Brass Plastic Molding Inserts & Injection Molding Inserts

Premium Manufacturer & Exporter from India | ISO 9001:2015, ISO 14001:2015, ISO 45001:2018 Certified

Price: US$ 12.30/kilogram

We are one of the leading manufacturers and exporters of Brass Plastic Molding Inserts and Brass Injection Molding Inserts from India. We have been supplying precision-engineered Brass inserts to the world market for many decades. Our comprehensive range includes threaded inserts for plastic, rotomolding inserts, blow molding inserts, and specialized injection molding inserts designed for various industrial applications. With over three decades of manufacturing excellence, we have established ourselves as a trusted supplier to major markets in USA, Europe, Australia, and Asia. Our state-of-the-art manufacturing facility employs advanced CNC machining, precision turning, and quality control processes to ensure consistent delivery of superior Brass inserts. We specialize in both standard and custom-engineered solutions, offering flexibility in design, material grades, plating options, and dimensional specifications. Our technical expertise spans across multiple industries including automotive, electronics, appliances, furniture, and industrial equipment manufacturing.

Product Overview & Types

Brass Plastic Molding Inserts

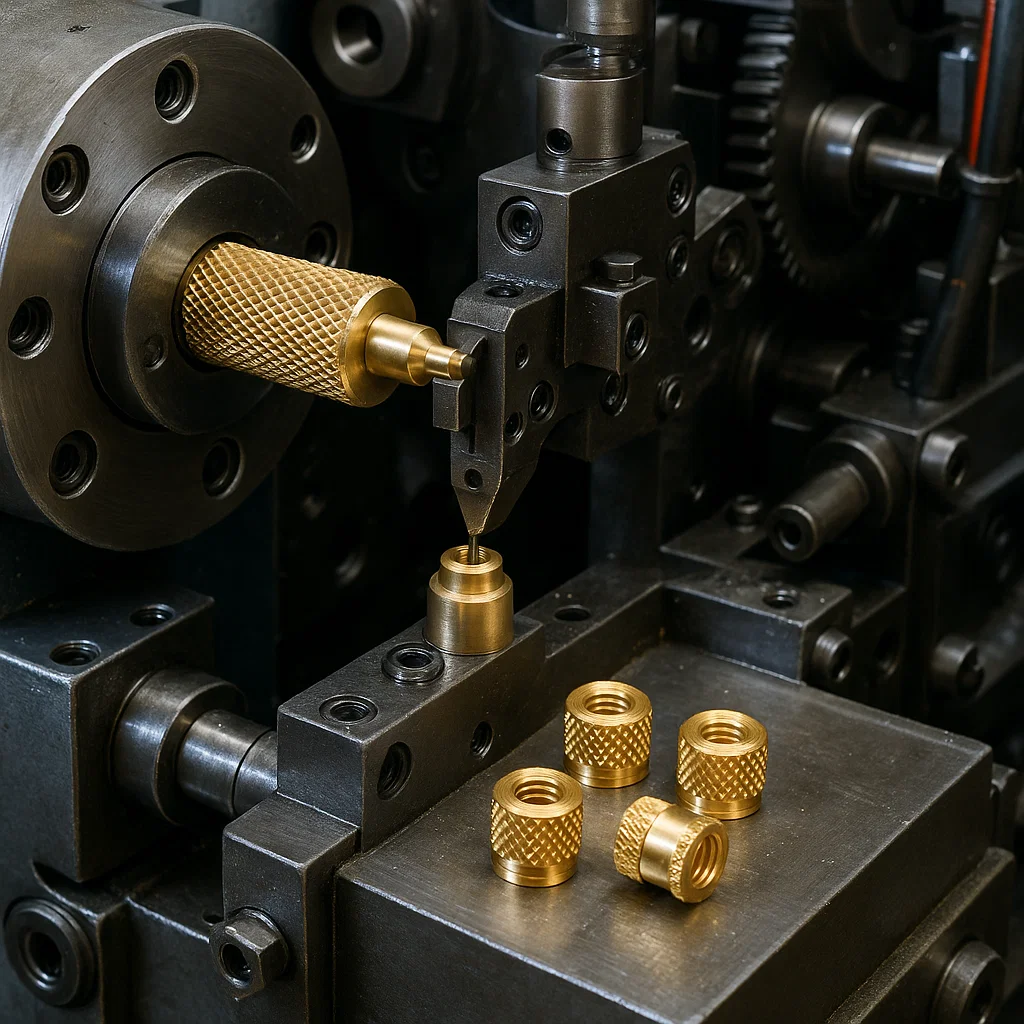

Our Brass Plastic Molding Inserts are precision-manufactured components designed to be embedded within plastic parts during the molding process. These inserts provide robust threaded connections, enhanced durability, and superior mechanical properties compared to plastic-only assemblies. Manufactured from high-grade Brass alloys including CuZn37, CuZn39Pb3, and CuZn40, these inserts offer excellent corrosion resistance, electrical conductivity, and thermal properties. The external surface features specialized knurling patterns, hexagonal shapes, or diamond knurls to ensure optimal retention within the plastic matrix. Applications include electronic enclosures, automotive components, furniture hardware, and industrial assemblies where reliable threaded connections are essential.

Brass Injection Molding Inserts

Brass Injection Molding Inserts are specifically engineered for high-volume injection molding processes where inserts are placed in molds before plastic injection. These inserts feature optimized geometries including tapered profiles, retention grooves, and heat-distribution designs to withstand injection pressures up to 2000 bar and temperatures reaching 300°C. Our injection molding inserts incorporate advanced design features such as venting channels, overflow areas, and thermal expansion accommodations. Material options include free-cutting Brass grades like CuZn36, CuZn38As, and CuZn39Pb2 for superior machinability and dimensional accuracy. These inserts are widely used in consumer electronics, appliance manufacturing, telecommunications equipment, and precision mechanical assemblies.

