Copper CSK Head Screws, Copper Flat Head Screws, Copper Pan Head Screws & Copper Machine Screws

We are one of the leading manufacturers and exporters of Copper screws and Copper fasteners from India. We have been supplying premium quality Copper CSK head screws, Copper flat head screws, Copper pan head screws, and Copper machine screws to the world market for many decades. Our extensive experience of over three decades in precision machining and fastener manufacturing has established us as a trusted partner for industries requiring high-quality Copper fastening solutions. With state-of-the-art manufacturing facilities, advanced CNC machinery, and stringent quality control processes, we deliver superior Copper screws that meet international standards including ASTM, DIN, BS, IS, and JIS specifications. Our commitment to excellence, combined with competitive pricing and reliable delivery schedules, makes us the preferred choice for customers across marine, electrical, plumbing, automotive, and architectural industries worldwide. We specialize in both standard and custom Copper screw manufacturing, offering flexibility in dimensions, threading, and finishing to meet specific application requirements.

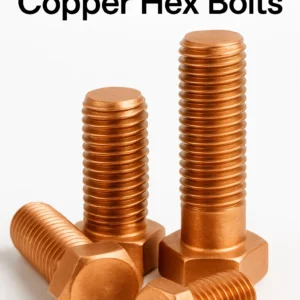

Product Overview

Copper screws represent one of the most versatile and corrosion-resistant fastening solutions available in the market today. Our comprehensive range of Copper CSK head screws, Copper flat head screws, Copper pan head screws, and Copper machine screws caters to diverse industrial applications where superior electrical conductivity, antimicrobial properties, and exceptional corrosion resistance are paramount. Manufactured from high-grade Copper alloys, these fasteners exhibit excellent mechanical properties including good tensile strength, outstanding ductility, and remarkable resistance to atmospheric corrosion, making them ideal for marine environments, electrical installations, plumbing systems, and architectural applications.

The natural antimicrobial properties of Copper make these screws particularly valuable in healthcare facilities, food processing equipment, and public infrastructure where hygiene is critical. Our precision manufacturing processes ensure consistent threading, accurate dimensional tolerances, and superior surface finish across all product variants. Each Copper screw undergoes rigorous quality testing to guarantee compliance with international standards and optimal performance in demanding applications.

Copper CSK Head Screws (Countersunk Head Screws)

Copper CSK head screws, also known as Copper countersunk head screws, feature a flat-topped head with an angled bearing surface that sits flush with the material surface when fully installed. These screws are engineered for applications requiring a smooth, flush finish without protruding heads that might interfere with adjacent components or create safety hazards. The countersunk design distributes load effectively across the material surface, providing excellent holding power while maintaining aesthetic appeal.

Our Copper CSK head screws are manufactured using precision cold heading and thread rolling processes, ensuring consistent head geometry and accurate thread pitch. The angled head design typically features 82-degree or 90-degree countersink angles to match standard drill bit specifications. These screws find extensive application in electrical panel assembly, marine hardware installation, decorative metalwork, and architectural applications where both functionality and appearance are important considerations. The superior corrosion resistance of Copper makes these screws particularly suitable for outdoor installations and marine environments where standard steel fasteners would quickly deteriorate.

Copper Flat Head Screws

Copper flat head screws are characterized by their completely flat head profile that sits flush with the material surface when properly installed with appropriate countersinking. These screws offer the ultimate in low-profile fastening solutions, making them ideal for applications where any protrusion above the surface level is unacceptable. The flat head design provides maximum bearing area for load distribution while maintaining the sleek appearance required in high-end architectural and decorative applications.

Manufacturing of Copper flat head screws involves precision machining processes to achieve the exact flatness and dimensional accuracy required for proper installation. The head diameter is carefully controlled to provide adequate bearing surface while ensuring compatibility with standard countersink drill bits. These screws are particularly popular in boat building, electrical conduit installation, decorative hardware applications, and precision instrument assembly where the combination of Copper’s electrical conductivity and the flush mounting capability is essential for both performance and aesthetics.

Copper Pan Head Screws

Copper pan head screws feature a low-profile rounded head with a flat bearing surface, offering an excellent balance between head height and bearing area. The pan head design provides superior clamping force compared to other head styles while maintaining a relatively low profile that doesn’t significantly protrude above the material surface. This design characteristic makes pan head screws versatile fasteners suitable for a wide range of applications where moderate head clearance is acceptable.

