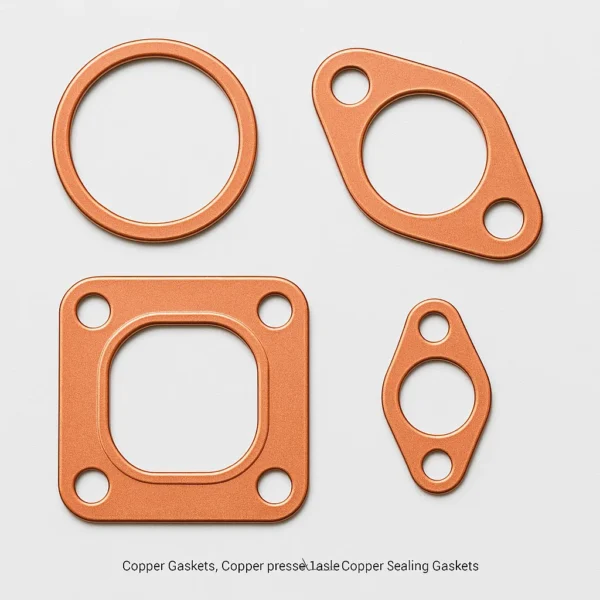

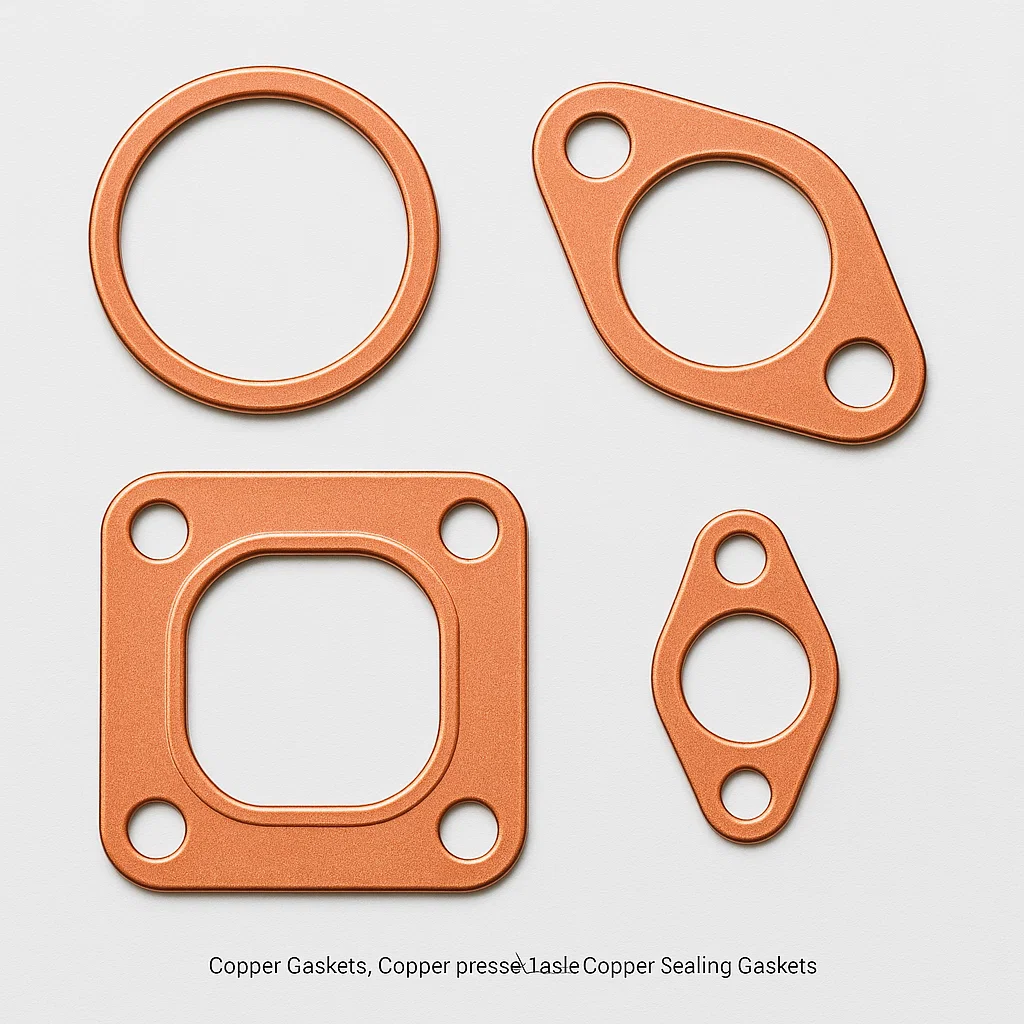

Copper Gaskets , Copper Seals, Copper Sealing Gaskets – Manufacturer & Exporter from India

High-Performance Copper Gaskets, Copper Sealing Washers & Copper Pressed Components

We are one of the leading manufacturers and exporters of Copper Gaskets, Copper Sealing Gaskets, Copper Pressed Gaskets, Copper Engine Gaskets, Copper Sealing Washers, and Copper Pressed Components from India. We have been supplying high-precision Copper sealing solutions to the world market for many decades.

Our expertise covers custom-engineered sealing profiles, deep-drawn geometries, flat punched washers, and high-temperature Copper gasket assemblies used in Automotive, HVAC, Oil & Gas, Electrical, Instrumentation, and Heavy Engineering equipment. With more than 30 years of global exposure, we support OEMs and distributors across the USA, UK, Europe, Middle East, and Australia with fast turnaround times, engineered improvements, and superior tolerance control. Our manufacturing process integrates high-grade Copper alloys, state-of-the-art CNC machining, hydraulic pressing, power presses, and automated deburring. Every part is manufactured in compliance with ASTM, DIN, BS, IS, JIS and international dimensional standards with full traceability, material certificates, and application-driven customization.

Overview – Copper Gaskets for High-Temperature & High-Pressure Sealing

Copper Gaskets are precision-engineered sealing components designed to withstand elevated temperatures, corrosive media, thermal cycling, and extreme pressure fluctuations. These gaskets are widely used in engines, compressors, flanges, exhaust assemblies, turbo systems, refrigeration units, and vacuum chambers. Due to Copper’s exceptional thermal conductivity, ductility, creep resistance, and malleability, Copper Sealing