High Quality Copper Machined Parts, Copper Screw Machine Parts , Copper Components, Copper Turned Components, Copper CNC Machined parts, Copper CNC Machined Components.

We are one of the leading manufacturers and exporters of high-quality Copper Machined Parts, Copper Screw Machine Parts, Copper Components, Copper Turned Components, and Copper CNC Machined Components from India. We have been supplying precision-engineered Copper parts to the world market for many decades, serving industries such as Automotive, Aerospace, Electrical, Plumbing, and Industrial Machinery. Our commitment to quality, adherence to international standards, and ability to deliver customized solutions make us a preferred partner for global clients.

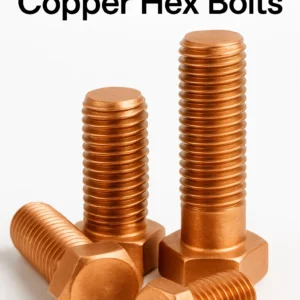

Overview of Our Copper Machined Components

1. Copper Machined Parts

Copper Machined Parts are precision-engineered components manufactured using high-grade Copper alloys for superior conductivity, corrosion resistance, and durability. These parts are widely used in electrical applications, heat exchangers, and plumbing systems. We produce Copper Machined Parts in various grades, including C101 (Oxygen-Free Copper), C110 (Electrolytic Tough Pitch Copper), C145 (Tellurium Copper), and C172 (Beryllium Copper). Our machining processes include CNC Turning, Milling, Drilling, and Grinding, ensuring tight tolerances (up to ±0.005 mm) and superior surface finishes.

2. Copper Screw Machine Parts

Copper Screw Machine Parts are manufactured using automatic screw machines for high-volume production with consistent accuracy. These parts are commonly used in fasteners, connectors, and electrical terminals. We work with ASTM B152, DIN 1787, and JIS H3100 standards, ensuring compliance with global specifications. Our screw machining capabilities allow us to produce complex geometries with excellent repeatability and minimal material wastage.

3. Copper Components

Our Copper Components are designed for high-performance applications requiring thermal conductivity, electrical efficiency, and anti-corrosive properties. We supply Bushings, Bearings, Valves, Nozzles, and Custom Fabricated Parts in grades like C360 (Free-Cutting Brass), C464 (Naval Brass), and C630 (Aluminum Bronze). These components undergo precision turning, milling, and surface treatments (electroplating, polishing, anodizing) to meet industry demands.

4. Copper Turned Components

Copper Turned Components are produced using CNC Lathes and Swiss-Type Turning Machines, ensuring high dimensional accuracy. These parts are essential in hydraulic systems, medical devices, and instrumentation. We offer mirror finishes, knurling, and threading with tolerances as tight as ±0.01 mm. Common materials include C260 (Cartridge Brass) and C220 (Commercial Bronze).

5. Copper CNC Machined Parts

Our Copper CNC Machined Parts are crafted using 5-axis CNC machines for intricate designs and tight tolerances. These parts are ideal for aerospace, defense, and precision engineering applications. We use ASTM B133, BS 2875, and ISO 5182 compliant materials, ensuring global acceptance.

6. Copper CNC Machined Components

These components are designed for high-load and high-wear applications, including gears, couplings, and sensor housings. We specialize in prototyping and mass production, offering EDM, Laser Cutting, and Micro-Machining for ultra-precise parts.

Material Grades & International Standards

| Material Grade | Equivalent Standards | Properties |

|---|---|---|

| C101 (Oxygen-Free Copper) | ASTM B152, DIN 1787, JIS H3100 | High conductivity, excellent ductility |

| C110 (ETP Copper) | ASTM B133, BS 2875, EN 13601 | Good machinability, corrosion-resistant |

| C145 (Tellurium Copper) | ASTM B301, DIN 17660 | Free-machining, high strength |

| C172 (Beryllium Copper) | ASTM B196, EN 12163 | High fatigue resistance, non-sparking |

| C360 (Free-Cutting Brass) | ASTM B16, JIS H3250 | Excellent machinability, good corrosion resistance |

| C464 (Naval Brass) | ASTM B21, DIN 17660 | Marine-grade, high strength |

Manufacturing Processes & Machinery Used

CNC Turning & Milling (5-axis CNC Machines)

Swiss-Type Automatic Screw Machining

Precision Grinding & EDM

Laser Cutting & Micro-Machining

Surface Finishing (Polishing, Electroplating, Passivation)

Industries We Serve

Automotive (Bushings, Connectors)

Aerospace (Sensor Housings, Valve Components)

Electrical & Electronics (Terminals, Heat Sinks)

Medical Devices (Surgical Instruments, Implants)

Industrial Machinery (Gears, Shafts)

Tolerances & Performance Metrics

Standard Tolerances: ±0.01 mm

Surface Finish: Up to 0.4 µm Ra

Turnaround Time: 4-6 weeks (custom orders accepted)

Quality Certifications: ISO 9001:2015, RoHS, REACH Compliant

Why Choose Us?

✔ 30+ Years of Global Manufacturing Experience

✔ Customized Packaging with Branding Options

✔ Fast Turnaround & Just-in-Time Delivery

✔ Strict Adherence to ASTM, DIN, JIS Standards

✔ 24/7 Customer Support & Technical Assistance

Customer Testimonial

“We have been sourcing Copper CNC Machined Components from this supplier for over five years. Their precision, on-time delivery, and excellent customer service make them our preferred partner.”

– John Carter, Engineering Manager (USA)

Glossary of Terms

CNC Machining: Computer-controlled precision machining.

Swiss-Type Turning: High-precision turning for small, complex parts.

Electroplating: Coating for corrosion resistance.

Tolerance: Permissible limit of dimensional variation.

Related Search Terms

Precision Copper Turned Components

High-Conductivity Copper Parts

CNC Machined Copper Bushings

OEM Copper Screw Machine Parts

Custom Copper Electrical Components

Call to Action (CTA)

📞 Call Us

📧 Email for Brochure: sales@conexscrews .com

💬 WhatsApp for Instant Quote

🛒 Request a Custom Quote