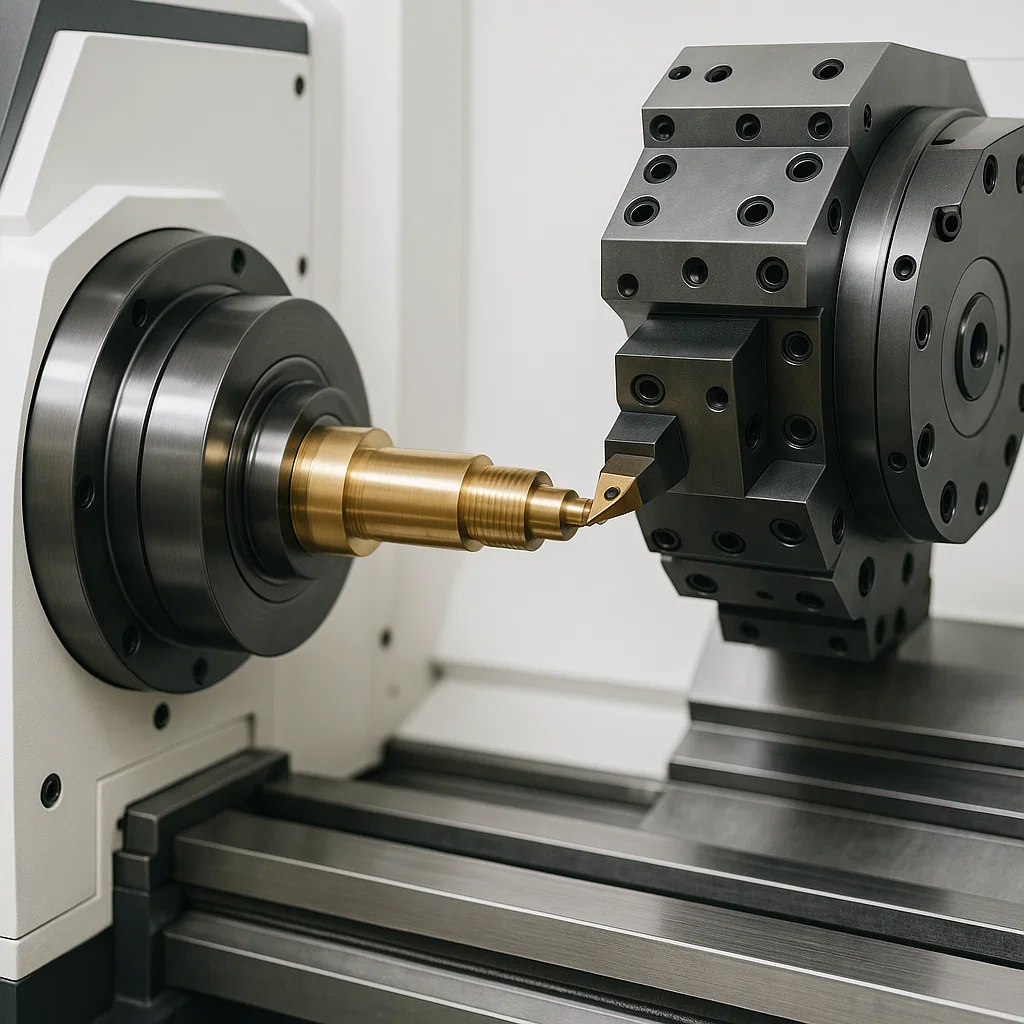

Precision Brass CNC Machined Parts , Brass CNC Turned Components and

Price: US$ 12.30/kilogram

We are one of the leading manufacturers and exporters of precision Brass CNC machined parts and turned components from India. We have been supplying high-quality Brass components to the world market for many decades. Our state-of-the-art manufacturing facility combines advanced CNC machining technology with traditional craftsmanship to deliver superior quality Brass components that meet the most demanding specifications. With over three decades of experience in precision machining, we have established ourselves as a trusted partner for industries requiring critical Brass components worldwide. Our comprehensive range includes standard and custom Brass CNC machined parts, precision turned components, screw machine parts, and specialized alloy variants including DZR Brass and Lead Free Brass components. We maintain stringent quality control measures throughout our manufacturing process, ensuring every component meets international standards including ASTM, DIN, BS, IS, and JIS specifications. Our commitment to excellence, combined with competitive pricing and reliable delivery schedules, makes us the preferred choice for OEMs and distributors across global markets.