Inserts for Plastic Injection Molding

Our comprehensive range of Inserts for Plastic Injection Molding encompasses various configurations including straight-wall inserts, flanged inserts, closed-end inserts, and self-tapping variants. These components are manufactured to withstand the demanding conditions of injection molding including rapid temperature cycling, high pressures, and aggressive plastic materials. Surface treatments include passivation, anodizing, and specialized coatings to prevent galvanic corrosion and enhance adhesion with thermoplastics. Design features incorporate stress-relief geometries, controlled expansion zones, and optimized thread forms for maximum pull-out strength and torque resistance.

Threaded Inserts for Plastic

Threaded Inserts for Plastic applications are engineered to provide permanent, reusable threaded connections in plastic assemblies. Available in metric (M3 to M12) and unified thread systems (6-32 to 1/2-13), these inserts feature precision-cut threads with controlled pitch accuracy of ±0.02mm. External configurations include knurled, hexagonal, and slotted designs for various installation methods including heat insertion, ultrasonic insertion, and press-fitting. Material specifications comply with international standards including ASTM B16, DIN 17660, and JIS H3100 for consistent quality and performance. Applications span automotive interiors, consumer electronics, medical devices, and industrial equipment where field serviceability is crucial.

Brass Inserts for Plastic Molding

Specialized Brass Inserts for Plastic Molding are designed with enhanced retention features and optimized thermal properties for demanding molding applications. These inserts incorporate advanced geometries including undercuts, barbs, and expansion zones to maximize mechanical interlocking with plastic substrates. Material selection focuses on Brass alloys with controlled lead content (typically <0.25%) for environmental compliance and superior machinability. Surface finishes include bright annealing, chemical etching, and specialized texturing to promote optimal plastic-to-metal adhesion. Quality control processes ensure dimensional accuracy within ±0.05mm and surface finish Ra values below 1.6μm for consistent molding performance.

