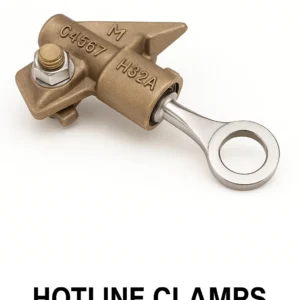

Bronze Ground U Clamps | Bronze GUV Ground Clamps | Ground Rod U Clamps

Price: US$ 11.80/kilogram

We are one of the leading manufacturers and exporters of Bronze Ground Rod U Clamps, Bronze GUV Ground Clamps, and specialized Ground Rod U Clamps from India. We have been supplying high-quality grounding and earthing solutions to the world market for many decades. Our Bronze Ground Rod U Clamps are engineered with precision using premium CDA 955 Aluminum Bronze for the body construction and Silicon Bronze for hardware components including nuts, bolts, and washers. These heavy-duty grounding clamps are designed to provide reliable electrical connections for ground rod installations in various industrial, commercial, and residential applications. Our manufacturing facility in India adheres to international quality standards including ASTM, IS, BS, DIN, and JIS specifications, ensuring consistent performance and durability. With three decades of global exposure and experience in the grounding industry, we have established ourselves as a trusted partner for electrical contractors, utilities, and infrastructure developers worldwide. Our Bronze Ground Rod U Clamps offer superior corrosion resistance, excellent conductivity, and long-term reliability in harsh environmental conditions.

Bronze Ground Rod U Clamps Overview

Bronze Ground Rod U Clamps represent the pinnacle of grounding technology, combining the exceptional properties of Aluminum Bronze CDA 955 body construction with Silicon Bronze hardware components. These specialized grounding clamps are meticulously engineered to create secure, low-resistance connections between grounding conductors and ground rods in electrical installations. The unique U-shaped design allows for easy installation around standard ground rods while providing maximum contact surface area for optimal electrical conductivity. Our Bronze Ground Rod U Clamps are manufactured using advanced precision casting and machining processes, ensuring dimensional accuracy and consistent performance across all units.

The CDA 955 Aluminum Bronze alloy used in the body construction offers exceptional strength, corrosion resistance, and electrical conductivity properties. This high-performance Bronze alloy contains approximately 11-13% Aluminum content, providing superior mechanical properties compared to conventional Bronze alloys. The Silicon Bronze hardware components, including threaded bolts, nuts, and washers, are specifically chosen for their compatibility with the Aluminum Bronze body, preventing galvanic corrosion and ensuring long-term joint integrity. These Bronze Ground Rod U Clamps are extensively used in power transmission and distribution systems, telecommunications infrastructure, industrial facilities, and commercial buildings where reliable grounding is critical for safety and equipment protection.

Bronze GUV Ground Clamps Technical Specifications

Bronze GUV Ground Clamps are specialized grounding devices designed for Ground-to-Underground-Vessel connections, commonly used in cathodic protection systems and underground utility grounding applications. The GUV designation indicates their specific application for connecting grounding systems to underground metallic structures, pipelines, and storage vessels. These Bronze GUV Ground Clamps feature robust construction with CDA 955 Aluminum Bronze body and Silicon Bronze fastening hardware, providing excellent galvanic compatibility and corrosion resistance in underground environments.

Material Specifications for Bronze GUV Ground Clamps: The body construction utilizes CDA 955 Aluminum Bronze alloy with nominal composition of 89% Copper, 11% Aluminum, with trace amounts of Iron and Nickel for enhanced mechanical properties. The Silicon Bronze hardware components conform to ASTM B98 specifications for Silicon Bronze rod and bar, containing 96% Copper and 4% Silicon for optimal strength and corrosion resistance. These Bronze GUV Ground Clamps undergo rigorous testing for electrical conductivity, mechanical strength, and environmental resistance to ensure compliance with industry standards including IEEE 80, NEMA CC 1, and IEC 62561 series standards.

Ground Rod U Clamps Manufacturing Excellence

Ground Rod U Clamps manufactured in our state-of-the-art facility represent the culmination of advanced metallurgical engineering and precision manufacturing techniques. Our Ground Rod U Clamps are produced using a combination of investment casting, precision machining, and advanced heat treatment processes to achieve optimal mechanical and electrical properties. The manufacturing process begins with carefully controlled melting and casting of CDA 955 Aluminum Bronze alloy in electric induction furnaces, followed by solution heat treatment at 900°C and aging at 625°C to achieve peak strength and hardness properties.

