Bronze Vise Connectors | Bronze Grounding Connectors|Bronze Vise Clamps – Premium Grounding Solutions

High-Performance Bronze Grounding Vise Connectors

We are one of the leading manufacturers and exporters of Bronze Vise Connectors from India. We have been supplying high-quality electrical grounding connectors to the world market for many decades. Our Bronze Vise Connectors are precision-engineered to provide superior electrical conductivity, corrosion resistance, and mechanical strength for a wide range of grounding applications in telecommunications, power transmission, construction, and industrial installations.

Product Overview

Vise Connectors

Vise Connectors are specialized electrical components designed to establish reliable electrical connections between conductors and ground rods. Featuring a robust design with a U-bolt mechanism, these connectors provide a secure clamping force that ensures consistent electrical continuity even in demanding environmental conditions. Our Vise Connectors are engineered for quick and easy installation, requiring minimal tools while maintaining maximum contact surface area between the connector and conductors. Each connector undergoes rigorous quality control processes to ensure excellent electrical performance, structural integrity, and long service life. These connectors are compatible with various conductor materials including Copper, Aluminum, and ACSR, making them versatile solutions for diverse electrical grounding requirements in substations, towers, residential installations, and industrial facilities.

Bronze Vise Connectors

Bronze Vise Connectors represent the premium tier in our connector lineup, manufactured from high-quality Bronze alloys that deliver exceptional electrical conductivity paired with outstanding corrosion resistance. The specialized Bronze composition, typically consisting of Copper with Tin and other alloying elements, provides enhanced mechanical properties and exceptional performance in harsh environments including coastal areas, chemical plants, and underground installations. These Bronze Vise Connectors maintain their electrical and mechanical properties even after years of exposure to corrosive elements, ensuring the integrity of critical grounding connections. The natural oxide layer that forms on Bronze creates a protective barrier that prevents further degradation, making these connectors particularly suited for outdoor applications where weathering resistance is essential. Our Bronze Vise Connectors comply with international standards for electrical grounding components, including ASTM B187, ASTM B937, and IEC 60364-5-54 specifications.

Bronze Grounding Connectors

Bronze Grounding Connectors are specifically designed for establishing and maintaining reliable earth connections in electrical systems. These specialized connectors feature optimized design elements that maximize contact surface area for enhanced electrical conductivity while providing robust mechanical connection between grounding conductors and earth termination systems. Our Bronze Grounding Connectors are manufactured from high-performance Bronze alloys containing precise percentages of Copper, Tin, and other elements to achieve the ideal balance of conductivity, strength, and corrosion resistance. The components undergo specialized heat treatment processes to enhance their mechanical properties and electrical performance characteristics. These connectors are engineered to withstand ground potential rise events, lightning strikes, and fault currents while maintaining their structural and electrical integrity throughout their service life. They are extensively tested for mechanical strength, electrical conductivity, and environmental durability according to IEEE 837, UL 467, and CSA C22.2 standards.

Grounding Vise Connectors

Grounding Vise Connectors integrate specialized vise-grip mechanisms with grounding functionality to create robust earth connections for electrical systems. These connectors feature precision-engineered clamping surfaces that establish and maintain optimal electrical contact between conductive elements and grounding systems. Our Grounding Vise Connectors incorporate advanced design elements including serrated contact surfaces, optimized bolt tensioning systems, and protective finishes that ensure reliable performance in varied environmental conditions. The comprehensive product range includes models for parallel and perpendicular conductor connections, tap connections, and specialized applications requiring specific dimensional or performance characteristics. Each connector is manufactured with precise dimensional tolerances to ensure consistent installation quality and electrical performance. Grounding Vise Connectors are essential components in comprehensive earthing systems for telecommunications infrastructure, power distribution networks, industrial facilities, and lightning protection systems.

