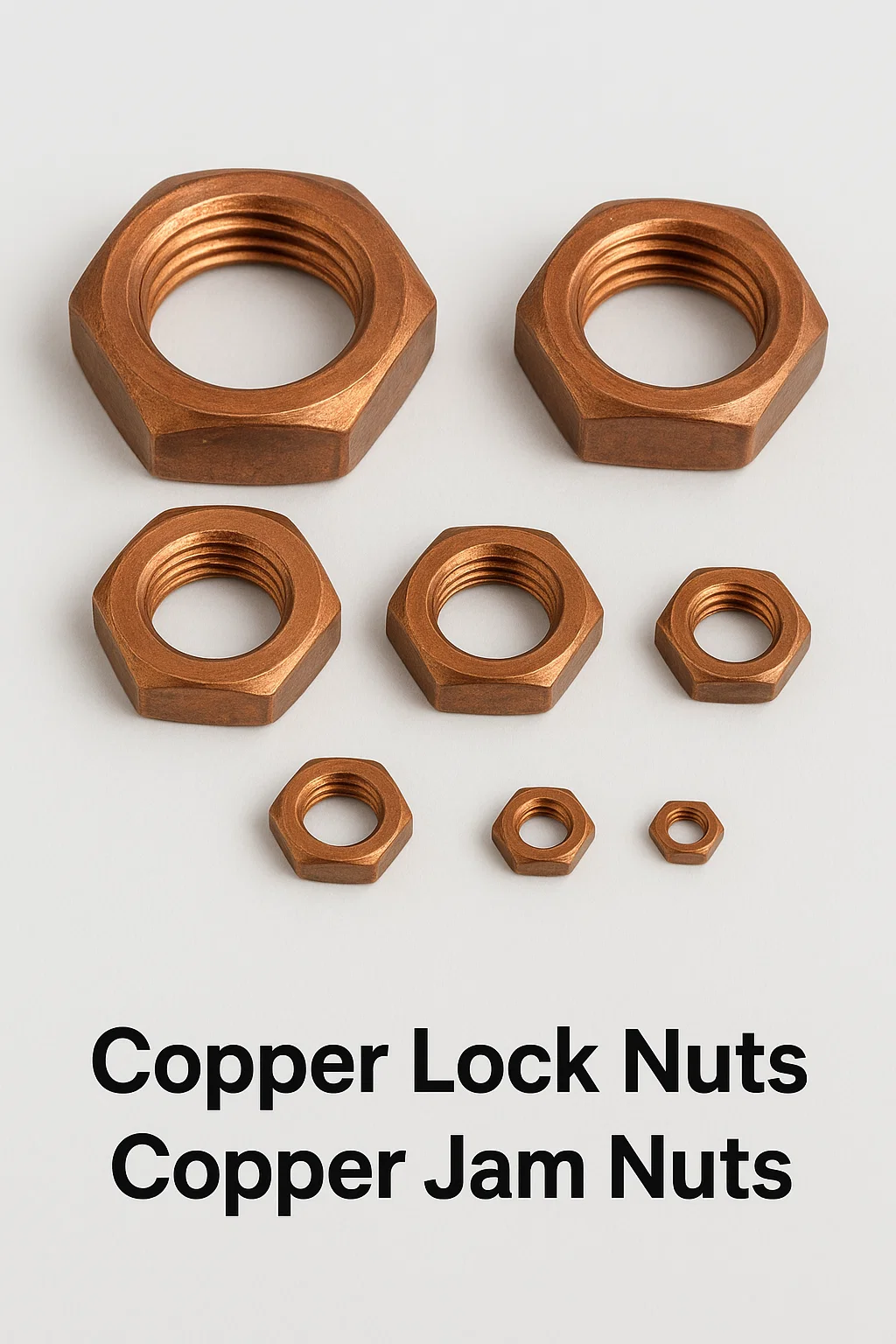

Premium Copper Hex Lock Nuts, Panel Nuts, Thin Nuts & Copper Jam Nuts

Price: US$ 11.90/Kilo

We are one of the leading manufacturers and exporters of Copper hex lock nuts, panel nuts, thin nuts, and jam nuts from India. We have been supplying premium quality Copper fasteners to the world market for many decades. Our extensive range of Copper nuts encompasses various specialized designs including hex lock nuts, panel mounting nuts, thin profile nuts, and jam nuts, each engineered to meet specific industrial requirements. With over three decades of manufacturing excellence, we have established ourselves as a trusted supplier of high-grade Copper fasteners across global markets. Our state-of-the-art manufacturing facilities utilize advanced CNC machining technology and precision forming equipment to produce Copper nuts that comply with international standards including ASTM, DIN, BS, IS, and JIS specifications. We maintain stringent quality control measures throughout our production process, ensuring dimensional accuracy, surface finish excellence, and mechanical property consistency. Our commitment to innovation and customer satisfaction has enabled us to serve diverse industries including marine engineering, electrical applications, telecommunications, architectural hardware, and specialized industrial equipment manufacturing.

Product Overview

Copper Hex Lock Nuts

Copper hex lock nuts represent a specialized category of threaded fasteners designed with an integrated locking mechanism to prevent loosening under vibration and dynamic loading conditions. These nuts feature a hexagonal external profile for easy installation using standard wrenches and incorporate either nylon insert technology or deformed thread patterns to create reliable thread locking action. The inherent properties of Copper material make these nuts particularly suitable for applications requiring excellent electrical conductivity, corrosion resistance in marine environments, and antimicrobial characteristics. Our manufacturing process involves precision machining of high-grade Copper alloys followed by thread forming operations that maintain optimal thread engagement while preserving the locking functionality. The dimensional accuracy of our Copper hex lock nuts ensures consistent performance across temperature variations and mechanical stress cycles.

Copper Panel Nuts

