Brass Inserts, Brass Molding Inserts & Brass Plastic Molding Inserts

We are one of the leading manufacturers and exporters of Brass molding inserts and Brass plastic molding inserts from India. We have been supplying precision-engineered Brass threaded inserts, Brass ultrasonic inserts, Brass injection molding inserts, and specialized Brass knurled inserts to the world market for many decades. Our comprehensive range includes Brass hex inserts, Brass expansion inserts, Brass roto molding inserts, and custom-designed threaded inserts manufactured to meet international standards including IS, BS, ASTM, DIN, and JIS specifications. With over three decades of global exposure and experience in precision manufacturing, we deliver superior quality Brass molding components that ensure reliable performance in demanding applications across automotive, electronics, aerospace, and industrial sectors. Our state-of-the-art manufacturing facilities utilize advanced CNC machining, precision turning, and automated production processes to manufacture Brass inserts with exceptional dimensional accuracy and consistent quality. We specialize in both metric and imperial thread configurations including BSW, BSP, UNC, and UNF standards, offering complete customization capabilities to meet specific customer requirements with flexible production schedules and competitive turnaround times.

PRICE: US$ 11/Kilogram

Product Overview

Brass molding inserts represent a critical component in modern manufacturing processes, providing threaded connections and reinforcement in plastic molded parts. These precision-engineered components are manufactured from high-grade Brass alloys, offering excellent corrosion resistance, superior electrical conductivity, and exceptional mechanical properties. Our comprehensive product portfolio encompasses various insert types designed for specific molding applications including injection molding, ultrasonic welding, heat insertion, and rotational molding processes.

The versatility of Brass molding inserts makes them indispensable in applications requiring reliable threaded connections in plastic assemblies. These components are engineered to withstand the thermal and mechanical stresses encountered during molding operations while maintaining precise thread integrity and dimensional stability. Our manufacturing expertise extends to producing custom insert geometries, specialized thread configurations, and application-specific designs that meet stringent industry requirements.

Brass Inserts

Brass inserts form the foundation of our comprehensive product range, manufactured from premium-grade Brass alloys that deliver exceptional performance in demanding applications. These precision-engineered components are produced using advanced manufacturing processes including CNC machining, cold heading, and precision turning operations. Our Brass inserts feature superior corrosion resistance, excellent electrical conductivity, and remarkable durability, making them ideal for applications in electronics, automotive, aerospace, and industrial sectors.

The manufacturing process involves careful selection of raw materials conforming to international standards such as IS 319, BS 2874, ASTM B36, DIN 17660, and JIS H3250. Our quality control systems ensure consistent dimensional accuracy, surface finish, and mechanical properties across all production batches. These Brass inserts are available in various configurations including straight, flanged, and custom geometries to meet specific application requirements.

Brass Molding Inserts

Brass molding inserts represent specialized components designed specifically for integration into plastic molding processes. These inserts are engineered to withstand the thermal cycling and mechanical stresses encountered during molding operations while maintaining precise dimensional stability and thread integrity. Our manufacturing capabilities encompass various insert types including heat-set inserts, press-fit inserts, and molded-in inserts, each optimized for specific molding applications and material combinations.

The design considerations for Brass molding inserts include thermal expansion coefficients, material compatibility, and molding process parameters. Our engineering team collaborates with customers to develop customized solutions that optimize insert performance and ensure reliable assembly operations. These components are manufactured with tight tolerances and superior surface finishes to facilitate seamless integration into molding processes.

Brass Plastic Molding Inserts

Brass plastic molding inserts are specifically engineered for embedding into plastic components during injection molding, compression molding, and other plastic forming processes. These precision components provide reliable threaded connections and structural reinforcement in plastic assemblies, eliminating the need for post-molding machining operations. Our Brass plastic molding inserts feature optimized geometries that promote excellent plastic flow and minimize stress concentrations around the insert interface.

The manufacturing process incorporates advanced design features such as undercuts, knurls, and specialized surface treatments that enhance the mechanical bond between the Brass insert and plastic substrate. These components are available in various thread specifications including metric (M3, M4, M5, M6, M8, M10, M12) and imperial (UNC, UNF, BSW, BSP) configurations, ensuring compatibility with diverse assembly requirements and international standards.

Brass Ultrasonic Inserts

Brass ultrasonic inserts are precision-engineered components designed for installation using ultrasonic welding technology. These specialized inserts feature unique geometries and surface treatments that optimize energy transfer during ultrasonic installation, ensuring consistent and reliable insertion performance. The manufacturing process incorporates specific design elements such as energy directors, installation guides, and stress relief features that facilitate automated assembly operations.