Material Specifications

Material Grades

Our Bronze Vise Connectors are manufactured from premium bronze alloys that meet or exceed international standards:

| Standard | Grade | Composition | Application |

|---|---|---|---|

| ASTM B584 | C83600 | Cu: 85%, Sn: 5%, Pb: 5%, Zn: 5% | General purpose, moderate strength |

| ASTM B584 | C90300 | Cu: 88%, Sn: 8%, Zn: 4% | High-strength applications |

| ASTM B584 | C93700 | Cu: 80%, Sn: 10%, Pb: 10% | High corrosion resistance |

| BS EN 1982 | CC491K | Cu: 85-87%, Sn: 9-11%, P: 0.2-0.6% | European standard for marine applications |

| DIN 1705 | RG7 | Cu: 88%, Sn: 7%, Zn: 3%, Pb: 2% | German standard for electrical components |

| JIS H5120 | BC6 | Cu: 88%, Sn: 6%, Zn: 4%, Pb: 2% | Japanese standard for electrical applications |

| GB/T 5231 | ZCuSn10Pb1 | Cu: 89%, Sn: 10%, Pb: 1% | Chinese standard for high-strength applications |

| IS 318 | LTB-2 | Cu: 87%, Sn: 10%, Zn: 3% | Indian standard for electrical fittings |

All our Bronze alloys are carefully selected to provide:

- Superior electrical conductivity (minimum 15% IACS)

- Excellent corrosion resistance in varied environments

- High mechanical strength (tensile strength >30,000 psi)

- Optimal thermal performance (high melting point >1600°F)

Manufacturing Process

Our Bronze Vise Connectors are manufactured using state-of-the-art processes:

- Alloy Preparation: Custom bronze alloys are prepared in induction furnaces with precise temperature control for optimal metallurgical properties.

- Casting: We employ both sand casting and permanent mold casting techniques depending on production volume and part complexity.

- CNC Machining: High-precision CNC milling and turning operations ensure dimensional accuracy and surface finish quality.

- Threading & Drilling: Specialized threading equipment creates precision threads for bolts and adjustment screws.

- Surface Treatment: Optional surface treatments including tin plating, passivation, or protective coatings are applied based on application requirements.

- Quality Testing: Every batch undergoes electrical conductivity testing, dimensional inspection, and mechanical load testing.

- Assembly: U-bolts, washers, and other components are assembled using semi-automated processes.

- Final Inspection: 100% visual inspection and random sampling for detailed quality control.

Machinery Employed

- Advanced 5-axis CNC machining centers (DMG MORI, Haas)

- Induction melting furnaces with digital temperature control

- Automated tapping and threading stations

- Computerized dimensional measurement systems

- Hydraulic testing equipment for mechanical strength verification

- Electrical conductivity testing apparatus

- Environmental test chambers for accelerated weathering tests

Product Specifications

Bronze Vise Connector Catalog

| Product Code | Description | Main Conductor Range | Tap Conductor Range | Thread Size | Load Rating | Packaging |

|---|---|---|---|---|---|---|

| A1 1002 | Standard Bronze Vise Connector | #2 AWG – 250 MCM | #6 AWG – 2/0 AWG | 3/8″ | 5,000 lbs | 50/box |

| A1-1003 | Heavy-Duty Bronze Vise Connector | 1/0 AWG – 500 MCM | #2 AWG – 4/0 AWG | 1/2″ | 7,500 lbs | 25/box |

| A1-1004 | Extra Heavy-Duty Bronze Vise Connector | 4/0 AWG – 750 MCM | 1/0 AWG – 250 MCM | 5/8″ | 10,000 lbs | 20/box |

| A1-2001 | Parallel Bronze Vise Connector | #6 AWG – 2/0 AWG | #8 AWG – #2 AWG | 5/16″ | 2,500 lbs | 100/box |

| A1-2002 | Perpendicular Bronze Vise Connector | #2 AWG – 4/0 AWG | #6 AWG – 1/0 AWG | 3/8″ | 4,000 lbs | 50/box |

| A1-3001 | Ground Rod Bronze Vise Connector | 1/2″ – 1″ Rod | #6 AWG – 4/0 AWG | 3/8″ | 5,000 lbs | 50/box |

| A1-3002 | Heavy-Duty Ground Rod Bronze Vise Connector | 5/8″ – 1″ Rod | #2 AWG – 250 MCM | 1/2″ | 7,500 lbs | 25/box |

| A1-4001 | T-Tap Bronze Vise Connector | #2 AWG – 4/0 AWG | #6 AWG – 2/0 AWG | 3/8″ | 4,000 lbs | 40/box |

| A1-5001 | Multi-tap Bronze Vise Connector | 1/0 AWG – 350 MCM | Up to 4 taps #6 AWG – #2 AWG | 1/2″ | 6,000 lbs | 20/box |

| A1 -6001 | Compression-type Bronze Vise Connector | #2 AWG – 250 MCM | N/A | N/A | 5,000 lbs | 50/box |