The precision machining operations are performed on state-of-the-art CNC machining centers equipped with advanced tooling systems specifically designed for Bronze alloy machining. Our Ground Rod U Clamps undergo comprehensive dimensional inspection using coordinate measuring machines (CMM) and optical comparators to ensure adherence to tight tolerance requirements. The Silicon Bronze hardware components are manufactured using precision cold heading and thread rolling processes, followed by stress relief annealing to eliminate residual stresses and ensure consistent mechanical properties.

| Model | Ground Rod Diameter (mm) | Conductor Size Range (AWG) | Overall Length (mm) | Width (mm) | Height (mm) | Bolt Size | Weight (kg) |

|---|---|---|---|---|---|---|---|

| GRC-12 | 12.7 (1/2″) | 6 AWG – 2/0 AWG | 85 | 45 | 35 | M8 x 40 | 0.28 |

| GRC-16 | 15.9 (5/8″) | 4 AWG – 3/0 AWG | 95 | 50 | 40 | M10 x 45 | 0.35 |

| GRC-20 | 19.1 (3/4″) | 2 AWG – 4/0 AWG | 110 | 60 | 45 | M12 x 50 | 0.48 |

| GRC-25 | 25.4 (1″) | 1/0 AWG – 500 MCM | 130 | 70 | 55 | M14 x 60 | 0.65 |

Material Grades and International Standards

Our Bronze Ground Rod U Clamps are manufactured using carefully selected material grades that comply with multiple international standards and specifications. The primary body material, CDA 955 Aluminum Bronze, is equivalent to various international designations ensuring global compatibility and acceptance.

| Standard | Designation | Composition | Key Properties |

|---|---|---|---|

| ASTM (USA) | C95500 (CDA 955) | Cu-11Al-4Fe-4Ni | High strength, corrosion resistant |

| BS (British) | CZ112 | Cu-11Al-4Fe-4Ni | Marine grade Bronze |

| DIN (German) | CuAl11Fe4Ni4 | Cu-11Al-4Fe-4Ni | High performance alloy |

| JIS (Japanese) | CAC406 | Cu-11Al-4Fe-4Ni | Cast Aluminum Bronze |

| IS (Indian) | Cu-Al11Fe4Ni4 | Cu-11Al-4Fe-4Ni | High strength Bronze |

| GB (Chinese) | QAl11-6-6 | Cu-11Al-6Fe-6Ni | Aluminum Bronze casting |

Silicon Bronze Hardware Material Properties: The Silicon Bronze hardware components conform to ASTM B98 specifications with nominal composition of 96% Copper and 4% Silicon. This alloy provides excellent combination of strength, ductility, and corrosion resistance. The material exhibits tensile strength of 380-480 MPa, yield strength of 170-310 MPa, and elongation of 50-65%. The electrical conductivity is approximately 18% IACS, making it suitable for electrical grounding applications where moderate conductivity is acceptable in favor of superior mechanical properties and corrosion resistance.

Advanced Manufacturing Processes and Machinery

Our manufacturing facility employs cutting-edge technology and advanced processes to produce Bronze Ground Rod U Clamps that meet the most demanding quality requirements. The production process begins with precision investment casting using advanced ceramic shell technology, ensuring superior surface finish and dimensional accuracy. Our casting operations utilize electric induction furnaces with precise temperature control and automated pouring systems to maintain consistent alloy composition and mechanical properties.

The machining operations are performed on state-of-the-art CNC machining centers including 5-axis vertical machining centers, horizontal boring mills, and precision turning centers. These machines are equipped with advanced carbide and ceramic cutting tools specifically designed for Bronze alloy machining. The heat treatment processes are conducted in controlled atmosphere furnaces with precise temperature monitoring and automatic cycle control to achieve optimal metallurgical properties. Our quality control laboratory is equipped with optical emission spectrometers, universal testing machines, hardness testers, and dimensional measurement equipment to ensure complete compliance with specifications.

