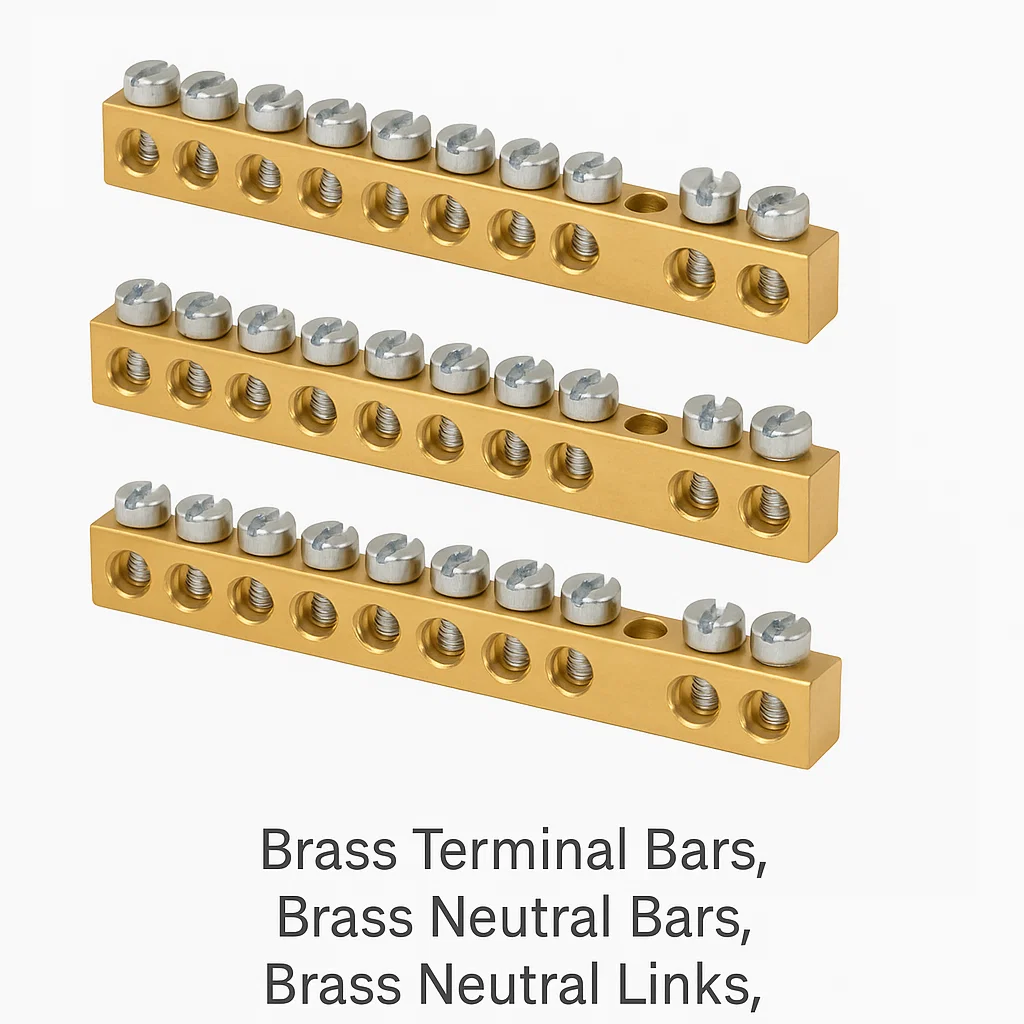

Brass Terminals, Brass Neutral Bars, Brass Neutral Links, Brass Terminal bars

Brass Terminal Bars | Brass Neutral Bars | Brass Neutral Links

Overview: High-Performance Brass Terminal Bars for Electrical Distribution Systems