Brass CNC Machined Parts

Brass CNC machined parts represent the pinnacle of precision manufacturing, combining the excellent machinability of Brass alloys with computer-controlled machining accuracy. Our CNC machining centers utilize multi-axis capabilities to produce complex geometries with exceptional dimensional accuracy and surface finish. The inherent properties of Brass, including superior corrosion resistance, electrical conductivity, and antimicrobial characteristics, make these components ideal for demanding applications in electronics, plumbing, automotive, and marine industries. Our manufacturing process employs advanced CAD/CAM software integration, allowing for seamless transition from design concept to finished product. The machinability index of Brass (typically 100% compared to other metals) enables us to achieve intricate details, sharp corners, and fine thread specifications that would be challenging with other materials. Our CNC machined Brass parts undergo rigorous dimensional inspection using coordinate measuring machines (CMM) and optical measurement systems to ensure compliance with customer specifications.

Brass CNC Turned Components

Brass CNC turned components showcase the versatility of rotational machining processes applied to Brass alloys, producing cylindrical, conical, and complex turned geometries with exceptional concentricity and surface finish. Our CNC turning centers feature live tooling capabilities, sub-spindle operations, and automatic bar feeding systems to maximize productivity while maintaining precision. The excellent chip formation characteristics of Brass alloys allow for high-speed turning operations, resulting in superior surface finishes often requiring minimal secondary operations. Our turned components encompass shafts, bushings, sleeves, connectors, fittings, and custom rotational parts designed to customer specifications. The thermal conductivity and dimensional stability of Brass ensure consistent machining parameters throughout production runs, contributing to repeatable quality and reduced cycle times. Post-machining operations including threading, knurling, grooving, and drilling are seamlessly integrated into our turning processes.

CDA 360 CNC Brass Machined Parts

CDA 360 CNC Brass machined parts, also known as C36000 Free Cutting Brass, represent the gold standard for high-speed precision machining applications where superior machinability and exceptional surface finish are critical requirements. CDA 360 Brass contains approximately 60-63% Copper, 35.5-38.5% Zinc, and 2.5-3.5% Lead, creating an optimal alloy composition that provides outstanding chip formation characteristics and extended tool life during CNC machining operations. The lead content in CDA 360 acts as a natural lubricant during cutting operations, enabling higher spindle speeds, increased feed rates, and superior surface finishes compared to lead-free alternatives. Our CNC machining capabilities for CDA 360 components encompass complex geometries, intricate internal features, and tight tolerance specifications achievable through the alloy’s exceptional dimensional stability during machining. These components find extensive applications in automotive fuel systems, hydraulic assemblies, electrical connectors, and precision instrumentation where the combination of machinability, corrosion resistance, and mechanical properties creates optimal performance characteristics. Our quality assurance protocols for CDA 360 parts include comprehensive chemical composition verification, mechanical property testing, and dimensional inspection to ensure compliance with ASTM B16 specifications and customer requirements.

C360 Brass Screw Machine Parts

C360 Brass screw machine parts leverage the exceptional machinability characteristics of this premium free-cutting alloy to produce high-volume, precision components with remarkable consistency and cost-effectiveness. C360 Brass screw machine operations utilize the alloy’s superior chip breaking properties and natural lubricity to achieve rapid production cycles while maintaining dimensional accuracy and surface finish quality throughout extended production runs. Our Swiss-type CNC screw machines are specifically optimized for C360 Brass processing, incorporating specialized tooling geometries, cutting parameters, and coolant systems that maximize the alloy’s inherent machinability advantages. The production of C360 screw machine parts encompasses complex multi-axis operations including simultaneous turning, milling, drilling, threading, and forming operations performed in a single machine setup, resulting in superior concentricity and reduced handling costs. Common applications include precision fasteners, electrical terminals, automotive components, plumbing fittings, and instrumentation parts where high-volume production requirements demand both speed and precision. Our screw machine capabilities for C360 Brass extend to bar stock diameters from 3mm to 32mm, with length-to-diameter ratios exceeding 15:1 for specialized long components, while maintaining bore tolerances as tight as ±0.0005 inches and surface finishes ranging from 16-32 microinches Ra depending on application requirements.