Our Brass ultrasonic inserts are manufactured to exacting standards with precise dimensional control and surface finish requirements. The insert geometry includes optimized knurl patterns, installation depths, and thermal characteristics that ensure proper plastic flow and minimize installation stresses. These components are extensively tested for ultrasonic compatibility and installation consistency across various plastic materials and molding conditions.

Brass Roto Molding Inserts

Brass roto molding inserts are specialized components designed for integration into rotational molding processes, where components are formed through heating and rotating plastic materials in hollow molds. These inserts must withstand extended heating cycles and thermal stresses while maintaining dimensional stability and thread integrity. Our manufacturing process incorporates specific design features and material treatments that optimize performance in rotational molding applications.

The unique requirements of rotational molding demand careful consideration of thermal expansion, plastic flow characteristics, and mold release properties. Our Brass roto molding inserts are engineered with specialized geometries that promote uniform plastic distribution and minimize stress concentrations. These components undergo rigorous testing to ensure consistent performance across various rotational molding cycles and material combinations.

Brass Hex Inserts

Brass hex inserts feature hexagonal external geometries that provide superior retention and anti-rotation properties in plastic assemblies. These precision-manufactured components are designed to prevent rotation during screw installation and provide enhanced holding power in plastic substrates. The hexagonal configuration distributes installation and operational stresses more effectively than cylindrical designs, resulting in improved long-term reliability.

Manufacturing of Brass hex inserts involves precision machining operations that maintain tight tolerances on the hexagonal geometry and internal threads. Our quality control processes ensure consistent hex dimensions and thread specifications across all production batches. These components are available in various hex sizes and thread configurations to accommodate diverse assembly requirements and torque specifications.