The manufacturing process for Copper pan head screws utilizes advanced cold forming techniques to create the distinctive rounded head profile with precise dimensional control. The larger bearing surface of the pan head distributes clamping loads more effectively than smaller head designs, reducing the risk of material damage or pull-through in thin materials. These screws are extensively used in electrical equipment assembly, plumbing fixtures, marine hardware, and general construction applications where reliable fastening performance and corrosion resistance are required. The natural patina development of Copper over time provides additional aesthetic appeal in architectural applications.

Copper Machine Screws

Copper machine screws are precision-threaded fasteners designed for use with tapped holes or nuts, featuring uniform threading along their entire shank length. These screws are engineered for applications requiring precise dimensional tolerances, reliable threading engagement, and consistent performance under varying load conditions. Machine screws differ from self-tapping screws in that they require pre-threaded holes for installation, providing superior holding power and reliability in critical applications.

Our Copper machine screws are manufactured using precision thread rolling and cutting processes to achieve accurate thread profiles conforming to metric, unified, and other international threading standards. The uniform shank diameter and precise threading ensure reliable engagement with tapped holes and nuts, providing consistent clamping force and resistance to loosening under vibration. These screws are widely used in electrical equipment assembly, precision machinery, electronic enclosures, and instrumentation where the electrical conductivity of Copper combined with precise mechanical properties is essential for optimal performance.

Material Grades and International Standards

Our Copper screws are manufactured from various high-quality Copper alloys conforming to international standards including DIN, ISO, ASTM, BS, JIS, and IS specifications. Each grade is selected for specific performance characteristics and application requirements. The selection of appropriate Copper grade depends on factors such as required strength, corrosion resistance, electrical conductivity, and environmental conditions.

| Standard | Grade/Designation | Composition | Key Properties | Applications |

|---|---|---|---|---|

| ASTM B124 / ISO 1337 | C11000 (ETP Copper) | 99.9% Cu min | High conductivity, excellent corrosion resistance | Electrical, marine applications |

| ASTM B133 / DIN 17662 | C14200 (Phosphor Bronze) | Cu-4% Sn-0.2% P | High strength, spring properties | Heavy-duty mechanical applications |

| DIN 17666 / ISO 5182 | CuSn6 (Bronze) | Cu-6% Sn | Good strength, wear resistance | Marine hardware, bearings |

| BS 2870 / DIN 17670 | C101 (OFHC Copper) | 99.95% Cu min | Highest purity, maximum conductivity | Electronics, precision instruments |

| JIS H3100 / ISO 1337 | C1020 (Oxygen-free Copper) | 99.96% Cu min | Ultra-high conductivity, weldability | High-end electronics, aerospace |

| IS 1897 / DIN 40500 | Cu-ETP Grade A | 99.90% Cu min | Good conductivity, formability | General electrical applications |

| GB/T 5231 / ISO 1337 | T2 (Chinese Standard) | 99.90% Cu min | Standard conductivity grade | General purpose applications |

| DIN 17665 / ISO 5182 | CuSn4 (Tin Bronze) | Cu-4% Sn | Good corrosion resistance, strength | Marine, chemical industry |

| DIN 17671 / ISO 5182 | CuZn37 (Brass) | Cu-37% Zn | Good machinability, strength | Decorative, mechanical applications |

Manufacturing Processes and Machinery

Our state-of-the-art manufacturing facility employs advanced production techniques and precision machinery to ensure consistent quality and dimensional accuracy in every Copper screw produced. The manufacturing process begins with careful selection and inspection of raw Copper materials, followed by precision machining operations using computer-controlled equipment.

Cold Heading Process: Copper wire or rod material is fed into high-speed cold heading machines that form the screw head through a series of progressive forming dies. This process ensures consistent head geometry, eliminates material waste, and maintains the grain structure integrity of the Copper material. Our cold heading machines can handle various head configurations including CSK, flat head, and pan head designs with precise dimensional control.

Thread Rolling: Screw blanks undergo thread rolling operations using precision thread rolling machines that form threads through displacement rather than cutting. This process produces stronger threads with better surface finish and improved fatigue resistance compared to cut threads. Thread rolling also work-hardens the thread surface, increasing durability and resistance to wear.