Brass Inserts for Rotomolding

Brass Inserts for Rotomolding applications are specifically engineered to withstand the unique challenges of rotational molding processes including extended heating cycles, centrifugal forces, and thick-wall plastic formation. These inserts feature robust construction with increased wall thickness, enhanced retention geometries, and thermal expansion accommodations for temperature excursions up to 350°C. Design specifications include radiused transitions, stress-relief features, and controlled surface textures to prevent stress concentration and promote uniform plastic flow. Material grades emphasize high-temperature stability and oxidation resistance while maintaining dimensional integrity throughout multiple heating and cooling cycles.

Brass Blow Molding Inserts

Our Brass Blow Molding Inserts are precision-manufactured for integration into blow-molded containers, bottles, and hollow plastic components. These inserts feature specialized sealing geometries, pressure-resistant designs, and optimized weight distribution for consistent placement during the blow molding process. Material specifications emphasize Brass alloys with excellent thermal conductivity and corrosion resistance for contact with various liquids and chemicals. Design features include integrated sealing surfaces, thread protection areas, and controlled thermal expansion coefficients to maintain seal integrity across temperature ranges from -40°C to +120°C.

🔧 BRASS INSERT MANUFACTURING PROCESS FLOW

Raw Material Selection → CNC Machining → Thread Cutting → Quality Inspection → Surface Treatment → Final Testing → Packaging → Global Shipping

Material Grades & International Standards

| Material Grade | International Standard | Composition | Key Properties | Applications |

|---|---|---|---|---|

| CuZn37 (CW508L) | EN 12164, ASTM B16 | Cu 63%, Zn 37% | High corrosion resistance, excellent machinability | General purpose inserts, marine applications |

| CuZn39Pb3 (CW614N) | DIN 17660, BS 2874 | Cu 58%, Zn 39%, Pb 3% | Superior machinability, good strength | High-volume production, automotive |

| CuZn40 (C28000) | ASTM B36, JIS H3100 | Cu 60%, Zn 40% | Excellent cold working properties | Electronic applications, precision parts |

| CuZn36 (C26000) | ASTM B19, DIN 17672 | Cu 64%, Zn 36% | High strength, good ductility | Heavy-duty applications, industrial equipment |

| CuZn38As (CW511L) | EN 12165, JIS H3250 | Cu 62%, Zn 38%, As 0.1% | Dezincification resistance, potable water safe | Plumbing, water systems, food industry |

Manufacturing Processes & Machinery

Our advanced manufacturing facility employs state-of-the-art CNC machining centers, multi-spindle automatic lathes, and precision turning equipment to produce Brass inserts with exceptional accuracy and consistency. Primary manufacturing processes include precision CNC turning on Swiss-type machines capable of maintaining tolerances of ±0.02mm, thread cutting using single-point threading tools and thread rolling operations for enhanced surface finish and fatigue resistance. Secondary operations encompass knurling using diamond pattern tools, hexagonal machining for wrench engagement, and specialized grooving for enhanced retention characteristics.

Primary Manufacturing Equipment

CNC Swiss Turning Centers: Citizen Cincom L20, Tsugami SS38-5AX

Multi-spindle Automatics: Index MS32-8, Wickman 6-75

Thread Rolling Machines: Profiroll TR-42, Grob G350

Quality Control: Zeiss CMM, Mitutoyo Profile Projectors

Specialized Processes

Heat Treatment: Stress relief annealing at 275°C

Surface Finishing: Barrel tumbling, vibratory finishing

Plating Operations: Nickel, Zinc, Tin electroplating

Testing: Dimensional inspection, pull-out testing, torque analysis

Typical Parts Produced & Applications

Our manufacturing capabilities extend to producing diverse Brass insert configurations for various industrial applications. Standard products include straight knurled inserts for electronic enclosures with lengths ranging from 3mm to 50mm, flanged inserts for automotive applications with integrated sealing features, and closed-end inserts for furniture hardware requiring aesthetic finishing. Specialized products encompass custom-threaded inserts for medical devices, high-temperature variants for appliance manufacturing, and corrosion-resistant grades for marine applications.

