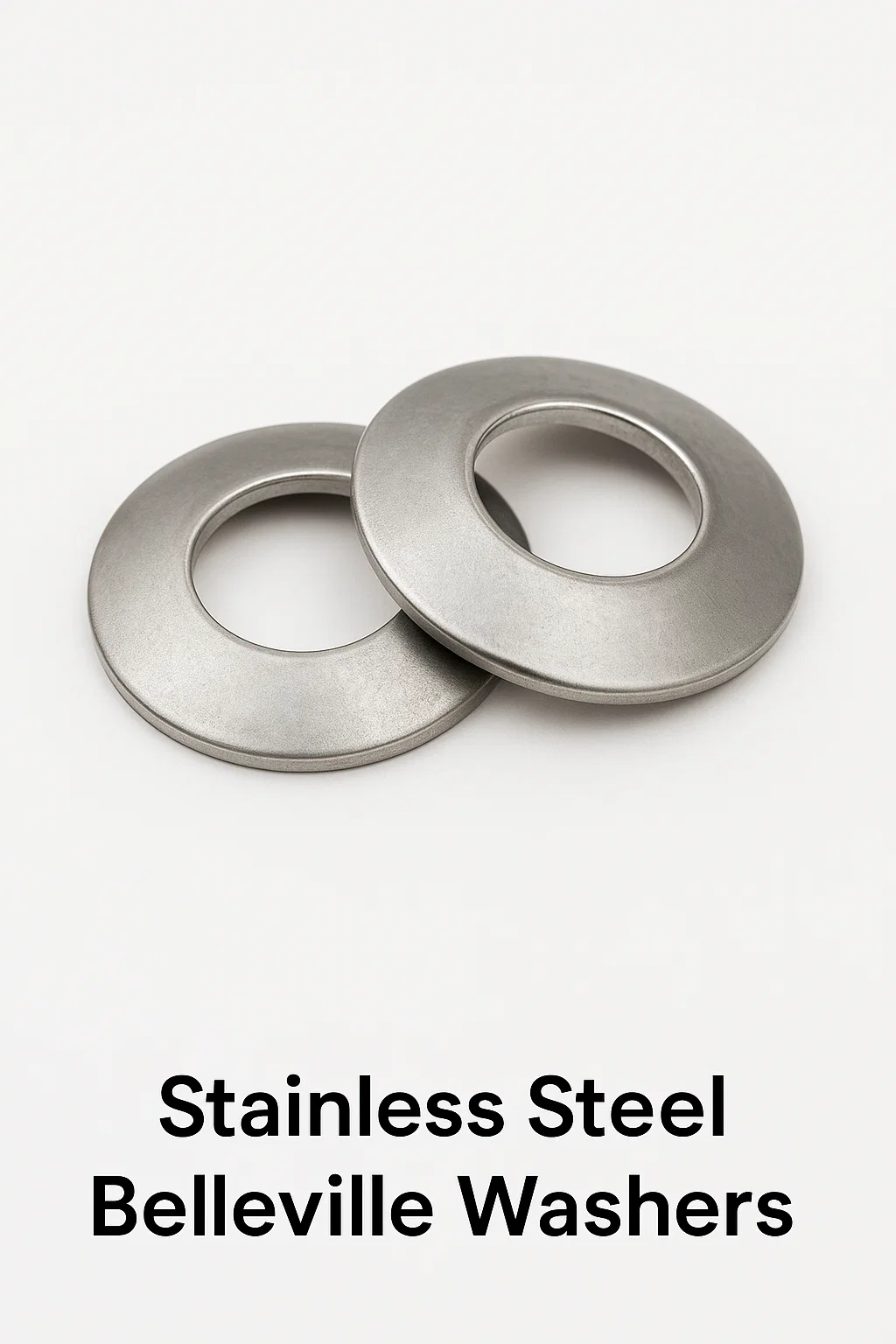

Stainless Steel Belleville Washers – Premium Spring Washers for Industrial Applications

High Quality Stainless Steel Belleville Washers

Stainless steel Belleville washers, also known as conical spring washers, disc springs, or coned-disc springs, are specialized fastening components designed to provide controlled spring force and maintain bolt tension in demanding applications. These precision-engineered washers feature a distinctive conical shape that delivers consistent load distribution and exceptional performance in corrosive environments. We also offer Bronze Belleville Washers in phosphor Bronze and Silicon Bronze grades.

