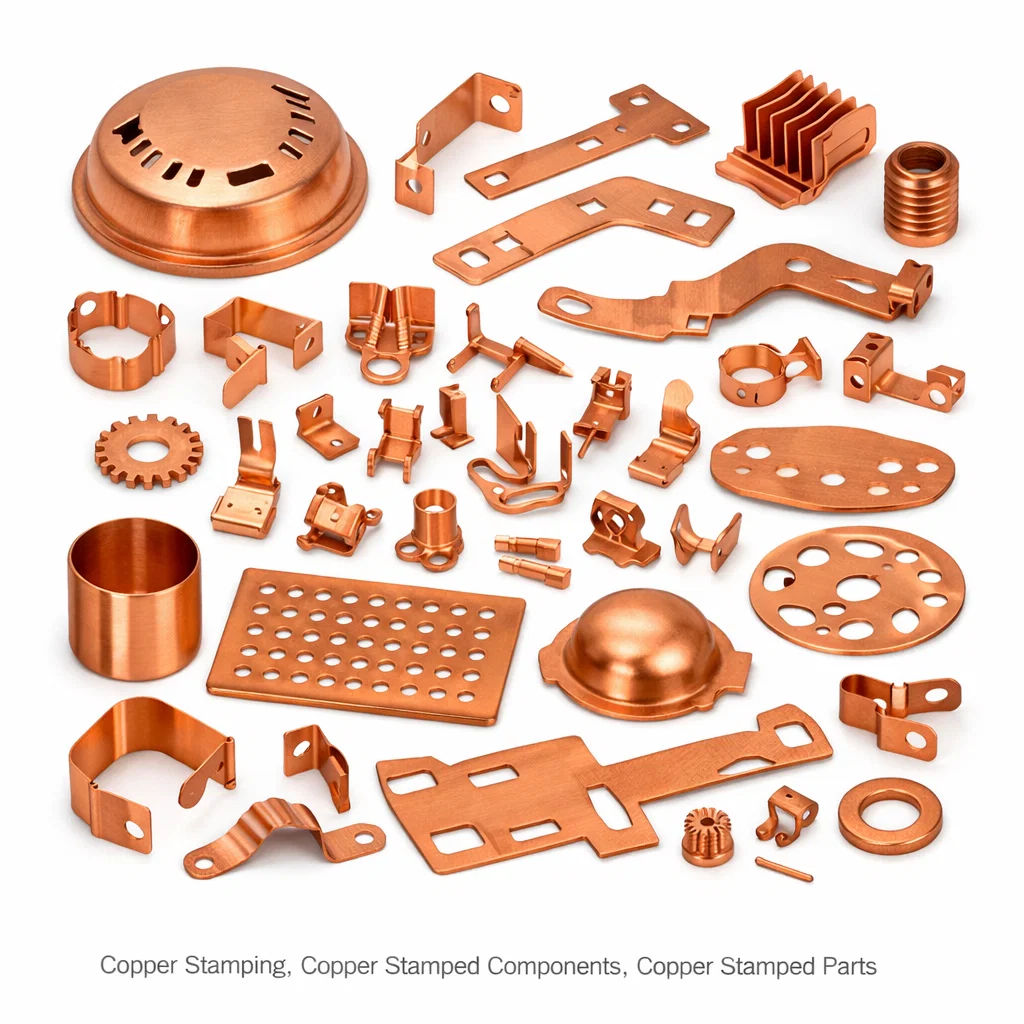

Copper Stamping & Copper Stamped Parts –

Comprehensive Overview of Copper Stamping Services

Price: US$ 13.90/kilogram, CIF US port

Copper stamping represents a cornerstone manufacturing process in the precision metal fabrication industry, utilizing high-tonnage mechanical and hydraulic presses to transform flat Copper sheet metal into functional three-dimensional components through controlled deformation. We are one of the leading manufacturers and exporters of Copper Stamping, Copper Stamped Parts, and Copper Stamped Components from India. We have been supplying precision Copper electrical stampings and Copper sheetmetal stamping parts to the world market for many decades. Our state-of-the-art manufacturing facility in Jamnagar combines traditional metalworking expertise with modern CNC-controlled stamping technology to deliver components that meet the stringent requirements of electrical, automotive, renewable energy, and industrial sectors across North America, Europe, and the Asia-Pacific region. The versatility of Copper as a stamping material stems from its exceptional electrical conductivity (ranking second only to Silver), superior thermal properties, excellent corrosion resistance, and remarkable formability that allows complex geometries to be achieved without compromising material integrity. Over three decades of specialized experience in Copper stamping has enabled our engineering team to develop proprietary tooling designs and progressive die systems that maximize material utilization while maintaining dimensional accuracy within ±0.05mm tolerances for critical applications.

Understanding Copper Stamping Technology

Copper Stamping encompasses a broad spectrum of cold-forming operations including blanking, piercing, bending, coining, embossing, and deep drawing, all executed on dedicated stamping presses ranging from 25-ton mechanical units for light-gauge work to 400-ton hydraulic systems for heavy-duty applications. The process begins with precision tool and die design using advanced CAD/CAM software, followed by CNC machining of hardened tool steel dies that can withstand millions of stamping cycles while maintaining dimensional consistency. Progressive stamping dies allow multiple operations to be performed in a single press stroke as the Copper strip advances through sequential stations, dramatically improving production efficiency for high-volume requirements. Transfer stamping provides an alternative approach for larger components where robotic arms move workpieces between individual die stations, offering greater flexibility for complex geometries that exceed the capabilities of progressive tooling. Our stamping capabilities extend from prototyping quantities of 100 pieces using soft tooling to production runs exceeding 500,000 components utilizing fully hardened precision dies with expected tool life surpassing two million impressions.