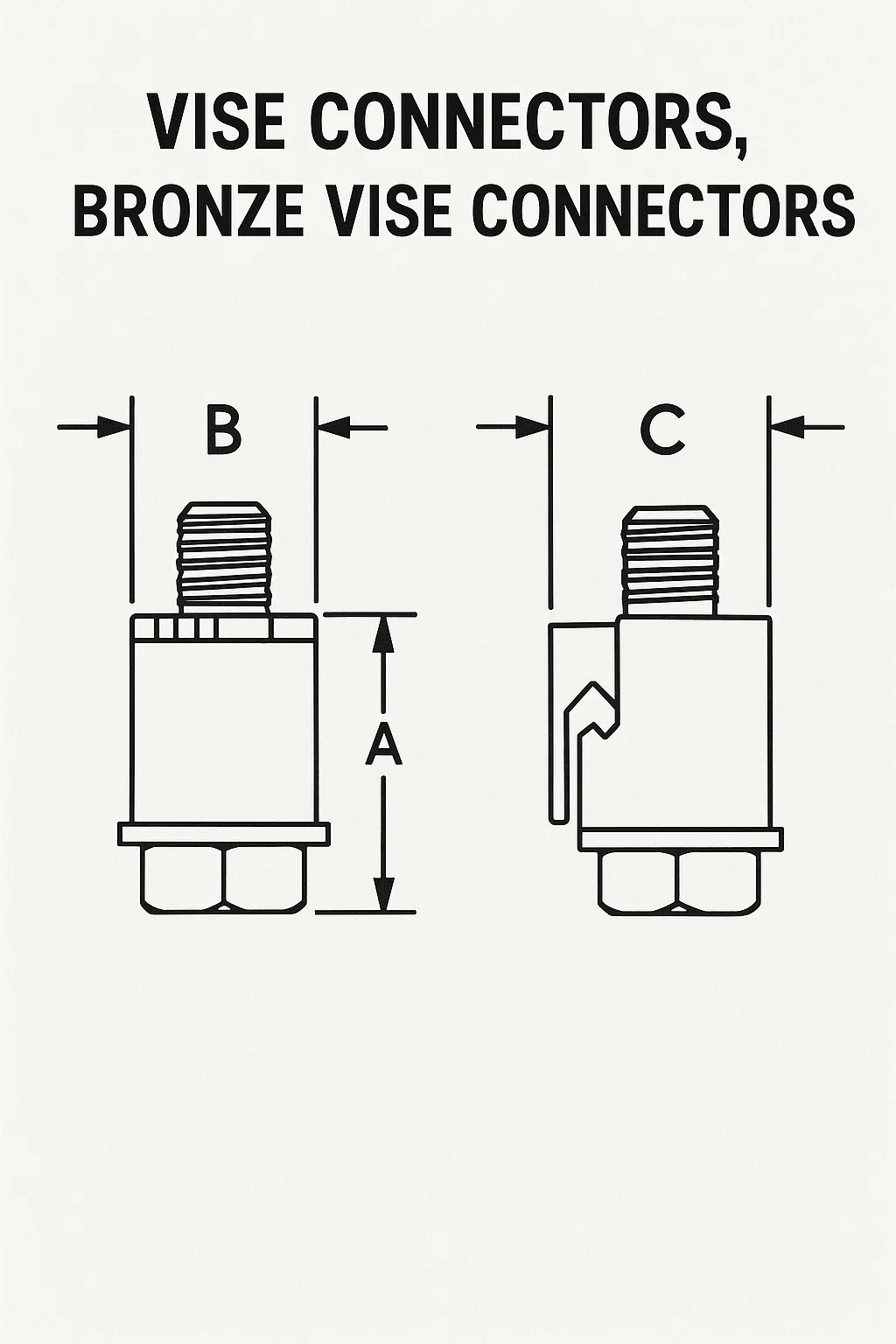

Key Dimensional Specifications

| Dimension | BVC-1002 | BVC-1003 | BVC-1004 | BVC-2001 | BVC-2002 |

|---|---|---|---|---|---|

| Length (A) | 2.5″ | 3.2″ | 4.0″ | 2.0″ | 2.8″ |

| Width (B) | 1.2″ | 1.5″ | 1.8″ | 1.0″ | 1.4″ |

| Height (C) | 1.3″ | 1.6″ | 2.0″ | 1.1″ | 1.5″ |

| Bolt Length (D) | 1.75″ | 2.25″ | 2.75″ | 1.5″ | 2.0″ |

| Weight | 0.35 lbs | 0.65 lbs | 0.95 lbs | 0.25 lbs | 0.45 lbs |

| Torque Specification | 15-20 ft-lbs | 25-30 ft-lbs | 35-40 ft-lbs | 10-15 ft-lbs | 15-20 ft-lbs |

Applicable Standards & Certifications

Our Bronze Vise Connectors meet or exceed basic requirements of:

- UL 467: Grounding and Bonding Equipment

- IEEE 837: Standard for Qualifying Permanent Connections Used in Substation Grounding

- ANSI C119.4: Connectors for Use Between Aluminum-to-Aluminum or Aluminum-to-Copper Conductors

- CSA C22.2 No. 41: Grounding and Bonding Equipment

- IEC 61238-1: Compression and Mechanical Connectors for Power Cables

- NEMA CC1: Electric Power Connection for Substations

- ASTM B117: Salt Spray (Fog) Testing

Performance Characteristics

Electrical Performance

- Conductivity: Minimum 15% IACS (International Annealed Copper Standard)

- Contact Resistance: Less than 50 micro-ohms when properly installed

- Current Rating: Varies by model, typically 90-120% of connected conductor rating

- Fault Current Capacity: Withstands minimum 10kA for 3 seconds without damage

Mechanical Performance

- Tensile Strength: Exceeds 40,000 psi

- Clamping Force: Maintains consistent pressure through thermal cycling

- Pull-Out Resistance: Minimum 5,000 lbs for standard models

- Vibration Resistance: Tested to withstand 500 hours of vibration without loosening

Environmental Performance

