36000 (USA), equivalent to CuZn36Pb3 (Europe), C3601 (Japan), CZ121 (BS), and IS 319 Grade I (India).

Manufacturing Processes: CNC turning, milling, and drilling with high-speed machining for efficiency.

Machinery Used: 5-axis CNC machining centers and automated lathes.

Typical Parts Produced: Pipe fittings, electrical connectors, and valve stems.

Finish: Polished or nickel-plated for corrosion resistance.

Industries Served: Plumbing, electrical, and automotive.

Tolerances: ±0.01 mm, with precision up to ±0.002 mm for specific applications.

Turnaround Time: 4-6 weeks.

Brass Lead-Free CNC Turned Parts

Overview: Brass Lead-Free CNC Turned Parts are manufactured from eco-friendly, lead-free Brass alloys like C27450, C46400, and C69300, compliant with RoHS, NSF/ANSI 372, and EN 12165 standards for potable water applications. These parts are ideal for environmentally conscious industries, offering excellent corrosion resistance and machinability without compromising safety.

Material Grades: C27450, C46400, C69300 (USA); CuZn37, CuZn21Si3P (Europe); C2700, C6801 (Japan); CZ109, CZ137 (BS); IS 4170 (India).

Manufacturing Processes: Precision CNC turning and threading with automated quality checks.

Machinery Used: Swiss-type CNC lathes and multi-axis turning centers.

Typical Parts Produced: Plumbing fittings, valves, and connectors for potable water systems.

Finish: Passivated or polished for enhanced durability.

Industries Served: Plumbing, medical, and food processing.

Tolerances: ±0.01 mm.

Turnaround Time: 4-6 weeks.

Brass DZR Grade CNC Machined Parts

Overview: Brass DZR Grade CNC Machined Parts (Dezincification Resistant) are designed for applications requiring resistance to dezincification corrosion, particularly in harsh environments like marine and plumbing systems. These parts are manufactured from DZR Brass alloys like CZ132, C35330, and C48600, meeting standards such as BS EN 12163, ASTM B124, and IS 3488.

Material Grades: CZ132, C35330, C48600 (USA); CuZn36Pb2As, CuZn40Pb2As (Europe); C4621 (Japan); CZ114, CZ115 (BS); IS 3488 Grade DZR (India).

Manufacturing Processes: CNC milling, turning, and drilling with stringent quality control.

Machinery Used: High-precision CNC lathes and vertical machining centers.

Typical Parts Produced: Marine fittings, valve bodies, and pipe connectors.

Finish: Chrome-plated or passivated for corrosion resistance.

Industries Served: Marine, plumbing, and oil & gas.

Tolerances: ±0.01 mm.

Turnaround Time: 4-6 weeks.

Brass Swiss Type CNC Machining

Overview: Brass Swiss Type CNC Machining involves the use of Swiss-type CNC lathes to produce small, intricate Brass components with exceptional precision. This method is ideal for high-volume production of complex parts with tight tolerances, commonly used in medical and electronics industries.

Material Grades: C36000, C27450, C26000, C69300 (USA); CuZn39Pb3, CuZn37, CuZn21Si3P (Europe); C3601, C2700, C6801 (Japan); CZ121, CZ109 (BS); IS 319 Grade I, IS 4170 (India).

Manufacturing Processes: Swiss-type CNC turning with sliding headstock technology for precision.

Machinery Used: Swiss-type CNC lathes like Citizen and Star machines.

Typical Parts Produced: Micro connectors, pins, and medical implants.

Finish: Polished or electroplated for enhanced aesthetics.

Industries Served: Medical, electronics, and aerospace.

Tolerances: ±0.005 mm for micro-components.

Turnaround Time: 4-6 weeks.

Why Choose Our Brass CNC Machined Parts?

Our Brass CNC Machined Parts stand out due to our commitment to quality, precision, and customer satisfaction. With over three decades of global experience, we offer unmatched expertise in precision CNC machining. Our ability to customize parts to exact specifications, combined with flexible production timelines and customized packaging with customer logos, ensures a tailored experience. We maintain excellent communication throughout the process, providing regular updates and responsive customer support. Our faster turnaround times (4-6 weeks) and adherence to international standards like ASTM, DIN, JIS, BS, and IS make us a preferred choice for industries worldwide. Additionally, our eco-friendly options, such as Lead-Free CNC Turned Parts, cater to environmentally conscious markets.

Material Property Table

| Material Grade | Standard | Tensile Strength (MPa) | Yield Strength (MPa) | Corrosion Resistance | Machinability |

|---|---|---|---|---|---|

| C36000 (CDA 360) | ASTM B16, IS 319 | 550 | 310 | Good | 100% |

| C27450 (Lead-Free) | ASTM B927, IS 4170 | 400 | 200 | Excellent | 80% |

| CZ132 (DZR) | BS EN 12163, IS 3488 | 450 | 250 | Excellent (DZR) | 85% |

| C26000 (Cartridge Brass) | ASTM B19, JIS C2600 | 430 | 180 | Good | 70% |

| C46400 (Naval Brass) | ASTM B21, JIS C4641 | 540 | 230 | Excellent | 60% |

Typical Dimensions and Tolerances

| Part Type | Diameter (mm) | Length (mm) | Tolerance (mm) |

|---|---|---|---|

| Fittings | 5-50 | 10-100 | ±0.01 |

| Connectors | 3-30 | 5-80 | ±0.005 |

| Valves | 10-60 | 20-120 | ±0.01 |

Packaging and Shipping

We offer customized packaging solutions, including customer-specific labels and logos, to meet branding requirements. Our Brass CNC Machined Parts are securely packed in corrosion-resistant materials to ensure safe delivery. We provide global shipping options, including air and sea freight, with tracking and insurance for peace of mind. Our efficient logistics network ensures timely delivery within 4-6 weeks, with expedited options available.