Brass CNC Screw Machine Parts

Brass CNC screw machine parts represent high-volume precision manufacturing of small to medium-sized components utilizing advanced screw machine technology combined with CNC control systems. These parts are characterized by their excellent dimensional repeatability, superior surface finish, and cost-effectiveness for large production quantities. Our Swiss-type CNC screw machines excel in producing complex Brass components with multiple machining operations performed simultaneously, including turning, milling, drilling, threading, and forming operations. The inherent machinability of Brass alloys, combined with their self-lubricating properties, enables extended tool life and consistent surface finishes throughout production runs. Common applications include precision fasteners, electrical contacts, valve components, instrument parts, and miniature mechanical assemblies. Our screw machine capabilities extend to bar stock diameters ranging from 1mm to 32mm, with length-to-diameter ratios exceeding 20:1 for specialized applications.

DZR Brass CNC Components

DZR (Dezincification Resistant) Brass CNC components are specifically engineered for applications requiring enhanced corrosion resistance in aggressive environments, particularly where dezincification corrosion is a concern. DZR Brass alloys incorporate specific alloying elements and controlled microstructures that significantly improve resistance to selective leaching of zinc from the alloy matrix. Our CNC machining capabilities for DZR Brass encompass complex geometries while maintaining the enhanced corrosion resistance properties inherent in these specialized alloys. These components are particularly valuable in potable water systems, marine applications, and industrial processes involving corrosive media. The machining characteristics of DZR Brass require specialized cutting parameters and tool geometries to optimize surface finish and dimensional accuracy while preserving the protective microstructural features. Our quality assurance protocols include specific testing procedures to verify dezincification resistance in accordance with international standards including ASTM B858 and ISO 6509.

Lead Free Brass CNC Machined Parts

Lead Free Brass CNC machined parts address the critical requirements of applications where lead content must be minimized or eliminated entirely, particularly in potable water systems and food-grade applications. Our Lead Free Brass alloys comply with stringent regulations including NSF/ANSI 61, California Proposition 65, and European RoHS directives, while maintaining excellent machinability and corrosion resistance properties. The absence of lead in these alloys requires modified machining parameters and specialized tooling to achieve optimal surface finishes and dimensional accuracy. Our CNC machining processes for Lead Free Brass incorporate advanced cutting fluids and optimized tool geometries to compensate for the reduced machinability compared to traditional leaded Brass alloys. These components find extensive applications in plumbing fixtures, water meter assemblies, beverage dispensing equipment, and medical device components where lead contamination is strictly prohibited.

CZ121 Brass CNC Machined Components

CZ121 Brass CNC machined components utilize one of the most versatile and widely specified Brass alloys, offering an optimal balance of strength, corrosion resistance, and machinability characteristics. CZ121 (also known as Naval Brass or Admiralty Brass) contains approximately 70% Copper and 30% Zinc, providing excellent mechanical properties and superior resistance to stress corrosion cracking. Our CNC machining capabilities for CZ121 Brass encompass complex geometries, tight tolerances, and superior surface finishes suitable for both functional and aesthetic applications. The alloy’s excellent hot and cold working properties translate to superior chip formation during machining operations, enabling high-speed cutting and extended tool life. CZ121 components are particularly valued in marine hardware, architectural applications, electrical connectors, and precision instruments where both mechanical strength and corrosion resistance are critical requirements.

CNC Brass Machining in India

CNC Brass machining in India represents a significant competitive advantage in the global manufacturing landscape, combining advanced technology with skilled craftsmanship and cost-effective production capabilities. India’s manufacturing sector has invested heavily in state-of-the-art CNC machining centers, quality management systems, and technical expertise to serve international markets with precision Brass components. Our Indian manufacturing facility incorporates ISO 9001:2015 certified quality management systems, advanced inspection equipment, and continuous improvement methodologies to ensure consistent product quality and customer satisfaction. The availability of high-quality Brass raw materials, combined with favorable exchange rates and established logistics networks, enables competitive pricing without compromising quality standards. Our engineering team possesses extensive experience in Design for Manufacturability (DFM) principles, providing valuable input to customers during the product development phase to optimize component designs for cost-effective production.

