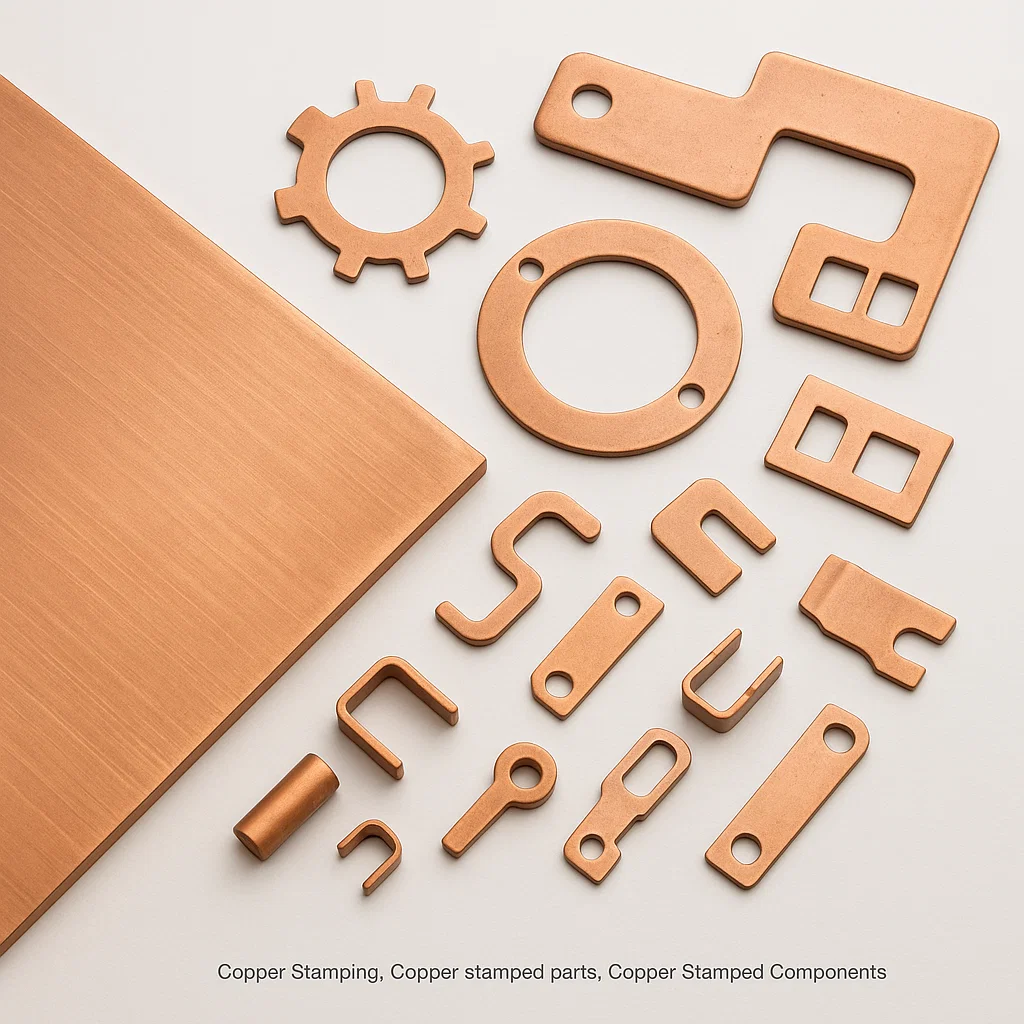

Copper Stamping | Copper Stamped Parts | Copper Pressed Components

We are one of the leading manufacturers and exporters of Copper Stamping, Copper Pressed Components & Electrical Contacts from India. We have been supplying precision Copper stampings, high-conductivity Electrical Contacts, Copper busbars, switchgear components, and custom Copper pressed parts to the world market for many decades. Our manufacturing setup includes advanced high-speed stamping presses, progressive die tooling, compound dies, hydraulic presses, CNC turret punching, and robotic part handling systems. With decades of experience in high-conductivity Copper alloys, we support industries such as Switchgear, Power Distribution, Automotive, Renewable Energy, Electrical Panels, Busbar Systems, HVAC, Telecom, and Industrial Control Systems. Every component is manufactured to stringent engineering standards using globally accepted grades, controlled processes, and world-class inspection. Our technical team ensures design-to-manufacture optimization, cost efficiency, precision tolerances, and global export readiness, establishing us as a trusted supplier to OEMs worldwide.

