HOTLINE CLAMPS – LIVELINE CLAMPS

Hotline Clamps and Liveline Clamps: High-Performance Electrical Connectivity Solutions

The modern electrical grid demands uncompromising reliability, and our range of precision-engineered connectors provides exactly that for high-voltage utility applications. We are one of the leading manufacturers and exporters of Hotline Clamps and Liveline Clamps from India. We have been supplying high-quality Bronze and Aluminium electrical connectors to the world market for many decades. Our expertise lies in crafting durable, corrosion-resistant distribution and transmission hardware that facilitates seamless hot-tap connections under load. By utilizing advanced metallurgy and rigorous testing protocols, we ensure that every Bronze Hotline Clamp and Aluminium Stirrup Bail Clamp meets the stringent safety requirements of global utilities. Our facility integrates decades of manufacturing heritage with modern CNC technology to deliver products that withstand extreme environmental stressors while maintaining optimal electrical conductivity. Whether you are managing an urban distribution network or a remote rural electrification project, our components offer the mechanical strength and thermal stability necessary for long-term service life.

PRICE: US$ 4.20/each

Comprehensive Product Overview and Material Engineering

Our Hotline Clamps (also known as live-line connectors) are specifically designed for making branch connections to overhead lines without de-energizing the circuit. These connectors feature a “duckbill” or “C-clamp” design that allows linemen to install them using an insulated shotgun stick or hot-stick. The engineering focus here is on contact pressure and surface area; our clamps utilize high-strength Bronze or Aluminium alloys to minimize resistance and heat generation. We cater to a wide range of conductor types, including ACSR, AAC, and AAAC, ensuring that the bimetallic interfaces are managed correctly through specialized plating and inhibitors. Our production line adheres to international quality benchmarks, ensuring that thread tolerances on the eye-bolts are precise enough to prevent seizing during high-torque installations in the field.

Specialized Variants and Applications

Bronze Hotline Clamps are the industry standard for copper-to-copper or copper-to-aluminum connections where maximum mechanical strength and corrosion resistance are non-negotiable. We cast these using high-grade Bronze alloys that exhibit superior tensile strength, making them ideal for heavy-duty industrial environments and coastal regions where salt-spray corrosion is a significant threat. These clamps are often fitted with tin-plating to facilitate bimetallic compatibility, preventing galvanic corrosion at the contact point.

Bronze Liveline Clamps serve a critical role in tap-off applications where the main line remains energized. These are engineered with a wide-jaw profile to accommodate various wire diameters while ensuring a secure, vibration-proof grip. Our Bronze variants are favored by utilities in Europe and the USA for their longevity and ability to maintain constant spring-pressure over decades of thermal cycling, which is essential for preventing power losses and potential line failures.

Aluminium Hotline Clamps are manufactured from high-strength, heat-treated Aluminium alloys, offering a lightweight yet robust solution for aluminium-to-aluminium distribution lines. These clamps are often preferred for their excellent strength-to-weight ratio and natural resistance to atmospheric oxidation. We treat the contact surfaces with specialized conductive grit and oxidation inhibitors to ensure that the electrical interface remains clean and efficient even in fluctuating weather conditions.