| Product Category | Typical Applications | Size Range | Material Options | Key Features |

|---|---|---|---|---|

| Electronic Inserts | PCB mounting, connector assemblies | M2 – M8 | CuZn37, CuZn40 | EMI shielding, conductivity |

| Automotive Inserts | Dashboard components, door panels | M4 – M12 | CuZn39Pb3, CuZn36 | Vibration resistance, durability |

| Furniture Hardware | Cabinet doors, drawer assemblies | M5 – M10 | CuZn38As, CuZn37 | Aesthetic finish, strength |

| Industrial Equipment | Machine housings, control panels | M6 – M16 | CuZn39Pb3, CuZn36 | High strength, corrosion resistance |

Technical Specifications & Dimensional Chart

| Thread Size | External Diameter (mm) | Length Range (mm) | Hole Diameter (mm) | Torque Rating (Nm) | Pull-out Force (N) |

|---|---|---|---|---|---|

| M3 x 0.5 | 4.5 – 5.5 | 3 – 20 | 4.2 | 1.5 | 1200 |

| M4 x 0.7 | 5.5 – 6.5 | 4 – 25 | 5.2 | 2.8 | 1800 |

| M5 x 0.8 | 6.5 – 7.5 | 5 – 30 | 6.4 | 4.5 | 2500 |

| M6 x 1.0 | 8.0 – 9.0 | 6 – 35 | 7.8 | 7.2 | 3200 |

| M8 x 1.25 | 10.0 – 11.5 | 8 – 40 | 9.5 | 15.0 | 4500 |

| M10 x 1.5 | 13.0 – 15.0 | 10 – 50 | 12.5 | 28.0 | 6000 |

Surface Finishes & Plating Options

We offer comprehensive surface treatment options to enhance corrosion resistance, improve aesthetics, and provide specialized functional properties. Standard finishes include bright brass with natural oxide formation, providing excellent electrical conductivity and moderate corrosion protection. Electroplated finishes encompass nickel plating (5-15 microns) for enhanced corrosion resistance and improved wear characteristics, zinc plating with chromate conversion coating for automotive applications requiring superior salt spray resistance, and tin plating for electronics applications requiring lead-free solderability and oxidation resistance.

Standard Finishes

Natural Brass: As-machined, passivated

Nickel Plated: 8-12μm thickness, bright finish

Zinc Plated: 5-8μm with yellow chromate

Tin Plated: 3-5μm for electronics

Specialized Coatings

Black Oxide: Enhanced aesthetics

Anodized: Hard surface, wear resistance

PTFE Coating: Low friction applications

Custom Colors: Per customer specification

Industries & Applications

Brass Plastic Molding Inserts serve critical functions across diverse industries requiring reliable threaded connections in plastic assemblies. The automotive sector utilizes these inserts extensively in dashboard assemblies, door panel mechanisms, seat adjustment systems, and under-hood applications where thermal cycling and vibration resistance are essential. Electronics and telecommunications industries rely on Brass inserts for PCB mounting systems, connector assemblies, equipment enclosures, and antenna mounting applications where electrical conductivity and EMI shielding properties are valuable.

Consumer appliance manufacturers integrate Brass inserts into washing machine control panels, refrigerator door mechanisms, microwave oven assemblies, and HVAC equipment requiring long-term reliability and corrosion resistance. Furniture and building hardware applications include cabinet door hinges, drawer slide mechanisms, window hardware, and architectural fixtures where aesthetic appearance and mechanical strength are paramount. Medical device manufacturing incorporates precision Brass inserts in diagnostic equipment, surgical instruments, and patient monitoring systems where biocompatibility and precision are critical requirements.

