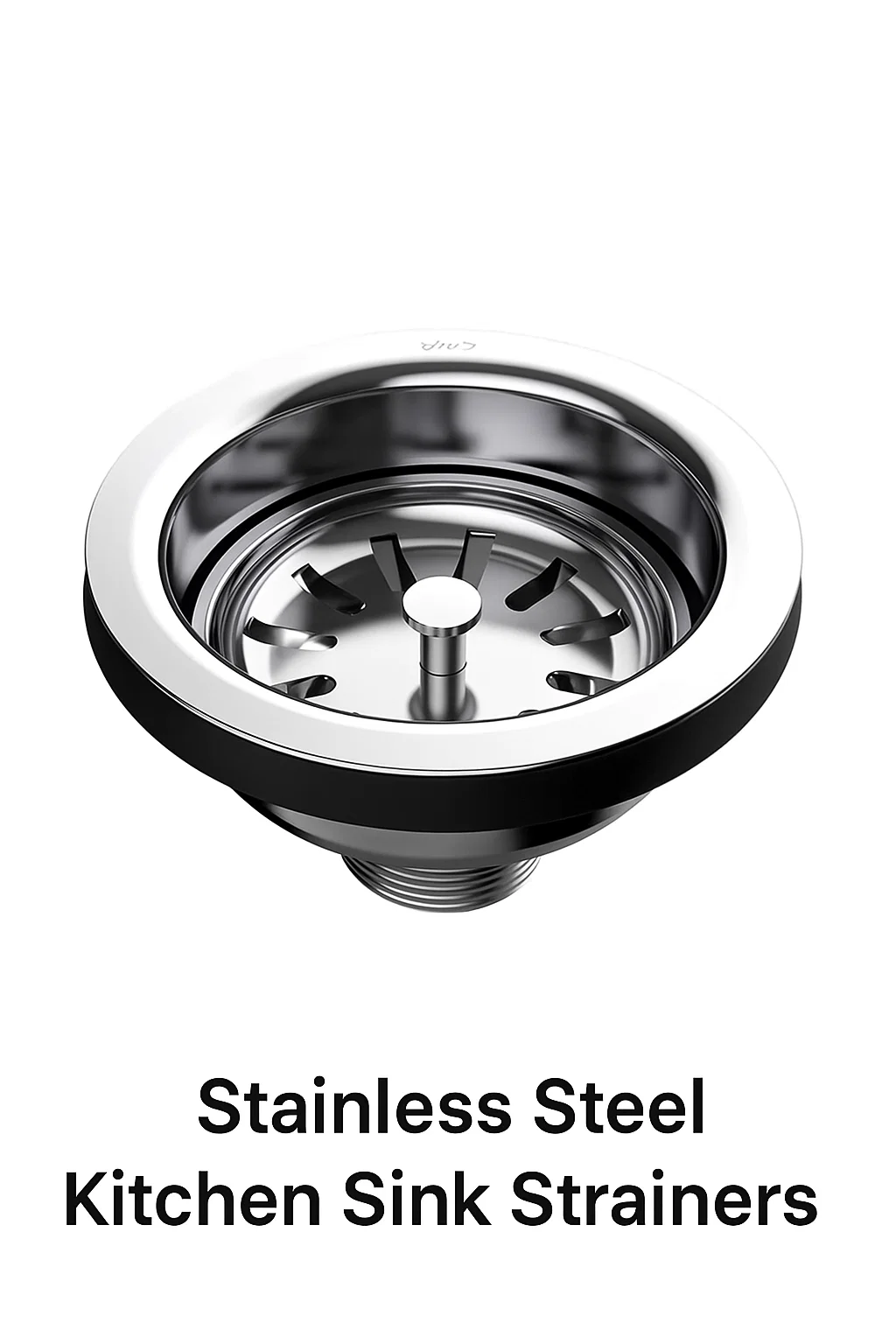

Stainless Steel Sink Strainers, Stainless Steel Sieves – Premium Kitchen Drain Solutions

We are one of the leading manufacturers and exporters of Stainless Steel Sink Strainers from India. We have been supplying premium kitchen sink strainers, drain filters, and basket strainers to the world market for many decades. Our comprehensive range of sink strainers includes perforated basket strainers, mesh sink filters, and custom-designed drain catchers that provide superior filtration performance in residential and commercial kitchen applications. With over three decades of manufacturing excellence, we specialize in producing high-quality Stainless Steel sink strainers using advanced pressing, punching, and polishing techniques. Our state-of-the-art manufacturing facility utilizes precision machinery to create durable, corrosion-resistant sink strainers that meet international quality standards including ASTM, DIN, BS, and JIS specifications. Each sink strainer undergoes rigorous quality control processes to ensure optimal performance, longevity, and customer satisfaction. Our extensive product portfolio caters to diverse market requirements, from standard kitchen sink strainers to specialized industrial drain filters, making us the preferred choice for importers, distributors, and OEM partners worldwide.