We are one of the leading manufacturers and exporters of Brass Terminal Bars, Brass Neutral Bars, Brass Neutral Links, Brass Terminal Links, and Bronze Terminals from India. We have been supplying precision-engineered electrical terminal connectors and neutral distribution bars to the world market for many decades. Our comprehensive range of terminal connecting bars encompasses Brass busbar terminals, Copper terminal blocks, Bronze terminal links, and specialized neutral earthing bars designed for control panel assemblies, switchgear enclosures, distribution boards, and industrial electrical installations. These electrical terminal bars serve as critical junction points for neutral wire connections, earth bonding, and power distribution in low voltage and medium voltage electrical systems. Manufactured from high-conductivity Brass, Bronze, and Copper alloys with Stainless Steel or galvanized Steel terminal screws, our terminal distribution blocks conform to international electrical standards including IS, BS, DIN, IEC, and UL specifications. With advanced CNC machining capabilities, hot forging processes, and precision brass extrusion technology, we produce custom terminal bars in various cross-sectional profiles, hole configurations, and plating finishes including tin-plated, nickel-plated, and silver-plated options to ensure superior electrical conductivity, corrosion resistance, and long-term reliability in diverse environmental conditions ranging from residential electrical panels to heavy industrial switchgear applications.

Our manufacturing facility specializes in producing terminal connector bars ranging from compact 2-way neutral links to large 12-way brass busbar distribution blocks, accommodating wire sizes from 1.5mm² to 240mm² and current ratings from 15A to 800A. The terminal bars are engineered with precise hole spacing, thread configurations (M3, M4, M5, M6, M8, M10), and mounting options to facilitate seamless integration into electrical enclosures, control cabinets, junction boxes, and outdoor weatherproof installations. We maintain strict quality control protocols throughout the manufacturing process, from raw material testing of Brass ingots and Bronze rods to final dimensional inspection and electrical conductivity testing, ensuring every brass neutral bar and terminal link meets or exceeds international quality standards. Our engineering team works closely with customers to develop customized terminal bar solutions, including special hole patterns, mounting hole configurations, insulated terminal bars, and terminal blocks with integrated bus bar extensions for specialized applications in renewable energy systems, industrial automation, marine electrical systems, railway signaling, telecommunications infrastructure, and building management systems.

Product Categories: Comprehensive Range of Terminal Bars and Neutral Links

Brass Terminal Bars: Brass terminal bars represent the most versatile category of electrical connecting components used extensively in control panel wiring, distribution board assemblies, and switchgear installations. Manufactured from high-grade Brass alloys such as CuZn37 (CW508L), CuZn39Pb3 (CW614N), and C36000 free-cutting Brass, these terminal distribution bars offer excellent electrical conductivity ranging from 25% to 28% IACS (International Annealed Copper Standard), combined with superior machinability for precision hole drilling and threading operations. The brass terminal connector bars are produced through hot forging or brass extrusion processes followed by CNC machining to achieve tight dimensional tolerances of ±0.05mm on hole centers and ±0.02mm on thickness variations. Standard configurations include linear terminal bars with equidistant hole spacing, L-shaped corner terminal bars for cabinet mounting, and T-junction terminal bars for branching circuits. The terminal bars feature countersunk or through-holes tapped to metric (M3, M4, M5, M6, M8) or imperial (6-32, 8-32, 10-32) thread standards, accommodating various terminal screw types including pan head, hex head, and slotted screws manufactured from zinc-plated Steel, Stainless Steel grade 304 or 316, or brass screws for non-magnetic applications. Surface treatments include natural Brass finish, tin-plated coating (typically 5-10 microns thickness) for enhanced solderability and oxidation resistance, nickel-plated finish (8-15 microns) for improved corrosion protection in harsh environments, and silver-plated terminals (3-5 microns) for maximum electrical conductivity in high-current applications. These brass busbar terminals find applications in motor control centers, programmable logic controller (PLC) cabinets, variable frequency drive (VFD) installations, lighting control panels, HVAC control systems, and industrial process control equipment where reliable neutral connections and earth bonding are essential for electrical safety and system performance.