Quality Control & Testing

Our comprehensive quality control program ensures consistent product performance through rigorous dimensional testing, material verification, and functional validation. Dimensional inspection utilizes coordinate measuring machines (CMM) with accuracy of ±0.001mm for critical dimensions, optical comparators for thread profile verification, and automated gauging systems for high-volume production monitoring. Physical testing encompasses tensile strength verification per ASTM B557, hardness testing using Rockwell and Vickers methods, and torque-tension relationship analysis for threaded connections.

Chemical composition analysis employs X-ray fluorescence spectroscopy for material verification and lead content confirmation for RoHS compliance. Functional testing includes pull-out force measurement using specialized fixtures, torque breakaway testing for thread integrity, and thermal cycling evaluation for temperature-sensitive applications. Salt spray testing per ASTM B117 validates corrosion resistance performance, while accelerated aging tests ensure long-term dimensional stability and mechanical properties retention.

REACH Registered

Performance Metrics & Tolerances

| Parameter | Standard Tolerance | Precision Grade | Test Method | Acceptance Criteria |

|---|---|---|---|---|

| External Diameter | ±0.05mm | ±0.02mm | CMM measurement | 100% inspection |

| Thread Pitch | ±0.02mm | ±0.01mm | Thread gauge verification | Go/No-Go gauging |

| Length | ±0.1mm | ±0.05mm | Digital caliper measurement | Statistical sampling |

| Surface Finish | Ra 1.6μm | Ra 0.8μm | Profilometer analysis | Per drawing specification |

| Concentricity | 0.05mm TIR | 0.02mm TIR | Runout measurement | Critical dimension control |

Material Properties

| Property | CuZn37 | CuZn39Pb3 | CuZn40 | Test Standard |

|---|---|---|---|---|

| Tensile Strength (MPa) | 380-450 | 360-420 | 340-410 | ASTM B557 |

| Yield Strength (MPa) | 140-200 | 130-180 | 120-170 | ASTM B557 |

| Elongation (%) | 45-55 | 40-50 | 35-45 | ASTM B557 |

| Hardness (HV) | 90-120 | 85-115 | 80-110 | ASTM E384 |

| Thermal Conductivity (W/mK) | 110-120 | 105-115 | 100-110 | ASTM E1461 |

| Electrical Resistivity (nΩm) | 60-70 | 65-75 | 70-80 | ASTM B193 |

Comprehensive Q&A Section

Technical Questions & Expert Answers

Q1: What is the maximum operating temperature for Brass plastic molding inserts?

A: Our Brass inserts can operate continuously at temperatures up to 200°C for standard grades, with specialized alloys capable of 300°C operation for short-term exposure during injection molding processes.

Q2: How do you ensure proper retention in thermoplastic materials?

A: We employ specialized external geometries including diamond knurling, hexagonal profiles, and precision-engineered undercuts with retention forces exceeding 3000N for M6 inserts in standard ABS plastic.

Q3: What thread standards do you manufacture?

A: We produce metric threads (ISO 262), unified threads (ANSI B1.1), and custom threads including fine pitch variants, with pitch accuracy maintained within ±0.01mm tolerance.

Q4: Can you provide RoHS compliant Brass inserts?

A: Yes, all our standard grades comply with RoHS 2.0 directives with lead content <0.1% and comprehensive material certificates provided with each shipment.

Q5: What are the typical pull-out force values?

A: Pull-out forces range from 1200N for M3 inserts to 6000N for M10 inserts in standard ABS plastic, with higher values achievable in reinforced thermoplastics.

Q6: Do you offer custom knurling patterns?

A: We provide standard diamond knurl (0.8mm pitch), straight knurl, and custom patterns including helical knurls and specialized retention geometries per customer specifications.

Q7: What is your minimum order quantity?

A: Standard products have MOQ of 1000 pieces, while custom designs require minimum 2500 pieces depending on complexity and material grade.