- Corrosion Resistance: Passes 1,000+ hours salt spray test per ASTM B117

- Temperature Rating: -40°F to +350°F (-40°C to +175°C)

- UV Resistance: No significant degradation after 2,000 hours UV exposure

- Chemical Resistance: Resistant to oils, fuels, mild acids, and common chemicals

Applications & Industries

Our Bronze Vise Connectors are widely used across multiple industries:

- Electrical Utilities: Substation grounding, transmission tower grounding

- Telecommunications: Cell tower grounding, equipment cabinets, cable shielding

- Construction: Building grounding systems, lightning protection

- Industrial: Manufacturing facilities, chemical plants, oil refineries

- Transportation: Railway signaling systems, airport ground networks

- Renewable Energy: Solar farms, wind turbines, energy storage systems

- Military & Defense: Communications installations, radar facilities

- Data Centers: Server room grounding, telecommunications grounding

Why Choose Our Bronze Vise Connectors?

Technical Excellence

- Superior Alloy Formulations: Our proprietary Bronze alloys deliver exceptional conductivity and corrosion resistance.

- Precision Manufacturing: State-of-the-art CNC machining ensures consistent quality and dimensional accuracy.

- Comprehensive Testing: Each production batch undergoes rigorous electrical and mechanical testing.

- Design Optimization: Our engineering team continuously refines designs for maximum performance and ease of installation.

Business Advantages

- Global Manufacturing Experience: Three decades of international manufacturing expertise.

- Customization Capabilities: We can modify designs to meet specific application requirements.

- Flexible Production Scheduling: Accommodate urgent orders with expedited production options.