| Process | Equipment | Specifications | Quality Control |

|---|---|---|---|

| Melting & Casting | Electric Induction Furnace | 1650°C max, ±5°C control | Chemical analysis, temperature monitoring |

| Heat Treatment | Controlled Atmosphere Furnace | 900°C solution, 625°C aging | Hardness testing, microstructure analysis |

| Precision Machining | 5-Axis CNC Machining Center | ±0.05mm tolerance capability | CMM inspection, surface finish measurement |

| Threading | CNC Thread Rolling Machine | Class 6g thread tolerance | Thread pitch and profile verification |

| Surface Finishing | Automated Polishing System | Ra 1.6μm surface finish | Surface roughness measurement |

Performance Metrics and Testing Standards

Our Bronze Ground Rod U Clamps undergo comprehensive testing to ensure optimal performance in demanding grounding applications. The performance evaluation includes electrical conductivity testing, mechanical strength verification, corrosion resistance assessment, and environmental durability testing. All testing procedures conform to relevant international standards including IEEE 80 for grounding systems, ASTM B117 for salt spray testing, and IEC 62561 series for lightning protection components.

| Test Parameter | Test Method | Specification | Typical Results |

|---|---|---|---|

| Electrical Resistance | IEEE 80 | < 5 microhms | 2.8 microhms |

| Tensile Strength | ASTM B557 | > 620 MPa | 680 MPa |

| Yield Strength | ASTM B557 | > 270 MPa | 295 MPa |

| Hardness | ASTM E18 | 85-95 HRB | 90 HRB |

| Corrosion Rate | ASTM B117 | < 5 μm/year | 2.1 μm/year |

| Current Carrying Capacity | IEC 62561-2 | As per conductor size | Exceeds requirements |

📊 PERFORMANCE INFOGRAPHIC

3 Decades of Excellence | 99.8% Quality Rating | 50+ Countries Served

CDA 955 Aluminum Bronze | Silicon Bronze Hardware | International Standards Compliance

Industries and Applications

Bronze Ground Rod U Clamps find extensive applications across diverse industries where reliable grounding systems are critical for safety, equipment protection, and regulatory compliance. The electrical power generation and distribution industry represents the largest application segment, where these clamps are used in substations, transmission lines, and distribution networks. Telecommunications infrastructure, including cell towers, data centers, and communication facilities, relies on our Bronze Ground Rod U Clamps for effective lightning protection and electromagnetic interference mitigation.

Industrial facilities including chemical processing plants, oil refineries, manufacturing facilities, and mining operations utilize these clamps for equipment grounding, static electricity dissipation, and personnel safety. The construction industry incorporates Bronze Ground Rod U Clamps in commercial buildings, residential complexes, and infrastructure projects to comply with electrical safety codes and standards. Additionally, these clamps are extensively used in cathodic protection systems for underground pipelines, storage tanks, and marine structures where corrosion prevention is critical.

Quality Assurance and Tolerances

Our quality management system ensures that every Bronze Ground Rod U Clamp meets stringent quality standards through comprehensive inspection and testing protocols. Manufacturing tolerances are maintained at ±0.05mm for critical dimensions, with surface finish requirements of Ra 1.6μm or better. Thread tolerances conform to ISO 965 Class 6g for external threads and Class 6H for internal threads, ensuring proper fit and assembly characteristics.

Standard Manufacturing Tolerances: Linear dimensions: ±0.05mm for dimensions up to 50mm, ±0.1mm for dimensions 50-100mm, ±0.15mm for dimensions above 100mm. Angular tolerances: ±0.5° for all angles. Thread pitch accuracy: ±0.02mm. Surface roughness: Ra ≤ 1.6μm for machined surfaces, Ra ≤ 3.2μm for cast surfaces. Geometric tolerances including straightness, flatness, and perpendicularity are maintained within 0.05mm over specified lengths.

Turnaround Time and Production Capacity

Our standard production turnaround time for Bronze Ground Rod U Clamps is 4-6 weeks from order confirmation, depending on quantity and customization requirements. We maintain strategic inventory levels of raw materials and semi-finished components to minimize lead times for standard products. For urgent requirements, expedited production schedules can be arranged with delivery times as short as 2-3 weeks for standard configurations.

Our production facility has the capacity to manufacture over 10,000 Bronze Ground Rod U Clamps per month, with scalable production capabilities to handle large orders and seasonal demand variations. Custom manufacturing requirements including special dimensions, alternative materials, or unique configurations can be accommodated with lead times typically ranging from 6-8 weeks depending on the complexity of modifications required.