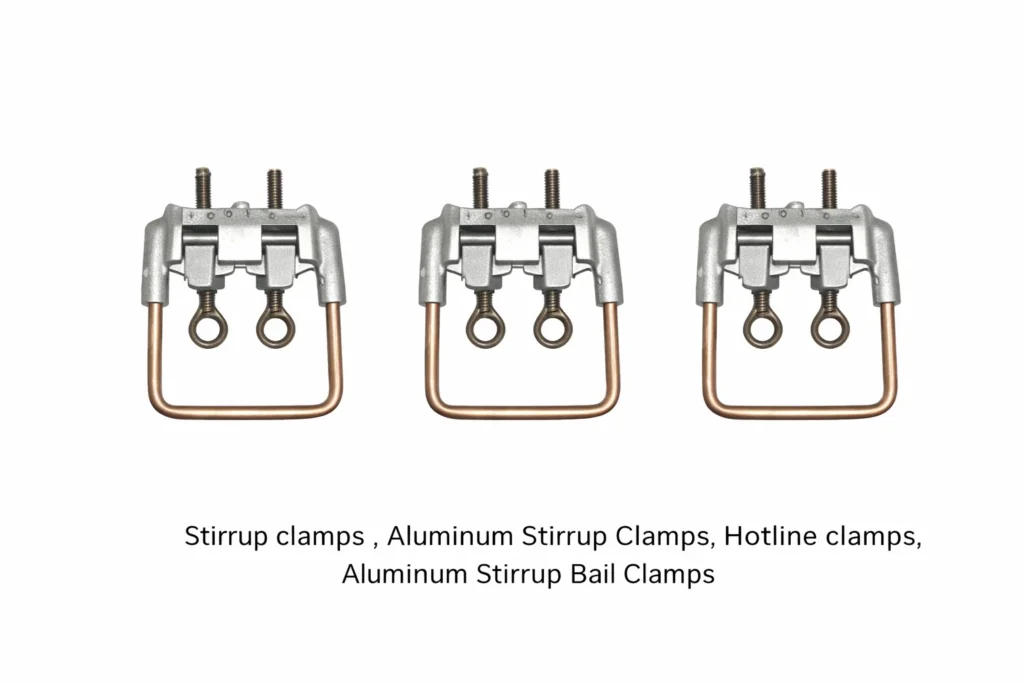

Aluminium Stirrup Bail Clamps provide a unique solution for protecting the main conductor from arcing and mechanical wear during frequent tap-on and tap-off operations. By providing a dedicated contact point (the bail), these clamps preserve the integrity of the primary cable. Our stirrups are designed with high-conductivity Copper or Aluminium bails, ensuring that the electrical transfer is smooth and the mechanical attachment to the main line remains permanent and undisturbed.

Global Material Standards and Technical Specifications

We manufacture our components using a variety of international material grades to ensure compatibility with localized engineering requirements across the globe.

| Region / Standard | Bronze Alloys (Cast/Forged) | Aluminium Alloys (Cast/Forged) |

| USA (ASTM) | ASTM B584 (C83600, C84400), B148 | ASTM B26 (356.0), B209 (6061) |

| International (ISO) | ISO 1338 (CuSn5Zn5Pb5) | ISO 3522 (AlSi7Mg) |

| Europe (DIN/EN) | DIN 1705 (RG5), EN 1982 | EN 1706 (AC-42100) |

| UK (BS) | BS 1400 (LG2, LG4) | BS 1490 (LM25, LM6) |

| Japan (JIS) | JIS H5121 (CAC406) | JIS H5202 (AC4C) |

| India (IS) | IS 318 (LTB2), IS 306 | IS 617 (4600), IS 737 |

Manufacturing Process: Our production workflow involves high-pressure die casting, gravity casting, or hot forging depending on the specific mechanical requirements. Following the primary shaping, components undergo precision CNC machining to define thread profiles and contact grooves. We utilize automated Shot Blasting and Vibratory Finishing to remove burrs and improve surface smoothness.

Machinery Used:

High-Pressure Casting Machines (250T – 600T)

CNC Turning Centers and VMC (Vertical Machining Centers)

Thread Rolling Machines for high-strength eyebolts

Electroplating lines for Tin, Silver, and Nickel finishes

Typical Parts Produced: Main clamp bodies, eyebolts, pressure pads, bails, stirrups, washers, and specialized terminal connectors for transformers and switchgear.

Dimensional Data and Performance Metrics

The following table represents a standard size chart for our most common Hotline Clamps. Note that we provide custom sizing based on specific conductor diameters.

| Part Ref | Main Line Range (mm) | Tap Line Range (mm) | Bolt Torque (Nm) | Rated Amps | Material Type |

| HL-B-01 | 6.0 – 15.0 | 4.0 – 10.0 | 25 – 30 | 300A | Bronze |

| HL-A-05 | 8.0 – 22.0 | 5.0 – 18.0 | 20 – 25 | 450A | Aluminium |

| ST-AB-12 | 10.0 – 35.0 | 6.0 – 20.0 | 35 – 40 | 600A | Al-Stirrup |

Tolerances: We maintain a general machining tolerance of $\pm 0.1mm$ for critical dimensions and $6g/6H$ for threaded components.

Turnaround Time: Standard orders are typically processed and ready for dispatch within 4 to 6 weeks, depending on the volume and customization requirements.

Why Choose Our Clamps? (The Manufacturer Advantage)

Selecting a partner for electrical infrastructure is a decision based on trust and technical capability. Here is why global procurement managers choose us:

Three Decades of Global Exposure: We have navigated the complexities of international trade and utility requirements for over 30 years, exporting to over 40 countries.

Engineering Consultancy: Our in-house engineering team doesn’t just take orders; we suggest technical drawing improvements to reduce costs and enhance field performance.

Customization and Flexibility: From custom branding and logos to specific alloy mixtures, we offer a level of flexibility that large-scale generic manufacturers cannot match.

Superior Packaging: We provide seaworthy, customized packaging with customer labels and QR codes for easy warehouse management at the destination.

Quality Assurance: Every batch undergoes rigorous testing, including conductivity tests, tensile strength verification, and salt spray testing for plating durability.

Technical Questions and Answers (Q&A)

Q1: What is the primary function of a Bronze Hotline Clamp in a distribution network?

A1: These clamps are used to connect tap conductors to energized primary lines. They provide a secure mechanical and electrical bridge, allowing utilities to expand or maintain the grid without interrupting power to existing customers.

Q2: Can Aluminium Hotline Clamps be used with Copper conductors?

A2: Yes, but only if they are specially plated (usually with Tin) and used with a high-quality joint inhibitor compound to prevent galvanic corrosion and oxidation between the dissimilar metals.

