BRASS MOLD IN INSERTS , BRASS INSERTS

Premium Brass Mold-In Threaded Inserts from Indian manufacturers

Price: US$ 11.00/Kilogram

We are one of the leading manufacturers and exporters of precision Brass Mold-In Threaded Inserts from India. We have been supplying high-quality molding inserts to the world market for many decades. Our expertise spans over three decades in manufacturing precision-engineered Brass mold-in threaded inserts that meet the most demanding industry standards. These specialized fastening solutions are designed for permanent installation during the plastic injection molding process, providing superior thread retention and load distribution compared to post-molding installation methods. Our advanced manufacturing capabilities and stringent quality control processes ensure consistent delivery of products that exceed customer expectations across automotive, electronics, aerospace, telecommunications, and medical device industries worldwide. We offer Brass CDA 360 free machining Brass inserts as well as DZR and Lead Free Brass inserts. We also offer lead free Brass screw machine parts, CNC components and DZR Brass Turned parts and Screw machine parts.

Product Overview

Brass Mold-In Threaded Inserts represent the pinnacle of precision fastening technology for thermoplastic and thermoset applications. These innovative components are specifically engineered to be positioned within injection mold cavities during the molding process, creating permanent, high-strength threaded connections that eliminate the need for secondary operations. The external diamond knurl pattern and precision-machined undercuts ensure maximum retention force and optimal load distribution throughout the host material.

Our mold-in blind threaded inserts feature closed-end designs that prevent plastic intrusion while maintaining thread integrity. The carefully calculated geometry provides exceptional pull-out resistance and torque performance, making them ideal for applications requiring reliable fastening in challenging environments. Each insert undergoes rigorous dimensional inspection and performance testing to guarantee compliance with international quality standards.

Material Grades & Specifications

International Brass Grade Standards

| Standard | Grade Designation | Copper (%) | Zinc (%) | Lead (%) | Other Elements | Application |

|---|---|---|---|---|---|---|

| ASTM B16 | C36000 (Free Cutting Brass) | 60-63 | 35.5-38.5 | 2.5-3.7 | – | High Machinability Inserts |

| ASTM B124 | C26000 (Cartridge Brass) | 68.5-71.5 | 28.5-31.5 | 0.07 max | – | Cold Working Applications |

| BS EN 12164 | CW614N (Lead Free) | 57-59 | 39-42 | 0.2 max | Si: 0.2-0.7 | Environmental Compliance |

| ASTM B124 | C69300 (Lead Free Silicon Brass) | 55-60 | 36.5-42.5 | 0.09 max | Si: 1.5-2.8 | Potable Water Systems |

| ASTM B138 | C89833 (Bismuth Brass) | 60-63 | 34.5-37.5 | 0.05 max | Bi: 1.2-2.0 | NSF 61 Certified Applications |

| BS EN 12164 | CW510L (Lead Free) | 75-79 | 20-24 | 0.05 max | Sn: 0.9-1.5 | Premium Lead Free Grade |

| ASTM B283 | C27400 (DZR Yellow Brass) | 62-65 | 34-37 | 0.15 max | As: 0.02-0.06 | Dezincification Resistant |

| BS EN 12164 | CW508L (DZR Brass) | 57-60 | 36.5-40 | 1.6-2.5 | As: 0.02-0.15, Al: 0.02-0.06 | Marine & High Chloride Environment |

| ASTM B371 | C35200 (DZR Leaded Brass) | 60-63 | 35.5-38.5 | 1.5-2.5 | As: 0.02-0.06 | Corrosion Resistant Machining |

| DIN 17660 | CuZn39Pb3 | 56-60 | 37-42 | 2.5-3.5 | – | Standard Machining Grade |

| JIS H3250 | C3602 (Free Cutting) | 57-61 | 35.5-42 | 1.8-3.7 | – | Precision Components |

| GB/T 4423 | HPb59-1 (Chinese Standard) | 57-60 | 38.5-42 | 0.8-1.9 | – | Cost-Effective Solutions |

