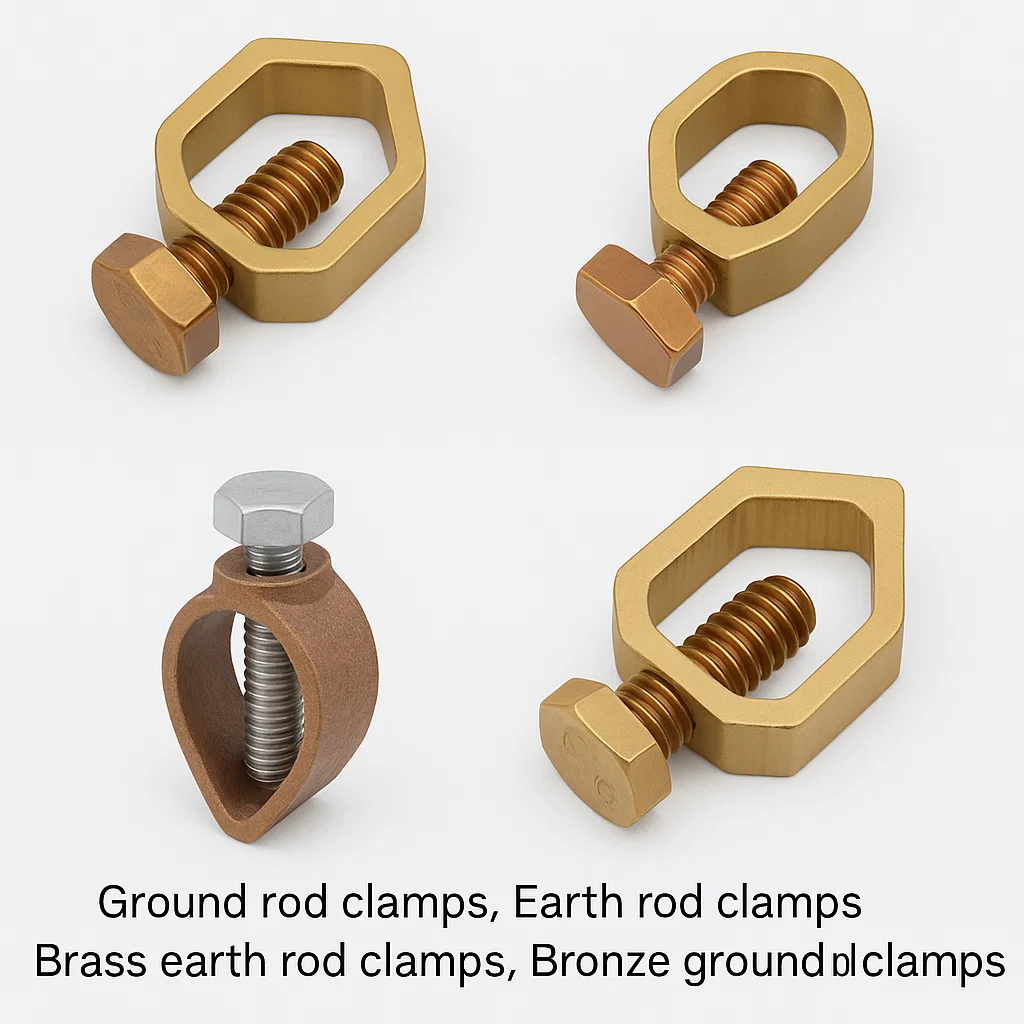

Ground rod Clamps, Bronze Ground rod clamps, Brass Earthing clamps, Brass Earth Rod Clamps, Grounding Connectors, Earth Rod Clamps