Brass Neutral Bars: Brass neutral bars, also known as neutral link bars or neutral distribution blocks, are specifically designed to provide a common connection point for multiple neutral conductors in electrical distribution systems, ensuring balanced load distribution and proper circuit protection. These neutral terminal bars are manufactured from high-conductivity Brass alloys conforming to standards such as IS 319 Type-1, BS 2874 CZ121, DIN 17660 CuZn37, ASTM B16 C36000, and JIS C3604 Brass specifications. The neutral bars typically feature a rectangular cross-section with dimensions ranging from 20mm x 3mm for residential applications to 100mm x 10mm for industrial distribution boards, with multiple tapped holes arranged in single or double rows to accommodate wire terminations from 1.5mm² to 95mm² cable sizes. The neutral terminal bars are designed with specific hole patterns matching standard DIN rail mounting dimensions (35mm spacing) or custom mounting configurations as per customer panel layouts. Advanced designs incorporate insulated neutral bars with molded polycarbonate or fiberglass-reinforced polyester insulation providing electrical isolation up to 1000V AC, integrated wire entry guides for organized cable management, and color-coded identification (typically blue for neutral connections as per IEC 60445 standards). Manufacturing processes include precision brass bar cutting, multi-spindle gang drilling for simultaneous hole creation, CNC tapping operations for thread formation, and automated deburring to remove sharp edges ensuring safe wire installation. Quality testing includes electrical resistance measurements (typically <0.01 ohms for proper neutral continuity), pull-out strength testing of threaded connections, and thermal cycling tests to verify dimensional stability under temperature variations from -40°C to +120°C. Brass neutral distribution bars are indispensable components in three-phase distribution boards, single-phase consumer units, modular distribution systems, and industrial control panels where multiple circuits require neutral wire consolidation for proper overcurrent protection device operation and earth fault detection.

Brass Neutral Links: Brass neutral links serve as compact, space-efficient terminal connectors specifically engineered for joining neutral conductors in confined electrical enclosures where full-length terminal bars may not be practical. These neutral link terminals typically consist of short brass bars (50mm to 150mm length) with 2 to 6 terminal positions, offering flexible neutral wire distribution options in small junction boxes, auxiliary control panels, and modular distribution systems. Manufactured from CuZn37 leaded Brass or CuZn39Pb3 free-machining Brass alloys providing machinability ratings of 90-100% (based on C36000 as reference), these neutral links undergo precision CNC milling operations to create chamfered edges, smooth surfaces, and accurately positioned mounting holes. The terminal connections utilize high-quality terminal screws with hexagonal socket heads (Allen type) or Phillips/slotted drive configurations, manufactured from corrosion-resistant materials including zinc-plated Carbon Steel grade 4.8 or 8.8, austenitic Stainless Steel grades 304 (A2) or 316 (A4), or Brass screws for completely non-ferrous assemblies in sensitive electronic applications. Design features include raised contact platforms ensuring positive wire-to-metal contact, spring washer compatibility for vibration-resistant terminations, and optional insulated mounting bases providing electrical isolation and mechanical protection. The neutral links accommodate various wire termination methods including direct insertion of solid conductors, ring terminal lugs, fork terminals, and ferrule-terminated stranded wires, with clamping forces ranging from 3Nm to 12Nm torque depending on screw size and terminal current rating. Surface finishing options encompass electroplated tin coating (matte or bright finish) providing excellent corrosion resistance and low contact resistance, electroless nickel plating offering uniform coverage on complex geometries, and immersion silver plating for high-frequency applications. These compact neutral terminal links are extensively used in residential circuit breaker panels, commercial lighting distribution boards, DIN rail mounted terminal block assemblies, photovoltaic solar system combiner boxes, and building automation system control panels where space optimization and modular installation flexibility are paramount design considerations.