Key Features and Benefits

Superior Corrosion Resistance: Manufactured from high-grade stainless steel alloys (typically 17-7 PH, 301, 316, or 410 stainless steel), these Belleville washers resist rust, oxidation, and chemical corrosion, making them ideal for marine, chemical processing, and outdoor applications.

Consistent Spring Force: The conical design provides predictable deflection characteristics and maintains uniform bolt preload over extended periods, preventing loosening due to vibration or thermal cycling.

Space-Efficient Design: Belleville spring washers offer high load capacity in minimal axial space, making them perfect for applications where space constraints are critical.

Temperature Stability: Stainless steel Belleville washers maintain their spring properties across wide temperature ranges, from cryogenic applications to high-temperature industrial processes.

Fatigue Resistance: Engineered for millions of load cycles without failure, these disc springs provide long-term reliability in dynamic applications.

Available Sizes and Specifications

Imperial Size Table (Inches)

| Size | Outer Diameter (OD) | Inner Diameter (ID) | Thickness Range | Load Range (lbs) |

|---|---|---|---|---|

| #4 | 0.112″ | 0.125″ | 0.006″ – 0.020″ | 5 – 25 |

| #6 | 0.138″ | 0.144″ | 0.006″ – 0.025″ | 8 – 40 |

| #8 | 0.164″ | 0.169″ | 0.008″ – 0.030″ | 12 – 60 |

| #10 | 0.190″ | 0.194″ | 0.008″ – 0.035″ | 15 – 85 |

| 1/4″ | 0.250″ | 0.281″ | 0.010″ – 0.040″ | 25 – 150 |

| 5/16″ | 0.312″ | 0.344″ | 0.012″ – 0.050″ | 40 – 240 |

| 3/8″ | 0.375″ | 0.406″ | 0.015″ – 0.060″ | 60 – 350 |

| 7/16″ | 0.437″ | 0.469″ | 0.018″ – 0.070″ | 80 – 480 |

| 1/2″ | 0.500″ | 0.531″ | 0.020″ – 0.080″ | 100 – 650 |

| 9/16″ | 0.562″ | 0.594″ | 0.022″ – 0.090″ | 125 – 850 |

| 5/8″ | 0.625″ | 0.656″ | 0.025″ – 0.100″ | 150 – 1,100 |

| 3/4″ | 0.750″ | 0.781″ | 0.030″ – 0.120″ | 220 – 1,600 |

| 7/8″ | 0.875″ | 0.906″ | 0.035″ – 0.140″ | 300 – 2,200 |

| 1″ | 1.000″ | 1.031″ | 0.040″ – 0.160″ | 400 – 3,000 |

| 1-1/8″ | 1.125″ | 1.156″ | 0.045″ – 0.180″ | 500 – 3,900 |

| 1-1/4″ | 1.250″ | 1.281″ | 0.050″ – 0.200″ | 625 – 5,000 |

| 1-1/2″ | 1.500″ | 1.531″ | 0.060″ – 0.240″ | 900 – 7,500 |

| 2″ | 2.000″ | 2.031″ | 0.080″ – 0.320″ | 1,600 – 15,000 |

Metric Size Table (Millimeters)

| Size | Outer Diameter (OD) | Inner Diameter (ID) | Thickness Range | Load Range (N) |