Ground Rod Clamps & Earth Rod Clamps – Premium Quality Grounding Solutions

We are one of the leading manufacturers and exporters of Ground Rod clamps, Earth rod clamps, and comprehensive grounding solutions from India. We have been supplying high-quality earthing and grounding components to the world market for many decades. Our extensive range of ground rod clamps includes Brass earth rod clamps, Bronze ground rod clamps, Copper grounding clamps, and specialized ground rod connectors manufactured through precision casting and hot stamping processes. With over three decades of engineering excellence, we deliver reliable grounding solutions that meet international safety standards including ASTM, BS, DIN, and JIS specifications. Our state-of-the-art manufacturing facility produces custom-engineered grounding clamps for electrical installations, telecommunications infrastructure, power distribution systems, and industrial applications worldwide. Every ground rod clamp undergoes rigorous quality testing to ensure optimal electrical conductivity, corrosion resistance, and mechanical strength for long-lasting performance in diverse environmental conditions.

Ground Rod Clamps – Heavy-Duty Electrical Grounding Solutions

Ground rod clamps are essential components in electrical earthing systems, providing secure mechanical and electrical connections between grounding conductors and driven earth rods. Our precision-manufactured ground rod clamps feature robust construction using high-grade Copper, Brass, and Bronze alloys, ensuring superior conductivity and corrosion resistance. These grounding clamps are engineered to accommodate various earth rod diameters from 12mm to 25mm, with standard conductor sizes ranging from 6mm² to 120mm². The clamp design incorporates deep threading and multiple contact points to maintain consistent electrical contact under thermal cycling and mechanical stress. Each ground rod clamp undergoes salt spray testing per ASTM B117 standards, demonstrating exceptional resistance to atmospheric corrosion in coastal and industrial environments.

Earth Rod Clamps – Professional Grade Earthing Hardware

Earth rod clamps serve as critical interface components in comprehensive earthing systems, facilitating reliable connections between earth electrodes and main earthing networks. Our earth rod clamps are manufactured using advanced hot stamping and precision casting techniques, resulting in dimensionally accurate products with consistent mechanical properties. The clamp body construction utilizes high-conductivity Copper alloys conforming to ASTM B187 specifications, while the clamping mechanism employs hardened Steel bolts with anti-seize coating for long-term serviceability. These earth rod clamps are designed to withstand fault current conditions up to 40kA for 1-second duration, making them suitable for high-voltage substation and industrial facility applications. The compact profile design allows installation in confined spaces while maintaining full electrical performance.

Brass Earth Rod Clamps – Superior Corrosion Resistance

Brass earth rod clamps combine excellent electrical conductivity with outstanding corrosion resistance, making them ideal for harsh environmental conditions and marine applications. Our Brass earth rod clamps are manufactured from CuZn37 and CuZn39Pb3 alloy grades conforming to BS EN 12164 and DIN 17660 standards. The Brass composition provides natural antimicrobial properties while maintaining electrical conductivity of approximately 28% IACS (International Annealed Copper Standard). Each Brass earth rod clamp features precision-machined conductor channels with radius corners to prevent stress concentration and conductor damage during installation. The natural dezincification resistance of our Brass alloys ensures long-term reliability in soil conditions with varying pH levels and moisture content.

Bronze Ground Rod Clamps – Heavy-Duty Industrial Applications

Bronze ground rod clamps offer exceptional mechanical strength and wear resistance for demanding industrial earthing applications. Our Bronze ground rod clamps are manufactured from high-strength Tin Bronze (CuSn8) and Aluminum Bronze (CuAl10Fe3) alloys meeting ASTM B505 and JIS H3250 specifications. The Bronze material composition provides superior resistance to stress corrosion cracking and maintains electrical conductivity of 15-20% IACS under extreme operating conditions. These Bronze ground rod clamps feature reinforced mounting lugs and heavy-duty clamping mechanisms capable of withstanding installation torques up to 40 Nm. The enhanced fatigue resistance of Bronze alloys ensures reliable performance in applications subject to thermal cycling and mechanical vibration.