Copper Stamped Parts Manufacturing Excellence

Copper Stamped Parts manufactured in our facility serve critical functions across diverse industrial applications where the unique combination of electrical conductivity, thermal management, and mechanical strength cannot be replicated by alternative materials. The inherent antimicrobial properties of Copper have recently expanded application opportunities in medical equipment and high-touch surface components, while its non-magnetic characteristics make Copper stamped parts indispensable in MRI equipment, precision instruments, and electromagnetic shielding applications. Our quality management system adheres to ISO 9001:2015 certification standards with comprehensive first-article inspection protocols, in-process statistical process control monitoring, and final dimensional verification using Mitutoyo coordinate measuring machines with 0.001mm resolution. Material traceability is maintained throughout the manufacturing process with heat lot identification ensuring complete documentation from raw material certification through final shipment, a critical requirement for aerospace, medical device, and military specification components. Post-stamping operations including deburring, vibratory finishing, and edge radiusing ensure that every Copper stamped part meets both dimensional requirements and safety standards for handling and assembly.

Precision Copper Stamped Components

Copper Stamped Components represent the outcome of integrating metallurgical knowledge, precision tooling engineering, and advanced press control systems to transform raw Copper sheet and strip into finished products that form the backbone of modern electrical infrastructure and electronic assemblies. The selection of appropriate Copper alloy grades plays a crucial role in component performance, with pure Copper (C11000) specified for maximum electrical conductivity applications while phosphor Bronze additions (C51000) enhance spring characteristics for electrical contacts and connectors. Our engineering team collaborates with customers during the design-for-manufacturability phase, identifying opportunities to optimize part geometry for stamping efficiency, reduce secondary operations, and improve overall cost-effectiveness without compromising functional requirements. Finite element analysis software allows virtual validation of forming operations before physical tooling investment, predicting material flow, identifying potential splitting or wrinkling issues, and optimizing blank size to minimize scrap generation. The precision achievable through modern Copper stamping rivals that of machined components for many applications while offering substantially lower unit costs at production volumes, making stamping the preferred manufacturing method for Copper electrical terminals, bus bar connections, and thermal management components.

Copper Sheetmetal Stamping Parts Production

Copper Sheetmetal Stamping Parts manufacturing utilizes Copper in thickness ranges from ultra-thin 0.15mm foils for flexible printed circuit applications to heavy-gauge 6.0mm plate for high-current bus bar systems and structural electrical components. The formability of Copper sheet varies significantly with thickness, grain structure, and temper condition, requiring careful selection of material specifications to match the complexity of forming operations while avoiding excessive thinning, wrinkling, or fracture during the stamping process. Our material procurement partnerships with leading Copper mills in Europe and Asia ensure consistent material quality with certified chemical composition, mechanical properties, and surface finish specifications that meet ASTM B152, EN 1652, or equivalent international standards. Sheetmetal stamping operations for Copper frequently incorporate compound dies that perform multiple operations simultaneously, progressive dies for high-volume production efficiency, or fine blanking technology when sheared edges with superior flatness and perpendicularity are required for critical mating surfaces. Surface preparation prior to stamping includes cleaning operations to remove rolling oils and oxidation that could interfere with subsequent plating processes, while post-stamping treatments range from simple degreasing to specialized chemical brightening for decorative applications or improved electrical contact performance.

Copper Electrical Stampings Specialization

Copper Electrical Stampings constitute our primary area of specialization, serving the demanding requirements of electrical switchgear manufacturers, transformer builders, renewable energy system integrators, and electric vehicle component suppliers who depend on precise Copper components to ensure safe and efficient electrical power distribution. The electrical performance of stamped Copper components depends critically on maintaining material conductivity throughout the forming process while achieving the mechanical properties necessary for reliable spring contact pressure, vibration resistance, and long-term dimensional stability under thermal cycling conditions. Our stamping processes are optimized to minimize work hardening in critical contact areas while utilizing controlled deformation to enhance strength in mounting and structural regions of components. Electrical stampings frequently require specialized surface treatments including tin plating for solderability and corrosion protection, Silver plating for ultra-low contact resistance in high-reliability applications, or nickel underplating as a diffusion barrier preventing Copper migration in elevated temperature environments. Quality assurance for electrical stampings includes 100% continuity testing for contact integrity, dimensional inspection of critical electrical clearance distances, and surface finish verification ensuring that plating thickness meets specification requirements for the intended service environment and expected component lifespan.

Material Grades and Specifications

| Material Grade | Standard | Composition | Electrical Conductivity | Primary Applications |

|---|---|---|---|---|

| C11000 (ETP Copper) | ASTM B152 | 99.9% Cu min | 101% IACS | Bus bars, electrical terminals, grounding components |

| C10200 (OF Copper) | ASTM B152 | 99.95% Cu min | 101% IACS | Vacuum tube components, waveguides, critical electrical contacts |

| C10100 (OFE Copper) | EN 1652 | 99.99% Cu min | 103% IACS | Semiconductor equipment, ultra-high vacuum systems |

| C11000 | DIN 1787 | Cu-ETP | 58 MS/m min | European standard electrical applications |

| C12200 (DHP Copper) | ASTM B370 | Cu + 0.015-0.040% P | 85% IACS | Resistance to hydrogen embrittlement, brazeable applications |

| C14500 (Tellurium Copper) | ASTM B301 | Cu + 0.4-0.7% Te | 95% IACS | Free-machining electrical components, screw terminals |

| C17200 (Beryllium Copper) | ASTM B194 | Cu + 1.8-2.0% Be | 25% IACS | Spring contacts, electrical connectors requiring high strength |

| C19400 (Copper-Iron) | ASTM B465 | Cu + 2.1-2.6% Fe | 65% IACS | Resistance welding electrodes, high-strength electrical parts |

| T2 (Chinese Standard) | GB/T 2059 | 99.9% Cu min | Similar to C11000 | Chinese market electrical components |

| C1100 (Japanese) | JIS H3100 | 99.90% Cu min | Equivalent to C11000 | Japanese standard electrical applications |

The selection among these Copper grades depends on the specific performance requirements of the stamped component, with trade-offs between maximum electrical conductivity, mechanical strength, formability, and cost optimization guiding material specification decisions.