CNC Machining: For custom specifications and complex geometries, we employ advanced CNC turning and milling centers capable of producing Copper screws with tight tolerances and complex features. Our CNC machinery includes multi-axis turning centers, precision milling machines, and automated drilling equipment for high-volume production.

| Manufacturing Equipment | Capability | Precision Level | Production Capacity |

|---|---|---|---|

| Multi-station Cold Headers | M2-M20 diameter range | ±0.05mm dimensional tolerance | 5000-15000 pieces/hour |

| Thread Rolling Machines | Metric, UNC, UNF threads | 6g thread tolerance class | 3000-8000 pieces/hour |

| CNC Turning Centers | Complex geometries, custom specs | ±0.02mm tolerance | 500-2000 pieces/hour |

| Surface Treatment Lines | Cleaning, passivation, coating | Uniform surface finish | 10000+ pieces/batch |

Dimensional Specifications

| Screw Size | Nominal Diameter (mm) | Head Diameter (mm) | Head Height (mm) | Thread Pitch (mm) | Length Range (mm) |

|---|---|---|---|---|---|

| M2 | 2.0 | 3.8-4.2 | 1.2-1.4 | 0.4 | 4-20 |

| M3 | 3.0 | 5.7-6.3 | 1.7-2.0 | 0.5 | 6-30 |

| M4 | 4.0 | 7.6-8.4 | 2.2-2.6 | 0.7 | 8-40 |

| M5 | 5.0 | 9.5-10.5 | 2.8-3.2 | 0.8 | 10-50 |

| M6 | 6.0 | 11.4-12.6 | 3.3-3.7 | 1.0 | 12-60 |

| M8 | 8.0 | 15.2-16.8 | 4.4-5.0 | 1.25 | 16-80 |

| M10 | 10.0 | 19.0-21.0 | 5.5-6.5 | 1.5 | 20-100 |

Material Properties and Performance Characteristics

| Property | Copper C11000 | Phosphor Bronze C14200 | Bronze CuSn6 | Test Method |

|---|---|---|---|---|

| Tensile Strength (MPa) | 220-290 | 345-450 | 300-380 | ASTM E8 |

| Yield Strength (MPa) | 70-180 | 140-350 | 120-250 | ASTM E8 |

| Elongation (%) | 45-55 | 8-20 | 15-25 | ASTM E8 |

| Hardness (HB) | 40-80 | 85-120 | 70-95 | ASTM E10 |

| Electrical Conductivity (%IACS) | 100-103 | 15-20 | 12-18 | ASTM B193 |

| Thermal Conductivity (W/m·K) | 390-400 | 60-80 | 50-70 | ASTM E1461 |

| Corrosion Resistance | Excellent | Excellent | Very Good | ASTM B117 |

Surface Finishes and Treatments

Our Copper screws are available with various surface finishes to enhance performance, appearance, and longevity depending on specific application requirements. The natural properties of Copper provide inherent corrosion resistance, but additional surface treatments can further improve performance in demanding environments.

Natural Copper Finish: Uncoated Copper screws develop a natural patina over time, providing enhanced corrosion protection and distinctive aesthetic appeal. This finish is ideal for architectural applications where the characteristic Copper appearance is desired.

Passivated Finish: Chemical passivation treatment creates a uniform protective oxide layer that enhances corrosion resistance while maintaining electrical conductivity. This treatment is particularly beneficial for marine and outdoor applications.

Lacquered Finish: Clear protective lacquer coating preserves the original Copper appearance while preventing tarnishing and oxidation. This finish is popular for decorative applications and indoor use where maintaining the bright Copper appearance is important.

Industries and Applications

Copper screws find extensive application across diverse industries due to their unique combination of properties including excellent electrical conductivity, superior corrosion resistance, antimicrobial properties, and aesthetic appeal. Our comprehensive range serves multiple sectors with specialized fastening solutions.

Marine Industry: Copper’s exceptional resistance to saltwater corrosion makes these screws invaluable for boat building, dock construction, marine hardware assembly, and underwater equipment installation. The antimicrobial properties also help prevent marine growth and biofouling.

Electrical and Electronics: High electrical conductivity and corrosion resistance make Copper screws essential for electrical panel assembly, grounding systems, transformer construction, and electronic equipment manufacturing where reliable electrical connections are critical.

Plumbing and HVAC: Copper screws are widely used in plumbing fixture installation, pipe support systems, heat exchanger assembly, and HVAC equipment where compatibility with Copper piping and resistance to moisture are essential.

Architecture and Construction: Decorative applications, roofing systems, gutter installation, and historical restoration projects benefit from Copper screws’ durability and distinctive appearance that complements Copper architectural elements.

Healthcare and Food Processing: The natural antimicrobial properties of Copper make these screws valuable for medical equipment, food processing machinery, and public facilities where hygiene is paramount.