Copper Stamping

Copper Stamping involves forming flat Copper and Copper-alloy sheets into precise shapes using progressive stamping, deep draw stamping, compound dies, bending, blanking, coining, and embossing. The high electrical conductivity and ductility of Copper allow complex geometries to be produced with excellent dimensional repeatability. Our stamping processes accommodate thicknesses from 0.20 mm to 8 mm, depending on the grade and application. We manufacture simple to highly complex stampings for electrical terminals, connectors, relay parts, power transmission units, switchgear hardware, battery connectors, motor assemblies, and grounding systems. Stamping is ideal for medium to high-volume production, where consistency, uniformity, and tight tolerances are critical. With fully controlled press parameters and rigid die maintenance systems, we deliver stable quality batch after batch.

Copper Stamped Parts

Our Copper Stamped Parts are engineered for applications requiring high conductivity, mechanical strength, and corrosion resistance. Parts are produced from ETP Copper (C11000), Oxygen-Free Copper (C10200/C10100), High-Strength Copper Alloys (C12000/C12200), and Brass/Bronze alloys when needed. We specialize in complex profiles with multiple features such as slots, tabs, countersinks, louvers, ribs, and multi-stage bends. Post-stamping operations include deburring, barrel finishing, laser engraving, threading, plating, assembly, and customized packing. Each stamped part undergoes full inspection using profile projectors, vernier measurement, thickness gauges, go/no-go fixtures, and material verification. These components are widely used in electrical cabinets, power distribution units, PCB assemblies, switchboards, and grounding applications.

Copper Stamped Components

Copper Stamped Components are produced to meet tight electrical and mechanical performance requirements. Our components offer high fatigue strength, long-term stability, and reliable current-carrying capacity. We manufacture custom-stamped profiles with complex bends, hole patterns, relief cuts, and stress-defined shapes. Applications include relay contacts, transformer terminals, capacitor connectors, EV power components, battery tabs, inverter hardware, and power electronics assemblies. With CAD/CAM-driven die design and simulation-based forming analysis, we ensure distortion-free stamping even for thin-gauge Copper. Dies are maintained using precision grinding and tool steel inserts to ensure consistent quality throughout the production lifecycle.

Copper Pressed Parts

Copper Pressed Parts are formed using hydraulic, mechanical, and pneumatic pressing systems capable of handling diverse shapes and thicknesses. Pressed components are used in switchgear, MCC panels, power electronics, energy storage solutions, industrial equipment, and motor control applications. Our capabilities include piercing, flanging, semi-deep drawing, forming ribs, embossing patterns, and joining features into Copper sheets. Pressed parts are designed to retain structural rigidity while maintaining conductivity and heat dissipation properties. We process high-purity Copper grades to ensure minimal resistive losses, making the components suitable for high-current carrying systems.

Copper Pressing

Copper Pressing combines forming force with precise tooling control to create components with stable electrical paths and consistent mechanical properties. Our presses range from 20 tons to 200 tons, supporting both light-gauge and heavy-duty Copper pressing. Copper Pressing is used for producing busbar links, switch components, breaker hardware, transformer terminals, electrical connectors, grounding links, and custom industrial parts. We use hardened tool steels and EDM-machined dies for accuracy and durability. Copper Pressing is ideal for maintaining flatness and dimensional stability in large surface-area components.

Copper Pressed Components

Our Copper Pressed Components are manufactured for industries where conductivity, mechanical strength, and heat dissipation are critical. Parts are produced with controlled tolerances, uniform surface finish, and burr-free edges. We manufacture components for switchgear assemblies, electrical distribution systems, power capacitors, transformers, motor controllers, and renewable energy equipment. Our team ensures compliance with ASTM, EN, DIN, IS, JIS, and customer-specific standards. Copper Pressed Components are available with custom stamping holes, bending features, formed edges, and surface enhancements such as tin plating, nickel plating, silver plating, and anti-oxidation coatings.