Manufacturing Processes and Equipment

Our Copper stamping operations utilize a comprehensive range of metalworking equipment and processes to accommodate components from simple flat washers to complex three-dimensional assemblies requiring multiple forming stages. Blanking operations employ high-precision shearing dies to cut Copper sheet into specific shapes with edge quality suitable for subsequent forming or as finished components, utilizing press tonnages matched to material thickness and part perimeter length. Piercing and punching creates holes, slots, and complex cutouts in Copper stampings using hardened punch and die combinations with clearances optimized for Copper’s ductility characteristics, typically 5-8% of material thickness to achieve clean sheared edges without excessive burr formation.

Bending operations transform flat Copper blanks into angular configurations using precision-ground V-dies or channel-forming tooling, with springback compensation calculated based on material temper, thickness, and bend radius to achieve final angular accuracy within ±1 degree. Coining applies extreme pressures exceeding the yield strength of Copper to create precise thickness control, embossed features, or surface densification in localized areas of stampings where improved flatness or reduced porosity enhances electrical contact performance. Deep drawing produces cup-shaped Copper components through multiple drawing stages with intermediate annealing when draw ratios exceed the formability limits of work-hardened material, commonly used for battery terminal cups, relay housings, and cylindrical electrical connectors.

Progressive stamping on our Bruderer, Komatsu, and Aida high-speed presses achieves production rates up to 400 strokes per minute for smaller Copper electrical terminals, with automatic strip feeding, scrap evacuation, and parts collection systems enabling unattended operation during production runs. Transfer stamping provides superior control for larger components or parts requiring operations that cannot be economically incorporated into progressive die designs, utilizing servo-driven press controls that optimize ram velocity, dwell time, and force application for each forming stage.

Secondary operations integrated into our Copper stamping workflow include deburring using vibratory finishing with ceramic media to remove sharp edges and create uniform edge radii, tapping for threaded mounting holes in terminal lugs and bus bar connectors, staking and riveting for assembly of multiple Copper components, and resistance welding when design requirements specify permanent joining of stamped elements.

Some Copper Stamped Products:

Copper Lugs serve as critical termination components in electrical power distribution systems, manufactured through precision stamping and forming operations that create the barrel configuration for wire insertion and compression, the mounting pad with bolt holes for mechanical connection, and the transition geometry that distributes mechanical stress while maintaining electrical conductivity. Our Copper lug production capabilities span from miniature 2.5mm² wire capacity terminal lugs for control circuits to heavy-duty 1000mm² cable lugs for industrial switchgear and transformer connections, with tongue configurations ranging from single-hole to multi-hole designs for parallel bus bar connections. Quality control for Copper lugs includes verification of barrel inner diameter tolerances ensuring proper conductor fit, inspection of tongue hole positioning and perpendicularity for secure bolted connections, and 100% continuity testing validating electrical integrity from barrel through tongue without excessive resistance increases at formed transitions.

Copper Pressed Terminal Lugs represent a specialized category of stamped electrical connectors manufactured through high-tonnage pressing operations that cold-form the Copper blank into a tubular barrel with integral mounting tongue in a single compression stroke, eliminating brazed or welded joints that could introduce electrical resistance or potential failure points under thermal cycling conditions. The pressing operation for terminal lugs requires precise control of forming pressure, die temperature, and material positioning to achieve consistent barrel roundness within ±0.2mm tolerance while maintaining tongue flatness specifications that ensure proper contact with bus bar surfaces. Post-pressing operations typically include drilling or punching of the mounting holes, deburring of the barrel entrance and tongue edges, and optional tin plating to enhance corrosion resistance and facilitate crimp connection to Aluminum or Copper conductors during field installation.

Copper Flat Connectors and Copper Tabs provide compact electrical interconnections in applications where space constraints or assembly requirements favor flat stamped geometries over cylindrical terminal configurations, commonly specified for battery pack assemblies, printed circuit board connections to external power sources, and transformer tap connections requiring frequent reconfiguration. Stamping of flat connectors utilizes progressive dies that perform blanking, hole punching, edge forming for stiffness, and tab bending operations in sequential press stations, with final component geometry optimized for automated assembly processes or hand insertion into mating electrical interfaces. Dimensional accuracy requirements for flat connector stampings focus on hole-to-hole positioning tolerances that ensure alignment with mating components, tab width and thickness consistency for reliable insertion force and retention, and overall flatness specifications preventing warpage that could compromise electrical contact pressure distribution.

Copper Busbar Links and Copper Jumpers function as flexible or rigid electrical connections between fixed bus bar installations, manufactured from Copper strip through stamping operations that create mounting holes, edge reinforcement features, and any required offset bends or angular transitions to accommodate physical spacing between connection points. The electrical performance of bus bar links depends on maintaining full cross-sectional area throughout the current path while minimizing sharp bends or narrow transitions that could generate localized heating under high current flow, requiring careful attention to minimum bend radii and fillet dimensions during stamping die design. Surface treatment for Copper bus bar components frequently includes tin plating thickness of 5-10 microns to prevent oxidation during storage and field installation while providing a solderable or brazeable surface for supplementary connection methods when specified by electrical design requirements.