Copper panel nuts are specifically engineered for mounting applications where fasteners must be secured to thin panels, enclosures, or chassis components. These nuts feature a flanged design with integrated mounting tabs or clinching features that provide secure attachment to sheet metal substrates without requiring access to the reverse side of the panel. The Copper construction offers superior electromagnetic interference (EMI) shielding properties, making these nuts ideal for electronic enclosures and telecommunications equipment. Our manufacturing process utilizes progressive die stamping and forming operations to create consistent flange geometry and optimal clinching force distribution. The material selection focuses on Copper alloys that provide the necessary strength for clinching operations while maintaining the ductility required for reliable panel engagement.

Copper Thin Nuts

Copper thin nuts, also known as jam nuts or low-profile nuts, are manufactured with reduced height dimensions compared to standard hex nuts while maintaining full thread engagement and load-carrying capacity. These specialized fasteners are essential in applications where space constraints require minimal fastener profile or where multiple nuts are used in stacked configurations. The Copper material provides excellent thermal conductivity and electrical grounding capabilities, making thin nuts particularly valuable in heat sink assemblies and electrical grounding applications. Our precision manufacturing process ensures consistent thickness tolerance across the entire product range, utilizing advanced thread rolling techniques that maintain thread strength despite the reduced nut height. The hexagonal configuration provides optimal wrench engagement while minimizing overall assembly height.

Copper Hex Jam Nuts

Copper hex jam nuts are precision-manufactured low-profile threaded fasteners designed for locking applications where standard height nuts would create interference or where multiple fasteners must be positioned in close proximity. These nuts typically feature approximately half the height of standard hex nuts while maintaining the same across-flats dimension for tool compatibility. The Copper construction provides natural lubricity and galling resistance, making jam nuts particularly effective in applications involving frequent assembly and disassembly cycles. Our manufacturing process incorporates specialized thread forming techniques that ensure optimal thread engagement despite the reduced nut height, while maintaining the material properties essential for reliable joint integrity. The hexagonal design facilitates installation in confined spaces while providing adequate torque transmission capability.