Copper Electrical Contacts

Copper Electrical Contacts are precision components designed to carry current efficiently and reduce contact resistance. Manufactured from ETP Copper, OFC, Silver-bearing Copper, and high-strength conductive alloys, these are used in switchgear, MCB/MCCB units, contactors, relays, power breakers, and industrial control panels. The contacts are stamped, pressed, or machined depending on application requirements. Each contact is inspected for flatness, conductivity, hardness, and plating thickness. Copper Electrical Contacts may be supplied with Silver plating, Nickel plating, Tin plating, or customized coatings to enhance durability and arc resistance.

Copper Pressed Busbars

Copper Pressed Busbars are structural current-carrying conductors used in switchgear, panels, substations, UPS systems, and EV power systems. We manufacture straight, bent, multi-bend, punched, embossed, and complex busbar profiles using progressive dies and hydraulic presses. Busbars can be supplied plain or with Tin/Silver/Nickel plating for oxidation control and improved contact performance. Our busbars support heavy electrical loads with consistent conductivity, minimal voltage drop, and excellent thermal dissipation. Thickness options range from 1 mm to 12 mm, depending on design and current requirements.

Copper Stamped Connectors

Copper Stamped Connectors are manufactured with high precision to ensure stable mechanical engagement and optimal electrical flow. These connectors are used in transformers, inverters, battery systems, automotive electronics, terminal blocks, and PCB-mounted electrical assemblies. We handle intricate stamping geometries with controlled spring characteristics. Stamped connectors are validated for conductivity, mechanical locking strength, plating adhesion, and fatigue performance. Through advanced production tooling, we achieve consistency in every dimension and profile.

Copper Switchgear Components

Copper Switchgear Components require exceptional durability, mechanical precision, and high conductivity for electrical safety and efficiency. We manufacture switchgear-grade parts such as current-carrying connectors, terminal plates, grounding contacts, breaker components, high-current busbars, fuse elements, shunts, and arc-resistant contact sets. All components follow strict industry standards and undergo rigorous inspection. Material traceability, plating consistency, and dimensional conformance ensure that parts seamlessly integrate into global switchgear assemblies.

International Material Standards for Copper

| Region | Standard | Equivalent Grade |

|---|---|---|

| USA | ASTM B152 / B187 / B33 | C11000, C10200, C12200 |

| Europe | EN 13599 / EN 13601 | CW004A, CW008A, CW024A |

| UK | BS 6017 | C101, C106 |

| Germany | DIN 1787 | E-Cu58, SF-Cu |

| China | GB/T 5231 | T1, T2, TU1 |

| Japan | JIS H3100 | C1100, C1020 |

| India | IS 191 / IS 1897 | ETP Copper, DHP Copper |

Manufacturing Processes

Copper stamping, hydraulic pressing, progressive die stamping, blanking, piercing, bending, coining, embossing, deep drawing (for selected designs), trimming, laser cutting, CNC punching, deburring, polishing, flattening, plating, heat treatment (when needed).

Machinery Used

High-speed stamping presses, mechanical and hydraulic presses, progressive die systems, CO₂/Nd:YAG laser cutting machines, turret punching machines, deburring machines, CMMs, profile projectors, plating tanks, automatic forming tools, and surface finishing machines.

Typical Copper Stamped Products

Electrical terminals, power connectors, grounding links, switchgear components, transformer terminals, EV battery connectors, inverter contacts, busbars, motor control hardware, telecom connectors, Transformer parts, Switchgear Contacts,

Dimension Table (Typical Range)

| Parameter | Range |

|---|---|

| Thickness (T) | 0.20 mm – 12 mm |

| Width (W) | 5 mm – 200 mm |

| Length (L) | 10 mm – 600 mm |

| Tolerances | ±0.05–0.20 mm |

| Hole Diameter | 1.5 mm – 30 mm |

Finishes & Plating Options

Tin Plating, Nickel Plating, Silver Plating, Gold Flash, Anti-Oxidation Coatings, Chemical Brightening, Vibratory Finishing, Deburring, Protective Oil Films.

