Aluminium Bronze casting, Aluminum Bronze Fittings, Aluminum Bronze Parts, Aluminum Bronze Sand Casting, Aluminum Bronze Permanent Mold casting, Aluminum Bronze Machined components, Aluminum Bronze Investment casting

Price US$ 12.35/Kilogram

Aluminium Bronze Casting, Components, and Machined Fittings | Precision Exporter from India

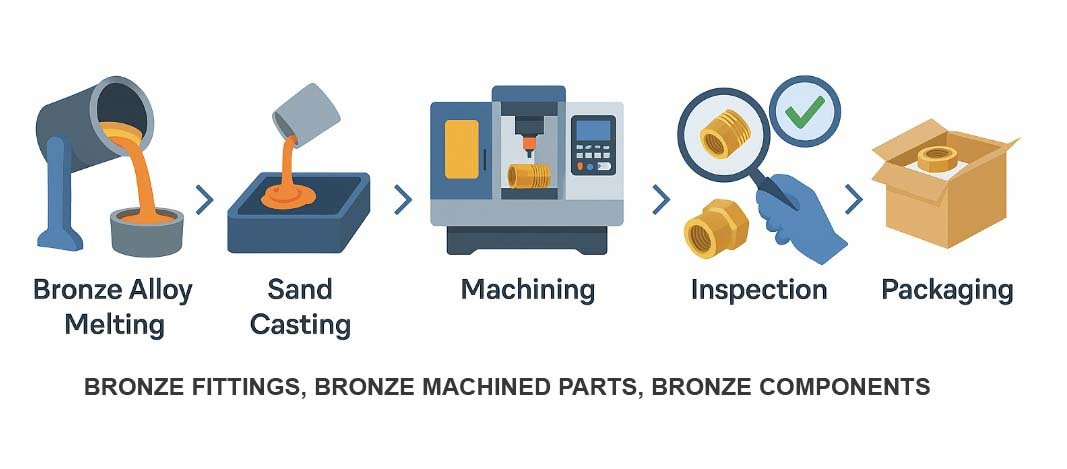

We are one of the leading manufacturers and exporters of Aluminium Bronze Castings, Bronze Fittings, and Precision Machined Parts from India from various Aluminium Bronze alloys including Ab1 ,Ab2 ,C95500, C95800 etc. We have been supplying high-performance, corrosion-resistant Aluminium Bronze components to the world market for many decades. Our manufacturing capabilities span sand casting, permanent mold casting, and investment casting in Aluminium Bronze alloys conforming to ASTM, BS, DIN, and JIS standards. With over 30 years of global exposure, our foundry and machine shop are equipped to produce custom parts for marine, oil & gas, defense, aerospace, mining, and heavy industrial applications. Our range of Phosphor Bronze casting, Phosphor Bronze Fittings , Phosphor Bronze machined parts and components is accepted well in the world.

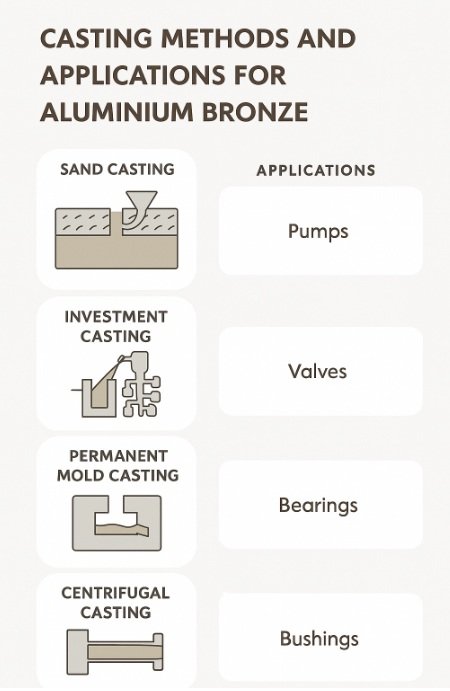

Aluminium Bronze Casting Aluminium Bronze Castings are produced using high-performance Copper-Aluminium alloys that offer superior resistance to seawater, chemical corrosion, and wear. We cast to international specifications including ASTM B148 (C95200 to C95900), BS 1400 AB1/AB2, DIN 1705 G-CuAl10Ni5Fe4, and JIS H5120 CAC702/703. Our processes include shell molding, gravity die casting, and investment casting. Typical components include impellers, pump housings, valve bodies, and flanges.