🔧 Manufacturing Process Flow

Material Grades and International Equivalents

| Standard | Grade/Designation | Composition (%) | Applications |

|---|---|---|---|

| ASTM B16 | C36000 (Free Cutting Brass) | Cu 60-63, Zn 35.5-38.5, Pb 2.5-3.5 | Screw machine parts, gears |

| BS EN 12163 | CZ121 (Naval Brass) | Cu 70-73, Zn 28-30 | Marine hardware, condenser tubes |

| DIN 17660 | CuZn39Pb3 | Cu 57-60, Zn 37-40, Pb 2.5-3.5 | High-speed machining components |

| JIS H3250 | C3604 | Cu 60-63, Zn 35.5-38.5, Pb 2.5-3.5 | Precision turned parts |

| IS 319 | Grade 1 | Cu 60-62, Zn 36-39, Pb 2.0-3.0 | General engineering applications |

| GB/T 5231 | HPb59-1 | Cu 57-60, Zn 39-42, Pb 0.8-1.9 | Automotive components |

| ASTM B584 | C83600 (Lead Free) | Cu 83-87, Zn 4-6, Sn 4-6, Pb <0.05 | Plumbing fittings, valves |

| EN 1982 | CC752S (DZR) | Cu 57-60, Zn 38-42, As 0.02-0.15 | Water system components |

Manufacturing Processes and Machinery

Our comprehensive manufacturing capabilities encompass multiple precision machining processes utilizing state-of-the-art CNC equipment and advanced manufacturing technologies. CNC Milling Operations are performed on multi-axis machining centers including 3-axis, 4-axis, and 5-axis configurations, enabling complex geometric features and superior surface finishes. Our milling capabilities include face milling, end milling, slot cutting, pocket machining, and contour milling operations with tolerances achievable to ±0.001 inches. CNC Turning Operations utilize precision lathes with live tooling capabilities, sub-spindle operations, and automatic bar feeding systems for high-volume production requirements. Swiss-Type CNC Screw Machines provide exceptional accuracy for small diameter components with complex machining requirements, incorporating simultaneous multi-axis operations for maximum efficiency.

CNC Machining Centers

Multi-axis milling capabilities with advanced CAM programming, spindle speeds up to 15,000 RPM, and precision positioning systems

CNC Turning Centers

Live tooling capabilities, sub-spindle operations, automatic bar feeders, and integrated quality measurement systems

Swiss CNC Machines

High-precision sliding headstock lathes for complex small parts, simultaneous multi-axis machining capabilities

Secondary Operations

Threading, knurling, drilling, tapping, broaching, and specialized finishing operations integrated into production workflow

Typical Parts Produced

Our production capabilities encompass a comprehensive range of Brass components serving diverse industrial applications. Precision Fasteners including machine screws, cap screws, socket head screws, and specialized threaded components manufactured to exacting dimensional tolerances. Electrical Components such as terminals, connectors, contact springs, bushings, and grounding components utilizing the excellent electrical conductivity properties of Brass alloys. Plumbing and Fluid Handling Components including valve stems, fittings, adapters, couplings, and pressure-rated components complying with international plumbing codes and standards. Automotive Components encompassing fuel system parts, hydraulic fittings, sensor housings, and transmission components designed for demanding automotive environments. Marine Hardware including propeller components, through-hull fittings, cleats, and corrosion-resistant hardware for saltwater applications.

Technical Specifications and Tolerances

| Parameter | Standard Tolerance | Precision Tolerance | Ultra-Precision |

|---|---|---|---|

| Linear Dimensions | ±0.005″ (±0.13mm) | ±0.002″ (±0.05mm) | ±0.001″ (±0.025mm) |

| Concentricity | 0.003″ (0.08mm) | 0.001″ (0.025mm) | 0.0005″ (0.013mm) |

| Surface Finish (Ra) | 32-63 μin (0.8-1.6 μm) | 16-32 μin (0.4-0.8 μm) | 8-16 μin (0.2-0.4 μm) |

| Roundness | 0.002″ (0.05mm) | 0.001″ (0.025mm) | 0.0005″ (0.013mm) |

| Thread Tolerance | 2B/3B Class | 3B/4B Class | Custom specifications |

Material Properties and Performance Characteristics

| Property | CZ121 Naval Brass | C36000 Free Cutting | Lead Free Brass | DZR Brass |