- Technical Support: Our engineering team provides installation guidance and application advice.

- Consistent Quality: ISO 9001:2015 certified manufacturing processes ensure reliable performance.

- Competitive Pricing: Direct manufacturing capabilities enable competitive pricing without compromising quality.

Customer Experience

- Responsive Communication: Our team provides quick responses to inquiries and technical questions.

- Comprehensive Documentation: Detailed product specifications, test reports, and installation guides.

- Supply Chain Reliability: Robust inventory management and production planning ensures consistent availability.

- Custom Packaging Options: Available with customer-specific labeling and packaging requirements.

- Technical Training: Installation and maintenance training available for large projects.

Packaging & Shipping

- Standard Packaging: Industrial-grade cardboard boxes with protective internal dividers

- Bulk Options: Available in wooden crates for large orders

- Customization: Customer-specific labeling and packaging available

- Export Packaging: ISPM-15 compliant wooden crates with moisture barrier protection

- Documentation: Complete packing lists, material certifications, and test reports

- Delivery Time: Standard lead time 4-6 weeks, expedited options available

- Shipping Methods: Sea freight, air freight, courier services available

- Minimum Order Quantity: 100 pieces for standard models, 500 pieces for custom designs

Frequently Asked Questions

Q: What is the difference between Bronze and Brass Vise Connectors? A: Bronze Vise Connectors typically contain Copper and Tin as primary alloying elements, providing superior corrosion resistance and mechanical strength compared to Brass connectors, which contain Copper and Zinc. Bronze connectors are preferred for underground and corrosive environments due to their enhanced resistance to dezincification and stress corrosion cracking.

Q: Can Bronze Vise Connectors be used with Aluminum conductors? A: Yes, but proper installation practices must be followed. We recommend using a conductive anti-oxidation compound at the connection point to prevent galvanic corrosion between dissimilar metals. Our BVC-1003 and BVC-2002 models are specifically designed for Copper-to-Aluminum connections.

Q: What is the recommended installation torque for Bronze Vise Connectors? A: Recommended torque values vary by model, ranging from 15 ft-lbs for smaller connectors to 40 ft-lbs for larger models. Always refer to the product-specific installation guide for precise torque specifications. Over-torquing can damage the connector or conductor, while under-torquing may result in poor electrical connection.

Q: How do I select the right Bronze Vise Connector for my application? A: Selection depends on several factors including conductor size, installation environment, current requirements, and mechanical load. Our technical team can assist in selecting the appropriate connector based on your specific parameters.

Q: What is the expected service life of your Bronze Vise Connectors? A: When properly installed, our Bronze Vise Connectors are designed for a service life of 30+ years in normal environments and 20+ years in harsh environments such as coastal or industrial areas. Regular inspection and maintenance can further extend service life.

Q: Do your Bronze Vise Connectors comply with UL 467 requirements? A: Yes, our Bronze Vise Connectors are designed and tested to meet or exceed UL 467 standards for grounding and bonding equipment. Certification documentation is available upon request.

Q: How do Bronze Vise Connectors perform in high-fault current situations? A: Our connectors are engineered to withstand high fault currents without damage. Standard models can handle 10kA for 3 seconds, while heavy-duty models can withstand up to 25kA. Actual performance depends on installation quality and system parameters.

Q: Can custom Bronze Vise Connectors be manufactured for specific applications? A: Yes, we offer custom design and manufacturing services for specialized applications. Minimum order quantities apply, and development lead times typically range from 4-8 weeks depending on complexity.

Q: What maintenance is required for Bronze Vise Connectors? A: Bronze Vise Connectors require minimal maintenance. We recommend periodic visual inspection for signs of corrosion or loosening, and torque verification during scheduled maintenance. In highly corrosive environments, applying protective coating during installation can further extend service life.

Q: Are your Bronze Vise Connectors suitable for direct burial applications? A: Yes, our Bronze Vise Connectors are suitable for direct burial applications due to their excellent corrosion resistance. For enhanced protection in highly corrosive soils, we recommend models with additional protective finishes or encapsulation.

Glossary of Technical Terms

Vise Connector

A mechanical clamp that secures electrical conductors using bolt-driven pressure, ensuring a stable and long-lasting electrical connection.