Price: US$ 12/Kilogram

Product Overview – Stainless Steel Sink Strainers

Stainless Steel sink strainers are essential kitchen accessories designed to prevent food particles, debris, and solid waste from entering drain systems while allowing water to flow freely. These precision-engineered components are manufactured through specialized metal forming processes including sheet metal pressing, CNC punching, and multi-stage polishing operations. Our sink strainers feature strategically positioned perforations or mesh patterns that optimize drainage efficiency while capturing unwanted materials. The robust construction ensures long-lasting performance in demanding kitchen environments, from residential applications to high-volume commercial food service operations. Available in various configurations including basket-style strainers, flat mesh sieves, and deep-draw basket strainers, our products accommodate different sink designs and drainage requirements.

Material Grades and Specifications

| Grade Designation | International Standards | Chromium Content | Nickel Content | Applications |

|---|---|---|---|---|

| 304 Stainless Steel | ASTM A240, DIN 1.4301, JIS SUS304, BS 304S15 | 18-20% | 8-10.5% | Standard kitchen sink strainers, residential applications |

| 316 Stainless Steel | ASTM A240, DIN 1.4401, JIS SUS316, BS 316S11 | 16-18% | 10-14% | Marine environments, commercial kitchens, food processing |

| 430 Stainless Steel | ASTM A240, DIN 1.4016, JIS SUS430, BS 430S15 | 16-18% | – | Economy grade sink strainers, decorative applications |

| 201 – 202 Stainless Steel | ASTM A240, GB/T 3280, JIS SUS201 | 16-18% | 3.5-5.5% | Cost-effective solutions, light-duty applications |

Manufacturing Processes and Machinery

Our advanced manufacturing facility employs sophisticated metalworking processes to produce precision sink strainers that meet exacting quality standards. The production sequence begins with material selection and preparation, where premium Stainless Steel sheets are inspected for chemical composition, surface quality, and dimensional accuracy. Deep drawing operations are performed using hydraulic presses ranging from 100-ton to 500-ton capacity, creating the characteristic bowl shape of basket strainers. CNC turret punching machines with multi-tool capabilities create precise perforation patterns, ensuring consistent hole diameter, spacing, and edge quality across all products.

Progressive stamping dies are utilized for high-volume production runs, incorporating multiple forming stages within a single press cycle. Rotary deburring equipment removes sharp edges and burrs from punched holes, enhancing safety and aesthetic appeal. The final polishing process employs vibratory finishing systems with ceramic media and specialized compounds to achieve the desired surface finish. Quality control throughout the manufacturing process includes dimensional verification using coordinate measuring machines (CMM), surface roughness testing, and corrosion resistance evaluation according to ASTM B117 salt spray standards.

Technical Drawing – Standard Sink Strainer Dimensions

Ø160mmOverall DiameterDepth: 25mm

| Dimension | Standard Size (mm) | Tolerance (±mm) | Custom Range Available |

|---|---|---|---|

| Overall Diameter | 160 | 0.5 | 120-220 |

| Basket Depth | 25 | 0.3 | 15-40 |

| Hole Diameter | 8 | 0.1 | 3-12 |

| Material Thickness | 0.8 | 0.05 | 0.5-1.5 |

| Flange Width | 15 | 0.2 | 10-25 |

Product Applications and Industries

Stainless Steel sink strainers serve critical functions across diverse industry sectors, providing reliable filtration solutions for various drainage applications. In residential kitchens, these components prevent food waste accumulation in plumbing systems while maintaining optimal water flow rates. Commercial food service establishments including restaurants, hotels, and institutional kitchens rely on heavy-duty sink strainers to handle high-volume waste streams and frequent cleaning cycles. Food processing facilities utilize specialized sink strainers designed for sanitary applications, featuring smooth surfaces and crevice-free construction that facilitate thorough cleaning and sanitation protocols.

Laboratory and healthcare facilities employ sink strainers manufactured from 316L Stainless Steel to ensure chemical compatibility and corrosion resistance in demanding environments. Marine applications require sink strainers with enhanced corrosion protection to withstand saltwater exposure and harsh operating conditions. Industrial manufacturing plants use custom-designed strainers for parts washing stations, equipment cleaning areas, and process drainage systems where durability and chemical resistance are paramount considerations.

