Silicon Bronze Casting, Silicon Bronze Parts, Silicon Bronze Fittings, Silicon Bronze casting Foundry, Silicon Bronze Cold Forming, Silicon Bronze Machined Parts, Silicon Bronze Casting Foundry

Silicon Bronze Casting, Parts & Fittings Manufacturer | Precision Foundry & Exporter from India

Price: US$ 12.20/Kilogram

We are one of the leading manufacturers and exporters of Silicon Bronze Castings and Bronze Cold Formed Components from India. We have been supplying high-performance Silicon Bronze Fittings, Machined Parts, and custom-engineered solutions to the world market for many decades. Our foundry is equipped to handle small to medium batches with full flexibility, quick turnaround, and strict adherence to international quality standards. With more than 30 years of global exposure, we have developed advanced capabilities in casting, cold forming, and precision machining of Silicon Bronze alloys. Our reputation is built on technical expertise, personalized customer support, and the ability to deliver complex parts across sectors such as marine, electrical, aerospace, oil & gas, and general engineering. . Our range of Phosphor Bronze casting, Phosphor Bronze Fittings , Phosphor Bronze machined parts and components is accepted quite well across the industries of the world.

Silicon Bronze Casting Silicon Bronze Castings are produced using premium Copper-Silicon alloys conforming to ASTM B584 (e.g., C87500, C87800), BS 1400, and EN 1982 standards. We employ both sand casting and investment casting processes depending on the geometry and required surface finish. Our process integrates shell molding, precise gating systems, and strict control over pouring temperature to ensure porosity-free, homogeneous castings.

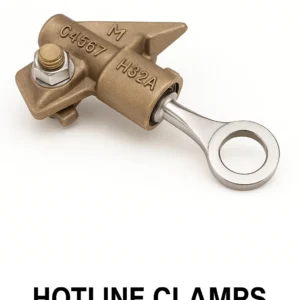

Silicon Bronze Parts We supply a wide variety of Silicon Bronze Parts including bushings, terminal connectors, impellers, marine hardware, valve bodies, and decorative components. These parts are produced with tight dimensional tolerances, excellent corrosion resistance, and consistent surface integrity. Our in-house CAD/CAM team helps customers with DFM (Design for Manufacturability) optimization.

Silicon Bronze Fittings Our range of Silicon Bronze Fittings includes threaded adapters, elbows, tees, unions, flanges, and couplings used in plumbing, marine, and high-corrosion environments. These are manufactured as per ANSI B16.15, ASME, and ISO specifications, available in sizes from 1/8″ to 4″ NPT/BSPT.

![]()

Silicon Bronze Casting Foundry Our state-of-the-art Silicon Bronze Casting Foundry in India is equipped with multiple casting methods to suit diverse part geometries and mechanical requirements. We specialize in:

- Silicon Bronze Sand Casting for robust and economical production of large and medium-sized components.

- Silicon Bronze Investment Casting (lost wax process) for highly precise, thin-walled, and intricate parts.

- Silicon Bronze Shell Molding / Resin Sand Casting for complex core sections with excellent surface finish.

- Silicon Bronze Centrifugal Casting for symmetrical parts such as bushings and sleeves, ensuring a dense and defect-free microstructure. All castings undergo rigorous quality checks including chemical analysis, NDT testing, and visual/dimensional inspection before dispatch.

Silicon Bronze Cold Forming Using grades like C65500 and C65100 conforming to ASTM B124, we cold-form precision parts like bolts, lugs, and inserts. Our high-speed presses and annealing furnaces ensure crack-free cold workability. We also provide thread rolling and surface finishing options.

Silicon Bronze Machined Parts Our CNC turning and VMC machining centers handle tight-tolerance Silicon Bronze Machined Parts like electrical lugs, marine shaft sleeves, and hydraulic fittings. We offer CNC tolerances up to ±0.01 mm and can supply parts in mill finish, polished, or nickel-plated as per customer requirements.

Silicon Bronze Cold Forged Fasteners Our Silicon Bronze Cold Forged Fasteners are manufactured using high-strength, corrosion-resistant alloys such as C65500 and C66300. These fasteners are ideal for applications in marine, electrical, architectural, and chemical processing industries due to their excellent resistance to seawater and atmospheric corrosion. We produce a full range of fasteners—hex bolts, machine screws, threaded rods, studs, and custom per-print geometries—using multi-station cold heading and thread rolling equipment. Each part is processed with post-forming stress relief and is available in natural, polished, or plated finishes. All fasteners conform to ASTM, DIN, ISO, or BS specifications and are quality checked for tensile, shear, and dimensional conformity.