Aluminum Bronze Fittings Our Aluminum Bronze Fittings include elbows, tees, reducers, adapters, unions, and threaded or flanged pipe connectors used in corrosive fluid handling and offshore environments. Produced as per ANSI, ASME B16.15, and ISO standards, these fittings are available with BSP/NPT threads, socket weld, or grooved ends. Material grades used include C95400, C95500, and AB2 with precision machining and leak-proof assembly.

Aluminum Bronze Parts We supply a broad range of Aluminum Bronze Parts including sliding bearings, guides, wear plates, nuts, couplings, sealing rings, and customized forgings or castings. All parts are engineered from marine-grade alloys such as C95800 or CuAl10Fe5Ni5, offering high strength, impact resistance, and galling resistance under extreme pressure and temperature conditions.

Aluminum Bronze Sand Casting Our Sand Casting operations for Aluminum Bronze are capable of handling up to 1,000 kg per casting using green sand, CO2 molds, and chemically bonded sands. This method is ideal for large and complex components such as pump casings, gear housings, and centrifugal sleeves. Strict controls ensure dimensional accuracy, minimal porosity, and consistent microstructure with post-casting heat treatment.

Aluminum Bronze Permanent Mold Casting For high-volume, dimensionally consistent components, we offer gravity Permanent Mold Casting using pre-heated steel molds. This technique produces parts with better surface finish and mechanical properties compared to sand casting. Typical items include bearings, valve trims, and marine propeller hubs. This process ensures low shrinkage, improved strength, and tight tolerance control.

Aluminum Bronze Machined Components We machine Aluminum Bronze castings and forgings using CNC lathes, VMCs, and precision boring machines to produce components with fine surface finish and strict dimensional tolerances. Our capabilities include 4-axis machining, deep boring, threading, and surface grinding. Machined parts include valve internals, hydraulic adapters, turbine rings, and engine sleeves.

Aluminum Bronze Investment Casting Investment Casting enables production of intricate, high-precision Aluminum Bronze parts with excellent repeatability. Ideal for aerospace, instrumentation, and defense applications, our wax-based precision casting systems offer tight tolerances, thin walls, and excellent surface finish. All castings undergo non-destructive testing, shot blasting, and dimensional inspection.

Material Grades and Standards

USA (ASTM / UNS Standards) for Aluminum Bronze

| ASTM/UNS | Alloy Name | Typical Composition | Applications |

|---|---|---|---|

| C95200 | General Purpose AB | Cu ~90%, Al 8.5%, Fe 0.5% | Bearings, bushings |

| C95300 | High Strength AB | Cu ~88%, Al 10.5%, Fe 1.5% | Marine hardware |

| C95400 | Aluminium Bronze | Cu ~85%, Al 10–11%, Fe 4% | Pumps, gears |

| C95500 | Nickel AB | Cu ~80%, Al 10%, Ni 5%, Fe 5% | Aerospace, valves |

| C95510 | High Strength | Cu ~78%, Al 10%, Ni 5.5%, Fe 5% | Wear parts |

| C95800 | Nickel AB (Marine Grade) | Cu ~83%, Al 9%, Ni 4.5%, Fe 3.5% | Saltwater resistance |

| C95900 | Ultra High Strength | Cu ~82%, Al 10.5%, Fe 3.5%, Ni 3.5% | High-load components |

