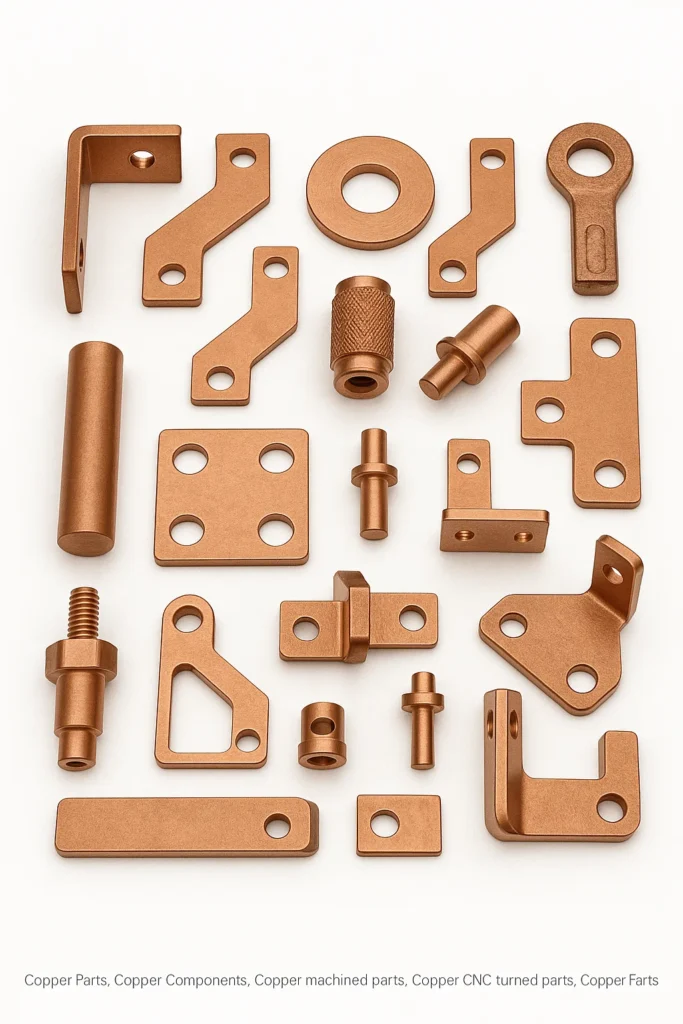

Copper Parts & Copper Components – Global Manufacturer & Exporter

Precision Copper Parts, Copper Machined components, Copper CNC Turned – Forged parts and components, Stamped & Custom-Engineered Copper Components

We are one of the leading manufacturers and exporters of precision-engineered Copper Parts and Copper Components from India. We have been supplying Copper machined components, Copper CNC turned parts, and a wide range of custom Copper industrial parts to the world market for many decades. Our product portfolio includes Copper machined parts, Copper Forged Parts, Copper Stamped Parts, Copper Milled Parts, Copper Pressed Parts and Copper Sheet Metal Components manufactured using international Copper grades and alloys. With a strong global footprint across USA, Europe, Middle East, UK, Australia and Asia, we offer engineering-grade quality, strict process control, fast turnaround times, and unmatched manufacturing flexibility. Our production facilities include advanced CNC machines, VMCs, SPMs, forging hammers, hydraulic presses, turret punching systems, and state-of-the-art inspection equipment. As an export-oriented manufacturer, we provide customised packaging, private-label shipments, engineering design optimisation and full technical support to OEMs, distributors and project companies worldwide.

Comprehensive Overview of Copper Parts & Copper Components

Copper Parts are used across electrical distribution systems, switchgear assemblies, transformers, automotive electronics, renewable energy systems, HVAC installations, telecom hardware, industrial machinery, and a wide range of current-carrying applications. High-conductivity Copper provides exceptional electrical performance, superior thermal dissipation, corrosion resistance and excellent machining properties. Our custom-designed Copper Components include connectors, terminals, bushings, clamps, contact shoes, inserts, washers, threaded parts, CNC turned Copper fittings, precision machined Copper blocks and Copper sheet metal parts.

We manufacture components using various Copper alloys such as ETP Copper, Oxygen-Free Copper (OFC), High-Conductivity Copper, Chromium Copper, Tellurium Copper, Phosphorised Copper and other specification-driven alloys depending on the performance needs. Each part undergoes strict quality validation, dimensional control and surface-finish inspection. Typical lead time for most Copper Parts is 4–6 weeks, with an option for faster production depending on volume and complexity.

Material Grades & International Standards for Copper Parts

Below is a complete material-grade reference used in USA, Europe, China, Japan and India.