Lead-Free & DZR Brass Specifications for Specialized Applications

DZR (Dezincification Resistant) Brass Alloys: Specially formulated with Arsenic and Aluminum additions to prevent selective leaching of Zinc in aggressive water conditions. Essential for marine applications, water treatment systems, and high-chloride environments where standard Brass would experience dezincification corrosion.

| Alloy Category | Key Benefits | Typical Applications | Compliance Standards |

|---|---|---|---|

| Silicon Brass (CW614N) | Good machinability, RoHS compliant, cost-effective | Electronics, appliances, general purpose | RoHS, REACH, BS EN 12164 |

| Bismuth Brass (C89833) | Excellent machinability, NSF 61 certified | Plumbing, potable water, food processing | NSF 61, NSF 372, California AB1953 |

| DZR Yellow Brass (C27400) | Superior corrosion resistance, dezincification immune | Marine hardware, water meters, valve components | ASTM B283, ISO 6509, BS 2874 |

| DZR Leaded Brass (C35200) | High machinability with corrosion resistance | Water treatment, chemical processing equipment | ASTM B371, AWWA C800 |

Advanced Material Properties

| Property | C36000 | C26000 | CW614N | Units |

|---|---|---|---|---|

| Tensile Strength | 340-380 | 315-455 | 360-500 | MPa |

| Yield Strength (0.2%) | 125-205 | 105-310 | 140-350 | MPa |

| Elongation | 53-68 | 53-68 | 25-45 | % |

| Hardness (HB) | 56-100 | 55-100 | 85-140 | HB |

| Electrical Conductivity | 26 | 27 | 28 | %IACS |

Manufacturing Processes & Machinery

Our state-of-the-art manufacturing facility employs advanced CNC Swiss-type automatic lathes and multi-spindle screw machines to achieve the precise tolerances required for mold-in insert applications. The manufacturing process begins with careful material selection and incoming inspection, followed by precision turning, threading, and knurling operations.

Primary Machinery

CNC Swiss Lathes: Citizen Miyano, Star SR-20R series for precision turning operations

Multi-Spindle Automatics: Davenport, New Britain machines for high-volume production

Thread Rolling Equipment: Waterbury Farrel machines for superior thread quality

Knurling Stations: Specialized diamond knurling tools for optimal retention patterns

Quality Control Equipment

CMM Systems: Zeiss Contura G2 for dimensional verification

Optical Comparators: Mitutoyo PH-3515F for profile inspection

Thread Gauges: Complete GO/NO-GO gauge sets per ISO 965

Surface Roughness Testers: Mitutoyo SJ-410 for finish verification

Manufacturing Process Flow

| Stage | Operation | Equipment | Quality Check |

|---|---|---|---|

| 1 | Raw Material Preparation | Bar Stock Cutting | Material Certification, Dimensional Check |

| 2 | Primary Turning | CNC Swiss Lathe | Diameter Tolerance ±0.013mm |

| 3 | Threading Operation | Thread Rolling/Cutting | Thread Pitch & Profile Verification |

| 4 | Knurling Process | Diamond Knurling Tools | Pattern Depth & Uniformity |

| 5 | Undercut Formation | Precision Grooving Tools | Depth & Position Accuracy |

| 6 | Surface Treatment | Plating/Coating Lines | Thickness & Adhesion Testing |

| 7 | Final Inspection | CMM & Optical Systems | Complete Dimensional Report |

Typical Parts Produced & Applications

🚗 Automotive Industry

Dashboard assemblies, electronic control units, lighting systems, air conditioning components, interior trim panels, and wire harness connectors requiring vibration-resistant fastening solutions.

💻 Electronics & Telecommunications

PCB mounting systems, enclosure assemblies, connector housings, heat sink attachments, cable management systems, and RF shielding applications.

✈️ Aerospace Applications

Cabin interior components, avionics housings, lightweight structural assemblies, environmental control systems, and non-critical fastening applications.

🏭 Industrial Equipment

Control panel assemblies, motor housings, pump components, instrumentation enclosures, and machinery access panels requiring reliable threaded connections.

🏠 Consumer Appliances

Kitchen appliances, home entertainment systems, power tool housings, furniture hardware, and recreational equipment assemblies.