Brass Terminal Links: Brass terminal links constitute a broader category of electrical connecting bars designed for general-purpose wire terminations beyond neutral connections, including line conductors, protective earth bonding, and equipment grounding applications across diverse voltage and current ratings. These terminal connecting links are engineered with versatile configurations including single-row terminal strips, double-row terminal bars, and multi-tier terminal blocks accommodating mixed wire sizes within a single assembly. Manufacturing utilizes premium Brass alloys such as C26000 Cartridge Brass (70% Copper, 30% Zinc) offering excellent cold-working properties, C27400 Yellow Brass providing enhanced dezincification resistance in plumbing and marine applications, and C28000 Muntz Metal (60% Copper, 40% Zinc) for heavy-duty industrial terminal applications requiring maximum strength. The production process encompasses hot extrusion of Brass billets through precision dies creating continuous profiles, followed by cut-to-length operations using high-speed circular saws or abrasive cutoff machines, CNC drilling centers equipped with multiple spindles for parallel hole creation, thread tapping using form taps or cut taps depending on material hardness, and comprehensive deburring operations employing vibratory finishing or tumbling processes. Design innovations include integrated bus bar extensions creating continuous electrical paths between terminal sections, slotted mounting holes allowing position adjustment during installation, captive screw mechanisms preventing fastener loss during maintenance operations, and wire entry funnels facilitating guided conductor insertion. Performance specifications encompass continuous current ratings from 10A to 600A (based on terminal size and conductor cross-section), short-circuit withstand ratings up to 20kA for 1 second, temperature rise limits of 50K above ambient at rated current, and contact resistance values below 5 milliohms ensuring minimal voltage drop and power loss. These brass terminal links serve critical functions in motor starter assemblies, power distribution centers, mining equipment electrical panels, oil and gas platform control systems, water treatment plant automation, and transportation infrastructure where robust, reliable terminal connections must withstand mechanical vibration, temperature extremes, and corrosive atmospheric conditions throughout extended service lifecycles.

Bronze Terminals: Bronze terminals represent specialized electrical connectors manufactured from Copper-Tin alloys (Phosphor Bronze, Aluminum Bronze, Silicon Bronze) offering superior mechanical strength, spring characteristics, and corrosion resistance compared to standard Brass terminals, making them ideal for demanding applications requiring enhanced durability and electrical performance. Phosphor Bronze terminals (typically C51000 or C52100 alloys containing 4.5-5.5% Tin and 0.15-0.25% Phosphorus) exhibit excellent fatigue resistance, electrical conductivity of approximately 15% IACS, and elastic properties enabling spring-loaded terminal designs for vibration-resistant connections. Aluminum Bronze terminals (C61400, C63000 alloys with 9-12% Aluminum) provide exceptional corrosion resistance in marine and industrial environments, combined with tensile strength exceeding 600 MPa and yield strength above 250 MPa for heavy-duty terminal applications. Manufacturing processes include precision Bronze casting using sand molds or investment casting for complex geometries, followed by CNC machining operations to achieve final dimensional tolerances, or alternatively cold-working of Bronze strips through progressive die stamping for high-volume terminal production. Bronze terminal bars feature similar configurations to Brass terminals including drilled and tapped holes for screw terminations, slot-type terminals accommodating quick-connect tab terminals, and compression-style terminals utilizing set screws or spring clamps. Surface treatments include natural Bronze patina providing inherent corrosion protection, tin-plated finishes enhancing solderability, and specialized coatings such as chromate conversion or organic protective finishes for extended environmental durability. The superior mechanical properties of Bronze terminals enable thinner cross-sections compared to Brass equivalents while maintaining equivalent current-carrying capacity, resulting in space-saving terminal designs for compact electrical enclosures. Bronze terminal connectors find specialized applications in maritime electrical systems, offshore platform installations, chemical processing plant controls, desalination equipment, mining machinery electrical panels, and railway traction systems where aggressive environmental conditions, mechanical stress, and thermal cycling demand terminal materials exceeding standard Brass performance characteristics.