Material Grades and Specifications

| Material Grade | Composition (%) | Tensile Strength (MPa) | Yield Strength (MPa) | Hardness (HB) | Applications |

|---|---|---|---|---|---|

| C10100 (99.99% Pure Copper) | Cu: 99.99, O2: 0.001 | 220-290 | 70-140 | 45-85 | Electrical, Electronics |

| C11000 (ETP Copper) | Cu: 99.90, P: 0.001-0.005 | 220-290 | 70-140 | 45-85 | General Purpose, Marine |

| C10200 (OF Copper) | Cu: 99.95, O2: 0.001 | 210-280 | 60-130 | 42-80 | High Conductivity Applications |

| C26000 (Cartridge Brass) | Cu: 68-72, Zn: 28-32 | 315-450 | 130-310 | 65-95 | Marine Hardware, Decorative |

Manufacturing Processes and Machinery

Our comprehensive manufacturing approach integrates multiple precision processes to ensure consistent quality and dimensional accuracy across our entire range of Copper nuts. The primary manufacturing processes include CNC precision machining utilizing multi-axis machining centers equipped with live tooling capabilities for complex geometries and tight tolerances. Our cold heading operations employ progressive forming dies to create net-shape or near-net-shape components with minimal material waste and optimal grain structure orientation.

Thread rolling processes are implemented using precision thread rolling machines that cold-form threads rather than cutting them, resulting in superior thread strength and surface finish quality. For panel nuts requiring clinching features, we utilize progressive die stamping operations with forming stations that create consistent flange geometry and optimal material flow characteristics.

Technical Drawings and Dimensional Data

Hex Lock Nut Technical Drawing

S (Across Flats)HCopper Hex Lock NutD = Nominal Thread DiameterS = Width Across Flats, H = Height

| Thread Size (M) | Pitch (mm) | Width Across Flats (mm) | Height – Standard (mm) | Height – Thin/Jam (mm) | Panel Nut Flange Ø (mm) |

|---|---|---|---|---|---|

| M3 | 0.5 | 5.5 | 2.4 | 1.2 | 8.0 |

| M4 | 0.7 | 7.0 | 3.2 | 1.6 | 10.0 |

| M5 | 0.8 | 8.0 | 4.0 | 2.0 | 12.0 |

| M6 | 1.0 | 10.0 | 5.0 | 2.5 | 14.0 |

| M8 | 1.25 | 13.0 | 6.5 | 3.2 | 18.0 |

| M10 | 1.5 | 17.0 | 8.0 | 4.0 | 22.0 |

| M12 | 1.75 | 19.0 | 10.0 | 5.0 | 26.0 |

International Standards Compliance

Our Copper nuts manufacturing processes strictly adhere to multiple international standards ensuring global compatibility and quality assurance. ASTM B124 governs the specifications for Copper and Copper alloy forgings, while DIN 934 and DIN 6923 establish dimensional requirements for hex nuts and flanged nuts respectively. BS 4190 covers Copper alloy nuts specifications, and IS 4218 provides Indian standard specifications for hex nuts. JIS B1181 establishes Japanese industrial standards for hex nuts, ensuring our products meet Asian market requirements.

| Standard | Specification | Application | Key Requirements |

|---|---|---|---|

| ASTM B124 | Copper & Copper Alloy Forgings | Material Properties | Chemical Composition, Mechanical Properties |

| DIN 934 | Hex Nuts – Product Grade A | Dimensional Standards | Thread Pitch, Width Across Flats, Height |

| BS 4190 | Copper Alloy Nuts | British Standards | Material Grade, Dimensional Tolerance |

| IS 4218 | Hex Nuts – Indian Standard | Domestic Compliance | Thread Specifications, Quality Grade |

| JIS B1181 | Hex Nuts – Japanese Standard | Asian Market Requirements | Dimensional Accuracy, Surface Finish |

Surface Finishes and Treatments

Our Copper nuts are available with various surface finishes to meet specific application requirements and environmental conditions. Natural Copper finish provides the inherent antimicrobial properties and electrical conductivity characteristics of pure Copper material. Bright finish involves mechanical polishing operations that create a reflective surface suitable for decorative applications and improved corrosion resistance.