🏥 Medical Devices

Non-implantable device housings, diagnostic equipment assemblies, laboratory instrument components, and medical cart systems requiring biocompatible fastening.

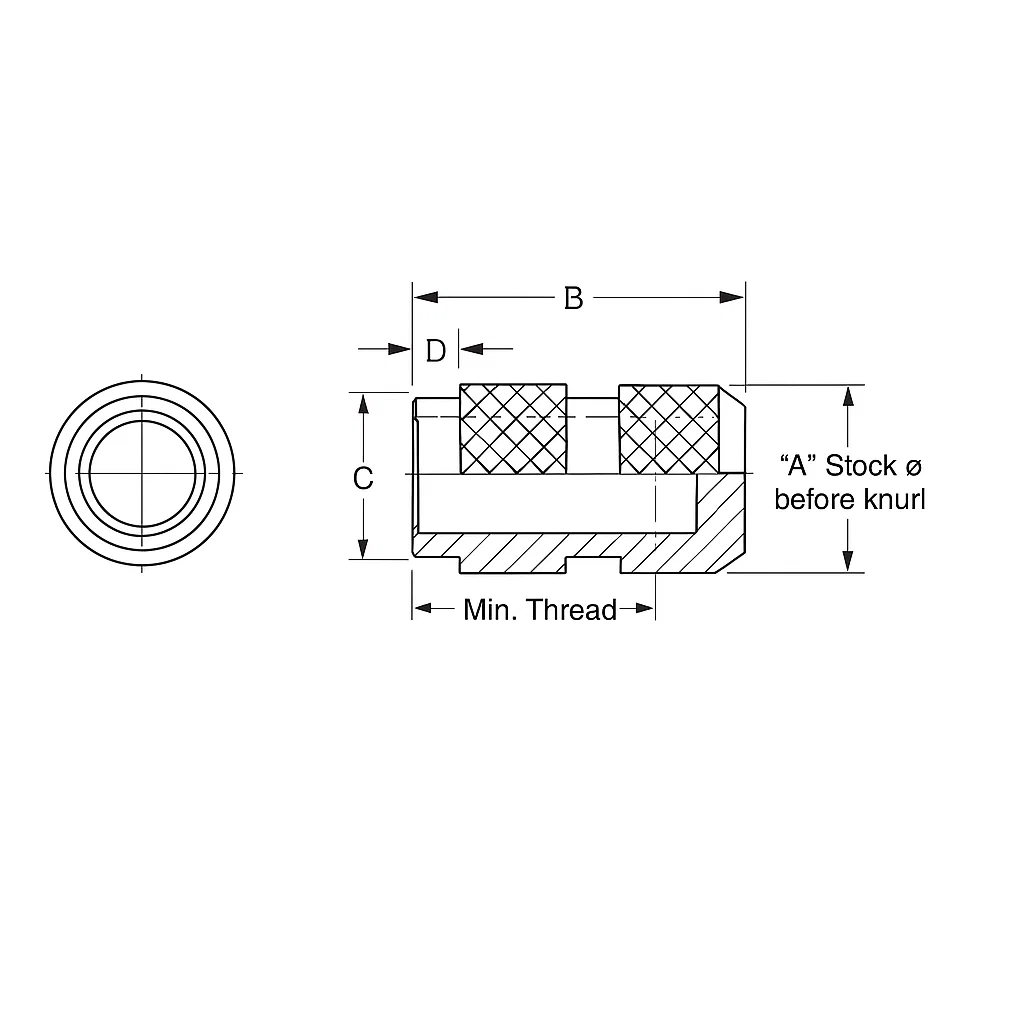

Technical Drawings & Dimensional Specifications

Standard Dimensional Range – Metric Threads (ISO)

| Thread Size | Nominal OD (mm) ‘A’ | Length Range (mm) ‘B’ | Knurl Depth (mm) | Wall Thickness (mm) |