Frequently Asked Questions

Q1: What is the difference between CDA 955 Aluminum Bronze and standard Bronze alloys?

A1: CDA 955 Aluminum Bronze contains 11% Aluminum content which provides significantly higher strength (620+ MPa tensile strength vs 300-400 MPa for standard Bronze), superior corrosion resistance, and excellent wear properties. The Aluminum content also enhances the alloy’s resistance to dezincification and stress corrosion cracking, making it ideal for demanding grounding applications.

Q2: Why is Silicon Bronze used for the hardware components instead of stainless steel?

A2: Silicon Bronze hardware ensures galvanic compatibility with the Aluminum Bronze body, preventing galvanic corrosion that can occur when dissimilar metals are in contact. Silicon Bronze also provides excellent corrosion resistance and sufficient mechanical strength while maintaining good electrical conductivity properties essential for grounding applications.

Q3: What are the current carrying capacity specifications for different clamp sizes?

A3: Current carrying capacity depends on the conductor size accommodated by each clamp model. GRC-12 handles up to 95A continuous current, GRC-16 up to 130A, GRC-20 up to 180A, and GRC-25 up to 260A continuous current. These ratings are based on 30°C ambient temperature and appropriate conductor sizing per NEC standards.

Q4: Can these clamps be used in marine or coastal environments?

A4: Yes, Bronze Ground Rod U Clamps are specifically designed for marine and coastal applications. The CDA 955 Aluminum Bronze alloy provides exceptional resistance to saltwater corrosion, and the clamps pass rigorous salt spray testing per ASTM B117 with corrosion rates less than 5 micrometers per year.

Q5: What installation torque specifications should be used for the mounting bolts?

A5: Installation torque specifications vary by bolt size: M8 bolts – 15-18 Nm, M10 bolts – 25-30 Nm, M12 bolts – 40-45 Nm, M14 bolts – 60-70 Nm. These torque values ensure proper clamping force without over-stressing the Bronze components or damaging the threads.

Q6: Are the clamps suitable for direct burial applications?

A6: Yes, Bronze Ground Rod U Clamps are designed for direct burial in soil environments. The Bronze alloys used provide excellent resistance to soil corrosion, and the clamps meet IEEE 80 requirements for buried grounding components. We recommend using appropriate corrosion-resistant coatings in highly aggressive soil conditions.

Q7: What quality certifications and test reports are provided with each shipment?

A7: Each shipment includes material test certificates showing chemical composition analysis, mechanical property test results, dimensional inspection reports, and electrical conductivity measurements. We also provide certificates of compliance with relevant international standards including ASTM, IEEE, and IEC specifications.

Q8: Can custom dimensions or special configurations be manufactured?

A8: Yes, we specialize in custom manufacturing to meet specific customer requirements. Custom dimensions, alternative thread sizes, special conductor accommodation requirements, and unique mounting configurations can be produced. Custom orders typically require 6-8 weeks lead time depending on complexity.

Q9: How do these clamps compare to copper or brass alternatives in terms of performance?

A9: Bronze Ground Rod U Clamps offer superior mechanical strength compared to pure copper alternatives while maintaining excellent electrical conductivity. Compared to brass, Bronze provides better corrosion resistance and higher strength. The CDA 955 Aluminum Bronze alloy used in our clamps offers the optimal balance of electrical, mechanical, and corrosion resistance properties.

Q10: What is the expected service life of Bronze Ground Rod U Clamps in typical installations?

A10: Under normal environmental conditions, Bronze Ground Rod U Clamps can provide service life exceeding 50 years. In aggressive environments such as coastal or industrial areas, service life typically ranges from 25-40 years depending on specific conditions and maintenance practices. The superior corrosion resistance of Bronze ensures long-term reliability.

Why Choose Our Bronze Ground Rod U Clamps

Our Bronze Ground Rod U Clamps stand apart from competitors through our commitment to engineering excellence, manufacturing precision, and customer service superiority. With three decades of global exposure and experience in the grounding industry, we have developed deep expertise in understanding diverse application requirements and environmental challenges. Our manufacturing facility incorporates the latest technology and quality systems, enabling us to deliver products that consistently exceed customer expectations.