Passivated finish utilizes chemical treatment processes to enhance natural corrosion resistance and create a uniform surface appearance. Tin plated finish provides improved solderability for electrical connections and enhanced corrosion protection in marine environments. Nickel plated finish offers superior wear resistance and maintains dimensional stability under mechanical stress conditions.

🔧 Manufacturing Excellence – Key Performance Indicators

⚡ Production Capacity

50,000+ units/month

🎯 Tolerance Accuracy

±0.02mm precision

🌍 Global Reach

45+ countries served

⏱️ Delivery Time

4-6 weeks standard

Similar Terms:

- Copper hex lock nuts manufacturer

- Copper panel nuts supplier

- Copper thin nuts exporter India

- Copper jam nuts wholesale

- Precision copper fasteners

- Marine grade copper nuts

- Electrical copper hardware

- Custom copper nuts manufacturing

- High conductivity copper fasteners

- Copper fasteners manufacturer India

- Copper hex lock nuts with nylon insert

- Marine grade copper panel mounting nuts

- Thin profile copper jam nuts for electronics

- Corrosion resistant copper fasteners supplier India

- Custom copper nuts manufacturer with global shipping

- ASTM compliant copper hex nuts exporter

- Precision machined copper lock nuts for marine applications

- High conductivity copper panel nuts for EMI shielding

- Copper hex nuts manufacturer Mumbai Maharashtra

- Export quality copper fasteners from India

Related Terms

- Copper alloy hex nuts

- Bronze hex lock nuts

- Brass panel nuts manufacturer

- Copper-zinc alloy fasteners

- Marine bronze nuts supplier

- Electrical copper terminals

- Copper grounding hardware

- Anti-corrosion copper nuts

- High strength copper fasteners

- Copper nuts with certification

Technical Terms

- C11000 copper hex nuts

- ETP copper panel nuts

- ASTM B124 copper fasteners

- DIN 934 copper hex nuts

- BS 4190 copper alloy nuts

- JIS B1181 copper nuts

- Thread rolling copper nuts

- CNC machined copper fasteners

- Cold headed copper nuts

- Precision copper hardware

Industries and Applications

Marine and Offshore Engineering applications utilize our Copper nuts for their exceptional corrosion resistance in saltwater environments and natural biofouling resistance properties. The material’s resistance to dezincification and stress corrosion cracking makes these fasteners ideal for seawater piping systems, hull fittings, and offshore platform components.

Electrical and Electronics Industries rely on Copper nuts for applications requiring high electrical conductivity and electromagnetic interference shielding. These include grounding systems, electrical panel assemblies, transformer connections, and telecommunications equipment where consistent electrical performance is critical.

Architectural and Construction projects incorporate Copper nuts in roofing systems, gutter assemblies, decorative hardware, and building envelope components where weather resistance and aesthetic appeal are important considerations. The natural patina development of Copper provides long-term corrosion protection while creating distinctive architectural features.

HVAC and Plumbing Systems benefit from Copper nuts’ thermal conductivity properties and compatibility with Copper piping systems. Applications include heat exchanger assemblies, refrigeration systems, and hot water distribution networks where thermal expansion compatibility is essential.

Quality Control and Tolerances

| Parameter | Standard Tolerance | Precision Grade Tolerance | Measurement Method |

|---|---|---|---|

| Thread Pitch Accuracy | ±0.05mm | ±0.02mm | Thread Pitch Gauge |

| Width Across Flats | ±0.1mm | ±0.05mm | Digital Calipers |

| Height Dimension | ±0.1mm | ±0.05mm | Micrometer |

| Concentricity | 0.05mm TIR | 0.02mm TIR | CMM Inspection |

| Surface Roughness | Ra 1.6μm | Ra 0.8μm | Profilometer |

Performance Metrics and Testing

Our comprehensive quality assurance program includes multiple performance verification tests to ensure consistent product reliability. Tensile strength testing verifies material properties according to ASTM standards, while torque-tension relationship testing establishes optimal installation parameters for various applications. Salt spray corrosion testing per ASTM B117 validates long-term performance in marine environments, with test durations extending to 1000+ hours for critical applications.