|---|---|---|---|---|

| 3mm | 3.0 | 3.2 | 0.15 – 0.50 | 22 – 110 |

| 4mm | 4.0 | 4.3 | 0.20 – 0.65 | 35 – 180 |

| 5mm | 5.0 | 5.3 | 0.25 – 0.80 | 55 – 280 |

| 6mm | 6.0 | 6.4 | 0.30 – 1.00 | 80 – 400 |

| 8mm | 8.0 | 8.4 | 0.40 – 1.25 | 140 – 750 |

| 10mm | 10.0 | 10.5 | 0.50 – 1.60 | 220 – 1,200 |

| 12mm | 12.0 | 12.5 | 0.60 – 1.90 | 320 – 1,750 |

| 14mm | 14.0 | 14.5 | 0.70 – 2.20 | 430 – 2,400 |

| 16mm | 16.0 | 17.0 | 0.80 – 2.50 | 560 – 3,200 |

| 18mm | 18.0 | 19.0 | 0.90 – 2.80 | 710 – 4,100 |

| 20mm | 20.0 | 21.0 | 1.00 – 3.20 | 880 – 5,200 |

| 22mm | 22.0 | 23.0 | 1.10 – 3.50 | 1,070 – 6,400 |

| 25mm | 25.0 | 26.0 | 1.25 – 4.00 | 1,375 – 8,500 |

| 30mm | 30.0 | 31.0 | 1.50 – 4.80 | 1,980 – 12,800 |

| 35mm | 35.0 | 36.0 | 1.75 – 5.60 | 2,700 – 18,000 |

| 40mm | 40.0 | 42.0 | 2.00 – 6.40 | 3,520 – 24,500 |

| 50mm | 50.0 | 52.0 | 2.50 – 8.00 | 5,500 – 40,000 |

Material Grades and Properties

Material Grades and Properties

Detailed Material Grade Specifications

| Material Grade | Type | Tensile Strength (ksi) | Yield Strength (ksi) | Corrosion Resistance | Cost Level |

|---|---|---|---|---|---|

| 17-7 PH | Precipitation Hardened | 200-230 | 185-215 | Excellent | Premium |

| 17-4 PH | Precipitation Hardened | 180-200 | 165-185 | Excellent | High |

| 301 Full Hard | Austenitic Work Hardened | 185-200 | 140-160 | Superior | Moderate |

| 301 3/4 Hard | Austenitic Work Hardened | 150-175 | 110-135 | Superior | Moderate |

| 316 | Austenitic | 85-95 | 35-45 | Superior | Moderate |

| 302 | Austenitic | 90-100 | 40-50 | Good | Standard |

| 410 | Martensitic | 115-130 | 85-100 | Moderate | Economy |

| 420 | Martensitic | 150-180 | 120-150 | Moderate | Economy |

| 15-5 PH | Precipitation Hardened | 170-190 | 155-175 | Excellent | High |

Material Grade Applications

17-7 PH (Premium Grade)

- Aerospace applications requiring maximum spring properties

- Critical load-bearing applications

- High-cycle fatigue requirements

- Temperature range: -300°F to +600°F (-184°C to +316°C)

301 Stainless Steel (Standard Grade)

- General industrial applications

- Marine environments

- Food processing equipment

- Temperature range: -425°F to +800°F (-254°C to +427°C)

316 Stainless Steel (Marine Grade)

- Chemical processing equipment

- Marine and saltwater applications

- Pharmaceutical industry

- Superior chloride corrosion resistance

410 Stainless Steel (Economy Grade)

- General purpose applications

- Mild corrosive environments

- Cost-sensitive projects

- Heat treatable for various hardness levels

Applications and Industries

Aerospace and Defense

- Aircraft engine mounts and assemblies

- Missile and rocket components

- Satellite deployment mechanisms

- Landing gear systems

Automotive and Transportation

- Valve spring applications

- Suspension components

- Brake system assemblies

- Transmission components

Industrial Manufacturing

- Pressure vessel assemblies

- Pump and compressor components

- Heavy machinery bolted joints

- Conveyor system hardware

Marine and Offshore

- Shipbuilding fasteners

- Offshore platform assemblies

- Subsea equipment

- Port and harbor structures

Chemical Processing

- Reactor vessel connections

- Pipeline flanges

- Valve assemblies

- Process equipment

Technical Specifications and Standards

ASTM Standards: Manufactured to ASTM F959 specifications for Belleville springs, ensuring consistent quality and performance.

Material Standards: Comply with ASTM A313, ASTM A693, and other relevant stainless steel standards.