Copper Grounding Clamps – Maximum Electrical Performance

Copper grounding clamps deliver maximum electrical conductivity and thermal performance for critical grounding applications in power generation, transmission, and distribution systems. Our Copper grounding clamps are manufactured from high-purity electrolytic Copper (C101) conforming to ASTM B187 and BS EN 13601 specifications. The 99.95% pure Copper composition ensures electrical conductivity of 100% IACS, providing the lowest resistance path for fault currents and lightning protection systems. Each Copper grounding clamp undergoes precision machining to achieve surface finish Ra 1.6 μm, ensuring optimal conductor contact and minimal connection resistance. The malleable properties of Copper allow custom forming to accommodate irregular conductor configurations and specialized mounting requirements.

Ground Rod Connectors – Versatile Earthing Connections

Ground rod connectors provide flexible interconnection solutions for complex earthing networks, accommodating multiple conductor sizes and rod configurations within single connection points. Our ground rod connectors feature modular design architecture allowing field assembly of custom grounding configurations without specialized tooling. The connector body construction utilizes high-strength Copper-Tin alloys with integrated strain relief mechanisms to prevent conductor fatigue under thermal expansion cycles. These ground rod connectors accommodate conductor combinations from solid Copper rods to stranded cables, with connection capacity ranging from 16mm² to 240mm² cross-sectional areas. Each connector assembly includes corrosion-resistant hardware and sealing compounds to maintain electrical integrity in underground installations.

Bronze Ground Rod Connectors with Stainless Steel Bolts – Premium Corrosion Protection

Bronze ground rod connectors with Stainless Steel bolts represent the premium solution for long-term earthing reliability in aggressive environmental conditions. The connector body manufactured from Silicon Bronze (CuSi3Mn1) provides exceptional strength-to-weight ratio while maintaining good electrical conductivity. The Stainless Steel bolts utilize Grade 316 austenitic Steel conforming to ASTM A193 specifications, offering superior chloride stress corrosion resistance and galling resistance. This material combination ensures compatible galvanic behavior, preventing accelerated corrosion at dissimilar metal interfaces. The Bronze ground rod connectors feature integrated cable strain relief and environmental sealing to IP68 standards, making them suitable for direct burial and underwater applications.

Manufacturing Processes & Quality Control

Casting Process: Our investment casting facility utilizes precision wax patterns and ceramic shell molding to produce dimensionally accurate ground rod clamps with excellent surface finish. The casting process employs controlled atmosphere melting furnaces maintaining precise temperature profiles for optimal alloy properties. Each casting batch undergoes spectrographic analysis to verify chemical composition within specified limits.

Hot Stamping Process: Hot stamping operations utilize servo-controlled hydraulic presses with precision die sets to form complex geometries while maintaining material integrity. The hot stamping process operates at controlled temperatures between 600-800°C depending on alloy composition, ensuring optimal formability without grain boundary embrittlement.

| Material | International Standard | USA Standard | European Standard | Chinese Standard | Japanese Standard | Conductivity (%IACS) |

|---|---|---|---|---|---|---|

| Electrolytic Tough Pitch Copper | ISO 1337 | ASTM B187 C101 | BS EN 13601 Cu-ETP | GB/T 5231 T2 | JIS H3100 C1100 | 100 |

| Free Cutting Brass | ISO 426-1 | ASTM B16 C360 | BS EN 12164 CuZn39Pb3 | GB/T 4423 HPb59-1 | JIS H3250 C3604 | 28 |

| Tin Bronze | ISO 2738 | ASTM B505 C90300 | BS EN 1982 CC491K | GB/T 1176 ZCuSn10P1 | JIS H5120 BC3 | 15 |

| Aluminum Bronze | ISO 2738 | ASTM B148 C95400 or C95500 | BS EN 1982 CC333G | GB/T 1176 ZCuAl10Fe3 | JIS H5120 BC7 | 13 |

| Silicon Bronze | ISO 2738 | ASTM B97 C65500 | BS EN 12163 CuSi3Mn1 | GB/T 4423 QSi3-1 | JIS H3250 C6511 | 20 |