Brass Knurled Inserts

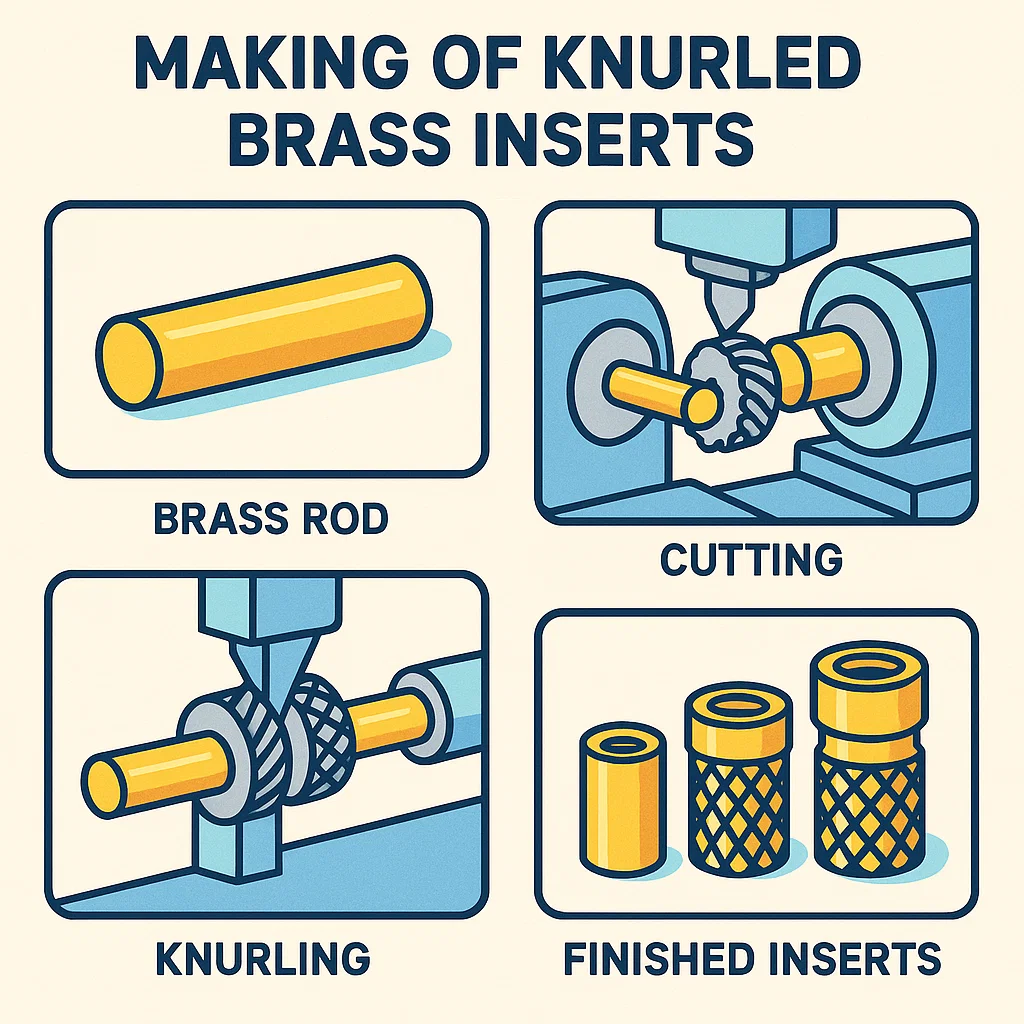

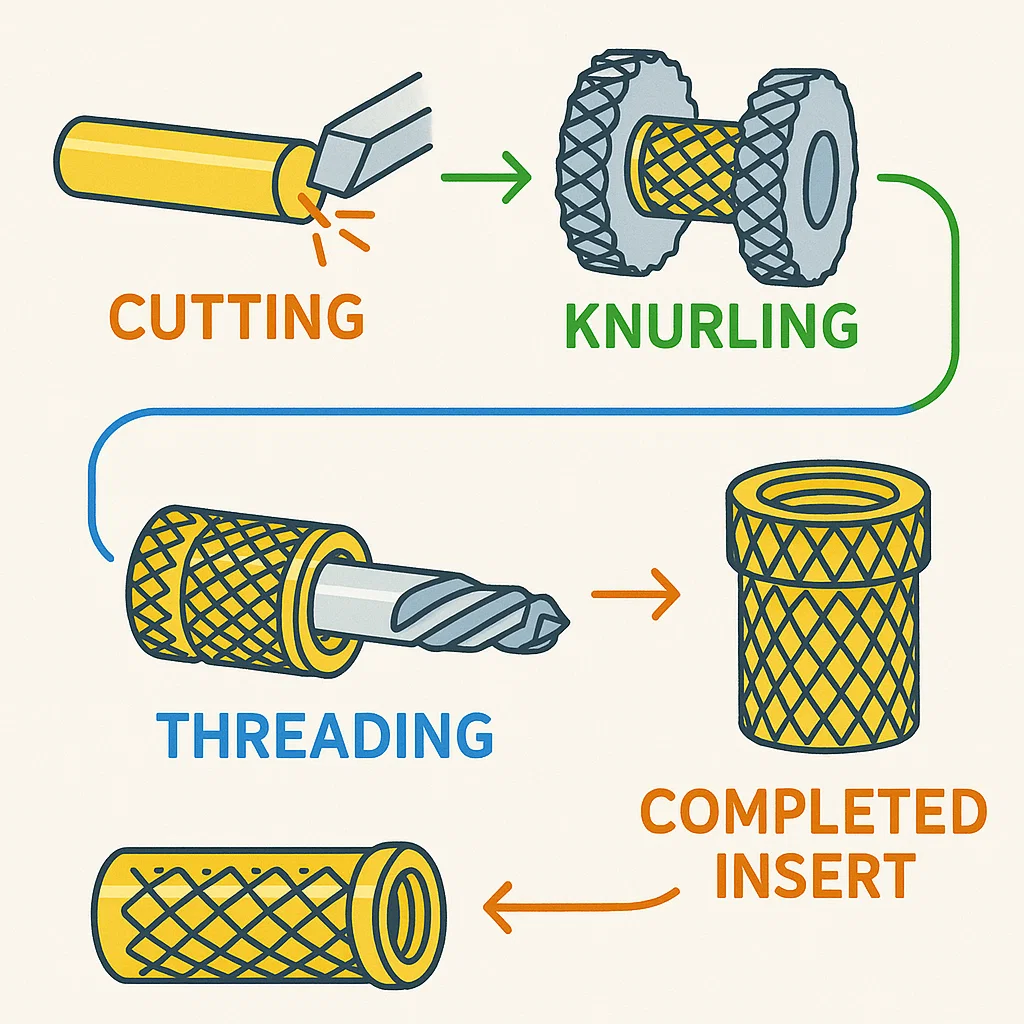

Brass knurled inserts feature precisely machined knurl patterns on the external surface that provide exceptional retention characteristics in plastic materials. The knurl geometry is optimized to maximize holding power while minimizing installation forces and plastic displacement. Our manufacturing process incorporates advanced knurling techniques that ensure consistent knurl depth, pitch, and surface finish across all production quantities.