Copper Earth Clips and Copper Grounding Straps provide essential safety connections between electrical equipment chassis and ground electrodes, stamped from high-conductivity Copper to ensure low-resistance current paths for fault current dissipation and electromagnetic interference shielding effectiveness. Stamping designs for grounding components emphasize large contact surface areas to minimize connection resistance despite surface oxidation or contamination, spring characteristics that maintain contact pressure under vibration and thermal expansion conditions, and mechanical strength sufficient to withstand the electromagnetic forces generated during short-circuit fault conditions. Our grounding strap production incorporates multiple stamping stages to create the spring-temper contact regions through controlled work hardening while maintaining softer, more ductile material in mounting areas where hole elongation or stress concentration could initiate fatigue failures during installation or service conditions.

Copper Transformer Tap Connectors enable voltage adjustment in power and distribution transformers through repositionable connections to tapped winding terminations, requiring stamped Copper components with precise dimensional control for reliable electrical contact combined with mechanical designs that facilitate field installation, adjustment, and long-term stability under continuous thermal cycling from transformer load variations. The stamping complexity for tap connectors typically exceeds simple terminal lug configurations due to the incorporation of spring elements for contact pressure maintenance, locking features to prevent inadvertent movement during transformer vibration, and multiple contact surfaces to ensure redundant current paths and minimize the impact of localized oxidation or contamination on overall connection resistance. Material selection for transformer tap connectors balances the high electrical conductivity requirements favoring pure Copper with the spring properties and wear resistance enhanced through alloying additions or post-stamping heat treatment processes.

Copper Switchgear Parts and Copper Contact Strips constitute a diverse family of stamped components serving circuit breaker, disconnect switch, and electrical panel applications where reliable current interruption, low contact resistance, and long mechanical life are critical safety and performance requirements. Stamping operations for switchgear components must accommodate the wide variation in part geometries from flat contact fingers and bus bar connections to complex three-dimensional moving contact assemblies incorporating spring elements, wear surfaces, and arcing horns for fault current protection. Surface treatments for switchgear Copper stampings range from bare Copper for protected indoor installations to Silver plating for critical contacts, tin plating for general corrosion protection, or nickel plating for enhanced wear resistance in high-cycle switching applications and corrosive industrial environments.

Copper Clamps for Pipes secure plumbing, HVAC, and industrial piping systems while providing electrical grounding connections between metallic pipes and building ground electrodes, manufactured through Copper stamping operations that form the semi-circular or U-shaped clamping profile, create mounting holes or threaded inserts for fastener attachment, and incorporate edge stiffening features to distribute clamping loads without deforming or damaging pipe surfaces. The spring characteristics of stamped Copper pipe clamps must accommodate the dimensional tolerances of the piping being secured while maintaining sufficient clamping force to prevent vibration-induced loosening or displacement during operational conditions, typically achieved through careful control of material temper and forming strains during the stamping process. Corrosion resistance is particularly critical for Copper pipe clamps in outdoor, underground, or marine environments where dissimilar metal contact between Copper components and Steel or Stainless Steel fasteners can accelerate galvanic corrosion, often addressed through the specification of tin-plated Copper or all-Copper fastener systems.

Copper EV Battery Parts and Battery Straps represent a rapidly growing application segment for Copper stamping technology as electric vehicle manufacturers demand high-reliability electrical interconnections capable of carrying hundreds of amperes between cylindrical or prismatic battery cells while maintaining dimensional stability and electrical integrity through thousands of charge-discharge thermal cycles. Stamping of EV battery components requires ultra-precise dimensional control to ensure proper fit within tightly-packaged battery assemblies, superior surface quality to enable resistance welding or ultrasonic welding attachment to battery terminals, and careful material selection balancing electrical conductivity requirements with mechanical properties that prevent creep deformation or stress relaxation under continuous electrical heating and mechanical vibration in vehicle operation. Quality assurance for battery Copper stampings includes 100% automated optical inspection to verify dimensional accuracy and surface defects, electrical resistance testing to validate conductivity specifications, and accelerated thermal aging protocols to confirm long-term reliability under the demanding service environment of automotive battery packs.

Copper Grounding Straps for electrical equipment, telecommunications installations, and lightning protection systems provide flexible electrical connections that accommodate mechanical movement, thermal expansion, or vibration isolation while maintaining low-resistance current paths for fault protection and electromagnetic interference control. Stamping operations for grounding straps utilize progressive dies that create repeating patterns of slots or perforations to enhance flexibility while maintaining adequate current-carrying cross-section, form the terminal attachment features at each end of the strap, and apply edge finishing operations to prevent conductor strand damage or installation hazards from sharp edges. Our grounding strap designs incorporate engineering analysis to balance the competing requirements of electrical conductivity favoring maximum cross-sectional area, mechanical flexibility requiring reduced effective stiffness, and long-term fatigue resistance demanding elimination of stress concentration features that could initiate crack propagation under cyclic flexing loads.

Copper Transformer Connectors enable the critical electrical interfaces between transformer windings, bushings, tap changers, and external power circuits, manufactured through precision Copper stamping processes that create contact surfaces meeting flatness and surface finish specifications for low-resistance bolted connections combined with mechanical strength to withstand electromagnetic forces during short-circuit conditions and thermal expansion stresses from transformer load cycling. The electrical design of transformer Copper connectors focuses on maximizing contact area to distribute current flow and minimize localized heating, incorporating multiple bolt holes to ensure redundant load paths and facilitate the high tightening torques required for aluminum-to-Copper transitions, and specifying surface treatments that remain stable and low-resistance through decades of service in oil-filled or air-insulated transformer environments. Our transformer connector production capabilities extend from small distribution transformer components weighing a few grams to heavy-duty power transformer bus connections exceeding 50 kilograms, with stamping and forming operations scaled appropriately to the component size while maintaining consistent quality standards and dimensional accuracy requirements.