Gaskets adapt perfectly to uneven mating surfaces and provide leak-proof joints. We manufacture all variants including Flat Copper Gaskets, Solid Copper Seals, Crush Copper Washers, Annealed Copper Sealing Gaskets, Deep-Drawn Copper Gaskets, and custom pressed-form Copper components for both static and dynamic joints.

Copper Gaskets

Copper Gaskets are solid-section rings or profiles made from high-conductivity Copper and Copper alloys to deliver stable sealing under thermal stress. These gaskets are annealed for softness, ensuring conformity between metal-to-metal surfaces. Our capabilities include flat, corrugated, spiral, and step-profile Copper Gaskets used in engines, pipe connections, instrumentation equipment, hydraulic systems, and vacuum lines where dimensional accuracy and heat tolerance are critical.

Copper Sealing Gaskets

Copper Sealing Gaskets are engineered for applications requiring gas-tight and fluid-tight joints. These are routinely used in exhaust manifolds, turbochargers, fuel systems, refrigeration compressors, and pressure vessels. The material’s plasticity ensures controlled deformation, resulting in full-face sealing even on imperfect flanges. Our Sealing Gaskets are manufactured in ASTM-B152, C11000, C12200 (DHP Copper), EN CW004A, CW024A, and JIS C1100 with process options including annealing, stamping, CNC trimming, and gasket profiling.

Copper Pressed Gaskets

Copper Pressed Gaskets are produced using hydraulic presses, progressive die sets, and deep-drawing tools that deliver complex geometry with consistent thickness control. These products are ideal where rigidity and profile depth matter—such as engine head assemblies, industrial burners, HVAC compressor plates, EGR valves, and sealing housings. Pressed Gaskets achieve exact deformation on installation, making them suitable for long-life sealing in high-pressure equipment.