The knurl pattern design considers factors such as plastic material properties, installation method, and operational requirements. Our engineering capabilities extend to developing custom knurl patterns for specific applications, including diamond knurls, straight knurls, and specialized retention features. These Brass knurled inserts undergo comprehensive testing to validate retention strength and installation consistency.

Brass Expansion Inserts

Brass expansion inserts are engineered with specialized geometries that expand during installation to provide secure retention in plastic substrates. These components feature expandable sections that deform plastically during installation, creating interference fits that resist pull-out forces. The manufacturing process incorporates precise control of expansion geometry and material properties to ensure consistent installation performance.

The design of Brass expansion inserts requires careful consideration of expansion mechanics, plastic deformation characteristics, and installation tooling requirements. Our engineering team develops customized expansion geometries that optimize retention strength while minimizing installation forces. These components are manufactured with tight tolerances and undergo rigorous testing to validate expansion performance and retention characteristics.

Brass Threaded Inserts

Brass threaded inserts represent the most common type of insert, featuring internal threads that provide reliable fastening points in plastic assemblies. These precision components are manufactured with high-quality threads that meet international standards and provide excellent thread engagement characteristics. Our manufacturing capabilities encompass various thread types including metric, imperial, and specialty thread configurations.

The thread manufacturing process utilizes precision tapping, thread rolling, and CNC threading operations to achieve superior thread quality and dimensional accuracy. Our quality control systems include comprehensive thread inspection using precision gauges and automated measurement systems. These Brass threaded inserts are available in various lengths, diameters, and thread pitches to accommodate diverse assembly requirements.

Brass Injection Molding Inserts

Brass injection molding inserts are specifically designed for integration into injection molding processes, where molten plastic is injected into molds containing pre-positioned inserts. These components must withstand high injection pressures and temperatures while maintaining precise positioning and dimensional stability. Our manufacturing process incorporates design features that optimize plastic flow and minimize stress concentrations around the insert.

The engineering considerations for Brass injection molding inserts include mold design compatibility, plastic flow characteristics, and thermal management. Our components feature specialized geometries that promote proper plastic encapsulation and minimize defects such as air traps and weld lines. These inserts undergo extensive testing to validate performance under various injection molding conditions and material combinations.

Thread Specifications

Our comprehensive thread capabilities encompass both metric and imperial thread systems, ensuring compatibility with global manufacturing standards and customer requirements. The thread manufacturing process utilizes precision tooling and automated inspection systems to maintain consistent thread quality and dimensional accuracy across all production quantities.

Thread Specifications Table:

| Thread Type | Standard | Pitch Range | Diameter Range | Application |

|---|---|---|---|---|

| Metric | ISO 262, DIN 13 | 0.5mm – 3.0mm | M3 – M20 | European, Asian Markets |

| BSW (British Standard Whitworth) | BS 84 | 12-32 TPI | 1/4″ – 1″ | British, Commonwealth |

| BSP (British Standard Pipe) | BS 21 | 11-28 TPI | 1/8″ – 2″ | Pipe Fittings |

| UNC (Unified National Coarse) | ASME B1.1 | 6-24 TPI | #4 – 1/2″ | North American General |

| UNF (Unified National Fine) | ASME B1.1 | 12-32 TPI | #6 – 1/2″ | Precision Applications |

Material Grades and Specifications

Our Brass molding inserts are manufactured from premium-grade Brass alloys sourced from certified suppliers and conforming to international material standards. The material selection process considers factors such as corrosion resistance, mechanical properties, electrical conductivity, and manufacturing characteristics to ensure optimal performance in diverse applications.

Material Grades Table:

| Material Grade | International Standards | Composition | Properties | Applications |

|---|---|---|---|---|

| Brass 360 | ASTM B16, UNS C36000 | Cu: 61.5%, Zn: 35.5%, Pb: 3% | Excellent machinability | General purpose inserts |

| Brass CZ121 | BS 2874, EN 12164 | Cu: 58-60%, Zn: 39-42% | Good corrosion resistance | Marine, electrical |

| Brass H62 | GB/T 5231, Chinese Standard | Cu: 60.5-63.5%, Zn: Balance | High strength, ductility | Automotive, electronics |

| Brass C2680 | JIS H3250, Japanese Standard | Cu: 64.0-70.0%, Zn: Balance | Superior formability | Precision components |

| Brass CuZn39Pb3 | DIN 17660, European Standard | Cu: 56-60%, Zn: 37-42%, Pb: 2.5-3.5% | Free machining | High-volume production |

| Brass 385 | IS 319, Indian Standard | Cu: 56-60%, Zn: 38-42%, Pb: 1.5-3.0% | Balanced properties | Industrial applications |

Manufacturing Processes and Machinery

Our state-of-the-art manufacturing facility incorporates advanced machinery and precision manufacturing processes to ensure consistent quality and dimensional accuracy across all production quantities. The manufacturing workflow integrates automated systems with skilled craftsmanship to deliver superior products that meet stringent customer specifications and international standards.