Sink Strainer Performance Metrics

Flow Rate vs. Filtration Efficiency 3mm

Quality Standards and Certifications

| Standard | Description | Test Parameters | Compliance Level |

|---|---|---|---|

| ASTM A240 | Chromium and Chromium-Nickel Stainless Steel Plate, Sheet, and Strip | Chemical composition, mechanical properties | Full compliance |

| DIN EN 10088 | Stainless Steels – List of stainless steels | Corrosion resistance, surface finish | Certified |

| JIS G 4304 | Hot-rolled stainless steel plate, sheet and strip | Dimensional tolerance, surface quality | Approved |

| BS EN 10088-2 | Technical delivery conditions for sheet/plate and strip | Mechanical properties, chemical analysis | Verified |

| IS 6911 | Stainless steel sheets and strips – Specification | Indian standard compliance | ISI marked |

Our Unique Selling Propositions

Custom Design Capability

Advanced CAD/CAM systems enable rapid prototyping and custom sink strainer development according to specific customer requirements including unique perforation patterns, specialized dimensions, and application-specific modifications.

Flexible Production Scheduling

Adaptive manufacturing processes accommodate both small batch custom orders and large-scale production runs with adjustable delivery timelines ranging from 2-8 weeks based on order complexity and quantity requirements.

Premium Packaging Solutions

Customized packaging options include branded cartons, retail-ready blister packs, and bulk industrial packaging with customer logos, product specifications, and multilingual labeling capabilities.

Global Market Experience

Three decades of international trade experience spanning 45+ countries with comprehensive understanding of regional preferences, regulatory requirements, and market-specific quality standards.

Technical Support Excellence

Dedicated engineering team provides comprehensive technical assistance including material selection guidance, application optimization, installation support, and post-delivery performance monitoring.

Quality Assurance Program

ISO 9001:2015 certified quality management system ensures consistent product quality through statistical process control, incoming material inspection, and final product verification protocols.

Dimensional Chart – Standard Sink Strainer Sizes

| Model Code | Overall Diameter (mm) | Basket Diameter (mm) | Depth (mm) | Hole Size (mm) | Material Thickness (mm) | Weight (grams) |

|---|---|---|---|---|---|---|

| SS-120-ST | 120 | 95 | 20 | 6 | 0.8 | 45 |

| SS-140-ST | 140 | 115 | 22 | 8 | 0.8 | 65 |

| SS-160-ST | 160 | 135 | 25 | 8 | 1.0 | 85 |

| SS-180-HD | 180 | 155 | 30 | 10 | 1.2 | 125 |

| SS-200-HD | 200 | 175 | 35 | 12 | 1.5 | 175 |

| SS-220-ID | 220 | 195 | 40 | 10 | 1.5 | 225 |

Frequently Asked Questions – Stainless Steel Sink Strainers

Q1: What is the difference between 304 and 316 Stainless Steel sink strainers?

A1: 316 Stainless Steel contains molybdenum (2-3%) which provides superior corrosion resistance, especially against chlorides and marine environments. 304 grade is suitable for standard kitchen applications, while 316 is recommended for commercial food service and coastal installations.

Q2: How do I determine the correct sink strainer size for my application?

A2: Measure the sink drain opening diameter and select a strainer with overall diameter 20-30mm larger than the drain opening. Consider the sink depth and available clearance space when selecting basket depth specifications.

Q3: What perforation pattern provides optimal drainage performance?

A3: Round holes with 6-8mm diameter arranged in concentric circles offer the best balance between filtration efficiency and flow rate. Larger holes (10-12mm) maximize flow but reduce particle retention capability.

Q4: Can sink strainers be customized for specific applications?

A4: Yes, we offer comprehensive customization including unique dimensions, special perforation patterns, alternative materials, custom finishes, and application-specific modifications with minimum order quantities starting from 500 pieces.

Q5: What is the expected service life of Stainless Steel sink strainers?

A5: Under normal residential use, quality Stainless Steel sink strainers typically last 10-15 years. Commercial applications may require replacement every 5-8 years depending on usage intensity and maintenance practices.

Q6: How should Stainless Steel sink strainers be cleaned and maintained?

A6: Regular cleaning with warm soapy water and soft brushes prevents buildup. For stubborn deposits, use mild acidic cleaners (vinegar solution) followed by thorough rinsing. Avoid abrasive cleaners that may scratch the surface finish.

Q7: What quality certifications do your sink strainers carry?

A7: Our products comply with ASTM A240, DIN EN 10088, JIS G 4304, and IS 6911 standards. Manufacturing facility is ISO 9001:2015 certified with documented quality management systems and traceability protocols.

Q8: What is the standard lead time for sink strainer orders?