Q8: How do you handle dimensional tolerances for injection molding?

A: We maintain ±0.02mm tolerance on critical dimensions with thermal expansion coefficients matched to injection molding temperature profiles for dimensional stability.

Q9: What surface treatments improve plastic adhesion?

A: Chemical etching, controlled oxidation, and specialized texturing treatments enhance mechanical interlocking with thermoplastics by up to 40% compared to smooth surfaces.

Q10: Can inserts be installed after molding?

A: Yes, we manufacture heat-insertion inserts for post-molding installation using thermal expansion, ultrasonic welding, or press-fitting techniques with specialized installation tooling.

Q11: What materials are compatible with food contact applications?

A: CuZn38As and CuZn37 grades comply with FDA 21 CFR 175.300 for food contact applications with appropriate surface treatments and passivation.

Q12: How do you prevent galvanic corrosion in dissimilar metal assemblies?

A: We apply barrier coatings including nickel plating, anodizing, or organic coatings to prevent galvanic cell formation with Steel or Aluminum components.

Q13: What is the typical delivery time for standard products?

A: Standard catalog items ship within 2-3 weeks, while custom products require 4-6 weeks including material procurement, manufacturing, and quality verification.

Q14: Do you provide installation guidelines?

A: Comprehensive installation manuals include temperature profiles, insertion force specifications, tooling requirements, and quality control checkpoints for each application type.

Q15: Can you manufacture inserts with internal threads?

A: We produce both external and internal threaded inserts including threaded bushings, captive nuts, and specialized internal geometries for unique assembly requirements.

Q16: What quality certifications do you maintain?

A: Our facility maintains ISO 9001:2015, ISO 14001:2015, and ISO 45001:2018 certifications with annual third-party audits and continuous improvement processes.

Q17: How do you handle material traceability?

A: Complete material traceability from raw material suppliers through finished products with batch coding, chemical analysis certificates, and manufacturing records maintained for 10 years.

Why Choose Our Brass Inserts?

Three Decades of Manufacturing Excellence

Our commitment to quality and innovation has made us a preferred supplier to global manufacturers across continents. We combine traditional craftsmanship with modern technology to deliver superior products consistently.

Technical Advantages

Precision Manufacturing: CNC Swiss machines with ±0.02mm accuracy

Advanced Materials: Premium Brass alloys with certified compositions

Innovative Design: Optimized geometries for maximum retention

Quality Systems: ISO certified processes with 100% inspection

Service Excellence

Global Experience: Serving USA, Europe, Australia for 30 years

Multilingual Support: Technical team fluent in multiple languages

Engineering Expertise: Custom design capabilities and optimization

Reliable Delivery: Consistent 4-6 week turnaround times

Competitive Advantages: Our strategic location in India provides significant cost advantages while maintaining world-class quality standards. Our engineering team possesses deep understanding of injection molding processes, thermoplastic behavior, and metal-plastic interface optimization. We offer flexible production scheduling to accommodate urgent requirements and provide customized packaging solutions including customer branding and labeling services.

Communication Excellence: Our multilingual technical support team ensures clear communication throughout the project lifecycle. We provide detailed engineering drawings, material certificates, and installation guidelines in customer-preferred languages and measurement systems. Regular project updates and proactive communication prevent delays and ensure customer satisfaction.

Customer Testimonials

“Outstanding quality and service! We’ve been sourcing Brass injection molding inserts from this supplier for over 8 years for our automotive dashboard assemblies. Their consistent quality, competitive pricing, and excellent communication have made them our preferred partner. The technical support team understands our requirements perfectly and always delivers on time.”

– Robert Thompson, Senior Procurement Manager, Michigan USA

“Exceptional engineering support and product quality. Their custom Brass inserts for our electronic enclosures exceeded our expectations. The team worked closely with our engineers to optimize the insert design, resulting in 15% improvement in assembly efficiency. Highly recommended for precision applications.”