Advanced Manufacturing Capabilities:

CNC Machining Centers: Our facility houses multiple CNC turning and milling centers equipped with advanced tooling systems and automated material handling. These machines provide exceptional dimensional accuracy and surface finish quality for complex insert geometries.

Precision Threading Equipment: Specialized thread rolling and cutting equipment ensures superior thread quality and consistency. Our threading capabilities include both standard and custom thread profiles manufactured to tight tolerances.

Automated Inspection Systems: Advanced coordinate measuring machines (CMM) and automated inspection systems provide comprehensive quality control throughout the manufacturing process, ensuring consistent product quality and dimensional accuracy.

Manufacturing Process Table:

| Manufacturing Process | Machinery Used | Tolerance Capability | Production Capacity |

|---|---|---|---|

| CNC Turning | Multi-axis CNC lathes with live tooling | ±0.01mm | 500,000 pcs/month |

| Thread Rolling | Automated thread rolling machines | ±0.02mm | 1,000,000 pcs/month |

| Knurling | Precision knurling equipment | ±0.005mm | 300,000 pcs/month |

| Heat Treatment | Controlled atmosphere furnaces | ±5°C temperature control | Batch processing |

| Surface Finishing | Automated plating and coating lines | 5-50 microns coating thickness | Variable capacity |

Dimensional Specifications and Tolerances

Our manufacturing processes maintain precise dimensional control and tight tolerances to ensure consistent product quality and reliable assembly performance. The dimensional specifications are established based on international standards and customer requirements, with comprehensive quality control systems monitoring all critical dimensions throughout production.

Dimensional Specifications Table:

| Insert Type | Outer Diameter (mm) | Length (mm) | Thread Size | Standard Tolerance |

|---|---|---|---|---|

| Standard Threaded | 4.0 – 20.0 | 5.0 – 50.0 | M3 – M12 | ±0.02mm |

| Knurled Insert | 4.5 – 22.0 | 6.0 – 60.0 | M3 – M16 | ±0.03mm |

| Hex Insert | 5.0 – 25.0 | 8.0 – 80.0 | M4 – M20 | ±0.02mm |

| Expansion Insert | 4.0 – 18.0 | 10.0 – 100.0 | M3 – M12 | ±0.05mm |

| Ultrasonic Insert | 3.5 – 15.0 | 4.0 – 40.0 | M2.5 – M10 | ±0.01mm |

Surface Finishes and Treatments

Our comprehensive surface treatment capabilities enhance the performance and durability of Brass molding inserts in demanding applications. The surface finishing processes are selected based on application requirements, environmental conditions, and customer specifications, ensuring optimal performance and longevity.

Surface Finish Table:

| Finish Type | Description | Thickness | Properties | Applications |

|---|---|---|---|---|

| Natural Brass | Machined surface finish | N/A | Standard electrical conductivity | General applications |

| Nickel Plating | Electroplated nickel coating | 5-25 microns | Enhanced corrosion resistance | Electronics, marine |

| Zinc Plating | Electroplated zinc coating | 8-15 microns | Corrosion protection | Automotive, industrial |

| Tin Plating | Electroplated tin coating | 2-10 microns | Excellent solderability | Electronic assemblies |

| Passivation | Chemical surface treatment | Molecular layer | Improved corrosion resistance | Precision applications |

| Anodizing | Specialized coating process | 10-25 microns | Wear resistance | High-performance applications |

Industries and Applications

Our Brass molding inserts serve diverse industries where reliable threaded connections and superior performance are critical requirements. The versatility and exceptional properties of Brass make these components suitable for demanding applications across multiple sectors, from precision electronics to heavy industrial machinery.

Automotive Industry The automotive sector relies extensively on Brass molding inserts for interior components, electrical assemblies, and under-hood applications. These components provide reliable fastening solutions in dashboard assemblies, door panels, electronic control units, and lighting systems. The excellent corrosion resistance and thermal stability of Brass ensure long-term reliability in automotive environments.