Q3: What are the benefits of using a Stirrup Bail Clamp over a standard tap?

A3: A stirrup protects the main conductor from “burning” or arcing damage caused by repeatedly installing and removing hot-line taps. The contact is made on the bail rather than the expensive primary wire.

Q4: How do you ensure the eyebolts do not seize over time?

A4: We use precision thread rolling and apply high-quality lubrication or specialized plating to ensure that the threads remain functional even after years of exposure to harsh outdoor elements.

Q5: What international standards do your Bronze Live line clamps follow?

A5: Our products are designed to meet or exceed ASTM B584 and BS 1400 standards, ensuring they meet the mechanical and chemical requirements for high-voltage electrical hardware.

Q6: Do you provide custom packaging for retail or utility-specific labeling?

A6: Absolutely. We offer customized packaging solutions, including barcoding, private labeling, and specific box quantities as per the importer’s or utility’s internal logistical requirements.

Q7: What is the typical lead time for an export order to the USA or Europe?

A7: Our standard production turnaround time is 4-6 weeks. Shipping time varies by destination, but we prioritize production schedules to meet urgent grid maintenance windows.

Q8: What finishes are available for corrosive environments?

A8: We offer Electro-tin plating, Silver plating, and Nickel finishing. For specific heavy-duty applications, we can also provide specialized coatings to withstand high-salinity coastal air.

Q9: How do you verify the electrical conductivity of the alloys used?

A9: We conduct melt-analysis for every batch using spectrometers and perform electrical resistance tests on the finished components to ensure they meet IACS (International Annealed Copper Standard) percentages.

Q10: Are your clamps suitable for ACSR (Aluminium Conductor Steel Reinforced) lines?

A10: Yes, our Aluminium and Bronze clamps are designed with jaw profiles that specifically accommodate the outer strands of ACSR without causing mechanical deformation or strand breakage.

Q11: Can your engineering team help modify a design for a specific tap size?

A11: Our team specializes in DFM (Design for Manufacturing). We can take your existing field requirements and suggest modifications to the clamp jaw or bail length for better performance.

Q12: What is the maximum voltage rating for these connectors?

A12: While the clamp itself is a conductor, it is typically used in distribution and transmission systems ranging from 11kV to 35kV, depending on the insulation clearances provided by the installation.

Q13: Why is Bronze preferred over Brass for these applications?

A13: Bronze offers superior tensile strength and better resistance to stress corrosion cracking compared to Brass, making it far more reliable for outdoor, high-tension electrical hardware.

Q14: Do you offer inspection reports with the shipments?

A14: Yes, every shipment is accompanied by a Material Test Certificate (MTC), dimensional inspection reports, and plating thickness verification as part of our quality protocol.

Q15: How do you handle bimetallic connections in your Stirrup Clamps?

A15: We utilize friction-welding or high-pressure mechanical bonding for bimetallic components, ensuring that the interface between Aluminium and Copper is hermetically sealed against moisture.

Customer Testimonials

“We have been sourcing Bronze Hotline Clamps from this Indian manufacturer for over five years. Their attention to thread tolerances and the consistency of their tin-plating is far superior to other vendors we’ve tried. Their ability to customize labels for our US distribution hubs has streamlined our logistics significantly.”

— Mark Richardson, Procurement Manager, USA

“Switching to their Aluminium Stirrup Bail Clamps helped us reduce line fatigue issues in our Canadian network. The engineering team was incredibly helpful in tweaking the bail dimensions to fit our specific hot-stick tools. Reliable, fast, and very professional communication.”

— Sarah Jenkins, Senior Grid Engineer, Canada

Glossary of Terms

Hot-Stick: An insulated pole used by linemen to work on energized high-voltage lines.

Bimetallic Corrosion: An electrochemical process where one metal corrodes when in electrical contact with another in the presence of an electrolyte.

IACS: International Annealed Copper Standard, a unit of electrical conductivity for metals.

ACSR: Aluminium Conductor Steel Reinforced; a type of high-capacity, high-strength stranded conductor.

Tap Conductor: A wire that branches off the main primary line to provide power to a transformer or another circuit.

Shipping and Packaging Information

We understand that electrical hardware is heavy and prone to surface damage during transit. Our Aluminium and Bronze components are individually poly-bagged to prevent oxidation and then packed into heavy-duty corrugated boxes. For sea freight, these boxes are palletized and shrink-wrapped with edge protectors. We offer FOB, CIF, and DDU shipping terms to all major global ports including New York, London, Hamburg, and Sydney.

Related Parts: Parallel Groove Clamps, Wedge Connectors, Split Bolt Connectors, Insulation Piercing Connectors, Grounding Clamps, Transformer Bushing Connectors, Dead-end Clamps.

Updated: 2026

Ready to upgrade your grid infrastructure? Contact us today for a Technical Brochure or a Custom Quote.