Manufacturing Tolerances and Quality Standards

Dimensional accuracy represents a critical performance parameter for Copper stamped components, with achievable tolerances dependent on material thickness, part geometry complexity, and the specific forming operations required. Standard commercial tolerances for Copper stamping operations typically fall within the following ranges:

- Hole diameter tolerance: ±0.10mm for diameters up to 25mm, ±0.15mm for larger holes

- Hole position tolerance: ±0.15mm relative to datum features within 100mm distance

- Bend angle tolerance: ±1.5 degrees for angles between 30-150 degrees

- Overall dimensional tolerance: ±0.20mm for features up to 50mm, ±0.30mm for larger dimensions

- Flatness tolerance: 0.5mm maximum deviation over 100mm span for non-formed areas

Enhanced precision tolerances approaching ±0.05mm are achievable through progressive die stamping with compensation for material springback, tool deflection, and thermal expansion factors, combined with statistical process control monitoring and periodic tool maintenance to prevent accuracy degradation from die wear.

Surface finish specifications for stamped Copper components range from mill finish with visible grain structure and minor surface imperfections acceptable for non-critical applications to bright annealed finish providing reflective surface appearance for decorative or high-visibility installations, with intermediate finishes including matte chemical treatment for reduced glare or specialized texturing for enhanced adhesion of subsequent coatings or adhesive bonding operations.

Plating and Surface Finishes

Surface treatment selection for Copper stampings considers the functional requirements of electrical conductivity, corrosion resistance, solderability, and aesthetic appearance while balancing the cost implications of additional processing operations.

Tin Plating represents the most common surface finish for Copper electrical stampings, providing excellent corrosion protection, superior solderability, and compatibility with both Copper and Aluminum conductor connections, typically applied to thickness of 2.5-10 microns through barrel plating for small components or rack plating for larger assemblies requiring precise thickness control and uniform coverage of complex geometries.

Silver Plating delivers the ultimate electrical performance for critical contact applications where minimum electrical resistance and maximum reliability justify the premium cost, typically specified in thickness of 2-5 microns for contact surfaces while leaving mounting areas unplated or tin-plated to reduce overall finishing costs without compromising contact function.

Nickel Plating serves as an effective diffusion barrier preventing Copper migration into contact surfaces at elevated temperatures, enhances wear resistance for mechanical sliding contacts, and provides corrosion protection superior to tin in harsh chemical environments, applied to thickness ranging from 2.5 microns for barrier applications to 25 microns when wear resistance is the primary specification driver.

Electroless Nickel offers uniform coating thickness on complex Copper stamping geometries without the thickness variations inherent in conventional electroplating processes, frequently specified for components requiring dimensional precision after plating or applications where complete coverage of recessed areas is critical for corrosion protection.

Industries and Applications

Copper stamped components manufactured in our facility serve essential functions across numerous industrial sectors including electrical power distribution, renewable energy systems, electric vehicle manufacturing, telecommunications infrastructure, HVAC and refrigeration equipment, consumer electronics, medical devices, aerospace systems, and industrial automation. The electrical transmission and distribution sector represents our largest market segment with Copper bus bar connectors, transformer components, and switchgear parts enabling the reliable delivery of electrical power from generation sources through transmission networks to industrial and residential end users.

Renewable energy applications including solar photovoltaic systems and wind turbine generators utilize Copper stamped terminals, grounding connectors, and bus bar assemblies to manage the collection and conversion of generated power while withstanding outdoor environmental exposure and thermal cycling from variable power output conditions. Electric vehicle manufacturers specify Copper battery interconnects, motor terminal assemblies, and charging system components that must deliver exceptional electrical performance and mechanical reliability through millions of charge-discharge cycles and decades of automotive service under vibration, temperature extremes, and corrosive environmental conditions.

Production Lead Time and Ordering

Standard production turnaround time for Copper stamped components ranges from four to six weeks from receipt of approved drawings and purchase orders through completion of manufacturing, quality inspection, and preparation for shipment. This timeline encompasses tooling design and fabrication for new part numbers requiring custom dies, material procurement ensuring appropriate Copper grade selection and certification documentation, production stamping operations including any required secondary processes, surface treatment application when specified, and comprehensive quality verification including dimensional inspection and electrical performance testing.

Expedited production schedules can be accommodated for urgent customer requirements through priority scheduling of tooling fabrication and dedicated press allocation, potentially reducing lead time to two to three weeks depending on part complexity and quantity requirements. Prototype quantities for design validation or first-article approval can often be produced within 10-14 days using soft tooling or single-stage dies that may not achieve the cost efficiency or dimensional precision of production progressive dies but provide functional components for testing and evaluation before committing to full production tooling investment.

Engineering Support and Customization Capabilities

Our technical engineering team brings three decades of Copper stamping experience to collaborative design-for-manufacturability consultations, providing customers with expert guidance on part geometry optimization, material selection, tolerance specification, and manufacturing process selection to achieve optimal balance of component performance, production efficiency, and total cost of ownership. Value engineering analysis identifies opportunities to reduce material waste, eliminate unnecessary secondary operations, and consolidate multiple components into single stamped assemblies without compromising functional requirements.

Custom tooling design capabilities extend from simple single-stage blanking dies for low-volume requirements to complex progressive dies incorporating 15 or more forming stations for high-volume production efficiency, with finite element analysis validation ensuring that forming operations remain within the material’s formability envelope while achieving specified dimensional accuracy and surface quality requirements. Prototype development services allow customers to validate component fit, form, and function before committing to production tooling investment, utilizing rapid tooling techniques or CNC machining to produce sample quantities for assembly verification and performance testing.