Material Specifications and International Grade Standards

The selection of appropriate Brass, Bronze, and Copper alloys for terminal bar manufacturing directly impacts electrical conductivity, mechanical strength, machinability, and corrosion resistance of the finished components. Our terminal bars are manufactured from internationally recognized alloy grades conforming to multiple standards systems to ensure global compatibility and material traceability.

| Material Type | Indian Standard (IS) | British Standard (BS) | ASTM (USA) | DIN (Germany) | JIS (Japan) | Chinese Standard (GB) |

|---|---|---|---|---|---|---|

| Free-Cutting Brass | IS 319 Type-1 | BS 2874 CZ121 | ASTM B16 C36000 | DIN 17660 CuZn39Pb3 | JIS H3250 C3604 | GB/T 4423 HPb59-1 |

| Leaded Brass | IS 319 Type-2 | BS 2874 CZ124 | ASTM B16 C37700 | DIN 17660 CuZn40Pb2 | JIS H3250 C3771 | GB/T 4423 HPb62-2 |

| Cartridge Brass | IS 410 | BS 2870 CZ106 | ASTM B36 C26000 | DIN 17660 CuZn30 | JIS H3100 C2600 | GB/T 2059 H70 |

| Yellow Brass | IS 410 | BS 2870 CZ108 | ASTM B36 C27400 | DIN 17660 CuZn37 | JIS H3100 C2700 | GB/T 2059 H65 |

| Phosphor Bronze | IS 6912 Grade-1 | BS 2870 PB102 | ASTM B103 C51000 | DIN 17662 CuSn5 | JIS H3110 C5191 | GB/T 4423 QSn6.5-0.1 |

| Aluminum Bronze | IS 306 | BS 2874 CA104 | ASTM B150 C61400 | DIN 17664 CuAl10Fe | JIS H3110 C6140 | GB/T 5231 QAl9-4 |

| Electrolytic Copper | IS 613 | BS EN 1976 Cu-ETP | ASTM B152 C11000 | DIN 1787 Cu-ETP | JIS H3100 C1100 | GB/T 5231 T2 |

Material Property Comparison Table:

| Material Property | Free-Cutting Brass (CuZn39Pb3) | Cartridge Brass (C26000) | Phosphor Bronze (C51000) | Aluminum Bronze (C61400) | Electrolytic Copper (C11000) |

|---|---|---|---|---|---|

| Electrical Conductivity (% IACS) | 26-28% | 27-30% | 13-15% | 12-15% | 100-103% |

| Tensile Strength (MPa) | 370-480 | 310-420 | 415-520 | 600-750 | 210-280 |

| Yield Strength (MPa) | 140-220 | 105-170 | 165-280 | 250-380 | 70-95 |

| Hardness (HB) | 85-110 | 55-85 | 95-130 | 140-180 | 45-60 |

| Machinability Rating (%) | 90-100 | 60-70 | 40-50 | 30-40 | 20-30 |

| Thermal Conductivity (W/m·K) | 115-125 | 120-135 | 50-65 | 40-60 | 385-395 |

| Coefficient of Expansion (10⁻⁶/K) | 19.9 | 19.9 | 17.8 | 16.2 | 16.5 |

| Density (g/cm³) | 8.50 | 8.53 | 8.80 | 7.65 | 8.94 |

| Corrosion Resistance | Good | Good | Excellent | Excellent | Very Good |

Manufacturing Processes and Advanced Production Machinery

Our state-of-the-art manufacturing facility employs sophisticated metalworking equipment and precision machining technologies to produce terminal bars meeting stringent dimensional tolerances and electrical performance specifications. The manufacturing process begins with raw material verification using X-ray fluorescence (XRF) spectrometers for composition analysis and optical emission spectroscopy (OES) for trace element detection, ensuring compliance with specified Brass, Bronze, and Copper alloy grades. Brass ingots and Bronze billets are subjected to hot extrusion processes using 500-ton to 2000-ton horizontal extrusion presses operating at temperatures between 650°C and 750°C, forcing heated metal through precision-hardened steel dies to create continuous bar profiles with consistent cross-sectional geometries. Alternative production methods include hot forging operations utilizing drop hammers or hydraulic forging presses for complex terminal bar shapes, followed by hot rolling on multi-stand rolling mills to achieve desired thickness reductions and material work hardening characteristics.