Dimensional Specifications

| Model | Rod Diameter (D) | Overall Length (L) | Overall Width (W) | Throat Opening (T) | Conductor Size | Bolt Size |

|---|---|---|---|---|---|---|

| GRC-12 (1/2″) | 12.7 | 85 | 45 | 15 | 6-35 mm² | M8 |

| GRC-16 (5/8″) | 15.9 | 95 | 50 | 18 | 16-50 mm² | M10 |

| GRC-20 (3/4″) | 19.1 | 110 | 55 | 22 | 25-95 mm² | M12 |

| GRC-25 (1″) | 25.4 | 125 | 65 | 28 | 50-120 mm² | M14 |

Surface Finishes & Plating Options

Our comprehensive surface treatment capabilities ensure optimal corrosion protection and electrical performance for diverse installation environments. Electroplating services include Tin plating per ASTM B545 for enhanced solderability, Nickel plating per ASTM B689 for wear resistance, and Silver plating per ASTM B700 for maximum conductivity. Chemical conversion coatings such as Chromate treatment per MIL-DTL-81706 provide additional corrosion resistance for Aluminum Bronze components. Organic coatings including epoxy powder coating per ASTM D6677 offer superior environmental protection with electrical insulation properties where required. All surface treatments undergo adhesion testing per ASTM D3359 and salt spray testing per ASTM B117 to ensure long-term durability.

Industries & Applications

Our ground rod clamps and earthing solutions serve diverse industrial sectors including Power Generation facilities requiring fault current protection and personnel safety systems. Telecommunications infrastructure utilizes our grounding clamps for equipment protection and signal integrity maintenance. Oil & Gas installations depend on our corrosion-resistant clamps for hazardous area earthing and cathodic protection systems. Railway electrification projects employ our heavy-duty clamps for traction system earthing and return current paths. Data Centers rely on our precision-engineered clamps for equipment grounding and electromagnetic interference mitigation. Chemical Processing plants utilize our specialized alloy clamps for corrosive environment applications and static electricity dissipation.

International Standards Compliance

| Standard | Title | Application |

|---|---|---|

| ASTM B187 | Standard Specification for Copper Bus Bar, Rod, and Shapes | Copper grounding conductors |

| BS EN 50164-1 | Lightning protection components – Requirements for connection components | Lightning protection earthing |

| IEC 62561-2 | Lightning protection system components – Requirements for conductors and earth electrodes | Earth electrode connections |

| DIN 48801 | Earth termination systems – Earth electrodes | German earthing standards |

| JIS C 8839 | Earthing materials and earthing work | Japanese grounding requirements |

| IS 3043 | Code of practice for earthing | Indian earthing standards |

Performance Metrics & Testing

Electrical Performance: Contact resistance maintained below 0.05 milliohms per connection point under standard test conditions. Current carrying capacity verified to 200% of rated conductor ampacity without thermal degradation. Impulse current withstand capability tested to 100kA peak with 8/20 microsecond waveform per IEC 62305 standards.

Mechanical Performance: Installation torque specifications verified from 15-40 Nm depending on clamp size and material. Tensile strength testing demonstrates minimum 2:1 safety factor over maximum conductor tension. Vibration resistance verified per MIL-STD-810 Method 514 for transportation and seismic conditions.

Environmental Performance: Salt spray testing per ASTM B117 demonstrates 1000+ hour corrosion resistance. Temperature cycling from -40°C to +85°C verifies thermal stability and connection integrity. UV exposure testing per ASTM G154 confirms outdoor installation compatibility.