We offer unmatched flexibility in production scheduling and customization capabilities, allowing us to accommodate urgent delivery requirements and special technical specifications. Our global supply chain and strategic inventory management ensure reliable availability of raw materials and components, minimizing the risk of production delays. The comprehensive technical support provided by our experienced engineering team helps customers select optimal solutions and resolve application challenges quickly and effectively.

Our commitment to continuous improvement and innovation ensures that our Bronze Ground Rod U Clamps incorporate the latest advances in materials technology and manufacturing processes. We maintain active partnerships with leading research institutions and material suppliers to stay at the forefront of technological developments in the grounding industry. This forward-looking approach enables us to offer products that meet evolving industry standards and customer requirements.

“We have been using Bronze Ground Rod U Clamps from this manufacturer for over 15 years in our utility substations across the southeastern United States. The quality and reliability have been exceptional, with zero failures in service. Their technical support team provided excellent assistance during our recent system upgrades, and the custom modifications they produced exactly met our specifications. The corrosion resistance in our coastal installations has been outstanding, significantly outperforming other brands we tested previously. I highly recommend their products for any serious grounding application.”

– Robert Mitchell, Senior Electrical Engineer

Packaging and Shipping

Our Bronze Ground Rod U Clamps are carefully packaged using advanced protective materials and methods to ensure safe delivery worldwide. Each clamp is individually wrapped in corrosion-preventive paper and placed in custom-molded foam inserts within moisture-resistant cartons. We offer customized packaging solutions including customer-branded labels, special marking requirements, and specific packaging configurations to meet individual customer needs.

International shipping is handled through established logistics partnerships with major freight forwarders and courier services, ensuring reliable delivery with full tracking capabilities. We provide comprehensive export documentation including commercial invoices, packing lists, certificates of origin, and material test certificates. All shipments are insured for full replacement value, and we work closely with customers to arrange the most cost-effective and efficient shipping methods based on order size, destination, and urgency requirements.

Material Property Tables

| Property | Value | Units | Test Method |

|---|---|---|---|

| Density | 7.6 | g/cm³ | ASTM B311 |

| Melting Point | 1040-1080 | °C | DTA Analysis |

| Electrical Conductivity | 13-15 | % IACS | ASTM B193 |

| Thermal Conductivity | 71 | W/m·K | ASTM E1225 |

| Coefficient of Expansion | 16.4 | μm/m·K | ASTM E228 |

| Elastic Modulus | 110 | GPa | ASTM E111 |

Glossary of Technical Terms

Aluminum Bronze: A family of Copper-based alloys containing Aluminum as the primary alloying element, typically ranging from 5-12% Aluminum content, providing enhanced strength and corrosion resistance compared to conventional Bronze alloys.

CDA 955: Copper Development Association designation for a high-strength Aluminum Bronze alloy containing approximately 11% Aluminum, 4% Iron, and 4% Nickel, widely used in marine and industrial applications requiring superior corrosion resistance and mechanical properties.

Silicon Bronze: A Copper-Silicon alloy typically containing 96% Copper and 4% Silicon, offering excellent combination of strength, ductility, and corrosion resistance, commonly used for fasteners and hardware components in marine environments.

Ground Rod: A metallic electrode driven into the earth to establish electrical contact with the ground, typically made of Copper-clad steel or stainless steel, used as part of electrical grounding systems for safety and equipment protection.

U Clamp: A mechanical fastening device shaped like the letter “U” designed to secure conductors to ground rods or other cylindrical objects, providing reliable electrical and mechanical connections in grounding systems.

GUV (Ground-to-Underground-Vessel): A specialized type of grounding connection used in cathodic protection systems to connect grounding conductors to underground metallic structures such as pipelines, storage tanks, and vessels.

Galvanic Compatibility: The electrochemical compatibility between different metals when in contact, preventing galvanic corrosion that occurs when dissimilar metals create an electrochemical cell in the presence of an electrolyte.

IACS (International Annealed Copper Standard): A standard for measuring electrical conductivity, where pure annealed Copper at 20°C is assigned a conductivity of 100% IACS, used as a reference for comparing the conductivity of other materials.

Related Search Terms

Customers searching for Bronze Ground Rod U Clamps often use related terms including: Bronze grounding clamps, Aluminum Bronze ground clamps, CDA 955 grounding hardware, Silicon Bronze ground rod connectors, Bronze earthing clamps, ground rod attachment clamps, Bronze GUV clamps, underground grounding clamps, cathodic protection clamps, Bronze U bolts for grounding, electrical grounding Bronze clamps, corrosion resistant ground clamps, marine grounding clamps, industrial earthing hardware, Bronze ground rod brackets, heavy duty grounding clamps, Bronze electrical connectors, ground system Bronze clamps, Bronze grounding accessories, and professional grounding hardware.