Table: Copper & Copper Alloy Grades (Global Comparison)

| Category | India (IS) | USA (ASTM/UNS) | Europe (EN/DIN) | Japan (JIS) | China (GB/T) |

|---|---|---|---|---|---|

| Pure Copper | IS 191 | C11000 (ETP), C10100 (OFC) | Cu-ETP (CW004A), Cu-OF (CW008A) | C1100, C1020 | T1, T2 |

| Tellurium Copper | IS 191 | C14500 | CuTeP (CW118C) | C1450 | TU1 |

| Chromium Copper | IS 6473 | C18200 | CuCr1 (CW106C) | C1820 | QCr0.5 |

| Phosphor Bronze | IS 7814 | C51000, C52100 | CuSn5, CuSn8 | C5191, C5210 | QSn6.5-0.1 |

| Aluminium Bronze | IS 305 | C95400, C95500 | CuAl10Fe5Ni5 | C6191, C6230 | QAl10-4-4 |

| Silicon Bronze | IS 7748 | C65100 | CuSi3Mn1 | C6510 | QSi3-1 |

| Brass (For mixed production) | IS 319 | C36000 | CuZn39Pb3 | C3604 | H62, H65 |

We can also produce to MIL, BS, SAE, ISO, IEC, UL and customer-specific standards.

Manufacturing Processes Used for Copper Parts

CNC Turning – For precision cylindrical components, inserts, terminals, threaded fittings and high-tolerance parts.

CNC Milling & VMC Machining – Used for Copper blocks, busbar parts, complex 3D geometries, manifolds, brackets and thermal plates.

Forging (Open & Closed Die) – Produces high-strength Copper Forged Parts with refined grain structure.

Stamping & Punching – Ideal for flat and thin components such as electrical contact strips, washers and terminals.

Sheet Metal Forming – For busbars, shrouds, copper enclosures, press-fit components and grounding strips.

Pressing & Deep Drawing – Used for clips, clamps, housings and structural Copper parts.

Threading, Knurling & Secondary Finishing – For completed industrial Copper Components.

Machinery Used in Copper Component Manufacturing

Our advanced facility includes:

CNC Turning Centers (Fanuc/Siemens control)

Sliding-Head Auto Lathes

VMC 3-Axis & 4-Axis

SPMs for high-volume production

Hydraulic & Mechanical Presses

Forging Hammers (0.5–3 Ton)

Turret Punch Press

Laser Cutting (for sheet metal)

Deburring Machine, Vibro Polishers

Spectrometer, CMM, Profile Projector, Surface Roughness Tester

Typical Copper Parts We Manufacture

Copper CNC Turned Parts

Copper Machined Connectors

Copper Busbar Components

Copper Forged Clamps & Joints

Copper Stamped Electrical Terminals

Copper Milled Blocks & Heat-Sink Bases

Copper Inserts, Bushings, Sleeves

Copper Pressed Brackets

Copper Sheet Metal Components

Custom Copper Fittings for Mechanical & Electrical Assemblies

Dimensional Drawing Example (Simplified Line Diagram)

Table: Example Dimensional Capabilities

| Parameter | Minimum | Maximum |

|---|---|---|

| Length (L) | 3 mm | 400 mm |

| Width (W) | 3 mm | 250 mm |

| Hole Diameter (D) | 1.5 mm | 50 mm |

| Thickness | 0.5 mm | 40 mm |

| CNC Turning Diameter | 2 mm | 120 mm |

(Custom sizes also accepted.)

Surface Finishes / Plating Options

| Finish Type | Standard | Use Case |

|---|---|---|

| Tin Plating | Matte/Bright | Electrical contacts, anti-corrosion |

| Nickel Plating | Bright | High wear resistance |

| Silver Plating | 3–8 μm | High-current conduction |

| Gold Plating | Selective | Sensor & communication hardware |

| Passivation | Clear | Oxidation resistance |

| Powder Coating | Custom colors | Mechanical part finishing |

| Natural Degreased Finish | As-machined | General industrial |

Industries Using Copper Parts

Electrical & Power Distribution

Transformers & Switchgear

Renewable Energy – Solar, Wind, EV Charging

HVAC, Refrigeration & Air-conditioning

Automotive & Rail Electronics

Telecom, Instrumentation & Sensors

Defense & Marine Equipment

Heavy Engineering, Pumps & Valves

Tolerances (General Guidelines)

| Process | Typical Tolerance |

|---|---|

| CNC Turning | ±0.02 mm |

| CNC Milling | ±0.03 mm |

| Stamping | ±0.05 mm |

| Forging (machined) | ±0.10 mm |

| Sheet Metal | ±0.15 mm |

Tighter tolerances available upon request.