🇬🇧 UK (BS 1400 Standard)

| BS 1400 | Equivalent | Composition | Applications |

|---|---|---|---|

| AB1 | ~C95400 | Cu ~89%, Al 10%, Fe 1% | General-purpose |

| AB2 | ~C95800 | Cu ~79%, Al 10%, Fe 5%, Ni 5% | Marine & seawater service |

| PB1 | Tin Bronze | Cu ~85%, Sn 10%, Pb 5% | Bearings (not Al bronze but related) |

🇩🇪 Germany (DIN / EN Standards)

| DIN / EN | Name | Composition | Notes |

|---|---|---|---|

| G-CuAl10Ni5Fe4 | EN 1982 | Cu ~80%, Al 10%, Ni 5%, Fe 4% | Standard for valve parts, marine |

| CuAl11Fe6Ni6 | EN 1982 | Cu ~77%, Al 11%, Fe 6%, Ni 6% | Heavy-duty, high strength |

| CuAl10Fe3Mn2 | EN 1982 | Cu ~83%, Al 10%, Fe 3%, Mn 2% | Good weldability, toughness |

🇨🇳 China (GB/T Standards)

| GB/T | Alloy Code | Composition | Applications |

|---|---|---|---|

| ZCuAl10Fe3 | Equivalent to C95400 | Cu ~87%, Al 10%, Fe 3% | Pump impellers, sleeves |

| ZCuAl9Mn2 | — | Cu ~89%, Al 9%, Mn 2% | Corrosion-resistant parts |

| ZCuAl10Ni5Fe4 | Close to G-CuAl10Ni5Fe4 | Cu ~80%, Al 10%, Ni 5%, Fe 4% | Valves, flanges |

🇯🇵 Japan (JIS Standards)

| JIS | Alloy Name | Composition | Use |

|---|---|---|---|

| CAC702 | AB | Cu ~85%, Al ~10%, Fe/Ni ~5% | High-strength castings |

| CAC703 | Nickel AB | Cu ~80%, Al 10%, Ni 5%, Fe 5% | Heat & seawater resistant parts |

| CAC406 | Low Al AB | Cu ~92%, Al ~5%, Fe/Ni | Light-duty applications |

⚙️ Comparison Across Standards (Typical Matches)

| US (ASTM) | UK (BS) | DE (DIN/EN) | JP (JIS) | CN (GB) |

|---|---|---|---|---|

| C95400 | AB1 | CuAl10Fe3 | CAC702 | ZCuAl10Fe3 |

| C95500 | — | CuAl10Ni5Fe4 | CAC703 | ZCuAl10Ni5Fe4 |

| C95800 | AB2 | CuAl10Ni5Fe4 | CAC703 | — |

| Standard | Grade | Composition | Description |

|---|---|---|---|

| ASTM B148 | C95400 | Cu-Al-Fe | General Purpose AB casting |

| ASTM B148 | C95500 | Cu-Al-Ni-Fe | High strength marine & aerospace grade |

| ASTM B148 | C95800 | Cu-Al-Ni-Fe | Sea water corrosion-resistant |

| BS 1400 | AB1, AB2 | CuAl10Fe3 / CuAl10Fe5Ni5 | British marine and pump grade |

| DIN 1705 | G-CuAl10Ni5Fe4 | German alloy for heavy-duty parts | |

| JIS H5120 | CAC702, CAC703 | Japanese precision casting bronze |

| Alloy Description | UNS | SAE | German Spec | British Spec | Typical Applications | |||||||

| Cu85 Sn5 Zn5 Pb5 | C83600 | 40 | CuSn5ZnPb | LG2 | Pump components, small gears, bearings, impellers, flanges, low pressure valves and fittings. | |||||||

| Cu83 Sn3 Zn8 Pb6 | C84400 | – | CuSn2ZnPb | *LG1 | Light duty bearings, general hardware, fixtures, low pressure valves and fittings. | |||||||