|---|---|---|---|---|

| Tensile Strength (MPa) | 340-450 | 340-400 | 300-380 | 380-420 |

| Yield Strength (MPa) | 140-200 | 125-180 | 120-160 | 150-180 |

| Elongation (%) | 45-60 | 50-65 | 40-55 | 35-45 |

| Hardness (HB) | 65-85 | 60-80 | 70-90 | 75-95 |

| Electrical Conductivity (%IACS) | 26-28 | 26-28 | 20-25 | 22-26 |

| Thermal Conductivity (W/m·K) | 110-120 | 115-125 | 95-105 | 100-110 |

Industries and Applications

Our precision Brass CNC machined components serve critical applications across numerous industries where reliability, performance, and compliance with stringent specifications are paramount. Automotive Industry applications include fuel injection components, brake system parts, hydraulic fittings, sensor housings, and transmission components where corrosion resistance and precision are essential. Electronics and Electrical Industry utilizes our components for connectors, terminals, grounding components, shielding applications, and precision contacts leveraging Brass’s excellent electrical conductivity properties. Plumbing and HVAC Systems rely on our Lead Free and DZR Brass components for valves, fittings, pump components, and water meter assemblies that must comply with potable water regulations. Marine and Offshore Industries depend on our corrosion-resistant Brass components for propeller hardware, through-hull fittings, deck hardware, and instrumentation components designed to withstand harsh saltwater environments. Medical Device Manufacturing utilizes our precision components for surgical instruments, diagnostic equipment, and implantable device components where biocompatibility and precision are critical requirements.

Quality Assurance and Testing

Our comprehensive quality management system incorporates advanced inspection methodologies, statistical process control, and continuous improvement protocols to ensure consistent product quality and customer satisfaction. Dimensional Inspection utilizes coordinate measuring machines (CMM), optical measurement systems, and precision gauging to verify compliance with customer specifications and international standards. Material Verification includes spectroscopic analysis, hardness testing, and mechanical property verification to confirm material composition and properties. Surface Finish Analysis employs profilometry and visual inspection techniques to verify surface quality requirements. Functional Testing encompasses pressure testing, electrical continuity verification, and application-specific performance validation where applicable. Our quality documentation includes comprehensive inspection reports, material certificates, and traceability records maintained throughout the production process.

Turnaround Time and Production Capabilities

Our standard production turnaround time ranges from 4-6 weeks for most Brass CNC machined components, with expedited delivery options available for urgent requirements. Production lead times vary based on component complexity, quantity requirements, material specifications, and secondary operation requirements. Prototype Development can typically be completed within 1-2 weeks, enabling rapid design validation and testing. Small to Medium Volume Production (1-10,000 pieces) maintains our standard 4-6 week delivery schedule with flexibility for customer-specific requirements. High Volume Production (10,000+ pieces) may require extended lead times but offers significant cost advantages through optimized production planning and material procurement. Our production planning system incorporates capacity management, material availability tracking, and customer priority scheduling to optimize delivery performance while maintaining quality standards.

Why Choose Our Brass CNC Machined Parts

Our three decades of experience in precision Brass machining, combined with state-of-the-art manufacturing capabilities and unwavering commitment to quality, positions us as the preferred partner for critical component requirements. Global Experience and Expertise encompasses extensive knowledge of international standards, application requirements, and customer expectations across diverse markets and industries. Advanced Manufacturing Technology includes the latest CNC machining centers, inspection equipment, and quality management systems to ensure consistent product quality and competitive lead times. Customization Capabilities extend beyond standard components to include design assistance, prototyping services, and specialized manufacturing processes tailored to unique customer requirements. Superior Communication and Customer Support provides dedicated project management, technical assistance, and responsive customer service throughout the entire product lifecycle. Flexible Production Scheduling accommodates varying volume requirements, expedited delivery needs, and just-in-time delivery programs to support customer inventory optimization strategies. Customized Packaging Solutions include customer-specific labeling, specialized packaging materials, and direct-to-line delivery programs that integrate seamlessly with customer manufacturing processes.

“We have been sourcing precision Brass components from this manufacturer for over 15 years, and their consistency in quality and delivery has been exceptional. Their engineering team’s expertise in Design for Manufacturability has helped us optimize our designs for cost-effectiveness while maintaining the high performance standards our aerospace applications require. The communication throughout the entire process is professional and responsive, making them a truly reliable partner for our critical component needs.”