Electronics and Telecommunications Electronics manufacturing utilizes Brass molding inserts for computer housings, telecommunications equipment, consumer electronics, and industrial control systems. The superior electrical conductivity and electromagnetic shielding properties of Brass make these components ideal for sensitive electronic applications where electrical performance is critical.

Aerospace and Defense Aerospace applications demand the highest quality standards and reliability, making our precision-manufactured Brass inserts ideal for aircraft interior components, avionics assemblies, and ground support equipment. These components meet stringent aerospace specifications and provide consistent performance in demanding operational environments.

Medical and Healthcare Medical device manufacturing relies on Brass molding inserts for diagnostic equipment, surgical instruments, and healthcare electronics. The biocompatibility and corrosion resistance of Brass ensure safe and reliable performance in medical applications where patient safety is paramount.

Industrial Machinery Industrial applications include machinery housings, control panels, pneumatic systems, and hydraulic equipment. The mechanical strength and durability of Brass inserts provide reliable fastening solutions in demanding industrial environments with exposure to chemicals, vibration, and temperature extremes.

Performance Metrics and Testing

Our comprehensive testing protocols ensure that all Brass molding inserts meet or exceed specified performance requirements. The testing procedures encompass dimensional verification, mechanical properties evaluation, and application-specific performance validation to guarantee consistent quality and reliability.

Performance Testing Table:

| Test Parameter | Test Method | Specification | Typical Results |

|---|---|---|---|

| Tensile Strength | ASTM B557 | ≥350 MPa | 380-420 MPa |

| Pull-out Force | Customer specific | ≥800 N | 850-1200 N |

| Torque Resistance | ISO 898-2 | ≥5 Nm | 6-12 Nm |

| Electrical Conductivity | ASTM B193 | ≥25% IACS | 28-32% IACS |

| Dimensional Accuracy | ISO 286 | ±0.02mm | ±0.015mm |

| Surface Roughness | ISO 4287 | Ra ≤1.6μm | Ra 0.8-1.2μm |

Quality Assurance and Certifications

Our quality management system is certified to ISO 9001:2015 standards, ensuring consistent quality and continuous improvement throughout all manufacturing processes. The quality assurance program encompasses incoming material inspection, in-process monitoring, and final product verification to guarantee that all products meet specified requirements.

Quality Certifications and Standards:

ISO 9001:2015: Comprehensive quality management system certification ensuring consistent product quality and customer satisfaction.

ISO 14001:2015: Environmental management system certification demonstrating our commitment to sustainable manufacturing practices.

RoHS Compliance: All products comply with RoHS (Restriction of Hazardous Substances) regulations for electronic applications.

REACH Compliance: Full compliance with European REACH regulations for chemical safety and environmental protection.

Customer Testimonials

“We have been sourcing Brass molding inserts from this company for over eight years for our automotive electronics manufacturing. Their consistent quality, competitive pricing, and excellent customer support have made them our preferred supplier. The technical expertise and flexibility to customize products according to our specific requirements sets them apart from other suppliers. Their ability to meet tight delivery schedules and provide comprehensive technical documentation has been invaluable to our operations.”

– Robert Johnson, Procurement Manager, Detroit , USA

Frequently Asked Questions

Q1: What is the minimum order quantity for Brass molding inserts? Our minimum order quantity varies by product type and specifications. For standard Brass threaded inserts, the minimum order is typically 1,000 pieces. For custom designs or specialized inserts, we can accommodate smaller quantities starting from 500 pieces. We offer flexible ordering options to meet diverse customer requirements.

Q2: Can you provide custom thread specifications and dimensions? Yes, we specialize in manufacturing custom Brass molding inserts with specific thread configurations, dimensions, and geometries. Our engineering team works closely with customers to develop tailored solutions that meet exact application requirements. We can produce metric, imperial, and specialty thread configurations with custom pitches and profiles.

Q3: What surface treatments are available for Brass inserts? We offer comprehensive surface treatment options including nickel plating, zinc plating, tin plating, passivation, and specialized coatings. The selection depends on application requirements such as corrosion resistance, electrical conductivity, and environmental conditions. Our technical team can recommend the most suitable surface treatment for your specific application.

Q4: How do you ensure consistent quality across production batches? Our ISO 9001:2015 certified quality management system includes comprehensive inspection protocols, statistical process control, and automated measurement systems. Every production batch undergoes dimensional verification, mechanical testing, and visual inspection. We maintain detailed quality records and provide certificates of compliance with all shipments.