Load Testing: Each batch tested for load deflection characteristics according to industry standards.

Surface Finish: Available in various finishes including passivated, electropolished, and shot peened for enhanced performance.

Design Considerations

Load Requirements: Calculate required load based on bolt preload specifications and safety factors.

Deflection Limits: Ensure operating deflection stays within 75% of flat solid height for optimal fatigue life.

Stacking Configurations: Multiple washers can be stacked in series (increased deflection) or parallel (increased load) arrangements.

Installation Torque: Follow proper torque specifications to achieve desired preload without over-stressing the washer.

Quality Assurance and Testing

All stainless steel Belleville washers undergo rigorous quality control including:

- Dimensional inspection using precision measuring equipment

- Load-deflection testing on statistical samples

- Material composition verification

- Surface finish inspection

- Fatigue testing for critical applications

Custom Manufacturing Capabilities

Special Sizes: Custom outer diameters, inner diameters, and thicknesses available for unique applications.

Material Variants: Specialized stainless steel alloys including Inconel, Hastelloy, and other exotic materials.

Surface Treatments: Custom coatings and treatments for enhanced performance in specific environments.

Engineering Support: Complete design assistance including load calculations, stress analysis, and application recommendations.

Ordering Information

When specifying stainless steel Belleville washers, provide:

- Outer diameter (OD)

- Inner diameter (ID)

- Material thickness

- Material grade

- Load requirements

- Quantity needed

- Special requirements or certifications

Advantages Over Alternative Spring Washers

Versus Helical Springs: Higher load capacity in smaller space, more predictable load characteristics.

Versus Wave Washers: Greater load capacity, better fatigue life, more precise load control.

Versus Lock Washers: Maintains consistent bolt tension, superior vibration resistance, no sharp edges.

Storage and Handling

Store stainless steel Belleville washers in clean, dry conditions to prevent contamination. Handle with clean tools to avoid surface damage that could initiate stress concentration points. Maintain proper inventory rotation to ensure fresh stock for critical applications.

Technical Support and Engineering Services

Professional engineering support available for:

- Load and deflection calculations

- Material selection guidance

- Custom design assistance

- Application troubleshooting

- Performance optimization

Stainless steel Belleville washers represent the premium choice for applications demanding reliable spring force, corrosion resistance, and long-term performance. Contact our technical team for detailed specifications, custom solutions, and expert application guidance.

Related Terms

- Stainless Steel Belleville Washers

- Conical Spring Washers

- Disc Springs Stainless Steel

- Coned Disc Springs

- Spring Washers Stainless

- Belleville Disc Springs

- Stainless Steel Disc Springs

- Conical Washers Stainless Steel

Technical Terms

- ASTM F959 Belleville Springs

- 17-7 PH Belleville Washers

- 301 Stainless Spring Washers

- 316 Marine Grade Disc Springs

- Precipitation Hardened Spring Washers

- Load Deflection Belleville Washers

- Fatigue Resistant Disc Springs

- High Temperature Spring Washers

- 1/4″ Belleville Washers Stainless

- 5/16″ Disc Springs Stainless Steel

- 3/8″ Conical Spring Washers

- 1/2″ Stainless Belleville Springs

- 3mm Belleville Washers Metric

- 5mm Disc Springs Stainless

- 6mm Conical Spring Washers

- 10mm Stainless Steel Disc Springs

Application terms

- Aerospace Belleville Washers

- Marine Grade Disc Springs

- Chemical Resistant Spring Washers

- Automotive Belleville Springs

- Industrial Conical Washers

- Pressure Vessel Spring Washers

- Valve Spring Disc Washers

- Flange Belleville Washers

Industry-Specific Terms

- Subsea Belleville Washers

- Petrochemical Disc Springs

- Food Grade Spring Washers

- Pharmaceutical Belleville Springs

- Nuclear Qualified Disc Springs

- Aerospace Grade Conical Washers

- Military Spec Belleville Washers

- Medical Device Spring Washers

- Custom Belleville Washers

- Made to Order Disc Springs

- Precision Spring Washers

- CNC Machined Belleville Springs

- Wire EDM Cut Disc Springs