– Robert Mitchell, Senior Procurement Manager, Advanced Aerospace Systems, USA

Packaging and Shipping

Our comprehensive packaging and shipping solutions are designed to protect product integrity during transportation while providing maximum convenience for customer receiving and inventory management processes. Standard Packaging utilizes moisture-resistant materials, protective cushioning, and clearly labeled containers with detailed packing lists and inspection documentation. Customized Packaging Solutions accommodate customer-specific requirements including branded packaging materials, specialized labeling systems, and direct-to-production-line delivery containers. International Shipping Expertise encompasses comprehensive documentation, customs clearance procedures, and logistics coordination to ensure timely delivery to global destinations. Our packaging materials are selected for environmental sustainability while maintaining superior protection characteristics throughout the supply chain.

Frequently Asked Questions

Q: What is the minimum order quantity for Brass CNC machined parts?

A: Our minimum order quantities vary based on component complexity and material specifications, typically ranging from 100-500 pieces for standard components, with prototype quantities as low as 25 pieces available for development projects.

Q: Can you provide material certificates and inspection reports?

A: Yes, we provide comprehensive material certificates including chemical composition analysis, mechanical property verification, and detailed dimensional inspection reports with every shipment, maintaining full traceability throughout the production process.

Q: What surface finishing options are available for Brass components?

A: Our surface finishing capabilities include natural Brass finish, nickel plating, chrome plating, passivation treatments, anodizing, powder coating, and specialized coatings for enhanced corrosion resistance or aesthetic requirements.

Q: Do you offer design assistance and engineering support?

A: Our experienced engineering team provides comprehensive design assistance including Design for Manufacturability (DFM) analysis, material selection guidance, tolerance optimization, and cost reduction recommendations during the product development phase.

Q: What quality certifications do you maintain?

A: We maintain ISO 9001:2015 certification for quality management systems, along with compliance to various international standards including ASTM, DIN, BS, IS, and JIS specifications relevant to Brass materials and machining processes.

Q: Can you accommodate rush orders or expedited delivery?

A: Yes, we offer expedited production and delivery services for urgent requirements, with rush orders typically completed within 2-3 weeks depending on component complexity and current production schedules.

Q: What is your typical machining tolerance capability?

A: Our standard machining tolerances are ±0.005 inches (±0.13mm), with precision capabilities extending to ±0.001 inches (±0.025mm) for critical dimensions using specialized equipment and inspection procedures.

Q: Do you provide prototyping services before production?

A: We offer comprehensive prototyping services including single-piece prototypes, small batch pilot runs, and design validation testing to ensure optimal component performance before full-scale production commitment.

Q: What industries do you primarily serve?

A: Our primary markets include automotive, electronics, plumbing/HVAC, marine, medical devices, aerospace, industrial equipment, and instrumentation industries requiring precision Brass components with stringent quality requirements.

Q: Can you handle both metric and imperial dimensional specifications?

A: Yes, our engineering and manufacturing teams are proficient in both metric and imperial measurement systems, with full capability to manufacture components to either specification system while maintaining required accuracy and documentation standards.

Q: What secondary operations can you provide?

A: Our secondary operation capabilities include threading, knurling, drilling, tapping, broaching, heat treatment, surface finishing, assembly operations, and specialized treatments to provide complete component solutions.

Q: Do you offer inventory management or just-in-time delivery programs?

A: We provide flexible inventory management solutions including scheduled releases, just-in-time delivery programs, and consignment inventory arrangements to support customer supply chain optimization and reduce inventory carrying costs.

Dimensional Specifications Chart

| Component Type | Diameter Range | Length Range | Thread Sizes | Typical Applications |

|---|---|---|---|---|

| Precision Fasteners | M2 – M16 (0.079″ – 0.630″) | 5mm – 100mm (0.197″ – 3.937″) | M2x0.4 to M16x2.0 | Electronics, automotive assemblies |

| Turned Bushings | 5mm – 50mm (0.197″ – 1.968″) | 10mm – 150mm (0.394″ – 5.906″) | N/A | Bearing assemblies, guides |

| Threaded Rods | M6 – M20 (0.236″ – 0.787″) | 50mm – 1000mm (1.968″ – 39.37″) | M6x1.0 to M20x2.5 | Structural connections |