Bronze

A corrosion-resistant alloy composed mainly of Copper and Tin, valued for its durability, conductivity, and performance in harsh environments.

Grounding

The act of electrically connecting equipment or structures to the earth, enabling safe dissipation of fault currents and static electricity.

IACS (International Annealed Copper Standard)

A global benchmark for electrical conductivity, where pure annealed Copper is rated at 100% IACS, serving as the reference point for other materials.

Galvanic Corrosion

An electrochemical process that accelerates corrosion when two dissimilar metals are electrically connected in the presence of an electrolyte.

Contact Resistance

The resistance to current flow at the interface between two electrical conductors, typically measured in micro-ohms; critical in low-voltage applications.

Dezincification

A form of selective corrosion in Brass where Zinc is removed from the alloy, weakening its mechanical integrity and electrical properties.

Ground Potential Rise (GPR)

The voltage difference that develops between a grounded system and remote earth during fault conditions, potentially hazardous if not managed.

MCM (Thousand Circular Mils)

A unit used to specify the cross-sectional area of electrical conductors, equal to 1,000 circular mils or approximately 0.5067 mm².

U-bolt

A U-shaped fastener with threaded ends, widely used to clamp pipes, rods, or conductors securely to surfaces or other hardware.

Related Terms

Bronze Electrical Connectors, Ground Clamps, Electrical Grounding Hardware, Substation Grounding Connectors, U-bolt Connectors, Earth Clamps, Copper Alloy Connectors, Parallel Groove Connectors, Split Bolt Connectors, Ground Rod Clamps, Bronze Ground Fittings, Corrosion-Resistant Electrical Connectors, Lightning Protection Connectors, Exothermic Welding Alternatives, Ground Grid Connectors, Bronze Electrical Fittings, Mechanical Grounding Connections, Utility Grade Connectors, Power Distribution Grounding Hardware, High-Conductivity Bronze Connectors

Material Properties

| Property | C83600 Bronze | C90300 Bronze | C93700 Bronze |

|---|---|---|---|

| Tensile Strength | 30,000 psi | 40,000 psi | 35,000 psi |

| Yield Strength | 14,000 psi | 18,000 psi | 16,000 psi |

| Elongation | 20% | 15% | 18% |

| Electrical Conductivity | 15% IACS | 12% IACS | 10% IACS |

| Thermal Conductivity | 59 BTU/ft hr °F | 52 BTU/ft hr °F | 47 BTU/ft hr °F |

| Specific Gravity | 8.83 | 8.78 | 8.91 |

| Melting Range | 1600-1660°F | 1660-1720°F | 1580-1600°F |

| Hardness (Brinell) | 60 | 70 | 65 |

Our Unique Selling Propositions

- Expert Engineering Team: In-house engineers with decades of experience in grounding system design

- Material Expertise: Specialized knowledge in Bronze metallurgy for electrical applications

- Custom Design Capability: Ability to develop application-specific solutions with rapid prototyping

- Vertical Integration: Control of manufacturing process from alloy formulation to final assembly

- Quality Assurance: 100% testing of critical parameters ensures consistent performance

- Global Experience: Three decades of supplying Bronze connectors to over 50 countries

- Technical Support: Comprehensive application engineering assistance before and after purchase

- Flexible Production: Ability to accommodate both standard and custom orders efficiently

- Value Engineering: Continuous improvement processes optimize design for performance and cost

- Ethical Manufacturing: Sustainable practices and responsible material sourcing

Contact Us for Your Bronze Vise Connector Requirements

Ready to enhance your electrical grounding systems with premium Bronze Vise Connectors? Our team is standing by to assist with your specific requirements.

- Request a Quote: Email us at for competitive pricing

- Download Technical Brochure: Complete our quick form to receive detailed product specifications

- Speak with an Application Engineer: Call usto discuss your technical requirements

- WhatsApp Support: Message us at for quick responses

- Custom Design Consultation: Schedule a video conference with our engineering team

For international inquiries: Our export specialists are available to provide shipping estimates, documentation requirements, and logistics assistance.