Materials & Grades Used

| Alloy Grade | UNS | Composition | Standards |

|---|---|---|---|

| C87500 | C87500 | Cu ~89%, Si ~4%, Zn ~4% | ASTM B584, BS 1400 AB2 |

| C87600 | C87600 | Cu ~88.5%, Si ~5%, Zn ~5% | ASTM B584 |

| C87800 | C87800 | Cu ~88%, Si ~4%, Zn ~5%, Pb-Free | ASTM B584, EnviroBrass II |

| C87400 | C87400 | Cu ~87%, Si ~4%, Zn ~6%, Pb ~3% | ASTM B584 |

| C87300 | C87300 | Cu ~88%, Si ~3%, Zn ~7%, Mn/Fe trace | ASTM B584 |

| C65500 | C65500 | Cu ~97%, Si ~2.8–3.0% | ASTM B124 (Cold Forming), EN 12163 |

| C65100 | C65100 | Cu ~96%, Si ~1.0–2.0% | ASTM B124 |

| C64700 | C64700 | Cu ~96%, Si ~1.2%, Zn ~2.5% | ASTM B124 |

| C66300 | C66300 | Cu ~95%, Si ~2.5%, Zn ~2.5% | ASTM B124 |

| CuSi3Mn1 | — | Cu-Si-Mn alloy | EN 1982 (Casting), EN 12163 (Wrought) |

| CuSi1 | — | Cu ~98.5%, Si ~1.2% | EN 12163, EN 12165 (Wrought Alloys) |

| CuSi2Zn3 | — | Cu-Si-Zn alloy | EN 12163 (Rod/Bar for Cold Forming) |

Machinery Used

- Induction melting furnaces (300–1000 kg)

- Shell molding lines

- CNC turning & VMC machining centers

- Thread rolling & cold heading machines

- Spectrometer, Ultrasonic Tester, Profile Projector

Typical Tolerances & Dimensions

| Feature | Tolerance |

| Cast Dimensions | ±0.3 mm per 100 mm |

| Machined Bores | ±0.01 mm |

| Thread Tolerance | ISO 965 Class 6g |

Industries Served

- Marine Hardware

- Electrical Connectors

- Hydraulic Components

- Decorative Hardware

- Oil & Gas Equipment

Surface Finish As-cast, shot-blasted, polished, nickel plated, or custom finishes.

Turnaround Time Typical lead time is 4–6 weeks, with expedited production possible for critical projects.

Performance Metrics

- Tensile Strength: 350–550 MPa

- Yield Strength: 200–400 MPa

- Elongation: 10–25%

- Corrosion Resistance: Excellent in saline and chemical environments

Why Choose Us

- Faster turnaround times and flexible batch sizes

- In-house design & customization support

- Decades of global export experience

- Custom logo & label packaging

- Multilingual customer support with detailed documentation

Packaging & Shipping All parts are packed in export-grade corrugated boxes or wooden crates, with desiccant and VCI bags if required. Custom barcode labels, QR codes, or customer logo packaging available.

Customer Testimonial “We have been sourcing custom Silicon Bronze fittings from Conex India for over 6 years. The quality is unmatched, communication is fast, and the delivery is always reliable. Highly recommended!” – Mark T., Chicago, USA

Typical Questions & Answers

- Do you supply to the USA and Europe? Yes, we are a regular exporter to North America and the EU.

- Can you supply test certificates? Yes, we provide material test reports, dimensional reports, and inspection logs.

- What is your MOQ? We are flexible—MOQ depends on the part.

- Do you offer rapid prototyping? Yes, via CNC and 3D sand printing.

- Can you machine to my drawing? Absolutely. We accept STEP, IGES, and 2D PDFs.

- What payment terms do you offer? TT, LC, and PayPal for small orders.

- Can you match a sample? Yes, we reverse-engineer from samples.

- Is packaging customizable? Yes, with customer logo, labels, and branding.

- Are your materials RoHS compliant? Yes, including Pb-free grades.

- Do you conduct third-party inspections? Yes, via SGS, BV, or TUV on request.

Glossary of Terms

- Casting: Pouring molten metal into a mold to solidify into a shape

- Cold Forming: Shaping metal at room temperature using pressure

- CNC Machining: Computer-controlled precision cutting of parts

- UNS Number: Unified Numbering System for alloy designation

- BSP/NPT: British/US thread standards for pipe fittings

Related Terms: Silicon bronze casting, Silicon Bronze Threaded Fittings, Silicon Bronze Flanges, Lead-Free Bronze Castings, Custom Bronze Machining, ASTM B584 Foundry India

For custom quotes, technical brochures, or product catalogs, email us or call/WhatsApp us .