| Electrical Contacts | 1mm – 10mm (0.039″ – 0.394″) | 5mm – 50mm (0.197″ – 1.968″) | Custom specifications | Switch assemblies, connectors |

| Valve Components | 10mm – 100mm (0.394″ – 3.937″) | 20mm – 200mm (0.787″ – 7.874″) | 1/4″ NPT to 2″ NPT | Plumbing, hydraulic systems |

| Marine Hardware | 8mm – 75mm (0.315″ – 2.953″) | 15mm – 300mm (0.591″ – 11.811″) | UNC/UNF threads | Through-hull fittings, cleats |

Performance Metrics and Standards Compliance

Our Brass CNC machined components consistently achieve superior performance metrics across critical parameters including dimensional accuracy, surface finish quality, and mechanical properties. Dimensional Accuracy Performance demonstrates capability index (Cpk) values exceeding 1.67 for critical dimensions, indicating robust process control and minimal variation. Surface Finish Consistency maintains Ra values within specified ranges across production lots, with standard deviations typically less than 10% of target values. Material Property Verification confirms tensile strength, yield strength, and hardness values within specified ranges for each alloy grade, supported by statistical process control data. Corrosion Resistance Testing validates performance in standardized salt spray testing (ASTM B117) and cyclic corrosion testing protocols relevant to specific application environments. Our quality metrics dashboard tracks key performance indicators including first-pass yield rates exceeding 98%, on-time delivery performance above 95%, and customer satisfaction scores consistently rating above 4.8 out of 5.0.

International Standards Compliance

| Standard Organization | Applicable Standards | Scope of Compliance | Certification Status |

|---|---|---|---|

| ASTM International | B16, B36, B124, B584, B858 | Material specifications, testing methods | Certified testing laboratory |

| British Standards (BS) | EN 12163, EN 1982, BS 2870 | Copper alloy specifications | Third-party verified |

| Deutsches Institut (DIN) | DIN 17660, DIN 1785, DIN 2401 | German engineering standards | Compliance verified |

| Japanese Industrial Standards | JIS H3250, JIS H3270, JIS H3100 | Japanese material standards | Testing capability certified |

| Indian Standards (IS) | IS 319, IS 6912, IS 1545 | Indian national standards | Bureau of Indian Standards registered |

| International Organization | ISO 6509, ISO 9001:2015 | Quality management, testing methods | Certified by accredited body |

Glossary of Technical Terms

CNC Machining: Computer Numerical Control machining utilizing pre-programmed computer software to control machine tool movements for precision manufacturing operations.

DZR (Dezincification Resistant): Brass alloys specifically formulated to resist selective corrosion of zinc from the alloy matrix in corrosive environments.

Lead Free Brass: Copper-zinc alloys with lead content below 0.25% (typically <0.05%) to comply with potable water regulations and environmental standards.

Swiss Screw Machining: Precision manufacturing process using sliding headstock lathes for high-volume production of small, complex components with tight tolerances.

Machinability Index: Relative measure of how easily a material can be machined compared to a reference material, with Brass typically rated at 100%.

Concentricity: Geometric tolerance specifying that all cross-sectional elements of a surface of revolution are common to a single axis.

Surface Roughness (Ra): Arithmetic average of surface profile deviations measured from the mean line, expressed in microinches or micrometers.

Cpk (Process Capability Index): Statistical measure of process capability indicating how well a process meets specification limits relative to natural variation.

Naval Brass (CZ121): Copper-zinc alloy containing approximately 70% Copper and 30% Zinc, known for excellent corrosion resistance and mechanical properties.

Free Cutting Brass: Leaded Brass alloys (typically C36000) optimized for high-speed machining operations with superior chip formation characteristics.

Related terms:

Our comprehensive Brass CNC machining capabilities encompass numerous related applications and search terms relevant to precision component manufacturing. Precision Brass Components include custom machined parts, turned components, and screw machine products serving diverse industrial applications. Brass Electrical Components encompass terminals, connectors, contacts, and grounding components utilizing excellent electrical conductivity properties. Brass Plumbing Components include fittings, valves, adapters, and pressure-rated components complying with international plumbing standards. Marine Brass Hardware covers through-hull fittings, propeller components, deck hardware, and corrosion-resistant marine applications. Automotive Brass Parts include fuel system components, hydraulic fittings, sensor housings, and transmission components designed for automotive environments. Custom Brass Machining Services provide design assistance, prototyping, small-batch production, and high-volume manufacturing solutions. Lead Free Brass Manufacturing addresses potable water applications, food-grade components, and environmentally compliant manufacturing requirements.