Packaging and Global Shipping

Packaging solutions for Copper stamped components are customized to the specific requirements of part geometry, quantity, and shipping destination, ranging from bulk packaging in corrugated cartons with foam or paper separation to prevent component damage during transit, to precision-counted packaging in compartmentalized plastic trays for automated assembly equipment, to blister packaging for retail distribution applications. Custom packaging incorporating customer logos, part numbers, and specification information can be provided to support just-in-time delivery requirements and streamline receiving operations at customer facilities.

International shipping expertise developed through decades of global export operations ensures that documentation, packaging, and logistics arrangements comply with importing country requirements while optimizing transportation costs through consolidation of multiple orders, selection of appropriate freight methods, and coordination with established logistics partners serving North American, European, and Asia-Pacific destinations. Export packaging incorporates moisture barrier materials, desiccant inclusion, and corrosion inhibitor treatment when specified to protect Copper components during ocean freight transit through tropical and marine environments.

Technical Properties of Copper Materials

| Property | Pure Copper (C11000) | Phosphor Bronze (C51000) | Beryllium Copper (C17200) |

|---|---|---|---|

| Electrical Conductivity | 101% IACS | 15% IACS | 25% IACS |

| Thermal Conductivity | 391 W/m·K | 42 W/m·K | 105 W/m·K |

| Density | 8.89 g/cm³ | 8.86 g/cm³ | 8.25 g/cm³ |

| Tensile Strength (Annealed) | 220 MPa | 400 MPa | 480 MPa |

| Tensile Strength (Hard) | 360 MPa | 760 MPa | 1380 MPa |

| Elongation (Annealed) | 45% | 48% | 35% |

| Hardness (Rockwell B) | 40 | 85 | 95 |

Dimensional Specifications for Common Copper Terminal Lugs

| Wire Size (mm²) | Barrel Length (mm) | Barrel Diameter (mm) | Tongue Width (mm) | Hole Diameter (mm) | Overall Length (mm) |

|---|---|---|---|---|---|

| 2.5 | 12 | 3.5 | 9.5 | 4.3 | 28 |

| 6 | 16 | 5.0 | 12.5 | 5.3 | 36 |

| 10 | 20 | 6.5 | 16.0 | 6.4 | 44 |

| 16 | 24 | 8.0 | 19.0 | 8.4 | 52 |

| 25 | 28 | 10.0 | 22.0 | 10.5 | 62 |

| 35 | 32 | 12.0 | 25.0 | 10.5 | 70 |

| 50 | 36 | 14.0 | 28.0 | 13.0 | 80 |

| 70 | 42 | 16.5 | 32.0 | 13.0 | 92 |

| 95 | 48 | 19.0 | 36.0 | 13.0 | 104 |

Why Choose Our Copper Stamping Services

Selecting the right manufacturing partner for Copper stamped components requires evaluation of technical capabilities, quality systems, responsiveness, and total value delivered beyond simple piece-price quotations. Our competitive advantages in the Copper stamping market include faster turnaround time through dedicated press capacity and streamlined production scheduling that minimizes queue time between operations, enabling delivery performance that consistently meets or exceeds customer expectations even during periods of high demand across the industry.

Superior customer support and communication represent core values embedded in our organizational culture, with dedicated account managers providing single-point contact for technical inquiries, order status updates, and resolution of any quality or delivery concerns, supported by engineering staff available for collaborative design discussions and rapid response to specification questions or change requests. English language proficiency throughout our commercial and technical teams facilitates clear communication with customers in North America, Europe, and other English-speaking markets, eliminating the misunderstandings and delays that can arise from language barriers in international manufacturing relationships.

Three decades of global experience serving customers across six continents has developed our understanding of diverse industry requirements, international quality standards, and export logistics complexities that affect successful component delivery, giving customers confidence that we can navigate the technical and commercial challenges of international supply relationships while maintaining consistent quality and reliability. Our production flexibility accommodates both large-volume continuous supply arrangements and smaller batch orders for specialty applications or prototyping requirements, with manufacturing systems and commercial terms structured to provide responsive service across the full spectrum of customer needs.

Engineering expertise and technical support capabilities enable us to function as an extension of customer design teams, contributing value through design optimization recommendations, material selection guidance, and manufacturing process innovations that improve component performance or reduce total cost while maintaining or enhancing quality levels. The ability to suggest technical drawing changes that improve manufacturability without compromising functional requirements has generated significant cost savings for customers while accelerating time-to-market for new product introductions.

Customized packaging solutions incorporating customer-specified labeling, lot tracking, and component protection methods support diverse assembly operations from manual production lines to fully automated pick-and-place equipment, with packaging designed to optimize material handling efficiency and minimize component damage during storage, shipping, and assembly operations. Investment in modern CNC press controls, precision measurement equipment, and quality management systems ensures that dimensional accuracy, surface finish, and electrical performance specifications are consistently achieved across production runs, with statistical documentation available to support customer quality validation requirements and continuous improvement initiatives.

Customer Testimonials

David Morrison, Electrical Engineer, Pennsylvania USA “Working with this Copper stamping supplier has been transformative for our transformer manufacturing operation. The engineering team’s willingness to collaborate on design optimization reduced our material costs by 18 percent while actually improving the electrical performance of our tap connectors. Their ability to hold ±0.05mm tolerances on critical hole spacing has eliminated the assembly alignment issues we experienced with previous suppliers, and the four-week lead time is exceptional for the custom progressive die work we require. Communication has been outstanding throughout our relationship with immediate responses to technical questions and proactive notifications of any potential delivery considerations. I particularly appreciate their flexibility in accommodating our packaging requirements with custom labeling and tray counts that integrate seamlessly with our automated assembly systems.”