Dimensional inspection protocols utilize coordinate measuring machines (CMM) and automated optical inspection systems to verify geometric accuracy and thread conformance. Material composition analysis employs X-ray fluorescence spectroscopy to confirm alloy chemistry compliance with specified grades. Hardness testing using Brinell and Vickers methods ensures consistent mechanical properties across production batches.

Frequently Asked Questions

Q1: What is the difference between Copper hex lock nuts and standard hex nuts?

A: Copper hex lock nuts incorporate specialized locking mechanisms such as nylon inserts or deformed threads that create resistance to loosening under vibration, while standard hex nuts rely solely on applied torque for retention.

Q2: Can Copper panel nuts be used in outdoor applications?

A: Yes, Copper panel nuts are excellent for outdoor applications due to Copper’s natural corrosion resistance and ability to form a protective patina layer that prevents further oxidation.

Q3: What is the maximum torque specification for M8 Copper hex nuts?

A: For M8 Copper hex nuts in C11000 grade, the recommended maximum torque is 15-18 Nm, depending on the specific application and thread lubrication conditions.

Q4: Are your Copper nuts suitable for high-temperature applications?

A: Copper nuts maintain their mechanical properties up to 200°C (392°F) for continuous operation, with short-term exposure capability up to 400°C depending on the specific alloy grade.

Q5: How do thin nuts compare to jam nuts in terms of functionality?

A: Thin nuts and jam nuts are essentially the same product category, both featuring reduced height (typically 50% of standard) while maintaining full thread engagement and load-carrying capacity.

Q6: What minimum order quantities do you require?

A: Our standard minimum order quantity is 1000 pieces per size and specification, though we can accommodate smaller quantities for prototyping and special applications.

Q7: Do you provide material certificates with shipments?

A: Yes, we provide comprehensive material test certificates (MTCs) including chemical composition analysis, mechanical property test results, and dimensional inspection reports with every shipment.

Q8: Can you manufacture Copper nuts to custom specifications?

A: Absolutely, we specialize in custom manufacturing with capabilities for non-standard dimensions, special alloy grades, unique surface treatments, and modified geometries based on customer requirements.

Q9: What packaging options are available for bulk orders?

A: We offer various packaging solutions including bulk bags, compartmentalized boxes, anti-tarnish protective wrapping, and custom branded packaging with customer labels and logos.

Q10: How do you ensure consistent quality across large production runs?

A: Our quality management system includes statistical process control (SPC), first-article inspection (FAI), in-process monitoring, and final inspection protocols with documented traceability throughout the manufacturing process.

Q11: What is the shelf life of Copper nuts in storage?

A: Properly stored Copper nuts have indefinite shelf life when kept in dry conditions with appropriate anti-tarnish protection to maintain surface appearance and dimensional stability.

Q12: Are your manufacturing processes environmentally compliant?

A: Yes, our manufacturing facility operates under ISO 14001 environmental management standards with waste minimization programs, energy efficiency initiatives, and responsible material sourcing practices.

Why Choose Our Copper Nuts

Three Decades of Manufacturing Excellence – Our extensive experience in Copper fastener manufacturing has enabled us to develop specialized expertise in material selection, process optimization, and quality assurance protocols that deliver consistently superior products to our global customer base.

Advanced Manufacturing Capabilities – We maintain state-of-the-art production facilities equipped with the latest CNC machining centers, precision forming equipment, and automated quality control systems that ensure dimensional accuracy and surface finish quality exceeding industry standards.

Customization Flexibility – Our engineering team works closely with customers to develop custom solutions including non-standard dimensions, special alloy formulations, unique surface treatments, and modified geometries tailored to specific application requirements.

Global Supply Chain Excellence – With established logistics networks spanning 45+ countries, we provide reliable delivery schedules, competitive freight solutions, and comprehensive export documentation support for international customers.