A8: Standard products are typically shipped within 4-6 weeks from order confirmation. Custom designs may require 6-8 weeks depending on complexity. Rush orders can be accommodated with expedited processing fees.

Q9: Do you provide samples for evaluation before placing bulk orders?

A9: Yes, we provide samples of standard products for quality evaluation. Custom sample development is available for qualified customers with specific application requirements and minimum order commitments.

Q10: What packaging options are available for sink strainer shipments?

A10: Standard packaging includes protective plastic bags with corrugated cartons. Custom options include retail blister packs, branded packaging with customer logos, and specialized protective packaging for fragile or high-value products.

“We have been importing Stainless Steel sink strainers from this manufacturer for over 8 years, and their consistent quality and reliability have made them our preferred supplier. The technical support team is extremely knowledgeable, and they consistently deliver products that exceed our specifications. Their ability to customize products according to our market requirements while maintaining competitive pricing has been instrumental in our business growth. The 316L grade sink strainers perform exceptionally well in our coastal market applications.”

– Michael Thompson, Procurement Manager, Kitchen Solutions Inc., California, USA

Material Properties – Stainless Steel Grades

| Property | 304 Grade | 316 Grade | 430 Grade | Test Method |

|---|---|---|---|---|

| Tensile Strength (MPa) | 515-620 | 515-670 | 450-600 | ASTM A370 |

| Yield Strength (MPa) | 205 min | 205 min | 280 min | ASTM A370 |

| Elongation (%) | 40 min | 40 min | 22 min | ASTM A370 |

| Hardness (HRB) | 92 max | 95 max | 88 max | ASTM E18 |

| Corrosion Rate (mm/year) | 0.02 | 0.01 | 0.05 | ASTM B117 |

Packaging and Shipping Information

Our comprehensive packaging solutions ensure product integrity during international transportation while meeting diverse customer requirements. Standard export packaging includes individual product protection using polyethylene bags with desiccant packets, followed by placement in custom-designed corrugated cartons with internal cushioning materials. Retail-ready packaging options feature attractive blister packs with product information, installation instructions, and multilingual labeling compliance with international marketing standards.

Bulk industrial packaging utilizes heavy-duty corrugated containers with internal dividers and protective foam inserts to prevent product damage during handling and transportation. Custom branding services include customer logo printing, product specification labels, barcode integration, and compliance marking according to destination country requirements. Packaging materials are selected for environmental compatibility and recycling compliance, supporting sustainable supply chain practices.

Glossary of Technical Terms

Austenitic Stainless Steel: Non-magnetic Stainless Steel grades (like 304, 316) with face-centered cubic crystal structure, offering excellent corrosion resistance and formability characteristics.

Deep Drawing: Metal forming process where sheet metal is radially drawn into a forming die to create hollow, three-dimensional shapes like sink strainer baskets.

Perforation Pattern: Systematic arrangement of holes in sheet metal designed to optimize drainage flow while maintaining structural integrity and filtration efficiency.

Passivation: Chemical treatment process that removes free iron from Stainless Steel surfaces and promotes formation of protective chromium oxide layer.

Progressive Stamping: Manufacturing process where multiple forming operations are performed sequentially within a single press cycle using a series of connected dies.

Surface Roughness (Ra): Measurement of surface texture quality typically expressed in micrometers, affecting both aesthetic appearance and cleanability characteristics.

Tensile Strength: Maximum stress that material can withstand while being stretched before breaking, critical for determining load-bearing capacity in applications.

Yield Strength: Stress level at which material begins permanent deformation, important for understanding elastic limits under operational loads.

International Standards Compliance

| Standard Organization | Standard Number | Title | Scope | Compliance Status |

|---|---|---|---|---|

| ASTM International | ASTM A240/A240M | Chromium and Chromium-Nickel Stainless Steel Plate, Sheet, and Strip | Material specifications | Fully Certified |

| DIN (Germany) | DIN EN 10088-2 | Stainless steels – Technical delivery conditions | Sheet and strip specifications | CE Marked |

| JIS (Japan) | JIS G 4304 | Hot-rolled stainless steel plate, sheet and strip | Dimensional and quality requirements | Approved |

| BS (British) | BS EN 10088-2 | Technical delivery conditions for sheet/plate | Mechanical properties | Verified |

| IS (Indian) | IS 6911 | Stainless steel sheets and strips | Indian standard compliance | ISI Mark |

| AISI (USA) | AISI 304/316 | Steel grade designations | Chemical composition standards | Confirmed |

Quality Control and Testing Procedures

Our comprehensive quality assurance program encompasses incoming material verification, in-process monitoring, and final product inspection protocols designed to ensure consistent performance and reliability. Material certification includes mill test certificates verifying chemical composition, mechanical properties, and surface finish specifications according to applicable international standards. Dimensional inspection utilizes coordinate measuring machines (CMM) with accuracy levels of ±0.01mm for critical dimensions including overall diameter, hole positioning, and depth measurements.