International Standards Compliance

Our Copper screws are manufactured in strict compliance with multiple international standards ensuring global compatibility and consistent quality across all markets. We maintain certifications and regular audits for the following standards:

| Standard Category | Standard Reference | Scope | Key Requirements |

|---|---|---|---|

| Screw Dimensions | DIN 963, DIN 965, DIN 7985 | Head geometry, thread specifications | Dimensional tolerances, head angles |

| Threading Standards | ISO 68-1, ISO 262, DIN 13 | Metric thread profiles and tolerances | Thread pitch, major/minor diameters |

| Material Standards | ISO 1337, DIN 40500, ISO 5182 | Copper alloy compositions and properties | Chemical composition, mechanical properties |

| Quality Management | ISO 9001:2015, DIN EN ISO 9001 | Quality management systems | Process control, documentation, auditing |

| Testing Methods | ISO 898, DIN 50114, ISO 3506 | Mechanical testing procedures | Tensile testing, hardness measurement |

| Surface Finish | ISO 4287, DIN 4768, ISO 25178 | Surface roughness parameters | Ra, Rz values, measurement methods |

| Corrosion Testing | ISO 9227, DIN 50021, ISO 11130 | Salt spray and corrosion resistance | Test duration, evaluation criteria |

| Dimensional Verification | ISO 1502, DIN 2999, ISO 5408 | Thread gauge verification | Go/No-go gauge requirements |

Quality Standards and Manufacturing Tolerances

Our manufacturing processes maintain strict adherence to international quality standards including ISO 9001:2015, DIN EN ISO 9001, and AS 9100 ensuring consistent product performance and reliability. All Copper screws undergo comprehensive quality control testing including dimensional verification per ISO 1502 and DIN 2999, material composition analysis according to ISO 1337 and DIN 40500, and mechanical property testing as per ISO 898 and DIN 50114 standards.

| Parameter | Standard Tolerance | Precision Tolerance | Test Method | Applicable Standard |

|---|---|---|---|---|

| Thread Pitch Diameter | 6g class | 5g class | Thread gauges per ISO 1502 | ISO 68-1, DIN 13 |

| Head Diameter | ±0.1mm | ±0.05mm | Calibrated measuring instruments | DIN 963, DIN 965, DIN 7985 |

| Overall Length | ±0.2mm | ±0.1mm | Digital height gauges | ISO 4762, DIN 912 |

| Concentricity | 0.1mm TIR | 0.05mm TIR | Coordinate measuring machine | ISO 1101, DIN 5480 |

| Surface Roughness | Ra 1.6 μm | Ra 0.8 μm | Surface roughness tester | ISO 4287, DIN 4768 |

| Thread Class | 6g tolerance class | 4g tolerance class | Thread ring/plug gauges | ISO 262, DIN 13-1 |

| Head Height | ±0.1mm | ±0.05mm | Micrometer measurement | DIN 963, ISO 7046 |

Production Turnaround Time

Our efficient manufacturing processes and well-established supply chain management enable us to maintain competitive delivery schedules while ensuring consistent quality standards. Standard production turnaround time is 4-6 weeks from order confirmation, with expedited delivery options available for urgent requirements.

For standard catalog items and common specifications, we maintain strategic inventory levels that allow for faster delivery times of 1-2 weeks. Custom specifications and special alloy requirements may require additional processing time, which will be clearly communicated during the quotation process. Our production planning team works closely with customers to accommodate specific delivery requirements and project schedules.

Frequently Asked Questions

A: Copper screws offer superior corrosion resistance in marine environments, excellent electrical conductivity for grounding applications, and natural antimicrobial properties that prevent marine growth. Unlike Stainless Steel, Copper doesn’t suffer from crevice corrosion in saltwater environments.

A: Yes, we specialize in custom Copper screw manufacturing and can produce virtually any head configuration, threading specification, or dimensional requirement. Our engineering team works with customers to develop optimal solutions for specific applications.

A: Our minimum order quantity varies depending on specifications, but typically ranges from 1000-5000 pieces for standard sizes. Custom specifications may have different MOQ requirements based on tooling and setup requirements.

A: Copper screws maintain their mechanical properties at moderate temperatures up to 200°C. For higher temperature applications, we recommend Phosphor Bronze alloys which offer better strength retention at elevated temperatures.

A: Absolutely. Our high-conductivity Copper grades (C11000, C101) offer 100%+ IACS conductivity, making them ideal for electrical grounding systems, bonding applications, and electrical panel assembly where reliable conductivity is essential.