Manufacturing Tolerances

| Dimension Type | Standard Tolerance | Precision Tolerance | Notes |

|---|---|---|---|

| Overall dimensions | ±0.5mm | ±0.2mm | Length, width, height |

| Hole diameters | ±0.1mm | ±0.05mm | Rod and bolt holes |

| Thread specifications | Class 2B | Class 3B | Internal threads |

| Surface finish | Ra 3.2 μm | Ra 1.6 μm | Contact surfaces |

| Concentricity | 0.1mm TIR | 0.05mm TIR | Critical alignments |

Grounding System Infographic

[Infographic Description: Visual representation showing ground rod clamp installation in a typical earthing system, with arrows indicating current flow paths and labels for each component including ground rod, clamp, conductor, and connection to main earthing terminal]

Lightning/Fault Current Flow

↓

┌─────────────────┐

│ Main Earthing │

│ Terminal │

└─────┬───────────┘

│ Copper Conductor

│

┌─────▼─────┐

│ GROUND ROD│ ← Our Clamp Here

│ CLAMP │

└─────┬─────┘

│

┌─────▼─────┐

│ Earth Rod │

│(Driven into│

│ Soil) │

└───────────┘

Frequently Asked Questions

Q1: What is the difference between ground rod clamps and earth rod clamps?

A: Ground rod clamps and earth rod clamps are functionally identical terms referring to the same grounding hardware. The terminology varies by regional preference, with “ground rod clamps” more common in North America and “earth rod clamps” preferred in European and Commonwealth countries. Both terms describe mechanical connectors that provide electrical continuity between earthing conductors and driven earth electrodes.

Q2: Which material is best for corrosive soil conditions – Brass, Bronze, or Copper ground rod clamps?

A: For highly corrosive soil conditions, Bronze ground rod clamps offer superior performance due to their excellent resistance to dezincification and stress corrosion cracking. Brass earth rod clamps provide good general corrosion resistance and are cost-effective for moderate soil conditions. Copper grounding clamps deliver maximum electrical conductivity but may require protective coatings in aggressive environments.

Q3: What torque specifications should be used for ground rod clamp installation?

A: Installation torque depends on clamp size and material composition. For Brass and Bronze ground rod clamps, apply 15-25 Nm for M8 bolts, 25-35 Nm for M10-M12 bolts, and 35-40 Nm for M14 bolts. Copper grounding clamps require slightly reduced torque (10-15% lower) to prevent galling. Always use calibrated torque tools and anti-seize compound on threads.

Q4: How do I select the correct ground rod clamp size for my application?

A: Ground rod clamp selection depends on three primary factors: earth rod diameter (typically 12.7mm to 25.4mm), conductor cross-sectional area (6mm² to 120mm²), and fault current magnitude. Verify that the clamp throat opening accommodates your conductor size with adequate clearance, and ensure the current rating exceeds your system fault current by minimum 25% safety margin.

Q5: Can ground rod connectors accommodate multiple conductors in a single connection?

A: Yes, our ground rod connectors feature multiple conductor ports allowing parallel connections of different conductor types and sizes. The modular design accommodates combinations of solid rods, stranded cables, and flat strip conductors within rated capacity limits. Each conductor port provides independent strain relief and environmental sealing.

Q6: What environmental testing do your earth rod clamps undergo?

A: All earth rod clamps undergo comprehensive environmental testing including 1000-hour salt spray exposure per ASTM B117, thermal cycling from -40°C to +85°C, UV radiation exposure per ASTM G154, and humidity testing per IEC 60068-2-78. Additionally, we perform accelerated corrosion testing in synthetic soil solutions matching various geographic soil chemistry profiles.

Q7: Are your grounding clamps suitable for direct burial applications?

A: Yes, our grounding clamps are specifically designed for direct burial installations. The material compositions and surface treatments provide long-term corrosion resistance in soil environments. Bronze ground rod connectors with Stainless Steel bolts offer premium performance for underground installations with IP68 environmental sealing and galvanic compatibility.

Q8: What quality certifications do your ground rod clamps maintain?

A: Our manufacturing facility maintains ISO 9001:2015 quality management certification, ISO 14001:2015 environmental management certification, and OHSAS 18001:2007 occupational health and safety certification. Products undergo third-party testing and certification to relevant national and international standards including UL, CSA, CE marking, and BIS certification for Indian standards.

Q9: Can you manufacture custom ground rod clamps for special applications?