|---|---|---|---|---|

| M2 x 0.4 | 3.2 ± 0.05 | 3.0 – 8.0 | 0.15 ± 0.03 | 0.6 min |

| M2.5 x 0.45 | 4.0 ± 0.05 | 4.0 – 10.0 | 0.20 ± 0.03 | 0.75 min |

| M3 x 0.5 | 4.8 ± 0.05 | 4.0 – 12.0 | 0.25 ± 0.05 | 0.9 min |

| M4 x 0.7 | 6.35 ± 0.08 | 5.0 – 15.0 | 0.30 ± 0.05 | 1.175 min |

| M5 x 0.8 | 7.9 ± 0.08 | 6.0 – 20.0 | 0.35 ± 0.05 | 1.45 min |

| M6 x 1.0 | 9.5 ± 0.10 | 8.0 – 25.0 | 0.40 ± 0.05 | 1.75 min |

| M8 x 1.25 | 12.7 ± 0.13 | 10.0 – 30.0 | 0.50 ± 0.08 | 2.35 min |

| M10 x 1.5 | 15.9 ± 0.13 | 12.0 – 35.0 | 0.60 ± 0.08 | 2.95 min |

Standard Dimensional Range – UNC Threads (ASME B1.1)

| Thread Size | Nominal OD (inch) | Nominal OD (mm)’A’ | Length Range (inch) ‘B’ | Length Range (mm) | Knurl Depth (inch) | Wall Thickness (inch) |

|---|---|---|---|---|---|---|

| 2-56 UNC | 0.125 ± 0.002 | 3.18 ± 0.05 | 0.125 – 0.375 | 3.2 – 9.5 | 0.006 ± 0.001 | 0.025 min |

| 4-40 UNC | 0.156 ± 0.002 | 3.96 ± 0.05 | 0.156 – 0.500 | 4.0 – 12.7 | 0.008 ± 0.001 | 0.030 min |

| 6-32 UNC | 0.188 ± 0.002 | 4.78 ± 0.05 | 0.188 – 0.625 | 4.8 – 15.9 | 0.010 ± 0.002 | 0.035 min |

| 8-32 UNC | 0.219 ± 0.003 | 5.56 ± 0.08 | 0.219 – 0.750 | 5.6 – 19.1 | 0.012 ± 0.002 | 0.040 min |

| 10-24 UNC | 0.250 ± 0.003 | 6.35 ± 0.08 | 0.250 – 0.875 | 6.4 – 22.2 | 0.014 ± 0.002 | 0.045 min |

| 1/4-20 UNC | 0.312 ± 0.004 | 7.92 ± 0.10 | 0.312 – 1.000 | 7.9 – 25.4 | 0.016 ± 0.002 | 0.050 min |

| 5/16-18 UNC | 0.375 ± 0.004 | 9.53 ± 0.10 | 0.375 – 1.250 | 9.5 – 31.8 | 0.018 ± 0.003 | 0.055 min |

| 3/8-16 UNC | 0.438 ± 0.005 | 11.13 ± 0.13 | 0.438 – 1.500 | 11.1 – 38.1 | 0.020 ± 0.003 | 0.060 min |

| 1/2-13 UNC | 0.562 ± 0.005 | 14.27 ± 0.13 | 0.562 – 2.000 | 14.3 – 50.8 | 0.024 ± 0.003 | 0.070 min |

Thread Quality Standards Comparison

| Thread System | Standard | Tolerance Class | Pitch Accuracy | Profile Tolerance |

|---|---|---|---|---|

| Metric ISO | ISO 965-1 | 6H (Standard) | ±0.002mm | Per ISO 965-2 |

| UNC Imperial | ASME B1.1 | 2B (Standard) | ±0.0001″ | Per ASME B1.2 |

| BSW British | BS 3643 | Class 2 (Normal) | ±0.002mm | Per BS 3643-2 |

| JIS Japanese | JIS B0209 | 6H (Medium) | ±0.002mm | Per JIS B0209-2 |

Surface Finishes & Treatments

Our comprehensive range of surface treatments ensures optimal performance and environmental compatibility across diverse applications. Each finish is applied using advanced electroplating and chemical processing techniques to achieve consistent quality and adherence to international standards.