Precision machining operations form the cornerstone of terminal bar production quality, employing Computer Numerically Controlled (CNC) machining centers equipped with multiple-axis capabilities for simultaneous drilling, tapping, and milling operations. Our CNC equipment inventory includes vertical machining centers with 3-axis, 4-axis, and 5-axis configurations, horizontal machining centers for high-volume production runs, and specialized gang drilling machines featuring 8 to 16 synchronized spindles for parallel hole creation ensuring perfect hole alignment across terminal bar lengths. Threading operations utilize rigid tapping attachments with synchronous spindle-feed coordination, achieving thread tolerances conforming to ISO 965 6H tolerance class for internal threads and minimizing tap breakage in work-hardened Brass materials. Surface finishing processes include CNC-controlled milling of mounting surfaces achieving flatness tolerances within 0.03mm per 100mm length, deburring operations using rotary wire brushes or abrasive nylon filament brushes removing sharp edges and metal burrs, and vibratory finishing in ceramic media for uniform surface smoothness and edge radiusing.

Electroplating and surface treatment operations employ rack plating or barrel plating processes depending on component geometry and production volumes. Tin electroplating utilizes alkaline or acid tin plating baths maintaining controlled current densities between 1-4 A/dm² and deposition rates producing uniform coating thickness of 5-10 microns (approximately 0.2-0.4 mils), with post-plating hot oil reflow treatment creating bright, solderable surfaces. Nickel electroplating employs Watts-type nickel plating solutions or sulfamate nickel baths for thick, ductile deposits, operating at current densities of 2-8 A/dm² and achieving coating thickness of 8-15 microns with excellent corrosion resistance. Silver electroplating uses cyanide-free silver plating solutions depositing high-purity silver layers 3-5 microns thick, providing maximum electrical conductivity and low contact resistance for high-current applications. Quality control equipment includes coating thickness gauges using X-ray fluorescence or eddy current principles for non-destructive measurement, adhesion testing per ASTM B571 using tape testing or bend testing methods, and salt spray testing per ASTM B117 verifying corrosion resistance through 96-hour to 500-hour exposure cycles.

Manufacturing Process Flow

Inspection

Forging

& Tapping

& Finishing

(if required)

Inspection

& Dispatch

Key Manufacturing Equipment Utilized:

| Equipment Category | Machine Type | Specifications | Application in Terminal Bar Production |

|---|---|---|---|

| Material Processing | Horizontal Extrusion Press | 500-2000 Ton Capacity, Temperature Control 650-750°C | Brass bar extrusion for continuous profile creation |

| Cutting Operations | High-Speed Circular Saw | Carbide-Tipped Blades, Coolant Delivery System | Precision cut-to-length operations, burr-free cutting |

| Drilling | CNC Multi-Spindle Gang Drill | 8-16 Synchronized Spindles, 0.02mm Positional Accuracy | Parallel hole drilling ensuring perfect alignment |

| Threading | CNC Tapping Centers | Rigid Tapping, ISO 965 Thread Tolerance | Internal thread creation for terminal screws |

| Milling | CNC Vertical Machining Centers | 3-5 Axis, Repeatability ±0.005mm | Surface milling, slot creation, custom features |

| Surface Treatment | Electroplating Line | Automatic Rack/Barrel System, 5000L Tank Capacity | Tin, nickel, silver plating for corrosion protection |

| Finishing | Vibratory Finishing Machine | Ceramic Media, Variable Frequency Control | Deburring, edge radiusing, surface smoothing |

| Quality Control | CMM Coordinate Measuring Machine | 0.003mm Accuracy, 3D Dimensional Measurement | Dimensional verification, hole position inspection |

Dimensional Specifications and Technical Drawings

Our terminal bars are manufactured in standardized dimensions as well as custom configurations tailored to specific electrical panel requirements. The following dimensional charts provide comprehensive specifications for commonly produced terminal bar formats.