| Cu63 Al6 Fe3 Mn3 Zn25 | C86300 | 430B | – | – | Heavy duty high strength alloy for gears, cams, slow speed heavy load bearings, screw down nuts. | |||||||

| Cu88 Sn8 Zn4 | C90300 | 620 | – | – | Bearings, bushings, piston rings, valve components, seal rings, steam fittings and gears. | |||||||

| Cu88 Sn10 Zn2 | C90500 | 62 | CuSn10Zn | *G1 | Marine pumps, valves, bearings, bushings, piston rings, steam fittings and gears. | |||||||

| Cu89 Sn11 | C90700 | 65 | CuSn12 | *PB1 | Heavy duty gears, high load bearings, bushings and worm wheels. | |||||||

| Cu88 Sn6 Zn4 Pb2 | C92200 | 622 | – | LG3 | Valves, fittings, Medium-pressure hydraulic and steam pressure parts for use up to 550 F (287 C). | |||||||

| Cu87 Sn11 Ni2 | C92500 | 640 | CuSn12Ni | CT2 | Gears, worm wheels – Good shock resistance, Automotive synchronizer rings. | |||||||

| Cu87 Sn11 Pb2 | C92700 | 63 | CuSn12Pb | LB3 | Heavy duty bearings, bushings, piston rings, valve components, steam fittings, gears. | |||||||

| Cu83 Sn7 Zn3 Pb7 | C93200 | 660 | CuSn7ZnPb | – | General utility bearings, bushings and wear plates for medium speeds and pressures. | |||||||

| Cu85 Pb10 Sn5 | C93500 | 66 | – | LB4 | High speed bearings, bushings, high speed light loading and light pressure parts. | |||||||

| Cu80 Pb10 Sn10 | C93700 | 64 | CuPb10Sn | LB2 | Bearings for high speed and heavy pressures, pump parts, pressure tight castings. | |||||||

| Cu78 Pb15 Sn7 | C93800 | 67 | CuPb15Sn | LB1 | Turbocharger bearings, bearings for general service and moderate pressures, railroad applications. | |||||||

| Cu75 Pb20 Sn5 | C94100 | 94 | CuPb20Sn | LB5 | High speed bearings for moderate loads, anti-seizing, conforms to shaft irregularities. | |||||||

| Cu87 Al10 Fe3 | C95400 | – | CuAl10Fe | – | High strength bearings, bushings, gears, worms, wear plates, valve seats and guides. | |||||||

| Cu81 Al10 Ni5 Fe4 | C95500 | – | CuAl10Ni | – | High strength bearings, corrosion resistant parts, aircraft valve guides and seats. | |||||||

| Cu80 Al10 Ni6 Fe4 | C95800 | – | CuAl10Ni | AB2 | Anti-fouling salt water corrosion resistant parts and general marine hardware. | |||||||

| Cu83 Sn7 Zn3 Pb7 | C93200 | 660 | CuSn7ZnPb | – | General utility bearings, bushings and wear plates for medium speeds and pressures. | |||||||

| Cu85 Pb10 Sn5 | C93500 | 66 | – | LB4 | High speed bearings, bushings, high speed light loading and light pressure parts. | |||||||

| Cu80 Pb10 Sn10 | C93700 | 64 | CuPb10Sn | LB2 | Bearings for high speed and heavy pressures, pump parts, pressure tight castings. | |||||||

| Cu78 Pb15 Sn7 | C93800 | 67 | CuPb15Sn | LB1 | Turbocharger bearings, bearings for general service and moderate pressures, railroad applications. | |||||||

| Cu75 Pb20 Sn5 | C94100 | 94 | CuPb20Sn | LB5 | High speed bearings for moderate loads, anti-seizing, conforms to shaft irregularities. | |||||||

| Cu87 Al10 Fe3 | C95400 | – | CuAl10Fe | – | High strength bearings, bushings, gears, worms, wear plates, valve seats and guides. | |||||||

| Cu81 Al10 Ni5 Fe4 | C95500 | – | CuAl10Ni | – | High strength bearings, corrosion resistant parts, aircraft valve guides and seats. | |||||||

| Cu80 Al10 Ni6 Fe4 | C95800 | – | CuAl10Ni | AB2 | Anti-fouling salt water corrosion resistant parts and general marine hardware.