Environmental Compliance and Sustainability

Our manufacturing operations incorporate comprehensive environmental management practices and sustainability initiatives to minimize environmental impact while maintaining superior product quality. Material Sustainability emphasizes the use of recycled Copper and Zinc content in our Brass alloys, with typical recycled content exceeding 85% of total material composition. Waste Reduction Programs include comprehensive chip recovery and recycling systems, coolant reclamation processes, and packaging material optimization to minimize waste generation. Energy Efficiency Initiatives encompass LED lighting systems, high-efficiency CNC equipment, and optimized production scheduling to reduce energy consumption per component produced. Environmental Compliance includes adherence to RoHS directives, REACH regulations, and local environmental standards governing manufacturing operations and product specifications. Our Lead Free Brass components specifically address environmental concerns related to lead contamination in potable water systems and consumer products.

Research and Development Capabilities

Our ongoing research and development initiatives focus on advancing Brass alloy compositions, manufacturing processes, and quality assurance methodologies to meet evolving customer requirements and industry standards. Alloy Development Programs investigate new Brass compositions optimized for specific applications, including enhanced corrosion resistance, improved machinability, and specialized property combinations. Process Optimization Research utilizes statistical analysis, design of experiments, and advanced manufacturing techniques to improve productivity, quality, and cost-effectiveness. Quality Enhancement Projects incorporate advanced inspection technologies, predictive quality control systems, and continuous improvement methodologies to exceed customer expectations. Application Engineering Support provides technical assistance for new product development, material selection guidance, and performance optimization for specific customer applications.

Training and Technical Expertise

Our technical team maintains extensive expertise in Brass metallurgy, precision machining technologies, and quality assurance methodologies through continuous training and professional development programs. Metallurgical Expertise encompasses comprehensive knowledge of Brass alloy properties, heat treatment processes, and corrosion mechanisms relevant to various application environments. Manufacturing Technology Training includes advanced CNC programming, setup optimization, and process control techniques to maximize productivity and quality. Quality System Competency covers statistical process control, measurement uncertainty analysis, and international standards compliance to ensure consistent product quality. Customer Service Excellence emphasizes technical communication skills, project management capabilities, and responsive customer support to enhance the overall customer experience.

Supply Chain Management and Sourcing

Our strategic supply chain management approach ensures consistent availability of high-quality raw materials, reliable delivery performance, and competitive pricing through established partnerships with leading Copper and Zinc suppliers. Raw Material Sourcing utilizes certified suppliers meeting international quality standards, with comprehensive material traceability and chemical composition verification for each lot received. Inventory Management Systems incorporate demand forecasting, safety stock optimization, and supplier performance monitoring to minimize material shortage risks while controlling inventory costs. Supplier Quality Programs include supplier audits, incoming inspection procedures, and continuous improvement initiatives to ensure consistent raw material quality. Logistics Optimization encompasses efficient transportation methods, customs clearance expertise, and delivery scheduling coordination to meet customer requirements while minimizing shipping costs.

Get Your Custom Brass CNC Machined Parts Quote Today

Ready to experience the superior quality and reliability of our precision Brass CNC machined components? Our experienced engineering team is standing by to assist with your specific requirements, provide technical guidance, and deliver comprehensive manufacturing solutions tailored to your applications.

Download Our Technical Brochure: Email us at sales@conexscews. com for comprehensive specifications, material property data sheets, and capability charts.

Schedule a Virtual Facility Tour: Contact our customer service team to arrange a virtual tour of our manufacturing facility and quality assurance laboratories.

Experience the difference that three decades of precision manufacturing expertise can make for your critical component requirements. Contact us today to discuss your Brass CNC machining needs and discover why leading manufacturers worldwide trust us for their most demanding applications.

Quality Assurance Promise: Every component backed by comprehensive inspection reports, material certificates, and our commitment to excellence in precision manufacturing.

Serving global markets with precision, reliability, and uncompromising quality since 1990.