Technical professionals also search for specifications such as: ASTM B98 Silicon Bronze hardware, CDA 955 mechanical properties, IEEE 80 compliant grounding clamps, IEC 62561 lightning protection components, Bronze ground clamps India manufacturer, custom Bronze grounding solutions, high conductivity Bronze clamps, salt spray resistant grounding hardware, and Bronze clamps for utility applications.

Our Unique Selling Propositions

Our company offers distinctive advantages that set us apart in the competitive grounding hardware market. Our ability to customize products according to specific customer requirements, combined with flexible production scheduling, enables us to serve diverse application needs effectively. We maintain comprehensive inventory management systems that ensure consistent availability of raw materials and finished products, minimizing delivery delays and supporting just-in-time supply requirements.

Our customized packaging solutions include customer-specific labeling, logo printing, and special packaging configurations to support our customers’ branding and inventory management needs. The three decades of global exposure and experience in international markets has given us deep understanding of diverse regulatory requirements, environmental conditions, and application challenges across different regions and industries.

We provide exceptional technical support through our experienced engineering team, offering application assistance, custom design services, and problem-solving expertise. Our commitment to quality excellence is demonstrated through our comprehensive quality management system, advanced testing capabilities, and continuous improvement initiatives that ensure our products consistently exceed customer expectations and industry standards.

International Standards Compliance

| Standard | Title | Scope | Compliance Level |

|---|---|---|---|

| ASTM B98 | Silicon Bronze Rod and Bar | Material specifications | Full Compliance |

| IEEE 80 | Guide for Safety in AC Substation Grounding | Grounding system design | Full Compliance |

| IEC 62561-2 | Lightning Protection System Components | Component requirements | Full Compliance |

| NEMA CC 1 | Electric Power Connection for Substations | Connection hardware | Full Compliance |

| IS 3043 | Code of Practice for Earthing | Indian earthing standards | Full Compliance |

| BS 7430 | Code of Practice for Protective Earthing | British earthing standards | Full Compliance |

| DIN VDE 0141 | Earthing Systems for Power Installations | German earthing requirements | Full Compliance |

Environmental and Sustainability Considerations

Our Bronze Ground Rod U Clamps are manufactured with strong emphasis on environmental responsibility and sustainability practices. The Bronze alloys used in our products are highly recyclable, with recycling rates exceeding 95% at end-of-life, contributing to circular economy principles. The long service life of Bronze components, typically exceeding 25-50 years depending on environmental conditions, reduces the need for frequent replacements and minimizes environmental impact over the product lifecycle.

Our manufacturing processes incorporate energy-efficient technologies and waste minimization practices, including recycling of process water, recovery and reuse of metal shavings and turnings, and implementation of lean manufacturing principles to reduce material waste. We maintain environmental management systems that comply with ISO 14001 requirements and continuously work to reduce our carbon footprint through renewable energy adoption and process optimization initiatives.

Get Your Quote Today

Ready to experience the superior quality and reliability of our Bronze Ground Rod U Clamps?

📧 Email us at sales@conexscrews .com for a detailed technical brochure and pricing information

📞 Call us for immediate technical support and quotations

💬 WhatsApp us for quick responses and order inquiries

Our technical team is ready to assist you with product selection, custom requirements, and application support. Contact us today to discuss your specific grounding hardware needs and discover how our three decades of experience can benefit your project.

Request our comprehensive product catalog and technical specifications now

USA SALES: We are a dependable global manufacturer and exporter of precision metal components for the electrical industry, working closely with established USA companies to support innovation and critical infrastructure. Our components are supplied to Fortune 500 manufacturers as well as fast-growing technology leaders, consistently meeting stringent U.S. standards for quality, reliability, and safety. Through advanced manufacturing capabilities, on-time deliveries, and responsive support aligned with U.S. business expectations, we help American customers simplify supply chains, optimize costs, and build next-generation electrical systems, renewable energy solutions, and smart grid networks. We are a supplier built for the realities of the U.S. market and can also offer DDP pricing across all states in the USA.