James Fletcher, Procurement Manager, Ontario Canada “After evaluating multiple Copper stamping suppliers for our switchgear component requirements, we selected this manufacturer based on their combination of technical capability, quality systems, and commercial responsiveness. The decision has proven excellent over two years of partnership supplying bus bar connectors and contact assemblies for our circuit breaker production. Their tin plating quality is consistently superior with uniform thickness distribution and excellent adhesion that has eliminated the peeling issues we encountered with other plating vendors. The engineering support provided during our new product development projects has been invaluable, with practical suggestions for stamping die design that reduced our component costs while maintaining the electrical and mechanical performance specifications our UL certification requires. Lead times are reliably met even during peak demand periods, and their willingness to maintain safety stock for our high-volume parts provides supply chain security for our production scheduling.”

Frequently Asked Questions About Copper Stamping

What minimum order quantity is required for custom Copper stamped parts? Minimum order quantities depend on whether production tooling investment is required, typically starting at 1000 pieces for components utilizing existing die designs and 5000-10000 pieces when custom progressive die fabrication is necessary to justify tooling costs. Prototype quantities from 50-500 pieces can be produced using soft tooling or secondary manufacturing processes to support design validation before committing to production volumes.

How do you ensure dimensional accuracy for tight-tolerance Copper electrical terminals? Dimensional accuracy is achieved through precision tool and die design using CAD/CAM systems, regular die maintenance and sharpening to prevent accuracy degradation from wear, statistical process control monitoring with coordinate measurement verification during production runs, and first-article inspection protocols validating that initial production meets all dimensional specifications before releasing quantities for shipment.

Can Copper stamped components be supplied with multiple plating options from the same production run? Yes, splitting production quantities between different surface finishes is readily accommodated by processing stamped components through alternative plating lines, with lot tracking systems maintaining identification of which components received each specific surface treatment to ensure correct packaging and delivery against purchase order line items specifying different plating requirements.

What documentation is provided with Copper stamped component shipments? Standard documentation includes material test certificates tracing chemical composition and mechanical properties to specific heat lots of Copper supplied by the mill, dimensional inspection reports for first-article or periodic verification measurements, plating thickness certificates when surface treatments are specified, and commercial packing lists detailing quantities and part numbers included in the shipment.

How does material temper selection affect the performance of Copper stamped parts? Material temper influences both the formability during stamping operations and the final mechanical properties of completed components, with soft annealed tempers providing maximum ductility for complex forming but lower strength, while hard or spring tempers offer higher strength and electrical spring characteristics but reduced formability requiring simpler part geometries or intermediate annealing between forming stages.

Can your Copper stamping capabilities accommodate components requiring secondary machining operations? Integrated manufacturing capabilities include CNC machining centers for drilling, tapping, milling, and turning operations that can be incorporated into production workflow either before stamping when blank preparation requires machined features, or after stamping when final dimensional accuracy or surface finish specifications exceed capabilities of the forming process alone.

What quality certifications and standards does your manufacturing facility maintain? Our facility maintains ISO 9001:2015 certification for quality management systems with regular surveillance audits validating continued compliance, ROHS conformity for restricted substance limitations in components destined for European markets, and manufacturing process controls meeting UL recognition requirements for electrical components when specified by customer applications.

How do you handle design changes or engineering modifications during production? Engineering change implementation follows formal change control procedures including revision level tracking, effectivity date coordination with customer requirements, and clear communication of any tooling modifications or process adjustments required to incorporate design changes, with first-article inspection and customer approval obtained before resuming production shipments of revised components.

What testing capabilities are available for electrical performance validation of Copper stamped terminals? In-house testing equipment includes digital micro-ohmmeters for electrical resistance measurement of completed assemblies, high-potential testing for dielectric strength verification, salt spray chambers for accelerated corrosion testing of plated components, and mechanical testing systems for pull strength, insertion force, and retention validation of terminal connections.

Can Copper stamping dies be modified to accommodate dimensional tolerance tightening after initial production? Die modifications to achieve tighter tolerances are possible through precision grinding of punch and die clearances, incorporation of sizing stations in progressive die sequences, or addition of coining operations that cold-work specific features to improved dimensional control, with feasibility dependent on the specific tolerance requirements and existing die design.

How does Copper sheet thickness affect stamping die design and component cost? Material thickness influences required press tonnage and die material selection with thicker gauges requiring larger clearances and higher forming forces, while also affecting material cost per component since Copper pricing is based on weight with thicker parts consuming more raw material per piece, potentially offset by reduced scrap percentage when optimized blank layouts are possible.

What lead time reduction options exist for urgent Copper stamping requirements? Expedited processing can reduce standard four-to-six week delivery to two-to-three weeks through priority tooling fabrication, dedicated press scheduling, and accelerated surface treatment processing, with premium pricing typically applied to offset overtime labor costs and schedule disruption to other customer orders during expedite accommodation.

Can you manufacture Copper stamped components meeting military or aerospace specifications? We maintain capabilities to produce components meeting MIL-SPEC requirements including enhanced documentation, material traceability to specific heat lots, dimensional inspection with certified measurement equipment, and specialized testing protocols when customer applications specify military or aerospace standards, subject to appropriate qualification and approval processes.

How do environmental regulations affect Copper stamping and surface treatment processes? Environmental compliance includes wastewater treatment systems for plating effluent neutralization, air filtration for press lubricant mist control, scrap Copper recycling programs minimizing landfill waste, and ROHS-compliant plating chemistries eliminating hexavalent chromium and lead from surface treatment processes when components are destined for markets with restricted substance regulations.