Superior Customer Support – Our technical support team provides application engineering assistance, material selection guidance, and post-delivery support to ensure optimal product performance in customer applications.

“We have been sourcing Copper hex lock nuts from this manufacturer for over 8 years for our marine equipment applications. Their consistent quality, technical expertise, and reliable delivery performance have made them our preferred supplier. The dimensional accuracy and corrosion resistance of their products have significantly reduced our field service requirements.”

– Michael Richardson, Procurement Manager, Marine Systems Inc., Houston, Texas

Packaging and Shipping

Our comprehensive packaging solutions are designed to protect product integrity during transportation while providing convenient handling for end users. Standard packaging includes moisture-resistant cardboard boxes with foam inserts and anti-tarnish paper wrapping to maintain surface appearance during storage and transit. Industrial packaging utilizes heavy-duty plastic containers with compartmentalized layouts for efficient inventory management and reduced handling time.

Custom packaging options include customer-branded labeling, specialized protective materials for sensitive applications, and bulk packaging solutions optimized for high-volume users. Our export packaging meets international shipping requirements with appropriate documentation, customs labeling, and protective materials suitable for extended transit times and multiple handling operations.

Material Property Tables

| Property | C10100 Pure Copper | C11000 ETP Copper | C10200 OF Copper | Units |

|---|---|---|---|---|

| Density | 8.94 | 8.89 | 8.94 | g/cm³ |

| Electrical Conductivity | 101 | 100 | 103 | %IACS |

| Thermal Conductivity | 391 | 388 | 393 | W/m·K |

| Melting Point | 1083 | 1083 | 1083 | °C |

| Coefficient of Expansion | 17.0 | 17.0 | 17.0 | ×10⁻⁶/°C |

| Modulus of Elasticity | 110 | 110 | 110 | GPa |

Turnaround Time and Production Scheduling

Our standard production turnaround time is 4-6 weeks from order confirmation, which includes material procurement, manufacturing operations, quality inspection, and packaging. For high-volume orders exceeding 50,000 pieces, production scheduling may extend to 6-8 weeks depending on specific size requirements and surface finish specifications. Express production services are available for urgent requirements with 2-3 week delivery schedules, subject to material availability and production capacity.

Prototype and sample orders typically require 7-10 working days for completion, allowing customers to evaluate product specifications before placing full production orders. Our blanket order programs enable customers to establish annual quantity commitments with scheduled releases, ensuring consistent supply availability while optimizing inventory management and reducing per-unit costs.

Glossary of Technical Terms

Across Flats: The distance measured between two parallel faces of a hexagonal nut, determining the wrench size required for installation and removal operations.

Clinching: A mechanical joining process where panel nuts are permanently attached to thin sheet metal substrates through controlled deformation without requiring access to the reverse side.

Cold Heading: A manufacturing process that shapes metal components at room temperature using high-pressure forming operations, resulting in improved material properties and dimensional accuracy.

Dezincification: A corrosion phenomenon affecting Copper-Zinc alloys where selective leaching of zinc occurs, leaving behind porous Copper structures with reduced mechanical properties.

Electromagnetic Interference (EMI): Unwanted electromagnetic radiation that can disrupt electronic device operation, often controlled using Copper shielding materials and grounding systems.

Galling: A form of adhesive wear that occurs when sliding surfaces experience material transfer and surface damage, particularly common in threaded fastener applications.

International Annealed Copper Standard (IACS): A conductivity measurement standard where pure Copper at 20°C represents 100% conductivity reference for electrical applications.

Jam Nut: A thin-profile nut designed for locking applications, typically featuring approximately half the height of standard nuts while maintaining full thread engagement capability.

Patina: A protective surface layer that naturally forms on Copper and Copper alloys when exposed to atmospheric conditions, providing long-term corrosion resistance.

Progressive Die Stamping: A manufacturing process using sequential forming stations to create complex components through multiple operations in a single press stroke.

Thread Rolling: A cold forming process that creates threads through plastic deformation rather than material removal, resulting in superior thread strength and surface finish.