Copper Seals

Copper Seals are compact metal sealing elements designed for precision leak-proof joints in hydraulic, pneumatic, and fuel injection systems. Depending on customer requirements, we manufacture them in annealed, half-hard, or full-hard temper with optional plating finishes. These Copper Seals replace fibre washers in high-temperature areas and provide superior resistance to vibration, friction, and chemical exposure.

Copper Sealing Washers

Copper Sealing Washers, often called crush washers, are widely used in automotive sump plugs, brake lines, oil lines, and hydraulic joints. Their controlled crush property ensures immediate sealing upon tightening. Our washers comply with DIN 7603, BS 4518, ASTM B152, and OEM specifications. They are available in Solid, Tapered, and Chamfered profiles, all manufactured with close dimensional tolerances and smooth burr-free edges.

Copper Pressed Parts

Copper Pressed Parts are formed using multi-stage progressive tools to achieve deep profiles, ribs, curves, and structural strength. Our facility handles thickness from 0.20 mm to 6 mm depending on design. These parts include domed discs, housings, covers, press-fit caps, exhaust rings, and electrical assembly plates used in switchgear, lighting, and pump industries.

Copper Engine Gaskets

These are precision-engineered sealing components designed to handle extreme temperatures, high combustion pressures, and continuous thermal cycling found in internal-combustion engines. Manufactured from high-conductivity Copper such as C11000, C12200, CW024A, or C1100, these gaskets provide excellent malleability and conformability, allowing them to seat perfectly against uneven cylinder head and engine block surfaces. Copper Engine Gaskets are often annealed to achieve controlled crush characteristics, resulting in highly reliable sealing for high-performance engines, turbocharged assemblies, diesel generators, compressors, and motorsport applications. Their superior heat dissipation minimizes hotspots, prevents blow-by, and ensures long-term durability even in aggressive environments involving oils, coolants, and combustion gases. These gaskets are preferred in demanding OEM and aftermarket engine builds where stability, repeatability, and leak-proof performance are essential.

Copper Pressed Components

Copper Pressed Components cover all specialty press-formed geometries used in Automotive, Railways, Marine, Electrical, and Industrial machinery. These components are manufactured with strict tolerances, superior surface finish, and optional surface treatment. We support prototype, small-batch, and large-volume manufacturing with tool design support.

Material Grades Used (All Global Standards)

| Region | Grade | Standard | Notes |

|---|---|---|---|

| USA | C11000, C10200, C12200, C12000 | ASTM B152, B75 | Oxygen-free & DHP Copper for superior sealing |

| Europe | CW004A, CW008A, CW024A | EN 1652, EN 1172 | High conductivity & DHP Copper |

| UK (BS) | C101, C103, C106 | BS 2870 | Engineering grade Copper |

| India (IS) | ETP Copper, DHP Copper | IS 191, IS 305 | Standard sealing Copper |

| Japan (JIS) | C1100, C1020 | JIS H3100 | Electrical & industrial Copper |

| China (GB) | T1, T2, TU1 | GB/T 2059 | High-purity grades |

| Other Alloys | Cu-Ni, Cu-Zn, Phosphor Bronze | ASTM/DIN/BS | For specialized sealing conditions |

Manufacturing Processes & Machinery Used

Copper Gaskets and Sealing Washers are manufactured using a combination of precision processes:

– CNC Turning, CNC Milling, and CNC Profiling

– Hydraulic Pressing (40–200 Tons)

– Power Press & Progressive Die Stamping

– Deep Drawing, Blanking, Annealing, and Tempering

– Vibratory Deburring, Polishing, Shot Blasting

– CMM inspection, surface roughness testing, hardness testing, and profile measurement

Our equipment includes AMADA, YCM, Haas CNC machines, Taiwanese power presses, furnace-based annealing lines, and high-precision measuring tools complying with ISO 9001 quality systems.