| |||||||

Machinery Used

- Induction Melting Furnaces (up to 1 ton)

- CNC Turning, VMC Machining Centers

- Shell & CO2 Molding Lines

- Die-Casting Machines

- Spectrometer, UT, MPI, Hardness Testers

Tolerances & Dimensional Range

| Parameter | Range / Tolerance |

| Casting Size | Up to 1000 mm dia / 1000 kg |

| Machining Tolerance | ±0.01 mm |

| Surface Finish | Up to Ra 1.6 µm |

| Threads | ISO Metric, UNF, NPT, BSP |

Finishes Available As-cast, Shot-Blasted, Machined, Polished, Passivated, Oil-Sealed, Epoxy Coated

Industries Served

- Marine and Shipbuilding

- Oil & Gas Exploration

- Petrochemical & Offshore

- Aerospace & Defense

- Water Treatment & Pumps

- Cement & Mining Equipment

Turnaround Time Standard lead time: 4–6 weeks, with urgent order handling capability.

Performance Metrics

- Tensile Strength: 600–850 MPa

- Yield Strength: 250–500 MPa

- Hardness: 120–180 HB

- Elongation: 10–15%

- Salt Spray Resistance: >1000 hrs for coated parts

Why Choose Us

- 30+ years of global export experience across Europe, USA, and Asia

- ISO 9001:2015 certified systems with full traceability

- CAD/CAM & simulation support for accurate modeling

- Custom packaging, logo marking, and laser engraving options

- Responsive technical support and multilingual team

Packaging & Shipping All parts are packed using moisture-barrier VCI wrap, desiccants, and export-grade wooden boxes or cartons. Barcoded labels, QR codes, and customer-specific packing available.

Customer Testimonial “Conex has been our go-to partner for custom Aluminium Bronze impellers and pump parts. The casting quality, turnaround, and their ability to adapt to our changing specs have been outstanding.” — Steve H., Houston, Texas, USA

Typical Q & A

- Do you provide test reports? — Yes, including Chemical, Mechanical & NDT.

- Can you reverse engineer from samples? — Yes, using 3D scanning.

- Do you export globally? — Yes, across Europe, USA, Middle East.

- Can you supply machined + raw castings? — Yes.

- Are materials certified? — Yes, as per ASTM, BS, JIS, DIN.

- Can you do pressure/leak testing? — Yes, hydro & pneumatic tests.

- Minimum order quantity? — From 10 pieces onwards.

- Do you do coatings? — Yes, epoxy, zinc, nickel, chrome.

- Are alloys RoHS compliant? — Yes.

- How are parts packed? — As per international export standards.

Glossary of Terms

- Aluminium Bronze: A corrosion-resistant Copper alloy with Aluminium and other elements.

- Sand Casting: Traditional mold casting with sand molds.

- Investment Casting: Precision casting using wax patterns.

- Permanent Mold Casting: Gravity die casting using steel molds.

- Machined Components: Parts processed to precision dimensions.

Related Terms Aluminum Bronze Valve Bodies, C95800 Bronze Castings, Machined Bronze Fittings, Marine Bronze Flanges, AB2 Casting Foundry India , Bronze casting foundry, Aluminum Bronze Hotline clamps, Bronze vise Connectors, Bronze transformer spade terminals, Bronze Connector,

Casting Methods and Applications for Aluminium Bronze

For custom quotes, datasheets, or samples, email us or WhatsApp us to request a quote now.