Terminal Bar Dimensional Reference

L (Overall Length)WP (Pitch)Ø DSide View – Brass Terminal Bar

Standard Dimension Table for Brass Terminal Bars:

| Part Number | No. of Terminals | Overall Length (L) mm | Width (W) mm | Thickness (T) mm | Hole Diameter (Ø) mm | Thread Size | Hole Pitch (P) mm | Current Rating (A) |

|---|---|---|---|---|---|---|---|---|

| BTB-2/20 | 2 | 60 | 20 | 3 | 4.2 | M4 | 25 | 15 |

| BTB-3/25 | 3 | 85 | 25 | 4 | 5.2 | M5 | 30 | 25 |

| BTB-4/30 | 4 | 115 | 30 | 5 | 6.5 | M6 | 32 | 40 |

| BTB-6/40 | 6 | 170 | 40 | 6 | 6.5 | M6 | 30 | 63 |

| BTB-8/50 | 8 | 220 | 50 | 8 | 8.5 | M8 | 30 | 100 |

| BTB-10/60 | 10 | 280 | 60 | 10 | 10.5 | M10 | 30 | 160 |

| BTB-12/80 | 12 | 340 | 80 | 10 | 10.5 | M10 | 30 | 250 |

| BTB-16/100 | 16 | 450 | 100 | 12 | 10.5 | M10 | 30 | 400 |

Manufacturing Tolerances: All dimensional tolerances conform to ISO 2768-m (medium) general tolerance standards unless otherwise specified. Critical dimensions include hole center-to-center distance tolerance of ±0.1mm, hole diameter tolerance of H11 (per ISO 286), overall length tolerance of ±0.3mm, width and thickness tolerance of ±0.2mm, flatness tolerance of 0.05mm per 100mm length, and perpendicularity of drilled holes to surface within 0.1mm per 25mm depth. Thread tolerances conform to ISO 965-1 tolerance class 6H for internal threads, ensuring proper engagement with standard metric screws manufactured to tolerance class 6g.

Surface Finishes and Plating Options

Surface treatment selection significantly influences the electrical performance, corrosion resistance, solderability, and aesthetic appearance of terminal bars. We offer comprehensive plating and finishing options customized to application requirements and environmental exposure conditions.

Natural Brass Finish: Unplated Brass terminals exhibit the characteristic golden-yellow metallic appearance of Copper-Zinc alloys, providing adequate corrosion resistance for indoor, climate-controlled environments. Natural Brass develops a protective oxide patina over time, which may increase contact resistance slightly but does not impair functionality in low-current control panel applications. This finish option offers cost advantages for budget-sensitive projects and applications where surface appearance is not critical.

Tin Plating (Electroplated): The most widely specified finish for electrical terminal bars, tin electroplating provides exceptional solderability, low contact resistance (typically <2 milliohms), and effective protection against atmospheric corrosion. Our tin plating process deposits pure tin (Sn 99.9%+ purity) in coating thickness ranging from 5 to 15 microns, conforming to standards such as ASTM B545, IEC 60352, and DIN 41651. Bright tin plating produces a lustrous, mirror-like surface through post-plating reflow treatment at 180-230°C, melting and redistributing the tin coating to eliminate porosity and create a smooth, highly solderable surface. Matte tin plating maintains the as-plated crystalline structure without reflow treatment, offering a satin appearance with equivalent electrical performance. Tin-plated terminals resist tin whisker formation through grain structure control and stress-relief processes, ensuring long-term reliability in electronic applications.

Nickel Plating (Electroplated): Nickel electroplating offers superior corrosion and wear resistance compared to tin plating, making it ideal for harsh industrial environments, outdoor installations, and high-vibration applications. Standard bright nickel plating deposits ductile, adherent nickel layers 8-15 microns thick over a copper strike undercoat, providing excellent substrate adhesion and uniform coverage. The nickel plating exhibits hardness values of 150-200 HV (Vickers), significantly harder than tin or silver plating, resisting mechanical abrasion during cable installation and removal cycles. Electroless nickel plating represents an alternative deposition method producing uniform coating thickness on complex geometries, including internal threaded holes, with excellent corrosion resistance and solderability (when phosphorus content is controlled below 5%). Nickel-plated terminals withstand salt spray exposure exceeding 500 hours per ASTM B117 without base metal corrosion, suitable for coastal installations, marine applications, and chemical processing facilities.