| Finish Type | Coating Thickness | Corrosion Resistance | Applications | Standards |

|---|---|---|---|---|

| Natural Brass | – | Standard | Indoor Electronics, General Purpose | – |

| Nickel Plated | 5-12 μm | Excellent | High Humidity Environments | ASTM B689, IEC 60068 |

| Tin Plated | 3-8 μm | Good | Food Grade, Electronics | ASTM B545, RoHS Compliant |

| Silver Plated | 2-5 μm | Excellent | High-End Electronics, RF Applications | ASTM B700, MIL-PRF-39470 |

| Zinc Plated | 8-15 μm | Very Good | Automotive, Industrial | ASTM B633, ISO 4042 |

| Passivated | 0.1-0.3 μm | Enhanced | Marine Applications | ASTM A967, ASTM B480 |

Precision Tolerances & Quality Standards

Our commitment to precision manufacturing ensures consistent dimensional accuracy and performance reliability. All products undergo comprehensive inspection using calibrated measuring equipment traceable to national standards.

| Feature | Tolerance (mm) | Measurement Method | Frequency |

|---|---|---|---|

| Outside Diameter | ±0.025 to ±0.050 | Micrometer/CMM | 100% Inspection |

| Overall Length | ±0.050 to ±0.100 | Digital Calipers/CMM | Statistical Sampling |

| Thread Pitch | Per ISO 965 Class 6H | Thread Gauges | First Article + Random |

| Knurl Depth | ±0.025 | Optical Comparator | Setup + Random |

| Concentricity | 0.050 TIR | CMM/Runout Gauge | Process Control |

Industries & Market Applications

Our Brass mold-in threaded inserts serve critical fastening requirements across multiple industry sectors. The versatility of our products enables engineers to specify reliable fastening solutions for diverse applications ranging from high-volume consumer electronics to demanding aerospace components.

🚗 Automotive Sector

Market Share: 35% of our production

Key Applications: ECU housings, dashboard assemblies, HVAC components, lighting systems, infotainment units, wire harness connectors

Performance Requirements: Temperature cycling -40°C to +125°C, vibration resistance per ISO 16750, salt spray resistance 240+ hours

📱 Electronics & Telecommunications

Market Share: 28% of our production

Key Applications: Smartphone housings, tablet assemblies, router enclosures, base station equipment, IoT device housings

Performance Requirements: EMI shielding compatibility, thermal management, miniaturization, RoHS compliance

Injection molding

Market Share: 15% of our production

Key Applications: Cabin interior panels, avionics housings, satellite components, UAV assemblies

Performance Requirements: FAR 25.853 flame resistance, low outgassing per ASTM E595, wide temperature range operation

🏭 Industrial Equipment

Market Share: 12% of our production

Key Applications: Control panels, motor housings, pump assemblies, instrumentation enclosures

Performance Requirements: Chemical resistance, IP65/IP67 sealing compatibility, long-term reliability

Manufacturing Lead Times & Delivery

Standard Turnaround Time: 4-6 weeks for custom mold-in insert specifications. Our flexible production scheduling and extensive inventory management system ensures optimal delivery performance while maintaining the highest quality standards.

| Order Type | Quantity Range | Lead Time | Special Requirements |

|---|---|---|---|

| Sample Orders | 1-100 pieces | 7-10 days | Engineering evaluation, first article inspection |

| Standard Production | 1,000-50,000 pieces | 4-6 weeks | Standard specifications, established tooling |

| High Volume Orders | 50,000+ pieces | 6-8 weeks | Capacity planning, quality validation |

| Custom Development | Varies | 8-12 weeks | New tooling, material certification, testing |

Performance Metrics & Testing

Comprehensive performance validation ensures our mold-in Brass threaded inserts meet demanding application requirements. Our testing laboratory maintains ISO/IEC 17025 accreditation and utilizes advanced equipment for mechanical and environmental testing.