Q5: What is the typical lead time for standard and custom orders? Standard Brass molding inserts typically have a lead time of 4-6 weeks from order confirmation. Custom designs may require additional time for tooling development and prototype validation, generally 6-8 weeks. We maintain strategic inventory levels for common specifications to support urgent requirements and offer expedited production services when needed.

Q6: Are your Brass inserts suitable for ultrasonic welding applications? Yes, we manufacture specialized Brass ultrasonic inserts designed specifically for ultrasonic welding applications. These inserts feature optimized geometries, energy directors, and surface treatments that ensure consistent installation performance and reliable retention in plastic substrates. We provide detailed installation guidelines and technical support for ultrasonic welding applications.

Q7: What documentation do you provide with shipments? All shipments include comprehensive documentation including certificates of compliance, material test certificates, dimensional inspection reports, and packaging lists. We can provide additional documentation such as RoHS certificates, REACH compliance statements, and country of origin certificates as required by customers or regulatory authorities.

Q8: Can you accommodate special packaging requirements? Absolutely. We offer customized packaging solutions including customer-branded packaging, specialized protective packaging, and automated assembly-friendly packaging formats. Our packaging capabilities include bulk packaging, precision counting, and anti-static packaging for sensitive applications. We can also incorporate customer labels and logos as per requirements.

Q9: What quality standards do your manufacturing processes follow? Our manufacturing processes comply with international standards including ISO 9001:2015, ISO 14001:2015, and industry-specific standards such as ASTM, DIN, JIS, and BS specifications. We maintain comprehensive quality control systems with statistical process control, automated inspection equipment, and certified measurement standards to ensure consistent product quality.

Q10: Do you provide technical support for insert selection and application? Yes, our experienced technical team provides comprehensive application support including insert selection, installation guidance, and troubleshooting assistance. We offer design consultation services to optimize insert performance for specific applications and can provide detailed technical documentation, installation procedures, and performance data to support customer engineering requirements.

Material Property Tables

The following tables provide comprehensive material property data for our Brass alloys, enabling engineers to make informed decisions regarding material selection and application suitability.

Material Properties Table:

| Property | Brass 360 | Brass CZ121 | Brass H62 | Brass C2680 | Units |

|---|---|---|---|---|---|

| Density | 8.5 | 8.4 | 8.5 | 8.6 | g/cm³ |

| Melting Point | 885-920 | 900-940 | 905-925 | 935-955 | °C |

| Thermal Conductivity | 115 | 120 | 109 | 125 | W/m·K |

| Electrical Conductivity | 26 | 28 | 27 | 30 | % IACS |

| Coefficient of Expansion | 20.5 | 20.0 | 20.3 | 19.9 | ×10⁻⁶/°C |

| Elastic Modulus | 97 | 100 | 105 | 110 | GPa |

| Hardness (HB) | 85-120 | 75-110 | 80-115 | 70-105 | Brinell |

Unique Selling Propositions

Why Choose Our Brass Molding Inserts?

Three Decades of Global Experience: With over 30 years of experience in manufacturing and exporting Brass molding inserts, we possess unmatched expertise in understanding diverse market requirements and delivering solutions that exceed customer expectations. Our extensive global exposure has enabled us to develop products that meet international standards and regional specifications.

Comprehensive Customization Capabilities: Our advanced engineering and manufacturing capabilities enable us to develop customized solutions for unique applications. From specialized thread configurations to complex geometries, we collaborate with customers to create tailored products that optimize performance and reduce assembly costs.

Flexible Production Scheduling: We understand that manufacturing schedules can be demanding and unpredictable. Our flexible production planning system allows us to accommodate urgent requirements, adjust delivery schedules, and provide expedited services when needed, ensuring that our customers’ production schedules remain on track.

Superior Customer Support: Our dedicated customer support team provides responsive communication, technical assistance, and comprehensive after-sales service. We maintain close relationships with customers throughout the entire process, from initial inquiry to final delivery, ensuring complete satisfaction with our products and services.

Advanced Quality Control Systems: Our state-of-the-art quality control systems incorporate automated inspection equipment, statistical process control, and comprehensive testing protocols. This ensures consistent product quality, dimensional accuracy, and reliability across all production batches.