A: Absolutely. Our engineering team specializes in custom grounding solutions for unique applications. We can modify standard designs for special conductor configurations, accommodate non-standard earth rod diameters, integrate multiple connection points, and provide custom materials or platings. Minimum order quantities for custom products typically start at 100 pieces.

Q10: What is the expected service life of Bronze ground rod clamps in marine environments?

A: Bronze ground rod clamps demonstrate excellent performance in marine environments with expected service life exceeding 25 years under normal operating conditions. The high Tin content provides natural corrosion resistance, while the absence of Zinc eliminates dezincification concerns. Regular inspection intervals of 5 years are recommended for critical applications.

Q11: How do grounding clamps perform under lightning strike conditions?

A: Our grounding clamps are designed to withstand lightning impulse currents up to 100kA peak with 8/20 microsecond waveform characteristics per IEC 62305 standards. The robust construction and high-conductivity materials ensure minimal impedance during lightning events, while the mechanical design prevents loosening due to electromagnetic forces.

Q12: What packaging options are available for international shipping?

A: Standard packaging includes moisture-barrier bags with desiccant, protective foam inserts, and labeled cardboard cartons suitable for sea freight. We offer customized packaging with customer logos and branding, vacuum-sealed moisture protection for long sea voyages, and specialized export crating for sensitive electronic equipment applications.

Q13: Do you provide technical support for grounding system design?

A: Yes, our technical support team provides comprehensive assistance including grounding system design reviews, connection hardware selection guidance, installation procedure development, and troubleshooting support. We can recommend optimal clamp configurations for specific soil resistivity conditions and fault current levels based on site-specific requirements.

Q14: What is the minimum order quantity for standard ground rod clamps?

A: Minimum order quantities vary by product type and material. Standard Brass and Bronze ground rod clamps have MOQ of 50 pieces per size. Copper grounding clamps require minimum 100 pieces due to material costs. Mixed orders combining different sizes can meet the total MOQ requirement across the product range.

Q15: How do I ensure proper electrical contact with ground rod clamps?

A: Proper electrical contact requires clean, oxide-free surfaces on both the earth rod and conductor. Use wire brushes or abrasive cloth to clean contact surfaces before installation. Apply joint compound or anti-oxidant paste to prevent oxidation. Torque bolts to specified values using calibrated tools, and perform resistance measurements to verify low-resistance connections below 0.05 milliohms.

Material Properties Comparison

| Property | Copper (C101) | Brass (CuZn37) | Tin Bronze (CuSn8) | Aluminum Bronze | Units |

|---|---|---|---|---|---|

| Electrical Conductivity | 59.6 | 16.8 | 9.0 | 7.8 | MS/m |

| Thermal Conductivity | 394 | 121 | 50 | 59 | W/m·K |

| Tensile Strength | 220-450 | 300-500 | 275-450 | 550-750 | MPa |

| Yield Strength | 70-350 | 120-400 | 130-200 | 250-550 | MPa |

| Elongation | 45-60 | 20-45 | 8-20 | 12-25 | % |

| Hardness | 40-90 | 60-120 | 70-120 | 150-250 | HB |

Why Choose Our Ground Rod Clamps

Three Decades of Global Experience: Our 30+ years of international experience in grounding solutions manufacturing provides unmatched expertise in material science, precision engineering, and quality control. We understand the diverse requirements of global markets and maintain extensive knowledge of international standards and regional preferences.

Faster Turnaround Times: Our streamlined production processes and inventory management system enable delivery within 4-6 weeks for standard products, significantly faster than industry averages. Emergency orders can be expedited with 2-3 week delivery for critical applications, supported by our flexible manufacturing scheduling system.

Superior Customer Communication: Our multilingual technical support team provides comprehensive pre-sale consultation, detailed technical documentation, and post-installation support. We maintain regular communication throughout the order process with proactive updates on production status, quality testing results, and shipping arrangements.

Customization Capabilities: Our in-house engineering team collaborates with customers to develop specialized grounding solutions for unique applications. We can modify existing designs, create entirely new products, and provide technical drawing reviews with optimization suggestions to improve installation efficiency and long-term performance.