| Test Parameter | Test Method | Typical Values | Standards |

|---|---|---|---|

| Pull-Out Force | Axial Tension Test | 800-2500 N (size dependent) | ASTM D4762, ISO 898 |

| Torque-Out Resistance | Rotational Torque Test | 2-15 Nm (size dependent) | IFI-100, DIN 53273 |

| Installation Force | Mold-In Force Measurement | Minimal resistance | Internal Protocol |

| Fatigue Resistance | Cyclic Loading | 10⁶ cycles @ 50% UTS | ASTM D7791 |

| Temperature Cycling | Thermal Shock | -55°C to +125°C, 1000 cycles | IEC 60068-2-14 |

| Salt Spray Resistance | Corrosion Testing | 240+ hours (plated versions) | ASTM B117, ISO 9227 |

Frequently Asked Questions (FAQ)

Q1: What plastic materials are compatible with mold-in inserts?

A: Our inserts work with most thermoplastics including ABS, PC, PA (Nylon), POM, PP, PE, and engineered plastics like PEI, PEEK. Thermoset materials like epoxy and phenolic resins are also compatible. Material selection depends on processing temperature and chemical compatibility.

Q2: How do mold-in inserts compare to heat-set inserts?

A: Mold-in inserts provide superior retention strength, eliminate secondary operations, reduce assembly time, and ensure consistent positioning. They’re ideal for high-volume production where post-molding installation would be costly or impractical.

Q3: What are the design considerations for mold tooling?

A: Pin diameter should match insert ID with +0.025/-0.000mm tolerance. Pin length should be 0.5-1.0mm shorter than insert length. Consider draft angles, gate location, and cooling channel placement to minimize flash formation and ensure proper flow.

Q4: Can inserts be used in thin-wall applications?

A: Yes, our inserts can be used in walls as thin as 1.5mm around the insert boss. Proper boss design with adequate draft and radius features is essential. We recommend minimum boss diameter of 1.5 × insert OD for optimal performance.

Q5: What surface treatments are available for food-grade applications?

A: We offer lead-free Brass grades with tin plating or passivated finishes that comply with FDA regulations. All materials and processes are documented for traceability and comply with food contact regulations.

Q6: How do you ensure consistent quality across large production runs?

A: Our ISO 9001:2015 certified quality system includes statistical process control, automated inspection systems, and comprehensive documentation. Each lot includes dimensional reports and material certificates.

Q7: What is the minimum order quantity for custom inserts?

A: MOQ varies by complexity – typically 1,000 pieces for standard modifications, 5,000 pieces for new tooling requirements. We offer flexible scheduling and can accommodate prototype quantities for evaluation.

Q8: Are metric and imperial thread options available?

A: Yes, we manufacture complete ranges of metric (M2-M12), unified (4-40 to 1/2-13), and BSW threads. Custom thread forms and pitches are available with appropriate minimum quantities.

Q9: What environmental testing capabilities do you offer?

A: Our laboratory performs temperature cycling, humidity testing, salt spray corrosion, UV exposure, chemical resistance, and mechanical testing per industry standards. Full test reports are available.

Q10: Can you provide design assistance for new applications?

A: Our application engineering team offers comprehensive design support including FEA analysis, material selection, tooling consultation, and prototype development. We work closely with mold makers and OEMs throughout the development process.

Why Choose Our Brass Mold-In Inserts

🎯 Competitive Advantages & Unique Selling Propositions

⚡ Faster Turnaround Times

Industry-leading 4-6 week standard delivery with expedited options available. Our streamlined production processes and advanced planning systems ensure reliable delivery performance.

🎯 Superior Customer Support

Dedicated application engineers provide technical consultation, design optimization, and ongoing support throughout product lifecycle. Multilingual support team available 24/7.

🌐 Global Exposure & Experience

Three decades of international experience serving Fortune 500 companies across six continents. Deep understanding of regional standards and compliance requirements.

🔧 Customization Capabilities

Flexible manufacturing systems accommodate custom dimensions, materials, finishes, and packaging. From prototype to million-piece production runs.

📦 Customized Packaging Solutions

Bulk packaging, individual trays, vacuum-sealed bags, and customer-labeled containers. Private labeling and direct-to-line packaging available.