Silver Plating (Electroplated): Silver electroplating delivers maximum electrical conductivity (approximately 106% IACS for pure silver) and lowest contact resistance among common plating materials, specified for high-current applications, radio frequency (RF) connections, and precision instrumentation terminals. Pure silver deposits 3-8 microns thick provide stable, low-resistance connections with minimal voltage drop, critical for power distribution busbars and high-current switching applications. Silver plating maintains electrical performance across wide temperature ranges and is resistant to oxidation at moderate temperatures, though exposed silver surfaces may develop tarnish (silver sulfide) in sulfur-containing atmospheres. Immersion silver plating offers a cost-effective alternative for thinner coatings (0.1-0.3 microns) providing temporary corrosion protection and excellent solderability for pre-tinned wire terminations.

Comparative Plating Performance Table:

| Performance Parameter | Natural Brass | Tin Plating | Nickel Plating | Silver Plating |

|---|---|---|---|---|

| Contact Resistance (milliohms) | 5-10 | 1-3 | 2-5 | 0.5-1.5 |

| Salt Spray Resistance (hours) | 24-48 | 96-240 | 500-1000 | 48-96 |

| Solderability | Fair | Excellent | Good | Excellent |

| Hardness (HV) | 80-120 | 10-20 | 150-250 | 60-90 |

| Temperature Stability (°C) | 200 | 150 | 400 | 300 |

| Relative Cost | 1.0x | 1.3-1.5x | 1.6-2.0x | 2.5-4.0x |

| Typical Coating Thickness (microns) | N/A | 5-15 | 8-15 | 3-8 |

Industries and Applications Utilizing Terminal Bars

Brass terminal bars, neutral bars, and neutral links serve as essential electrical distribution components across diverse industries requiring reliable, safe, and code-compliant neutral conductor connections, earth bonding, and wire termination solutions.

Electrical Panel Manufacturing: Low voltage switchgear assemblies, motor control centers (MCC), power distribution boards, consumer units, and modular distribution systems incorporate neutral terminal bars as primary neutral wire collection points ensuring balanced three-phase distribution and proper residual current device (RCD) operation. Terminal bars facilitate organized wire routing, maintenance accessibility, and compliance with electrical installation standards including IEC 61439, UL 508A, and NEC Article 408.

Building and Construction: Commercial building electrical systems, residential apartment distribution panels, hospital medical-grade power systems, data center electrical infrastructure, and intelligent building management systems utilize terminal bars for systematic neutral wire distribution, ground fault protection, and equipment grounding networks conforming to national electrical codes and green building certification requirements (LEED, BREEAM).

Industrial Automation: Programmable logic controller (PLC) cabinets, SCADA system control panels, industrial robot control stations, conveyor system electrical enclosures, and process automation equipment integrate terminal bars for organizing field device wiring, sensor connections, and actuator power distribution in manufacturing facilities, automotive assembly plants, food processing operations, and pharmaceutical production environments.

Renewable Energy: Solar photovoltaic combiner boxes, string inverter junction boxes, wind turbine nacelle control panels, battery energy storage system (BESS) enclosures, and microgrid distribution assemblies employ terminal bars for DC negative bus connections, AC neutral distribution, and grounding electrode conductor terminations meeting UL 1741, IEC 62109, and IEEE 1547 interconnection standards.

Transportation Infrastructure: Railway signaling cabinets, subway traction power substations,

🔥 Request Your Free Quote for Brass Terminals, Brass Neutral Links, Terminal bars – Get competitive pricing in 24 hours- sales@conexscrews.com

🔬 Schedule Technical Consultation – Discuss your specific requirements Call +91 22-43449300

📦 Order Sample Parts – Test our quality before committing Call +91 22-43449300

📞 Call Our Experts – Get immediate answers to your questions Call +91 22-43449300