Industries We Serve

Switchgear, Power Distribution, Electrical Panels, Automotive Electronics, Renewable Energy, UPS Systems, Battery Storage, Telecom Equipment, Consumer Electronics, Industrial Machinery.

Turnaround Time

Development: 4–6 weeks

Repeat production: 2–4 weeks, depending on tooling and volume.

Performance Metrics

| Property | Typical Value |

|---|---|

| Conductivity | 97–101% IACS |

| Hardness | 45–90 HV (depending on temper) |

| Tensile Strength | 220–260 MPa |

| Thermal Conductivity | ~400 W/m·K |

| Surface Flatness | ≤0.10 mm across 200 mm |

| Bend Fatigue | High (grade dependent) |

Q&A

1. Which Copper grades are best for stamping?

C11000, C10200, C12200, CW004A, and high-strength conductive alloys.

2. Do you support progressive die stamping?

Yes, for medium to high volumes with complex geometries.

3. Can you manufacture heavy busbars?

Yes, up to 12 mm thickness using hydraulic presses.

4. Do you provide plating?

Tin, Nickel, Silver, and custom coatings.

5. What industries use Copper stamped parts?

Switchgear, automotive, power distribution, electronics, telecom.

6. What tolerances can you maintain?

±0.05–0.20 mm depending on geometry and thickness.

7. Are your parts RoHS compliant?

Yes, RoHS & REACH documentation available.

8. Can you help optimize customer drawings?

Yes, our engineering team suggests manufacturability improvements.

9. Do you supply prototypes?

Yes—laser-cut + press-form prototypes before die development.

10. Are material certificates provided?

Yes—ASTM/EN/JIS/IS material certificates.

11. Can you handle large export quantities?

Yes, supported by multi-press lines and strong logistics.

12. Do you ship globally?

Yes—to USA, UK, Europe, Canada, Australia, Middle East, Asia.

13. What is the maximum width for stamping?

Up to 200 mm depending on grade.

14. Can you produce Silver-plated Copper Contacts?

Yes, for switchgear and high-current applications.

15. How do you ensure burr-free stamping?

Controlled die maintenance, finishing, and inspection.

Why Customers Choose Us

Three decades of engineering expertise, efficient communication, faster turnaround, design-to-cost optimization, customized packaging with client labels/logo, flexibility in production schedules, and strict quality control using global standards. Our ability to advise improvements in drawings ensures lower cost, improved functionality, and seamless mass production.

Packaging & Shipping

Anti-rust polybags, vacuum pouches, corrugated cartons, wooden crates, palletized loads, barcoded labels, customer-branded packaging. Shipping via DHL, FedEx, UPS, Air Freight, Sea Freight depending on urgency and volume.

Customer Testimonials

Michael R. (USA):

“The Copper stamped parts were exceptionally well made with consistent plating and perfect dimensions. Their engineering support saved us tooling costs.”

Oliver J. (UK):

“Reliable supplier with excellent communication. The Copper busbars and contacts exceeded our expectations in conductivity and finishing.”

Glossary of Terms

ETP Copper: Electrolytic Tough Pitch Copper with high conductivity.

OFC / OFHC Copper: Oxygen-Free Copper with superior conductivity and purity.

Progressive Die: Multi-stage stamping tool that performs multiple operations in one stroke.

IACS: International Annealed Copper Standard for electrical conductivity.

Busbar: A Copper conductor distributing electrical power in switchgear and panels.

Related Parts:

Copper stampings, Copper pressed components, Copper switchgear parts, Copper contacts India, Copper busbar stamping, Tin-plated Copper components, Copper electrical connectors, power distribution Copper parts.

Flow

Call to Action

For RFQs, drawings, prototypes, or technical discussions, email us or contact via phone/WhatsApp. We respond within 24 hours for all international inquiries.

UPDATED: 2025-26