Customized Packaging Solutions: We offer flexible packaging options including customer-branded packaging, specialized protective packaging, and automated assembly-friendly formats. Our packaging capabilities include bulk packaging, precision counting, and anti-static packaging for sensitive applications, with the ability to incorporate customer labels and logos.

Competitive Turnaround Times: Our efficient manufacturing processes and strategic inventory management enable us to provide competitive lead times of 4-6 weeks for standard products and 6-8 weeks for custom designs. We maintain buffer stock for common specifications to support urgent requirements and minimize delivery delays.

Packaging and Shipping

Our comprehensive packaging and shipping capabilities ensure safe delivery of products while meeting specific customer requirements and international shipping regulations. We utilize advanced packaging techniques and materials to protect products during transportation and storage.

Packaging Options

Standard Packaging: Products are packaged in moisture-resistant containers with appropriate cushioning materials to prevent damage during transportation. Standard packaging includes proper labeling with product specifications, quantity information, and handling instructions.

Custom Packaging: We offer customized packaging solutions including customer-branded packaging, specialized protective packaging, and automated assembly-friendly formats. Our packaging team can develop tailored solutions that optimize storage, handling, and assembly operations.

Anti-Static Packaging: For sensitive electronic applications, we provide specialized anti-static packaging that prevents electrostatic discharge damage during handling and storage. This packaging includes conductive materials and appropriate labeling to ensure proper handling procedures.

Bulk Packaging: Large quantity orders can be packaged in bulk containers with appropriate separation and identification systems to facilitate efficient inventory management and assembly operations.

Shipping and Logistics

Our logistics network provides reliable shipping services worldwide, with partnerships with major international carriers to ensure timely delivery and competitive shipping rates. We provide comprehensive tracking information and delivery confirmation for all shipments.

Documentation: All shipments include complete documentation including commercial invoices, packing lists, certificates of compliance, and any additional documentation required by customs authorities or customer specifications.

International Shipping: We maintain expertise in international shipping regulations and documentation requirements, ensuring smooth customs clearance and delivery to destinations worldwide.

Glossary of Terms

Understanding technical terminology is essential for proper product selection and application. The following glossary provides definitions for key terms and concepts related to Brass molding inserts and manufacturing processes.

Brass Molding Insert: A threaded fastener component made from Brass alloy, designed for integration into plastic molding processes to provide reliable threaded connections in plastic assemblies.

Ultrasonic Welding: A manufacturing process that uses high-frequency vibrations to create heat and pressure, enabling the installation of inserts into plastic components without requiring pre-formed holes.

Knurling: A mechanical surface treatment process that creates a regular pattern of ridges or indentations on the external surface of inserts to improve retention characteristics in plastic substrates.

Thread Pitch: The distance between adjacent threads on a threaded fastener, typically measured in millimeters for metric threads or threads per inch for imperial threads.

Pull-out Force: The maximum axial force required to remove an insert from its installed position, used as a measure of retention strength and installation quality.

Torque Resistance: The maximum rotational force that can be applied to an installed insert without causing rotation or failure, critical for applications requiring high torque values.

Injection Molding: A manufacturing process where molten plastic is injected into a mold cavity containing pre-positioned inserts, creating integrated plastic components with embedded threaded connections.

Heat Staking: An assembly process that uses controlled heating to soften plastic material around an insert, creating a mechanical bond when the material cools and solidifies.

Expansion Insert: A specialized insert design that features expandable sections that deform during installation to create interference fits and improved retention characteristics.

Thread Engagement: The length of thread contact between an insert and mating screw, critical for achieving proper joint strength and reliability.

Related Terms

Brass threaded inserts for plastic, Brass molding insert manufacturer, Brass ultrasonic welding inserts, Brass knurled inserts supplier, Brass hex inserts exporter, Brass expansion inserts India, Brass injection molding inserts, Brass roto molding inserts, Brass plastic inserts manufacturer, Brass insert threading services, Custom Brass molding inserts, Precision Brass inserts, Brass insert surface treatments, Brass insert quality control, Brass insert specifications, Brass insert applications, Brass insert installation, Brass insert retention, Brass insert torque resistance, Brass insert pull-out strength, Brass insert dimensional tolerance, Brass insert material grades, Brass insert finishing options, Brass insert packaging, Brass insert shipping, Brass insert technical support, Brass insert customization, Brass insert lead times, Brass insert minimum quantities, Brass insert certificates

Ready to Get Started?

Contact our technical team today to discuss your Brass molding insert requirements and discover how our expertise can enhance your manufacturing processes.

Contact Information:

- Email: sales@conexscrews. com