Surface quality evaluation employs visual inspection protocols supplemented by surface roughness measurements using contact and non-contact profilometers. Corrosion resistance testing follows ASTM B117 salt spray procedures with exposure durations ranging from 72 to 1000 hours depending on grade and application requirements. Mechanical property verification includes tensile testing, hardness measurement, and forming capability assessment to ensure material performance meets specification requirements.

| Test Parameter | Test Method | Acceptance Criteria | Testing Frequency |

|---|---|---|---|

| Chemical Composition | Optical Emission Spectroscopy | Per ASTM A240 requirements | Each material lot |

| Dimensional Accuracy | CMM Measurement | ±0.5mm tolerance | Statistical sampling |

| Surface Finish | Visual & Profilometer | Ra ≤ 0.8 μm | Each production batch |

| Hole Quality | Go/No-Go Gauges | ±0.1mm diameter tolerance | Continuous monitoring |

| Corrosion Resistance | Salt Spray Test ASTM B117 | No visible corrosion 72 hours | Weekly testing |

Installation and Maintenance Guidelines

Proper installation and regular maintenance ensure optimal performance and extended service life of Stainless Steel sink strainers. Installation procedures begin with thorough cleaning of sink drain opening to remove debris, old sealant, and surface contaminants. Dimensional verification confirms proper fit between strainer flange and sink opening, ensuring adequate sealing surface contact. Sealing compound application using food-grade plumbers putty or silicone sealant creates watertight seal preventing leakage and contamination.

Regular maintenance includes daily removal of collected debris, weekly deep cleaning with appropriate detergents, and monthly inspection for wear, damage, or corrosion indicators. Cleaning protocols emphasize gentle mechanical action using soft brushes and non-abrasive cleaners to preserve surface finish integrity. Replacement indicators include visible corrosion, enlarged perforations, structural deformation, or compromised sealing performance requiring immediate attention.

Performance Optimization and Troubleshooting

Common Performance Issues and Solutions

Slow Drainage: Typically caused by debris accumulation in perforations. Solution includes regular cleaning schedule and consideration of larger hole diameter specifications for high-debris applications.

Premature Wear: Often results from aggressive cleaning methods or chemical exposure. Implement proper cleaning protocols using pH-neutral detergents and soft cleaning tools.

Corrosion Development: May indicate inadequate material grade selection for application environment. Upgrade to 316L grade for enhanced chemical resistance.

Sealing Problems: Usually caused by improper installation or sealant degradation. Reinstall with fresh food-grade sealant ensuring proper surface preparation.

Environmental Considerations and Sustainability

Stainless Steel sink strainers contribute to environmental sustainability through material recyclability, extended service life, and reduced maintenance requirements. Material composition includes significant recycled content (typically 60-70%) while maintaining full performance characteristics and quality standards. End-of-life recyclability approaches 100% through established Stainless Steel recycling infrastructure worldwide, supporting circular economy principles.

Manufacturing processes employ energy-efficient equipment and waste minimization strategies including material yield optimization and scrap recycling programs. Product longevity reduces replacement frequency compared to alternative materials, minimizing overall environmental impact throughout product lifecycle. Chemical resistance eliminates need for frequent replacement due to corrosion, further supporting sustainable installation practices.

Market Trends and Future Developments

The global sink strainer market continues evolving driven by increasing demand for premium kitchen accessories, growing awareness of food safety requirements, and expanding commercial food service sectors. Design innovations focus on enhanced functionality including antimicrobial surface treatments, improved ergonomics, and aesthetic integration with contemporary kitchen designs. Material developments explore advanced Stainless Steel alloys with enhanced properties and specialized surface finishes for specific applications.

Market expansion in developing economies drives demand for cost-effective solutions while maintaining quality standards and performance requirements. Regulatory trends emphasize food safety compliance, environmental sustainability, and worker safety considerations throughout manufacturing and application phases. Technology integration includes automated manufacturing processes, advanced quality control systems, and digital supply chain management capabilities.

Contact Us for Premium Stainless Steel Sink Strainers

Ready to source high-quality Stainless Steel sink strainers for your business? Our technical team is standing by to assist with product selection, custom design development, and competitive quotations. With over three decades of manufacturing excellence and global export experience, we deliver reliable solutions that meet your exact specifications.