A: We manufacture Copper machine screws with metric (ISO), unified (UNC/UNF), BSW, and other international threading standards. Thread classes range from 6g standard to 4g precision depending on application requirements.

A: Store Copper screws in dry conditions with controlled humidity (below 50%) and good ventilation. For long-term storage, we recommend our lacquer-coated finish or sealed packaging with desiccant packets to prevent oxidation.

A: Yes, our Copper CSK head screws are designed with standard 82° or 90° countersink angles that are compatible with common countersink drill bits. We provide detailed installation guidelines with each order.

A: Each shipment includes material test certificates (MTCs), dimensional inspection reports, and compliance certificates for applicable standards (ASTM, DIN, BS, IS, JIS). Additional third-party testing certificates are available upon request.

A: Yes, we provide sample quantities (typically 25-100 pieces) for customer evaluation and testing. Sample costs are often credited against subsequent production orders above minimum quantities.

A: Our quality management system includes in-process inspection at each manufacturing stage, statistical process control, automated sorting systems, and final inspection using calibrated measuring equipment. All operators are trained and certified for their specific processes.

Why Choose Our Copper Screws

Three Decades of Manufacturing Excellence: Our extensive experience in precision fastener manufacturing, combined with deep understanding of Copper material properties, ensures superior product quality and reliability. We have successfully served thousands of customers across diverse industries worldwide, building a reputation for excellence and dependability.

Advanced Manufacturing Capabilities: Our state-of-the-art production facility features the latest CNC machinery, automated quality control systems, and precision measurement equipment. This technological advantage enables us to maintain tight tolerances, consistent quality, and competitive production costs while meeting the most demanding specifications.

Flexible Customization Options: Unlike many fastener suppliers, we offer extensive customization capabilities including non-standard dimensions, special threading, custom head configurations, and unique material grades. Our engineering team collaborates with customers to develop optimal solutions for specific applications.

Superior Customer Support: Our technical support team includes experienced engineers and materials specialists who provide comprehensive application guidance, installation recommendations, and ongoing technical assistance. We maintain clear communication throughout the order process and provide detailed documentation with every shipment.

Global Supply Chain Reliability: With established logistics networks and strategic inventory management, we ensure reliable delivery to customers worldwide. Our export documentation expertise and established shipping partnerships minimize delays and ensure smooth international transactions.

Competitive Pricing with Value: Our efficient manufacturing processes, strategic raw material procurement, and optimized operations enable us to offer competitive pricing without compromising quality. We provide excellent value through superior product performance, reliable delivery, and comprehensive customer support.

Custom Packaging Solutions: We offer flexible packaging options including custom labeling with customer logos, specialized packaging for automated assembly systems, and protective packaging for sensitive applications. This attention to detail reduces handling time and improves efficiency for our customers.

Packaging and Shipping

Our comprehensive packaging and shipping services ensure that Copper screws arrive in perfect condition, properly organized, and ready for immediate use. We understand that proper packaging is crucial for maintaining product quality during transit and optimizing customer efficiency upon receipt.

Standard Packaging Options: Copper screws are typically packaged in moisture-resistant poly bags with clear labeling indicating specifications, quantity, and lot numbers. For bulk quantities, we use sturdy cardboard boxes with foam padding to prevent damage during transportation. Anti-tarnish paper and desiccant packets are included when specified.

Custom Packaging Solutions: We offer specialized packaging including custom labels with customer part numbers and logos, small quantity packaging for retail applications, and automated assembly-friendly packaging such as tube feeding or tape-and-reel formats. Our packaging team works with customers to develop optimal solutions for their specific handling and storage requirements.

Export Packaging: For international shipments, we provide robust export packaging including wooden crates, steel drums, or specialized containers depending on quantity and destination requirements. All export packaging complies with international shipping regulations and destination country requirements.

Documentation and Certification: Each shipment includes comprehensive documentation including packing lists, material certificates, inspection reports, and any required export documentation. For international shipments, we provide commercial invoices, certificates of origin, and other documents required for customs clearance.

Customer Testimonial

Technical Glossary

Related Search Terms

Get Your Custom Copper Screw Quote Today

Ready to experience the superior quality and performance of our Copper screws, Copper CSK Screws, Copper Flat head Screws Our technical experts are standing by to help you select the optimal fastening solution for your specific application.

Contact Options:

📧 Email: sales@conexcsrews . com for detailed quotations and technical brochures.