🎖️ Quality Certifications

ISO 9001:2015, ISO 14001:2015, OHSAS 18001 certified. RoHS, REACH, and conflict minerals compliant. AS9100 aerospace certification in progress.

International Standards Compliance

| Standard Type | Designation | Scope | Compliance Level |

|---|---|---|---|

| Material Standards | ASTM B16, B124, B135 | Brass Alloy Specifications | Full Compliance |

| Threading Standards | ISO 965, ASME B1.1, DIN 13 | Thread Specifications | Class 6H Tolerance |

| Dimensional Standards | ISO 286, ANSI B4.1 | Tolerance Systems | IT7-IT9 Grades |

| Testing Standards | ASTM D4762, ISO 898 | Mechanical Testing | Laboratory Certified |

| Environmental Standards | IEC 60068, MIL-STD-810 | Environmental Testing | Test House Approved |

| Quality Standards | ISO 9001:2015, AS9100 | Quality Management | Third Party Certified |

Packaging & Shipping Solutions

Our comprehensive packaging and logistics capabilities ensure product integrity from factory to final assembly. We offer multiple packaging formats optimized for different handling and storage requirements.

📦 Standard Packaging Options

Bulk Bags: PE bags with desiccant for moisture protection

Compartmented Trays: Anti-static trays for automated handling

Tube Packaging: Individual tubes for small quantities

Vacuum Sealed: Long-term storage protection

🏷️ Custom Labeling Services

Private Labeling: Customer logo and part numbers

Bar Code Labels: EAN, UPC, Code 128 formats

QR Codes: Traceability and documentation links

Multi-Language: Regional language requirements

🚢 Global Shipping Network

Express Shipping: 3-5 days worldwide via DHL, FedEx

Economy Shipping: 7-14 days via air freight

Sea Freight: Large volume shipments, 15-30 days

Regional Hubs: Stock points in USA, Europe, Asia

📋 Documentation Package

Certificate of Compliance: Material and dimensional verification

Test Reports: Mechanical and environmental data

Traceability Records: Full production history

Customs Documentation: Commercial invoice, packing list, COO

“We have been using these Brass mold-in inserts from this Indian manufacturer for our automotive electronics assemblies for over 5 years. The quality consistency is outstanding, and their technical support team helped us optimize our mold design to eliminate flash issues. The delivery performance has been exceptional even during challenging supply chain periods. Their ability to provide custom solutions quickly has made them our preferred supplier for all threaded insert requirements.”

– Robert Chen, Senior Design Engineer, D****** Automotive Systems

Related Search Terms & Keywords

Related Terms: brass threaded inserts for plastic molding, injection molding hardware, mold-in fasteners, threaded brass bushings, knurled brass inserts, blind threaded inserts, plastic assembly hardware, molded-in fasteners, precision brass components, electronic enclosure hardware, automotive fasteners, threaded insert specifications, mold tooling accessories, thermoplastic fastening solutions, brass hardware manufacturing

Technical Glossary

Diamond Knurl Pattern

A crosshatch pattern machined into the external surface of the insert providing maximum retention force through mechanical interlocking with the host plastic material.

Mold-In Installation

A process where threaded inserts are positioned in the mold cavity before plastic injection, becoming permanently embedded during the molding cycle.

Blind Insert Design

A closed-end insert configuration that prevents plastic material from entering the threaded bore during the molding process.

Pull-Out Force

The maximum axial load that can be applied to an installed insert before failure occurs, typically measured in Newtons or pounds-force.

Torque-Out Resistance

The rotational force required to cause insert failure through spinning within the host material, measured in Newton-meters or inch-pounds.

Boss Design

A cylindrical protrusion in the molded part that houses the threaded insert, designed with specific wall thickness and geometry requirements.

Flash Formation

Unwanted plastic material that can form around the insert during molding due to improper tooling clearances or processing conditions.

Undercut Feature

Machined grooves in the insert body that provide additional mechanical retention through plastic material flow and solidification.

🚀 Ready to Get Started?

Contact our technical experts today for custom quotations, engineering support, and product samples. We’re committed to providing the perfect fastening solution for your application requirements.