– Sarah Mitchell, Design Engineer, London UK

“Reliable supplier with excellent service. Their Brass threaded inserts for our furniture hardware have consistently met our quality standards. The flexibility in customization and quick response to technical queries makes them invaluable to our operations. Looking forward to expanding our partnership.”

– David Wilson, Product Development Manager, Sydney Australia

Packaging & Shipping

Our comprehensive packaging solutions ensure product integrity throughout global transportation while minimizing environmental impact. Standard packaging utilizes recyclable cardboard containers with foam inserts for component protection, moisture barrier bags for corrosion prevention, and clearly labeled identification for easy inventory management. We offer customized packaging options including customer-branded containers, specialized protective packaging for precision components, and bulk packaging solutions for high-volume orders.

International shipping services encompass express courier delivery via DHL, FedEx, and UPS for urgent requirements, economical sea freight for large quantities, and consolidated shipments for cost optimization. All shipments include comprehensive documentation including commercial invoices, packing lists, material certificates, and country-specific requirements for customs clearance. Our logistics team coordinates delivery schedules to meet customer production requirements and provides real-time tracking information throughout the shipping process.

Custom Manufacturing Services

Tailored Solutions for Unique Requirements: Our engineering team specializes in developing custom Brass insert solutions for challenging applications requiring specialized geometries, material properties, or performance characteristics. We work closely with customers from initial concept through production implementation, providing design optimization recommendations, material selection guidance, and manufacturing feasibility analysis.

Custom Product Development Process: Share your technical drawings, quantity requirements, and special property specifications with our engineering team. We will analyze your requirements and provide optimized design recommendations within 48 hours. Our quotation includes detailed technical specifications, material options, manufacturing timeline, and competitive pricing for both prototype and production quantities. We guarantee rapid prototype delivery and smooth transition to volume production with consistent quality and delivery performance.

Custom Design Requirements: Please provide detailed technical drawings (PDF/DWG format), annual quantity forecasts, special material requirements, performance specifications, and application details. Our team will respond with optimized solutions and competitive quotations within 2 business days.

Glossary of Technical Terms

English Terms

Brass Insert: Threaded metal component embedded in plastic parts

Injection Molding: Manufacturing process for plastic parts using heated injection

Knurling: Textured surface pattern for enhanced retention

Pull-out Force: Maximum force required to extract insert from plastic

Thread Pitch: Distance between adjacent thread crests

Rotomolding: Rotational molding process for hollow plastic parts

Related Terms

Primary : Brass plastic molding inserts, Brass injection molding inserts, threaded inserts for plastic, Brass inserts plastic molding, rotomolding inserts, blow molding inserts, plastic injection molding inserts

Precision Brass threaded inserts for injection molding, custom Brass inserts for plastic applications, high-temperature Brass molding inserts, corrosion-resistant Brass plastic inserts, automotive grade Brass injection inserts, electronic assembly Brass threaded inserts

Technical Terms: Metal plastic hybrid assemblies, thermoplastic insert technology, CNC machined Brass components, precision threaded fasteners, molded-in metal inserts, plastic assembly hardware, industrial fastening solutions, custom metal insert manufacturing

Contact Us for Expert Solutions

Ready to discuss your Brass insert requirements? Our technical team is standing by to provide customized solutions for your specific applications. Get competitive quotes, technical support, and reliable delivery schedules.

Request Quote Download Brochure Technical Support

📧 Email: sales@conexscrews. com

📱 WhatsApp: +91-22 43449300

📞 Phone: +91-22 43449300

🌐 Website: www.conexscrews.com

Connect with our multilingual technical team for immediate assistance in English, Spanish, German, French, Italian, Russian, and Hindi.

Quality Assurance Promise: Every Brass insert undergoes rigorous quality control testing including dimensional verification, material analysis, and performance validation. We guarantee consistent quality, on-time delivery, and comprehensive technical support for all your plastic molding insert requirements.