Total Indicator Reading (TIR): A measurement of geometric deviation indicating the total variation of a surface or feature relative to a reference datum or axis.

Related Search Terms

Primary Keywords: Copper hex nuts manufacturer, Copper lock nuts supplier, Copper panel nuts exporter, Copper thin nuts India, Copper jam nuts wholesale, precision Copper fasteners, marine grade Copper nuts, electrical Copper hardware, custom Copper nuts manufacturing, high conductivity Copper fasteners

Long-tail Keywords: Copper hex lock nuts with nylon insert, marine grade Copper panel mounting nuts, thin profile Copper jam nuts for electronics, corrosion resistant Copper fasteners supplier India, custom Copper nuts manufacturer with global shipping, ASTM compliant Copper hex nuts exporter, precision machined Copper lock nuts for marine applications, high conductivity Copper panel nuts for EMI shielding

Industry-specific Terms: Marine hardware Copper fasteners, telecommunications Copper grounding nuts, HVAC Copper connection hardware, architectural Copper decorative nuts, electrical panel Copper mounting hardware, offshore platform Copper fasteners, heat sink Copper thin nuts, EMI shielding Copper panel nuts

International Market Presence

Our global market presence encompasses diverse geographical regions with established distribution networks and customer relationships spanning multiple decades. North American markets including United States, Canada, and Mexico represent significant portions of our export volume, particularly in marine, electrical, and construction industry applications.

European markets across United Kingdom, Germany, Netherlands, and Scandinavian countries value our compliance with stringent quality standards and environmental regulations. Asia-Pacific regions including Australia, Singapore, Japan, and South Korea benefit from our proximity and understanding of regional technical requirements and certification standards.

Middle Eastern markets particularly UAE, Saudi Arabia, and Qatar utilize our products in oil and gas industry applications where corrosion resistance and reliability are critical performance factors. Our African market presence includes South Africa, Nigeria, and Kenya, primarily serving mining and infrastructure development projects.

Environmental and Sustainability Commitments

Our manufacturing operations prioritize environmental responsibility through comprehensive sustainability initiatives and resource conservation programs. Material recycling programs ensure that Copper machining chips and production waste are collected, processed, and reintroduced into the manufacturing cycle, minimizing raw material consumption and environmental impact.

Energy efficiency initiatives include installation of high-efficiency manufacturing equipment, LED lighting systems, and optimized compressed air systems that reduce overall energy consumption per manufactured unit. Water conservation measures incorporate closed-loop cooling systems and water treatment facilities that minimize freshwater consumption and prevent contamination of local water resources.

Waste minimization strategies focus on lean manufacturing principles that optimize material utilization, reduce packaging waste, and implement comprehensive recycling programs for all manufacturing byproducts and consumable materials.

Technical Support and Engineering Services

Our comprehensive technical support services include application engineering consultation, material selection guidance, and custom design development assistance for specialized fastener requirements. Finite element analysis (FEA) capabilities enable optimization of custom designs for specific loading conditions and environmental factors.

Failure analysis services help customers identify root causes of fastener performance issues and develop improved solutions for enhanced reliability. Installation training programs provide customer personnel with proper torque specifications, thread preparation techniques, and quality control procedures for optimal joint performance.

Rapid prototyping services utilize advanced manufacturing technologies to produce sample quantities for evaluation and testing before full-scale production commitment. Our application testing laboratory conducts specialized performance verification tests including vibration resistance, corrosion exposure, and thermal cycling evaluations.

Request Your Custom Quote Today

Ready to experience the superior quality and reliability of our Copper nuts? Our technical team is standing by to assist with your specific requirements and provide detailed quotations for your applications.

Download Our Complete Product Brochure

Email us at sales@conexscrews . com to receive our comprehensive technical documentation including dimensional drawings, material specifications, and application guidelines.

Visit Our Manufacturing Facility

Schedule a plant visit to witness our manufacturing capabilities firsthand and discuss your specific requirements with our engineering team.