What design considerations optimize Copper stamped component manufacturing efficiency? Design-for-manufacturability principles include specifying generous bend radii to minimize forming stresses and potential for cracking, locating holes away from bend lines to prevent distortion, maintaining uniform material thickness to simplify die design, standardizing hole sizes to reduce punch inventory, and incorporating features that nest efficiently in strip layouts to minimize scrap generation and material costs.

Glossary of Copper Stamping Terms

Blanking – The stamping operation that cuts the outer profile of a Copper component from sheet or strip material, producing a finished part perimeter or a blank for subsequent forming operations in progressive or transfer die sequences.

Progressive Die – A stamping tool incorporating multiple stations where different operations are performed sequentially as Copper strip advances through the die with each press stroke, enabling high-volume production efficiency for complex components requiring several forming stages.

Springback – The elastic recovery of formed Copper after stamping pressure is released, requiring compensation in die design to achieve final angular dimensions matching specification requirements, with springback magnitude dependent on material temper, thickness, and bend radius.

Draw Ratio – The relationship between blank diameter and punch diameter in deep drawing operations, with maximum achievable ratios limited by the formability characteristics of specific Copper alloys and temper conditions before fracture or excessive thinning occurs.

Coining – A stamping operation applying extreme pressure to densify Copper material, improve dimensional accuracy, enhance surface finish, or create embossed features through cold working that exceeds the yield strength causing permanent plastic deformation.

Burr – The rough edge or sharp projection remaining on Copper components after shearing or punching operations, requiring secondary deburring processes to meet handling safety requirements and ensure proper fit with mating components during assembly.

IACS – International Annealed Copper Standard, the reference scale for electrical conductivity measurements with pure annealed Copper at twenty degrees Celsius defined as 100 percent IACS, allowing specification and comparison of electrical performance across different Copper alloys.

Temper Designation – The condition of Copper material regarding mechanical properties and internal grain structure, ranging from soft annealed providing maximum formability to spring hard offering highest strength, designated by standardized codes indicating the degree of cold work and any intermediate heat treatment.

Related Parts for Copper Stamping

Copper electrical stampings manufacturer, precision Copper stamping services, custom Copper terminal lugs, Copper bus bar fabrication, electrical Copper components, stamped Copper connectors, Copper grounding parts manufacturer, progressive die Copper stamping, Copper battery terminals, transformer Copper components, switchgear Copper parts, automotive Copper stampings, Copper sheetmetal fabrication, high conductivity Copper terminals, tin plated Copper stampings, Silver plated Copper contacts, Copper EV battery connectors, industrial Copper stamping, Copper lug manufacturer India, export Copper stamped parts, ASTM B152 Copper components, UL recognized Copper terminals, RoHS compliant Copper stampings, precision Copper blanking, deep drawn Copper components.

Why Partner With a Three-Decade Copper Stamping Specialist

Manufacturing excellence in Copper stamping derives from the accumulated knowledge of metallurgical behavior, tool design optimization, and process control refinement that can only be developed through years of production experience across diverse applications and industries. Our three decades of specialization in Copper component fabrication has created organizational competencies that new market entrants cannot replicate regardless of equipment investment, including engineering staff who understand the subtle material property variations between Copper alloy grades and their implications for formability and electrical performance, toolmakers who have refined progressive die design through thousands of development iterations, and quality technicians who recognize early warning signs of process drift before dimensional accuracy degradation reaches specification limits.

Long-term relationships with Copper material suppliers ensure priority allocation during periods of market tightness while providing access to specialty alloys and custom temper conditions not readily available through commodity distribution channels, advantages that translate into reliable material availability and consistent properties supporting customer production schedules. Established logistics networks and customs clearance expertise minimize the documentation delays and transportation uncertainties that can disrupt international supply chains, particularly valuable for components incorporated into just-in-time manufacturing systems where delivery reliability is as critical as product quality.

Continuous investment in manufacturing technology maintains competitiveness through adoption of servo-drive press controls improving forming precision, coordinate measurement systems enabling tighter tolerance verification, and plating line automation enhancing surface finish consistency while reducing processing costs passed through to customer pricing. The financial stability provided by decades of successful operation ensures that tooling investments required for new customer programs will be supported through volume ramp-up periods and that manufacturing capacity will remain available to support growing customer requirements without the supply disruptions possible from less-established suppliers.

Request Your Custom Copper Stamping Quote Today

Experience the manufacturing excellence and customer service commitment that has made us a trusted global supplier of precision Copper stamped components for three decades. Our engineering team is ready to collaborate on your Copper stamping requirements, providing technical expertise to optimize component designs for manufacturing efficiency, material selection guidance ensuring appropriate Copper grades for your electrical and mechanical performance needs, and competitive quotations reflecting our cost-efficient production capabilities backed by ISO 9001:2015 certified quality systems.

Contact us today to discuss your Copper stamping project requirements and discover how our combination of technical capabilities, production flexibility, and responsive customer support can enhance your component supply chain. Email us to request our detailed capabilities brochure showcasing equipment specifications, production examples, and customer success stories demonstrating our commitment to manufacturing excellence. Call or WhatsApp us to speak directly with our technical sales team who can answer your questions, provide preliminary design feedback, and outline the quotation process for your specific Copper stamping needs.

Whether you require prototype quantities for design validation, medium-volume production runs for specialized applications, or high-volume continuous supply programs supporting major manufacturing operations, we have the technical expertise, production capacity, and customer service commitment to become your preferred Copper stamping partner. Let us demonstrate how three decades of specialization in precision Copper component fabrication can deliver the quality, reliability, and value your applications demand.