Customer Testimonial

“We have been sourcing Brass CNC Machined Components from this Indian manufacturer for over five years, and their quality and service are unmatched. The precision of their CDA 360 CNC parts and their ability to meet tight tolerances have significantly improved our production efficiency. Their team is responsive, and the customized packaging with our logo adds a professional touch to our supply chain.” – John Miller, USA

Frequently Asked Questions (FAQ)

1. What is the typical turnaround time for Brass CNC Machined Parts? Our standard turnaround time is 4-6 weeks, with expedited options available.

2. Do you offer Lead-Free Brass CNC parts? Yes, we manufacture Lead-Free CNC Turned Parts compliant with RoHS and NSF/ANSI 372 standards.

3. What industries use your Brass CNC components? Our parts are used in automotive, plumbing, electronics, aerospace, marine, and medical industries.

4. Can you customize Brass parts to specific designs? Yes, we offer fully customized solutions using CAD/CAM software to meet exact specifications.

5. What tolerances can you achieve? Standard tolerances are ±0.01 mm, with tighter tolerances up to ±0.002 mm available.

6. What material grades do you use? We use grades like C36000, C27450, CZ132, C26000, C46400, and equivalents per ASTM, DIN, JIS, BS, and IS standards.

7. Do you provide surface finishing options? Yes, we offer polished, nickel-plated, chrome-plated, and passivated finishes.

8. What is DZR Brass, and why is it used? DZR (Dezincification Resistant) Brass, like CZ132, is used in harsh environments to prevent corrosion.

9. Can you provide customized packaging? Yes, we offer packaging with customer-specific labels and logos.

10. How do you ensure quality? We use automated quality checks, CMM inspection, and adhere to international standards.

Glossary of Terms

CNC Machining: Computer Numerical Control machining, a process using computer-controlled machines to shape Brass and other materials with high precision.

Brass CDA 360: A free-machining Brass alloy (C36000) with excellent machinability, used for precision components.

Lead-Free Brass: Brass alloys like C27450 with minimal or no lead content, compliant with environmental regulations.

DZR Brass: Dezincification Resistant Brass, designed to resist corrosion in harsh environments.

Swiss-Type CNC Machining: A precision machining process using sliding headstock lathes for small, complex parts.

Tolerance: The allowable deviation in dimensions, typically ±0.01 mm for Brass CNC parts.

Related Terms

Precision Brass Components, Custom CNC Machined Brass Parts, Brass Turned Fittings, Lead-Free Brass Machining, DZR Brass Components, Swiss CNC Brass Parts, High-Precision Brass Machining, Brass Alloy CNC Parts, CNC Brass Connectors, Brass Machined Valves, Naval Brass Components, Cartridge Brass Parts.

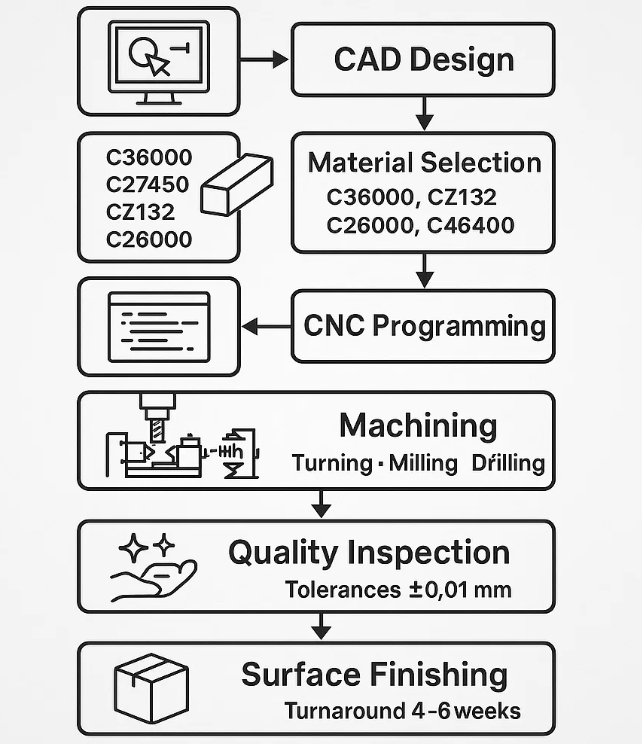

Infographic: Brass CNC Machining Process

[Infographic Description: A flowchart illustrating the Brass CNC machining process, starting with CAD design, followed by material selection (C36000, C27450, CZ132, C26000, C46400), CNC programming, machining (turning, milling, drilling), quality inspection, surface finishing, and packaging. Key metrics like tolerances (±0.01 mm) and turnaround time (4-6 weeks) are highlighted.]

Call-to-Action

Ready to elevate your projects with our Brass CNC Machined Parts? Request a quote today, email us for a detailed brochure, or contact us via phone/WhatsApp for personalized assistance.