Typical Parts Manufactured

Copper Sealing Washers, Copper Seals, Copper pressed parts, Copper pressed components, Copper sealing Gaskets, Copper Engine Gaskets, Turbocharger Gaskets, Exhaust Gaskets, High-Pressure Seals, Engine Head Gaskets, Housing Plates, Flange Gaskets, Flat Copper Rings, Deep-Drawn Cups, Pressed Covers, Electrical Brackets, Oil Line Washers, Fuel Injector Washers, Custom Copper Sealing Profiles.

Dimensional Table (Typical Range)

| Parameter | Range |

|---|---|

| ID (mm) | 2.0 – 150.0 |

| OD (mm) | 4.0 – 300.0 |

| Thickness | 0.2 – 6.0 mm |

| Tolerances | ±0.05 mm to ±0.10 mm |

| Hardness | 45–95 HV (as required) |

Plating & Surface Finish Options

Copper parts can be supplied in:

• Plain (Unplated)

• Nickel Plated

• Tin Plated

• Silver Plated

• PTFE-coated sealing surfaces

• Oxidation-resistant anti-tarnish coatings

Industries Using Copper Gaskets

Automotive OEMs, Aerospace sub-assemblies, HVAC & Compressors, Oil & Gas, Petrochemical plants, Refrigeration & Air-Conditioning, Electrical Switchgear, Transformers, Marine Engines, Railways, Pumps & Valves, Heavy Industrial Machinery, Motors & Generators, Hydraulic Equipment.

Turnaround Time

Standard production: 4–6 weeks

Rapid development for prototypes: 7–10 days

Custom tooling: 2–3 weeks

Performance Metrics

• High thermal conductivity (385–400 W/mK)

• Temperature range: up to +600°C

• Excellent creep resistance

• Uniform crush behaviour

• Superior sealing under vibration and pressure fluctuations

Why Choose Our Copper Gaskets & Sealing Components?

Our advantage lies in our 30+ years of global engineering experience, excellent communication skills, and a flexible manufacturing system capable of switching between small-batch prototypes and large-scale production without delays. Customers value our engineering support, where we recommend drawing improvements, thickness reduction, stamping optimization, and cost-saving alternatives. We also offer customized packaging with labels and barcodes, export-ready pallets, moisture-proof packaging, and dedicated account managers for USA/Europe. Our quality, integrity, and consistent delivery schedules set us apart from generic suppliers.

Customer Testimonials

John W. (USA) – “Copper Gaskets supplied by this team exceeded our expectations in finish, consistency, and sealing performance. Communication was excellent, and they delivered ahead of schedule.”

Michael P. (UK) – “Fantastic expertise. Their engineering inputs reduced our cost by 18%. Copper sealing washers were perfectly annealed and dimensionally accurate.”

Glossary of Terms

Annealed Copper – Softened Copper for improved sealing.

Crush Washer – A Copper washer designed to deform under load to create a seal.

Deep Drawing – A pressing process for forming deep shapes.

DHP Copper – Deoxidized High Phosphorus Copper used for sealing components.

ETP Copper – Electrolytic Tough Pitch Copper (high conductivity).

CNC Profiling – CNC machining to achieve accurate gasket profiles.

Progressive Die – A multi-stage stamping die for high-volume production.

Related Parts:

Copper Gasket Manufacturer India, Copper Seals, Copper Washer Supplier, Solid Copper Sealing Rings, Custom Copper Pressed Parts Exporter, Annealed Copper Gaskets, Copper Crush Washers, Copper Engine Gaskets, Copper Sealing Rings, Machined Copper Gaskets, High-Temperature Copper Seals.

Technicals:

COPPER GASKET PERFORMANCE FACTORS

---------------------------------

| Thermal Conductivity | 385 W/mK |

| Max Temp | 600°C |

| Pressure Resistance | High |

| Applications | Engines, HVAC, Oil & Gas |

---------------------------------

Call-to-Action

For quotes, drawings, brochures, or technical support, please email us or contact us on WhatsApp/phone. Our engineering team will assist with design optimisation, samples, and pricing.

Updated: 2025-2026