Flexible Production Scheduling: Our manufacturing flexibility accommodates urgent delivery requirements, seasonal demand variations, and custom production runs without compromising quality standards. We maintain strategic raw material inventory to support rapid production scaling and emergency order fulfillment.

Custom Packaging Solutions: We offer comprehensive packaging customization including customer branding, specialized protective packaging for sensitive environments, and export documentation services. Our packaging engineers design solutions to minimize shipping costs while ensuring product integrity during international transportation.

Packaging & Shipping Solutions

Our comprehensive packaging solutions ensure product integrity during international transportation while minimizing shipping costs and environmental impact. Standard packaging includes individual plastic bags with desiccant packets, protective foam inserts, and labeled cardboard cartons with handling instructions in multiple languages. Export packaging features moisture-barrier aluminum bags, shock-absorbing foam systems, and reinforced wooden crates for sea freight shipments. Custom packaging services include customer logo printing, color-coded size identification, and specialized protective packaging for electronic equipment manufacturers. All packaging materials comply with international shipping regulations and environmental standards including ISPM 15 for wooden packaging materials.

Turnaround Time & Delivery

Our efficient production planning and inventory management systems enable consistent delivery performance with standard turnaround time of 4-6 weeks for most product configurations. Express production services are available for urgent requirements with 2-3 week delivery possible depending on order complexity and current production schedule. Large volume orders exceeding 10,000 pieces may require extended delivery times of 8-10 weeks to ensure optimal quality control throughout the production run. We maintain strategic inventory of popular sizes in standard materials to support emergency delivery requirements and accommodate unexpected order increases during peak construction seasons.

Glossary of Technical Terms

Earthing System: Comprehensive network of earth electrodes, grounding conductors, and connection hardware designed to provide safe discharge path for electrical faults and lightning strikes.

Ground Rod Clamp: Mechanical connector device that provides electrical continuity between grounding conductors and driven earth electrodes, also known as earth rod clamp or grounding clamp.

Contact Resistance: Electrical resistance measured across connection interfaces, typically expressed in milliohms for grounding applications where low resistance is critical for safety and performance.

IACS (International Annealed Copper Standard): Reference standard for electrical conductivity measurements where pure annealed Copper represents 100% IACS conductivity at 20°C.

Dezincification: Corrosion process affecting Zinc-containing alloys where Zinc is selectively removed leaving porous Copper-rich structure with reduced mechanical strength and electrical conductivity.

Galvanic Compatibility: Electrochemical compatibility between dissimilar metals in electrical contact, preventing accelerated corrosion due to potential differences in electrolytic environments.

Fault Current: Abnormal electrical current flow during system faults, requiring grounding hardware capable of safely conducting high current levels without thermal or mechanical failure.

Impulse Current: High-magnitude, short-duration current characteristic of lightning strikes, typically specified as peak current with specific rise time and duration parameters per IEC 62305 standards.

Related Parts:

Earth clamps, Earthing clamps, Grounding accessories, Earth rod connectors, Ground electrode clamps, Electrical earthing hardware, Lightning protection clamps, Earth terminal clamps, Grounding lugs, Earth bonding clamps, Ground wire clamps, Earthing system components, Electrical ground clamps, Earth continuity clamps, Grounding hardware, Earth rod accessories, Ground connection clamps, Earthing terminals, Grounding connectors, Earth system hardware, Lightning rod clamps, Grounding electrodes, Earth protection clamps, Ground fault protection, Earthing conductor clamps

Request Your Custom Quote for Ground rod Clamps Today

Contact us today for your ground rod clamps and earthing hardware requirements.

🔥 Request Your Free Quote – Get competitive pricing in 24 hours- sales@conexscrews.com

🔬 Schedule a Consultation – Discuss your specific requirements Call +91 22-43449300

📦 Order Sample Parts – Test our quality before committing Call +91 22-43449300

📞 Call Our Experts – Get immediate answers to your questions Call +91 22-43449300