Performance Metrics (As Applicable)

| Property | Typical Value |

|---|---|

| Electrical Conductivity | 97–101% IACS |

| Thermal Conductivity | 380–400 W/m-K |

| Tensile Strength | 200–350 MPa (grade-dependent) |

| Yield Strength | 60–180 MPa |

| Hardness | 45–110 HB |

| Corrosion Resistance | Excellent in most industrial atmospheres |

Turnaround Time

Standard production lead time: 4–6 weeks

Fast-track orders: Available depending on complexity

Prototyping: 10–15 days

Packaging & Shipping

We offer export-grade packaging including:

Vacuum sealing

Anti-oxidation film

Polybags with customer logo

Bubble sheets, foam trays, corrugated boxes

Palletised wooden crates (fumigated)

Barcode / QR code / LOT traceability

Worldwide shipping via DHL, FedEx, UPS, EMS, Air Freight, Sea Freight.

Why Choose Us (Manufacturer in India With 30+ Years of Global Experience)

We provide:

Faster turnaround and flexible production schedules

Superior customer support and excellent communication

Engineering assistance for drawing optimisation

Ability to customise parts in any Copper grade

Manufacturing expertise across multiple metals including Brass, Copper, Bronze and Stainless Steel

Experience of exporting globally for more than 30 years

Custom packaging with customer labels, logo and branding

Ability to handle both small prototype orders and large production volumes

Our global clients choose us because we deliver consistent quality, reliable logistics, and transparent communication.

Customer Testimonials

John Peterson (USA)

“We have been sourcing Copper machined components from this supplier for years. Excellent dimensional accuracy, steady quality and very responsive support. Highly recommended.”

Matthew Clarke (UK)

“Their engineering team helped us optimise our part design, reducing weight and cost without compromising performance. Superb manufacturing partner with outstanding communication.”

Typical Customer Q&A (With Embedded Keywords)

1. What Copper grades do you use for CNC machining?

We use ETP Copper (C11000), OFC Copper (C10100), Tellurium Copper, Chromium Copper and custom alloys depending on conductivity, machinability and strength.

2. Can you manufacture custom-designed Copper Parts?

Yes, we specialise in customised Copper machined components based on drawings, samples or customer specifications.

3. What is your typical turnaround time for Copper Components?

Standard lead time is 4–6 weeks, but urgent orders can be fast-tracked depending on complexity.

4. Do you offer plating on Copper machined parts?

We provide Tin, Nickel, Silver, Gold and custom plating finishes with precise thickness control.

5. What tolerances can you achieve on CNC turned Copper parts?

We typically achieve ±0.02 mm on turning and ±0.03 mm on milling depending on part geometry.

6. Can you export Copper parts to USA, Europe and Australia?

Yes, we are a long-established exporter supplying customers across USA, UK, Canada, Australia and EU.

7. Do you provide drawings or design improvements?

Our engineering team can modify drawings to improve manufacturability and cost efficiency.

8. What packaging options are available for Copper Components?

Export-grade packaging, anti-oxidation films, labelled bags and custom branding options are available.

9. Are your Copper Forged Parts heat-treated?

Yes, certain Copper alloys undergo age-hardening or stress-relief processes depending on design.

10. What industries commonly use your Copper machined parts?

Electrical, automotive, renewable energy, switchgear, transformers, telecom and industrial machinery.

11. Can you supply Copper parts with UL or RoHS compliance?

Yes, we can source certified materials and provide compliance documentation.

12. Do you offer small quantity or prototype Copper Components?

Yes, prototypes can be produced within 10–15 days.

13. Can you combine Copper and Brass in a single assembly?

Yes, we manufacture hybrid assemblies using Copper, Brass and Stainless Steel.

14. What inspection equipment do you use?

We use CMM, spectrometer, height gauge, surface tester and profile projector.

15. Do you ship with part traceability?

Yes, we offer batch numbers, heat numbers, barcodes and QR codes for full traceability.

Glossary of Terms

IACS – International Annealed Copper Standard used to define electrical conductivity.

OFC Copper – Oxygen-Free Copper known for ultra-high conductivity.

ETP Copper – Electrolytic Tough Pitch Copper used for electrical Copper Components.

CNC Turning – High-precision machining for round-profile Copper Parts.

CNC Milling – Multi-axis machining for complex shapes and Copper blocks.

Forging – Hot-working process to enhance strength of Copper Forged Parts.

Stamping – High-speed metal pressing for flat Copper terminals and washers.

Tolerance – Allowed dimensional variation in machined Copper Components.

Plating Thickness – Micron-level coating applied to Copper Parts for conductivity or protection.

Related parts:

Copper Machined Parts

Copper CNC Turned Components

Copper Forged Clamps

Copper Stamped Electrical Terminals

Copper Sheet Metal Components

Custom Copper Connectors

Copper Busbar Parts

High-Conductivity Copper Components

Precision Copper Industrial Parts Manufacturer

Copper Machining Services India

CTA-

For enquiries, quotations or technical discussions, please email us or contact us on phone/WhatsApp. We will be happy to share drawings, brochures, sample photos and customised pricing.